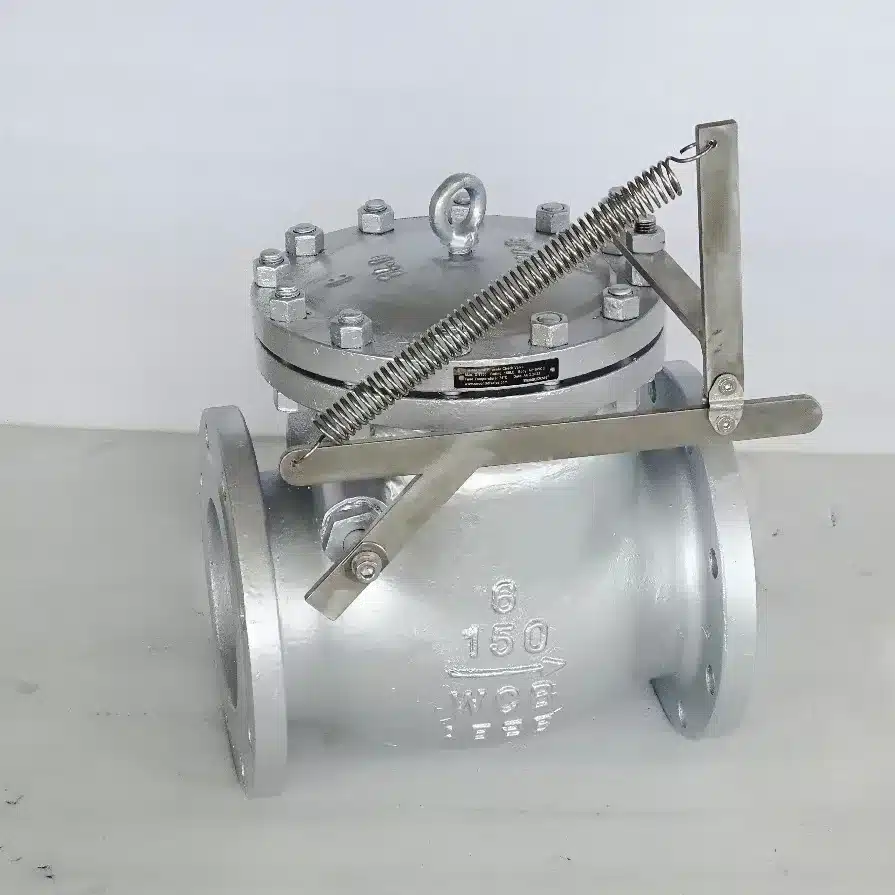

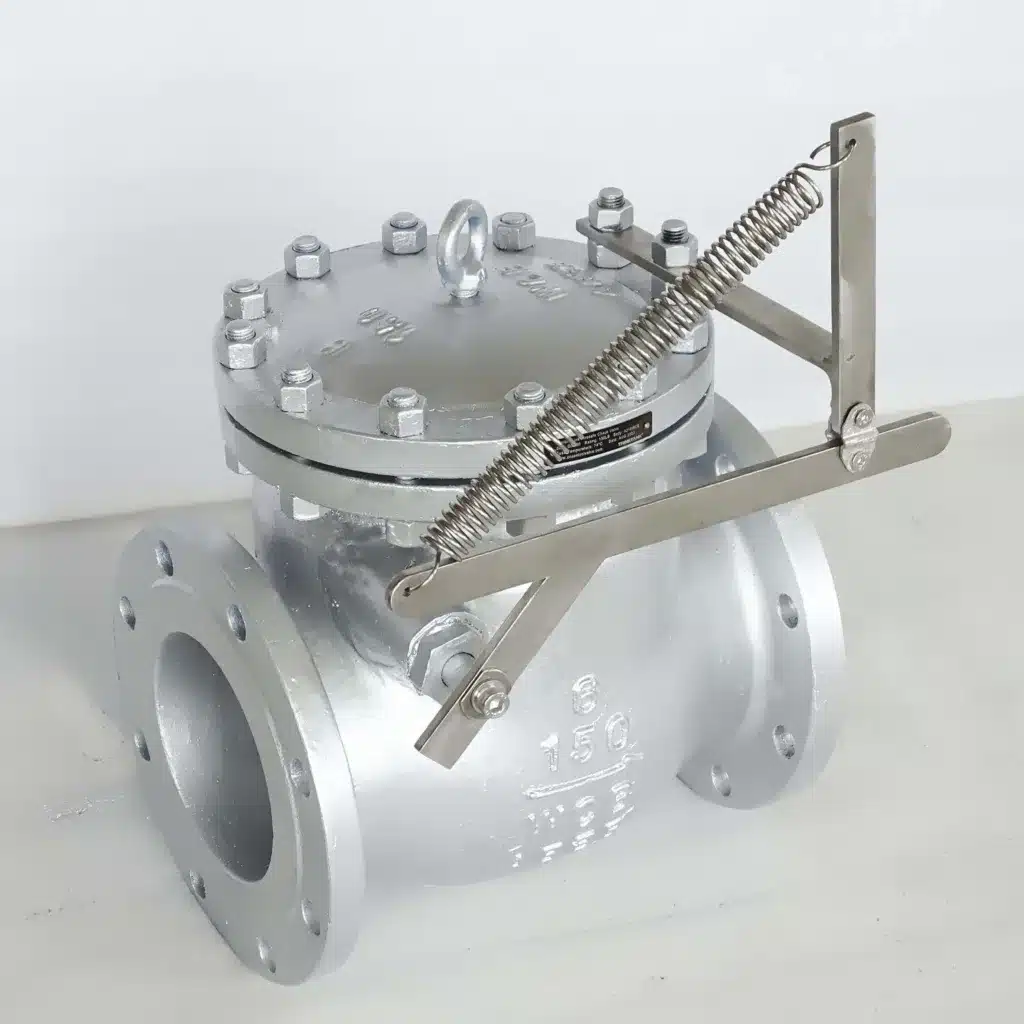

Exciting news from the engineering floor of THINKTANK! We have successfully completed the manufacturing of our state-of-the-art fusible link check valves. Every valve has undergone rigorous quality checks and has met our high standards of precision and reliability. These valves are specifically designed for applications ranging from refineries and petrochemical plants to offshore oil rigs, chemical process equipment, water and waste applications, and even superheated steam lines on ships.

I’m proud to announce that these valves are now ready for shipment, and we are eager to see them in action, serving various industries and ensuring optimal operational efficiency and safety. Our team has worked tirelessly, and it’s a moment of pride for all of us here at THINKTANK. We’re confident that our clients will be more than satisfied with the performance and durability of these valves.

What are Fusible Link Check Valves

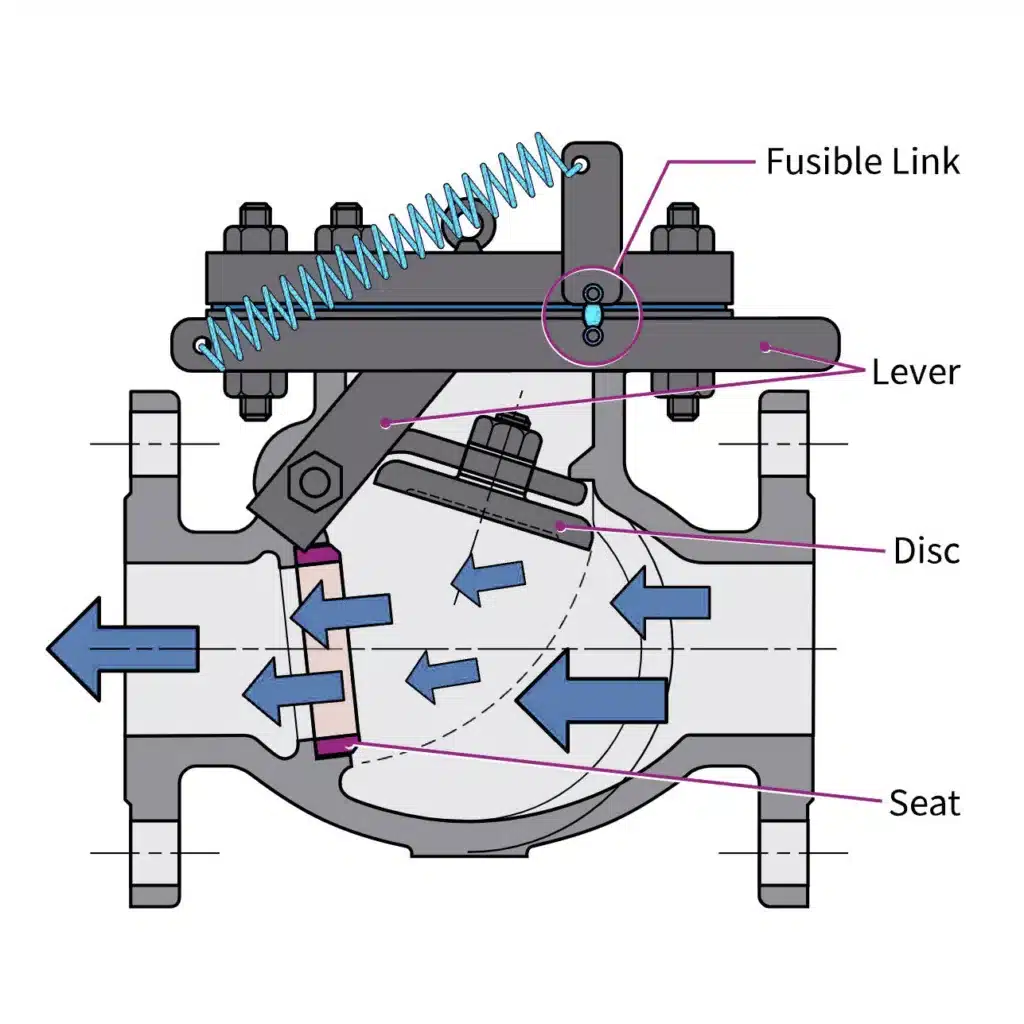

A fusible link check valve is a safety device used in systems where the flow of a substance, such as gas or liquid, needs to be controlled and shut off in the event of a fire or excessive heat. It consists of a check valve mechanism connected to a fusible link, which is designed to melt or break when exposed to high temperatures.

The check valve component of the device allows the substance to flow in one direction while preventing backflow in the opposite direction. This ensures that the substance only travels in the desired direction within the system. The fusible link is typically made of a material with a low melting point, such as a metal alloy or solder, which is engineered to weaken and fail at a specific temperature threshold.

How Fusible Link Check Valves Work

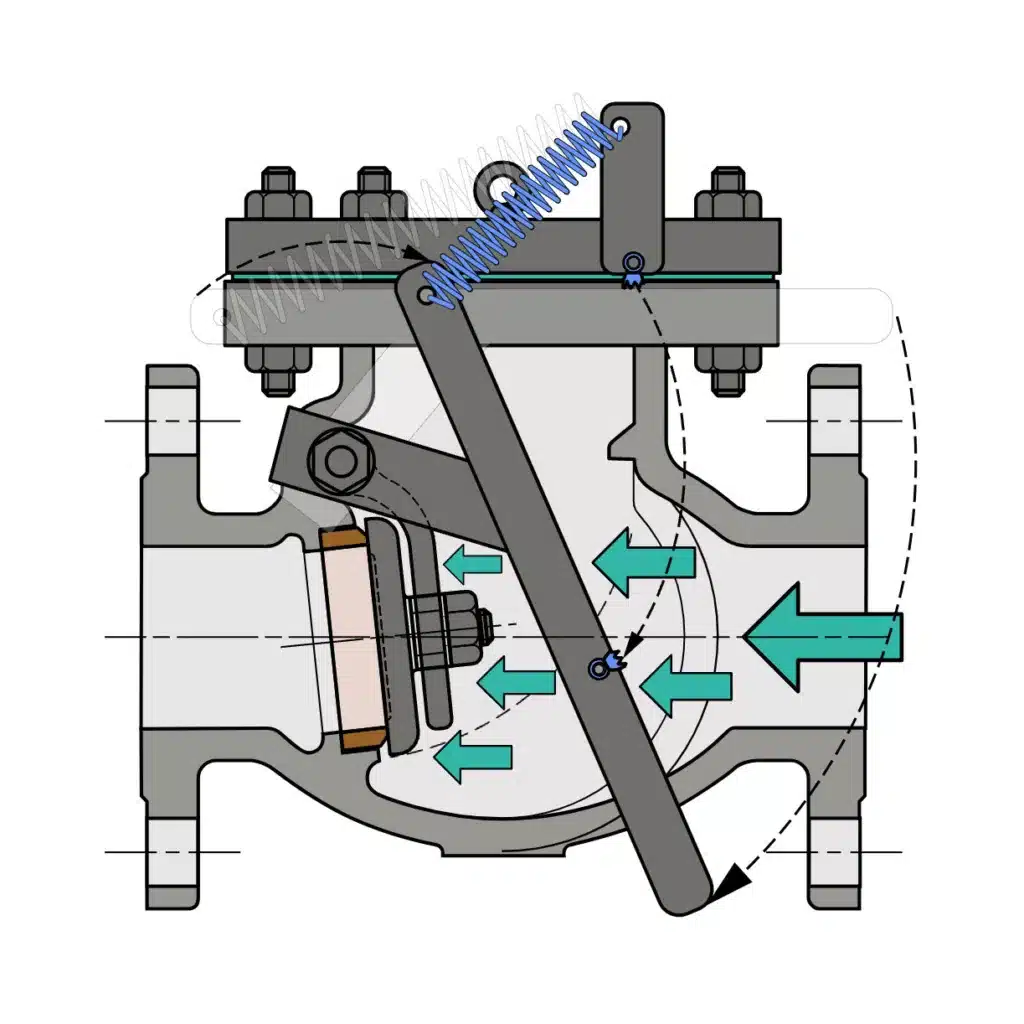

In the event of a fire or excessive heat, the surrounding temperature can cause the fusible link to melt or break, severing the connection between the check valve mechanism and the flow path. This action triggers the valve to close, shutting off the flow of the substance and preventing further movement within the system. By incorporating the fusible link check valve, potential hazards can be minimized by quickly isolating and containing the substance, reducing the risk of fire or spreading of dangerous materials.

Where are Fusible Link Check Valves Used

Fusible link check valves are commonly used in various industries and applications, including fire protection systems, fuel storage systems, HVAC systems, and industrial processes where the control of fluid or gas flow is crucial for safety. Regular maintenance and inspections are essential to ensure the reliability and integrity of the fusible link check valves, as they play a vital role in preventing potentially catastrophic incidents.

Here’s what you need to know about fusible link check valves:

Function

Fusible link check valves are primarily used to control the flow of fluids, gases, or air in systems where automatic shutoff is required in case of fire or excessive heat.

Fusible Link Mechanism

The core feature of these valves is the fusible link. When exposed to high temperatures, such as in a fire, the fusible link melts or breaks, triggering the valve to close and cut off the flow of the substance it is controlling.

Applications

Fusible link check valves find applications in various industries, including fire protection systems, gas shutoff systems, and emergency shutdown systems in hazardous environments.

Variety

Our fusible link check valves are available in different styles and sizes to suit various requirements, including ball valves with flanged ANSI specifications.

Fusible Link Check Valves Sizes & End Connections

- 150# ANSI Flanged: 2″ to 16″

- 300# ANSI Flanged: 2″ to 16″

Fusible Link Check Valve Materials

Body: Carbon steel or Stainless Steel

Disc: Carbon steel or Stainless Steel

Hanger Arm: Carbon steel or Stainless Steel

Seat: API 598 Trim 8 or 12

Cover Seal: Graphite

Fusible Link Trigger Set Temperatures Options:

- 135˚F

- 165˚F (Popular Standard Selection)

- 212˚F

- 280˚F

- 360˚F

These valves provide an essential safety feature in critical situations by automatically preventing the spread of potentially dangerous substances in the event of a fire or extreme heat. Their applications are diverse, making them crucial components in safety-critical systems.

In the event of an emergency shut-off, the fusible link melts, and the spring pulls the lever, moving the disc into the closed position against the seat.

Design Features

- Local and/or Remote Actuation

This feature allows users to operate the valve either directly at the valve location or from a distance, giving flexibility in various operational scenarios and ensuring safety in situations where direct access to the valve is not advisable. - Fire-Safe Fusible Link

In the event of a fire, the fusible link is designed to melt and activate the valve to shut off, preventing further fueling of the fire and reducing potential hazards. This ensures an added layer of protection in high-risk environments. - Economical Solution for Required Safety

The valves are cost-effective while still meeting essential safety requirements, providing both value and protection. - Versatility in Service Orientation

These valves can be installed in both horizontal and vertical positions, allowing for flexibility in system design and accommodating varied installation needs. - Rigorous Factory Testing to API 598

Every valve undergoes a thorough testing process in accordance with API 598 standards, ensuring its reliability and performance before reaching the end user. - Enhanced Seal with Back Pressure

The valve’s design ensures that increased back pressure only tightens the seal between the disc and seat, reducing potential leaks and ensuring optimal performance. - Manual Reset for Safety

Once the valve is closed, it cannot be reopened automatically. It requires a manual reset, serving as an essential safety feature to prevent unintended or unauthorized reactivation of the flow.

To all our stakeholders and clients, thank you for your continued trust and support. We promise to keep delivering innovative solutions to meet your ever-evolving needs. Safe shipping and successful installations ahead!