What Is a Knife Gate Valve

Knife gate valves are primarily made for isolation and on-off services in systems with high suspended particle contents. Knife gate valves are particularly useful for managing viscous, corrosive, and abrasive media in addition to the slurry. The valves are easy to use, relatively light in weight, and cost-effective with minimal pressure loss in the completely open position.

Where Are Knife Gate Valves Used

Knife gate valves often have a sharpened blade to cut through thick liquids and are made to function in some of the hardest situations.

They are particularly helpful in applications involving wastewater where corrosion is a significant problem. So, in addition to the valve design optimized for slurry media, it is advantageous to have a knife made of acid-proof stainless steel since it is less susceptible to corrosion damage and so requires less frequent maintenance or even replacement.

Knife gate valves should only be used in situations when a totally open or completely closed state is required; unless specifically intended to do so, they should not be used to control flow. Every time fluid is pushed up against a partially closed gate, a vibration occurs that slowly erodes the disc and seat. The knife gate valves are also made to open and close slowly in order to protect against the effects of the water hammer.

How Do Knife Gate Valves Work

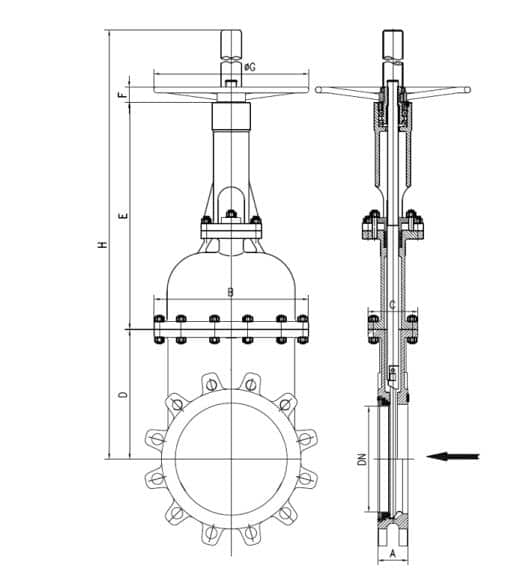

A part called a gate is used by a knife gate valve to operate. The gate’s job is to shut and open the passage of fluid. The valve actuator or handwheel, through the stem, provides power to shut and open the gate. The valve actuator or the valve handwheel is attached to the stem. The handwheel is turned counterclockwise to release the valve. The stem also turns in the same direction as the handwheel as it rotates. Threads on the stem are utilized to improve rotational motion. The gate travels upward as the stem spins, creating room for the fluid to pass through the valve as a result of the gate’s upward movement. The handwheel must be turned clockwise to shut the valve.

| Pros | Cons |

| Low-pressure drop | Can’t frequently operation |

| Durable | Long switching time |

| Lightweight | Can’t modulate to fluid capacity or pressure |

| Wide range of size | |

| Zero leakage | |

| Lower costs than other shutoff valves |

Supplier of Stainless Steel and A351 Cf8 304 Pneumatic Knife Pulp Gate Valves

A kind of valve called a stainless steel knife gate valve is driven by a threaded stem and features a knife-like structure within the body that is situated on the pipeline. The Stainless Steel Pulp Valve and other varieties in various sizes, scales, and specifications are produced and supplied by THINKTANK, a renowned manufacturer and supplier. Resilient and metal seated pneumatic knife valves come in a variety of sizes from 2″ to 54″.

What Is the Difference Between Gate Valve vs Knife Gate Valve

Both knife gate valves and wedge-type gate valves are typically intended for on-off services, in which the valve is either fully opened or fully closed. Because fluid pushing against a partially closed gate causes vibration and cavitation, which eventually damages the seat and the body, it is not advised to utilize any of these to control flow. Additionally, in order to lessen the possibility of water hammering, both types of valves are made to open and close slowly.

Both kinds are applicable in situations where:

- Slurry

- Heavy oil

- Flammable-free viscous liquids

- Seawater

- Wastewater

- Clean water

One of the ways the knife gate valve differs from the gate valve is that it frequently includes a sharpened disc to better cut through the slurry and viscous material. Additionally, compared to a gate valve, which is dimensionally broader, the knife gate valve has a shorter face-to-face length. Because of this, a knife gate valve is lighter than a gate valve. These are the primary variations and most likely two of the knife gate valve’s major benefits.

Gate valves are often found in distribution networks, and drinking water pump stations, drinking water mains whereas knife gate valves are typically found in wastewater treatment facilities, chemical industries, mining(coal), chemical industries, as well as many other industrial uses.

Types of Knife Gate Valves

1. Uni-directional Knife Gate Valve

A uni-directional Knife Gate Valve is an on/off uni-directional wafer valve used on an industrial pipeline. When the valve is dealing with particle flow, the unique valve construction avoids the possibility of blocking shutdown. The shear tension generated by the beveled knife gate valve design allows for easier fluid passage.

Wafer Type Knife Gate Valve in a Uni-directional Hopper Shape for Discharge, Material, and Bulk Handling

The wafer type knife gate in a uni-directional hopper shape is made for bulk handling services in the industrial sector (powdered and granular products). The unique body form makes it perfect for use as a silo outflow valve since it facilitates fluid movement. It is often used in sectors like:

- Chemical Plants

- Power Plants

- Mining Plants

- Beverage and Food

Typically, valves are positioned under silos or hoppers in vertical pipes with the seat on the upstream side to protect it from solids flow. This configuration protects the seat from early corrosion and gate blockage caused by solid buildup.

| Size | DN50-DN600 |

| Working Pressure | DN50-DN250(10Bars), DN450(5Bars), DN500-DN600(4Bars) |

| Standard | EN1092 PN10, ANSI B16.5 (Class 150) |

Lug Type Knife Gate Valve in Uni-directional MSS SP-81 for General Industrial

The lug type knife gate valve complies with standard MSS-SP-81 and TAPPI-TIS 405 which is a uni-directional design service for pulp paper, mining plants, power plants, the chemical industry, Beverage and food, and wastewater applications.

| Size | DN50-DN900 |

| Working Pressure | DN50-DN600(10Bars), DN750(7Bars), DN900(7Bars) |

| Standard | EN1092 PN10, ANSI B16.5 (Class 150) |

Lug Type Knife Gate Valve in Uni-directional AWWA C520-14 for General Industrial

The lug type knife gate valve complies with standard AWWA C520-14 for municipal and industrial services. The body and seat’s design guarantees a non-clogging cutoff on suspended particles in sectors like:

- Pulp and Paper

- Wastewater

- Food and Beverage

- Chemical Plants

- Power Plants

| Size | DN50-DN900 |

| Working Pressure | DN50-DN900(10Bars/150PSI) |

| Standard | DIN PN10, ANSI B16.5/B16.47 |

2. Through Conduit Knife Gate Valve

This valve has significant fugitive emissions. This sort of valve is appropriate for usage in settings where scales help prevent fluid leakage. The design of this type of knife gate valve has two seats and top and bottom gland packing.

Through Conduit Bi-directional Knife Gate Valve Wafer Style for High Density or Concentration Fluids or Media

This knife gate type is a through-conduit wafer valve developed for highly viscous fluids. The double-seat design guarantees a non-clogging shut-off for both forward and backward flow. The valve is utilized in a variety of demanding applications in sectors including:

- Wastewater Treatment Plants

- Pulp & Paper

- Chemical Industry

- Power Plants

| Size | DN50-DN1000 |

| Working Pressure | DN50-DN125(10Bars), DN150-DN250(8Bars), DN300-DN400(6Bars), DN450(5Bars), DN500-DN600(4Bars), DN700-DN1000(2Bars) |

| Standard | EN1092 PN10, ANSI B16.5 |

Through Conduit Bidirectional High Performance Knife Gate Valve Wafer Type for Media or Fluids with a High Consistency or Concentration

This knife gate valve is a bidirectional wafer valve intended for highly viscous liquids. The double-seat construction ensures a non-clogging shut-off for both normal and reverse flow. The valve is used in a variety of applications in sectors such as:

- Wastewater Treatment Plants

- Pulp & Paper

- Chemical Industry

- Power Plants

| Size | DN50-DN900 |

| Working Pressure | DN50-DN250(10Bars), DN300-DN900(6Bars, 8Bars with duplex steel gate) |

| Standard | DIN PN 6/10/16/25, ANSI B16.5 150LB. |

Through Conduit Bidirectional High Pressure Knife Gate Valve Wafer Type for Media or Fluids with a High Consistency or Concentration

Through conduit bidirectional high pressure knife gate valve wafer type designed for media with high consistency. The double seat design assures a non-clogging shut off on either normal or reverse flow. The valve is used for a variety of demanding applications in sectors such as:

- Wastewater Treatment Plants

- Pulp & Paper

- Chemical Plants

- Power Plants

| Size | DN300-DN1000 |

| Working Pressure | DN300-DN800(10Bars), DN900-DN1000(6Bars) |

| Standard | DIN PN10, EN1092 PN6/16/25, ANSI B16.5. |

Uni-directional Round and Square Port Wafer Style Knife Gate Valve for Discharge and Reject Applications

Uni-directional round and square port knife gate is a high-strength valve intended for challenging applications. This valve is appropriate for use in recycle applications, such as waste or dirt mounds of pulpers, high consistency cleaners, or as a solid material silo outlet.

The two-piece body with a circular inlet and a square exit that is bigger than the inlet prevents clogging.

| Size | DN100-DN600 |

| Working Pressure | DN100-DN400(7Bars), DN500-DN600(4Bars) |

| Standard | EN1092 PN10, ANSI B16.5 Class 150. |

3. Bonneted Knife Gate Valve

This kind of knife gate valve has a bonnet and is unidirectional. The body-bonnet construction is totally sealed, thus there is no leakage from the knife gate to the surroundings. For the protection of those around it, this valve is ideal for polluted or hazardous media.

4. Bidirectional Knife Gate Valve

The bidirectional knife gate valve is a bidirectional valve that allows for flow in both directions and has no leakage. The U-shaped form of the peripheral seat assures full-port flow and non-clogging shutdown. It is compatible with a variety of media, including chemicals, pulp stock, sludge, biofuel, slurry, and wastewater.

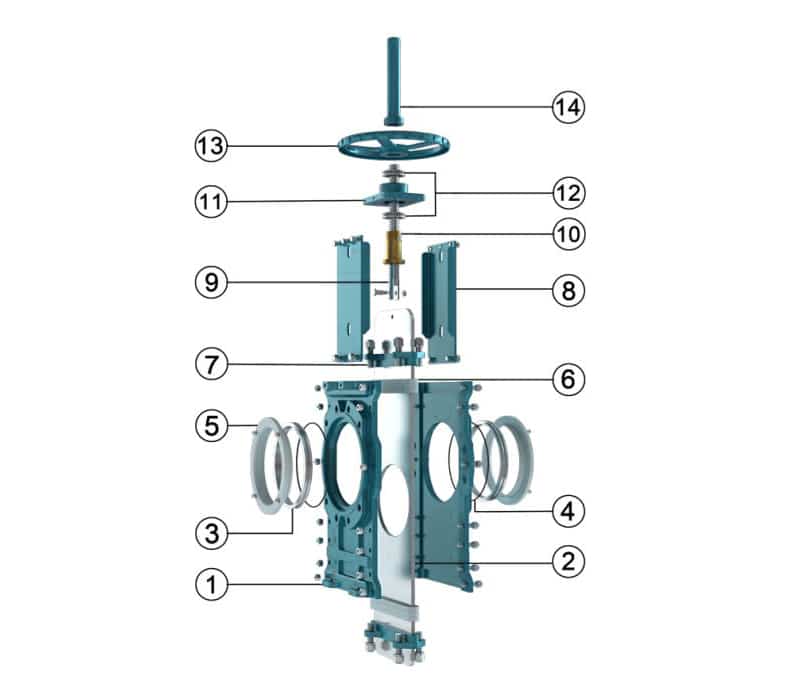

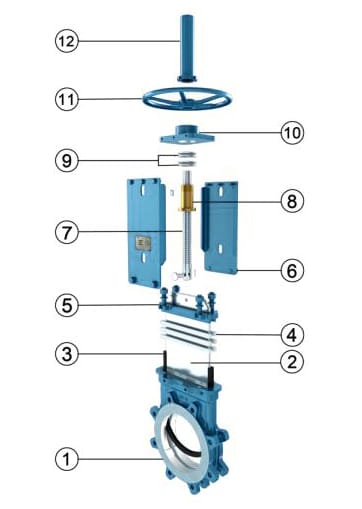

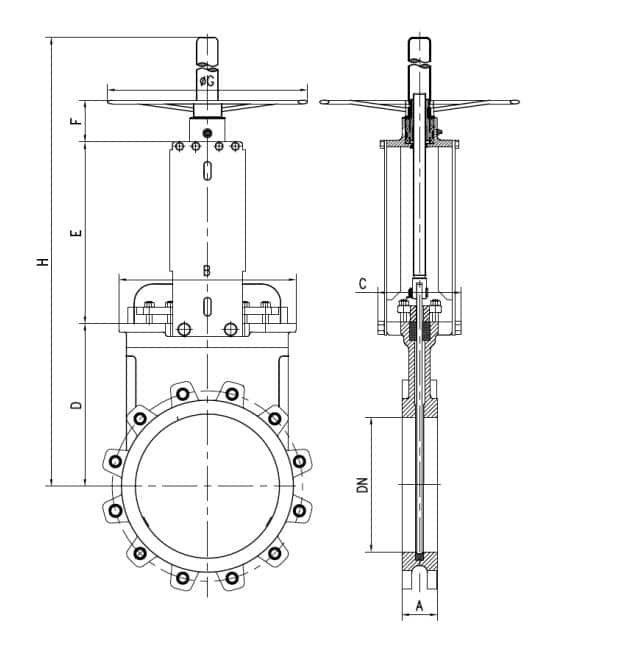

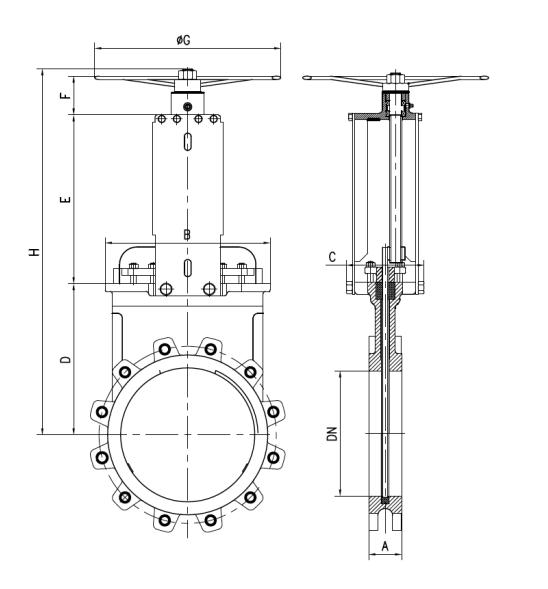

Knife Gate Valve Parts

| NO. | Parts Name | Material |

| 1 | Body | GGG40 |

| 2 | Gate | SS304 |

| 3 | Seat | Viton/EPDM |

| 4 | Packing | PTFE |

| 5 | Gland | A216Gr. WCB |

| 6 | Yoke | 45# |

| 7 | Stem | 2Cr13 |

| 8 | Stem Nut | Brass |

| 9 | Thrust Bearing | 65Mn |

| 10 | Bearing Housing | A216Gr. WCB |

| 11 | Handwheel | GGG30 (Epoxy Coated) |

| 12 | Stem Protector | SS304 |

| 13 | Fasteners | A2-70 |

Bi-directional Knife Gate Valve Wafer Type for General Industrial and Wastewater Treatment Plants

For ordinary industrial service applications, the bi-directional wafer type knife gate valve is a bidirectional valve. The body and seat are designed to prevent clogging in sectors such as:

- Wastewater treatment plants

- Beverage and Food

- Chemical plants

| Size | DN50-DN1200 |

| Working Pressure | DN50-DN125(16Bars), DN150-DN250(10Bars), DN300-DN400(6Bars), DN450(6Bars), DN500-DN600(4Bars), DN700-DN1200(2Bars) |

| Standard | EN1092 PN10 |

MSS SP-81 Bi-directional Knife Gate Valve Lug Type for Pulp and Paper

This knife gate is a bidirectional lug-type valve developed for industrial service applications in accordance with MSS-SP-81 and TAPPI TIS 405-8. The shape of the body and seat ensures non-clogging shutoff of suspended particles in sectors including:

- Pulp and Paper

- Wastewater

- Power Plants

- Mining Coal Application

- Chemical Industry

- Beverage and Food

| Size | DN50-DN900 |

| Working Pressure | DN50-DN600(10Bars/150Psi), DN750(7Bars/100Psi), DN900(7Bars/100Psi) |

| Standard | ASME B16.5 Class 150 |

Bi-directional Knife Gate Valve Wafer Type with Stainless Steel Rings for General Industrial

The stainless steel knife gate valve in bi-directional wafer type is used for pulp and paper, beverage and food, wastewater treatment plants, power plants, and the mining industry. The design of the body and seat ensures the non-clogging shut-off of suspended particles in sectors.

| Size | DN50-DN600 |

| Working Pressure | DN50-DN250(10Bars), DN300-DN400(6Bars), DN450(5Bars), DN500-DN600(4Bars) |

| Standard | DIN PN 10, ASME B16.5 Class 150 |

High Pressure Bi-directional Knife Gate Valve Wafer Type for Water Applications and General Industrial

A bi-directional valve called a knife gate is created for use in typical industrial service applications. The body and seat’s design guarantees a non-clogging cutoff on suspended particles in sectors like:

- Wastewater treatment plants

- Chemical plants

- Food and Beverage

| Size | DN80-DN600 |

| Working Pressure | DN80-DN600(16/20Bars) |

| Standard | EN1092 PN16, ASME B16.5 Class 150 |

5. Slurry Knife Gate Valve

Slurry Bi-directional Knife Gate Valve Wafer Type with Rubber Sleeves

This wafer type knife gate valve is created for a variety of industrial uses. Bi-directional shutoff is provided by the double-seated design. The two rubber sleeves and the valve body’s shape make the knife gate valve ideal for use in treating abrasive slurries in sectors like:

- Mining Industry

- Power Industry

- Chemicals

- Wastewater Plants

| Size | DN50-DN900 |

| Working Pressure | DN50-DN400(10Bars), DN450-DN600(6/10Bars), DN700-DN900(5Bars) |

| Standard | EN1092 PN10, ASME B16.5 Class 150 |

Slurry Bi-directional Full Flanged Heavy Duty Knife Gate Valve with Rubber Sleeves

This particular form of knife gate valve is a full-flanged, bi-directional valve with two metal-reinforced rubber sleeves for managing abrasive slurries, mostly in the following sectors:

- Mining Industry

- Power Industry

- Chemicals

- Wastewater Treatment Plants

| Size | DN80-DN900 |

| Working Pressure | DN80-DN400(10Bars), DN450-DN600(6/10Bars), DN750(5/10Bars), DN900(5/10Bars) |

| Standard | DIN PN10, ASME B16.5 Class 150 |

High Pressure Slurry Knife Gate Valve Full Flanged with Rubber Sleeves Bi-Directional

This particular form of knife gate is a bi-directional, full-flanged, heavy-duty valve with two metal-reinforced rubber sleeves for handling abrasive slurries, mostly in the following sectors:

- Mining Industry

- Power Industry

- Chemicals

- Wastewater Treatment Plants

| Size | DN80-DN900 |

| Working Pressure | DN80-DN900(20Bars, 300Psi) |

| Standard | DIN PN10, EN 1092-2, ASME B16.5 Class 300 |

6. Hopper Shape Knife Gate Valve

This valve features a hopper component at its top. This valve is excellent for bulk media processing. The valve manufacturers design this hopper type knife gate for usage in the chemical industries, food, mining, and others. This valve’s seat is positioned in the opposite direction to prevent seat wear, and valve obstruction, and to make it easier to close.

Wafer Type, Unidirectional Hopper-shaped Knife Gate Valve for Material and Bulk Handling Condition

Typically, valves are positioned under silos or hoppers in vertical pipes with the seat on the inlet side to protect it from solids flow. This configuration protects the seat from early deterioration and gate blockage caused by solid buildup. This hopper shape knife gate valve with wafer type is appropriate for use as a silo exit valve due to the body’s unique construction, which facilitates the fluid’s flow. Numerous industries, including:

- Chemical Plants

- Power Plants

- Beverage and Food

- Mining Industries

| Size | DN50-DN600 |

| Working Pressure | DN50-DN250(10Bars), DN300-DN400(6Bars), DN450(5Bars), DN500-DN600(4Bars) |

| Standard | EN1092 PN 10, ASME B16.5 Class 150 |

7. Square Port Knife Gate Valve

Square Port Knife Gate Valve in Uni-directional for Material, Discharge, and Bulk Handling

The square port knife gate valve is a low-pressure valve that is primarily utilized in bulk handling and silo outlet applications in several sectors, including:

- Wastewater treatment Plants

- Chemical plants

- Beverage and Food

- Mining Industries

- Power Plants

| Size | Square DN150x150 to DN600x600 |

| Working Pressure | DN150x150 to DN600x600(1Bar) |

| Standard | EN1092 PN 10, ASME B16.5 Class 150 |

8. Coal Burner Isolation Knife Gate Valve

Bi-directional Knife Gate Valve Wafer Type Used for Coal Burner Isolation

This wafer type knife gate is a bi-directional wafer valve that was created with the particular purpose of isolating the burner lines for pulverized coal in coal-fired boilers during maintenance. The valve is dust-tight, making it appropriate for use in various bulk handling applications like silo outflow valves. This valve conforms with DIN EN 14460 and was created for usage in ATEX (areas that might explode) (Explosion resistant equipment). In the case of an explosion, the valve can be employed as an efficient defense against flame spread when it is closed.

| Size | DN700-DN1000 |

| Working Pressure | DN700-DN1000(3Bars) |

| Standard | DIN PN10 |

NFPA Full Flange Knife Gate Valve in Uni-directional For Coal Burner Isolation

The uni-directional full-flange type knife gate valve was created specifically to separate the pulverized coal burner lines in coal-fired power plants. These valves were created in accordance with NFPA 85 specifications.

| Size | DN200-DN900 (8″-36″) |

| Working Pressure | DN700-DN1000(3.5Bars) |

| Standard | DIN PN10, ASME B16.5 Class 150 |

9. Split Body Knife Gate Valve

Split Body Knife Gate Valve Wafer Uni-directional Type

This knife gate valve is an excellent option for transferring heavy fluids or food, due to its accurate gate guidance inside the body and cast or fabricated construction.

| Size | DN50-DN1000 (2” to 40″) |

| Working Pressure | DN50-DN125(10Bars), DN150-DN250(8Bars), DN300-DN400(6Bars), DN450(5Bars), DN500-DN600(4Bars), DN700-DN1000(2Bars) |

| Standard | EN1092 PN10, ANSI B16.5 |

| Actuator | Handwheel, Pneumatic Actuator, Electric Actuator, or Hydraulic Actuator |

Split Body Knife Gate Valve Wafer Bi-Directional Type

Cast construction, bidirectional design, and accurate gate guidance within the body result in a valve suitable for the transport of very heavy fluids, in the food industry.

| Size | DN50-DN700 (2” to 28″) |

| Working Pressure | DN50-DN700(10Bars) |

| Standard | EN1092 PN10, ANSI B16.5 |

| Actuator | Handwheel, Pneumatic Actuator, Electric Actuator, or Hydraulic Actuator |

10. Transmitter Isolation Knife Gate Valve

Uni-Directional Wafer Type Knife Gate Valve for Transmitter Isolation

This wafer type uni-directional knife gate valve supply isolation of instrument level transmitter can be kept separate from a storage tank. With this valve in place, a transmitter can be replaced or fixed without stopping the process or draining the vessel.

| Size | DN80 |

| Working Pressure | PN10 |

| Standard | EN1092 PN10, ANSI B16.5 |

11. Double Gate Knife Gate Valve

Bi-directional Knife Double Gate Valve Wafer Type for Media or Fluids with a Very High Consistency or Concentration

The double gate knife valve is frequently used in the pulp and paper industry (recycling or secondary fiber processing) and was created to handle highly concentrated or polluted media. Both gates retract into the body and enable complete flow when they are in the open position. The gates drive stock and impurities like wires and staples into the flow when they close. The stroke time of traditional valves is cut in half. Every wear-and-tear component is replaceable.

| Size | DN100-DN600 |

| Working Pressure | DN100-DN250(10Bars), DN300-DN400(6Bars), DN450(5Bars), DN500-DN600(4Bars) |

| Standard | EN1092 PN10, ANSI B16.5 Class 150 |

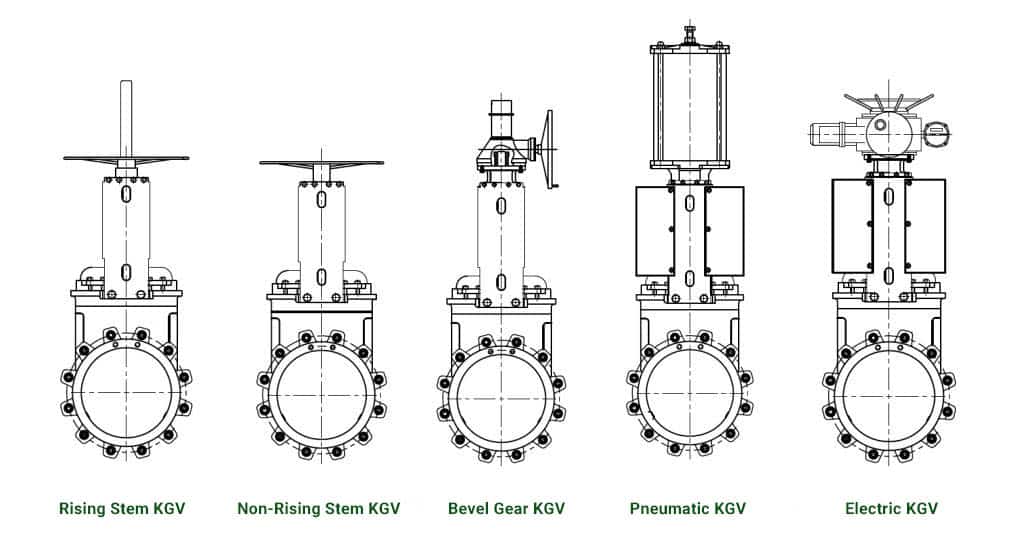

12. Rising Stem Knife Gate Valve

When the knife gate valve is opened, the stem rises over the handwheel, defining it as such. The stem descends when the valve is closed. The valve operator finds this sort of valve useful since it is simple to determine whether the valve is open or closed. It is advised to use this type of valve in situations where space is not a concern because it takes up a lot of space.

13. Non-rising Stem Knife Gate Valve

In this type of knife gate valve, when the valve is opened, the stem does not protrude over the handwheel. This kind of valve has a built-in indicator that lets you know when it is open or closed. This valve may be used in areas with restricted space since it takes up less space than the rising stem type.

Pneumatic Knife Gate Valve

With a pressure rating of Class 150, the pneumatic knife gate valve is offered in wafer, lugged, and flanged end connection sizes ranging from 50 mm to 600 mm. Metal seats and resilient seats, both of which can be ordered as unidirectional and bidirectional seats, are available for pneumatic knife gate valves. Electric and hydraulic actuators also can be used to operate the knife gate valve.

THINKTANK provides uni-directional and bi-directional soft and metal seated pneumatic knife gate valves in manual, electric, and pneumatic options. Pneumatic knife gate valves were created specifically for demanding applications. In order to handle the most demanding applications, the Knife gate valve is a one-piece full port cast stainless steel body that is completely lugged. This sturdy design ensures a better flow capacity and little pressure drop.

For a reliable cutoff, pneumatic knife gate valves use gates composed of stainless steel and other premium alloys that are ground with a super surface polish on both sides. The machined and carefully polished gland pockets provide a precise stem seal and leak-proof gland packing. High-Performance knife edge gate valves are offered in uni-directional and bi-directional designs, offering superior performance and value with a number of included features that rival those of competitors.

Pneumatic Knife Gate Valve Accessories:

Gear, pneumatic actuator, electric actuator, or hydraulic actuator all can drive knife edge gate valve for remote operation. Additionally offered are chain wheels and extended stem arrangements. Depending on the customer’s requirements, other accessories can be installed with pneumatic cylinder actuators, such as limit switches, solenoid valves, I/P converters, air filter regulators, and even positioners(for throttling flow).

With a shutdown capability that exceeds the specifications of the MSS SP-81 standard, both metal or soft seat options are offered.

Specifications

- Design Standard: MSS SP-81

- Face to Face: As per MSS SP-81

- Testing Standard: MSS SP -81

- Size Range: 50 mm to 600 mm

- Pressure Rating: DN50-DN300(150 psi), DN400-DN450(75 psi), DN500 -DN600(50 psi)

- Ends: Lug Type, Wafer Type, Flangeless, Flange Type

- Valve Operation: Cylinder Pneumatic Actuator, Bevel Gear, Electic Actuator, Chain Wheel, Lever, Handwheel

- Body Design: Round Port / Square Port/V Notch

Materials

a) Body

A wide variety of valve body materials are available for knife gate valves, such as cast iron, carbon steel, stainless steel, duplex steel, and other alloy materials.

- ASTM A216 GR.WCB

- ASTM A351 GR.CF8

- ASTM A351 GR.CF3

- ASTM A351 GR.CF8M

- ASTM A351 GR.CF3M

- Alloy 20

- Hast Alloy C

b) Knife Gate

To prevent distortion at high differential pressure and to maintain tight seating, pneumatic knife gate valves use thicker knife gates. Gates that are precisely machined and polished extend the life of seating components and efficiently cut even thick or very viscous fluids. To provide the finest possible seat tightness, the precision finish gate sealing face is lapped and offered in complete materials of construction.

a. Stainless Steel 304

b. Stainless Steel 304L

c. Stainless Steel 316

d. Stainless Steel 316L

e. Alloy 20

f. Hast Alloy C

g. Nitriding to approx. 600-1250 HV1 surface hardness

h. STL overlay on Gate Edge with min. 1.0mm thickness and min.40 HRC hardness

i. Any Other Special Gate Material

c) Stem :

Generally, the stem of a pneumatic knife gate valve uses stainless steel material to ensure the simple, smooth, long-life operation and trustworthy services. The knife edge gate valve may also be supplied with a stem cover on request for extra dust protection when the valve is open. The knife gate valve is available with extended stem arrangement up to DN2000 (80″) and in rising stem and non-risings stem design, stem m.o.c. is as follows:

a. Stainless Steel 410 (13% Cr.)

b. Stainless Steel 304

c. Stainless Steel 304L

d. Stainless Steel 316

e. Stainless Steel 316L

f. Alloy 20

g. Hast Alloy C

h. Any Other Special Material on request

d) Gland Packing

In addition to providing zero leakage from the gland part, the smooth completely machined packing chamber, cast gland follower, multiple packing, and true leveling all contribute to consistent compression of the packing. There are many different types of packing materials to choose from in order to ensure absolute sealing. The numerous types of M.O.C. that may be found in gland packings are as follows:

a. Standard General Service Packing Material

b. P.T.F.E. Impregnated Asbestos, maximum temperature up to 210 C.

c. High Temperature Graphite Asbestos Packing Material

d. Pure PTFE Packing Materials, maximum temperature up to 230 C.

e. Food Grade Packing Material

e) Seat Design

Both integral and renewable types of seats are offered with pneumatic knife edge gate valves. We may provide a replacement seat ring with a hard-facing knife surface for extremely abrasive applications. The service life of the valve is increased by the replaceable seat.

- Integral Metal to Metal Seat

- Renewable Metal to Metal Seat

- Renewable Elastomer Rubber Seat

- Renewable Ptfe Seat

- Deflector Cone.

Testing and Inspection

Body Test

The valve body must undergo a hydrostatic pressure test at 1.5 times the rated operating pressure to comply with standard MSS SP-81.

For example: if the pressure rating is 150psi, then the shell pressure test is 150×1.5=225psi.

Gate Test

The gate must undergo a hydrostatic pressure test to 1.1 times the rated operating pressure in accordance with MSS SP-81.

For example: if the pressure rating is 150psi, then the sealing test is 150×1.1=165psi.

Seat Test

For metal-to-metal seated knife gate valves, the MSS SP-81 specification allows a leakage rate of 40 cc per inch of diameter, per minute at 40 psi pressure. On a 10″ knife gate valve, this would be equal to 40 times 10, or 400cc per minute at 40psi pressure.

- When tested with water at 40 pressure delivered in the usual flow direction, the maximum permitted leakage is 0.6 GPM.

- When tested with water at 40 psi, there were no obvious leaks (for soft seated valves only).

Face-to-Face Inspection

To ensure simplicity of installation for the customer, independent of the valve manufacturer, MSS SP-81 has set face-to-face dimensions and tolerances for each valve size.

Final Thoughts

In this article, we have known the types of knife gate valves, knife gate valve parts, and application conditions. THINKTANK provides knife gate valves for wastewater treatment plants, chemical plants, seawater treatment plants, power plants, and many other projects in UAE, Germany, Italy, Spain, Singapore, Indonesia, etc. If you have relevant demand, please contact us for a free consultation.