What Means Water Mixing?

Water mixing is the mixing of water at different temperatures, and the resulting mixing temperature varies at different hot and cold flows. Here we have embedded Spirax Sarco calculator software to facilitate the reader to calculate the mixing temperature of water online. (Quoted from Spirax Sarco resources)

Using this tool, you may determine the combined temperatures of two different water sources. Knowing the temperatures of the hot and cold water as well as the needed temperature and flow rate of the mixing, the percentage flow and actual flow of each stream may be calculated.

Mixing Valve

A three-way mixing valve can usually replace two two-way valves and a three-way valve tube, which simplifies the engineering design and improve precision control. Also, it can enable the regulating of parameters such as pressure, flow rate, temperature, and liquid level. The trim design of the three-way mixing valve adopts a cage with a window and a plug side guide, which has good stability, low noise, large allowable differential pressure, and a simple connection. When the nominal diameter is small than DN100 and the differential pressure is low, the mixing valve can also be used for diverting conditions, the valve body can be used interchangeably. When the nominal diameter is larger than DN100 and the differential pressure is higher, the valve body can not be used interchangeably.

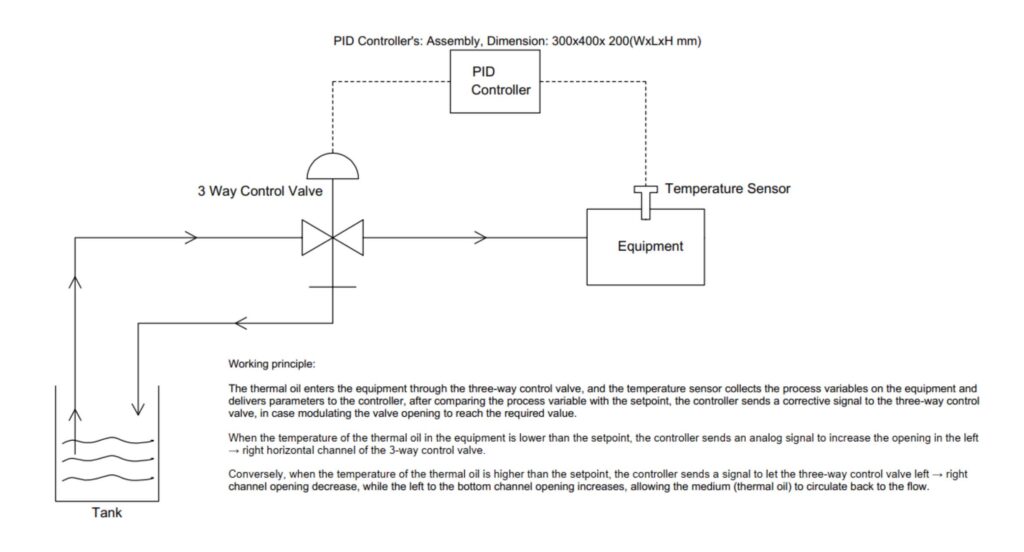

3-Way Mixing Control Valve

The pneumatic three-way control valve consists of a multi-spring diaphragm or cylinder/piston pneumatic actuator and a three-way mixing(diverting) valve with a cage thin-walled window-shaped plug. It has the advantages of a simple structure, lightweight, sensitive response, and accurate flow characteristics. Generally, it is assembled with an electric-pneumatic valve positioner or pneumatic-pneumatic valve positioner, and it can enable the remote automatic control of the process fluid. The pneumatic three-way control valve is widely used for precise control of gases, liquids, steam, and other media to maintain their process parameters such as pressure, flow, temperature, liquid level, and other parameters at a given value. Suitable for fluid through the three-way valve into two outflows or two fluids through the three-way valve into one fluid condition.

Pneumatic 3-way control valves are available in 3-way mixing flow and 3-way diverting flow

- Nominal Diameter: DN20 to DN350(3/4″ to 14″).

- Nominal Pressure: PN16 to PN100, JIS10K to JIS40K, Class 150LB to 600LB.

- Applicable Fluid Temperature Range: -60℃ to +450℃.

- Leakage Standard: Class IV.

- Flow Characteristics of three-way valves are linear and EQ%.

| Flow Characteristic | Linear and EQ% | |

|---|---|---|

| Adjustable Range | 30:1 | |

| Rated Cv Value | Cv5.3 to Cv1600 | |

| Allowable Leakage | Metal: IV(0.01% Rated valve Capacity) | |

| Performance | Pneumatic Actuated | Electric Actuated |

| Intrinsic Error % | ±1.5 | ±1.0 |

| Hysteresis Error % | ≤1.5 | ≤1.0 |

| Dead Band % | ≤0.6 | ≤1.0 |

| Initial&End Point Deviation % | ±2.5 | ±2.5 |

| Deviation of Rated Stroke % | ≤2.5 | ≤2.5 |

Final Thought

This post we have shared with you for water mixing, if your case is under steam or oil condition, please just feel free to contact us for sizing and selection. THINKTANK is a well-known manufacturer of control valves, we provide OEM service for many brands, such as ABB, Bray, and Siemens. Sincerely look forward will be a long-term business partner of yours.