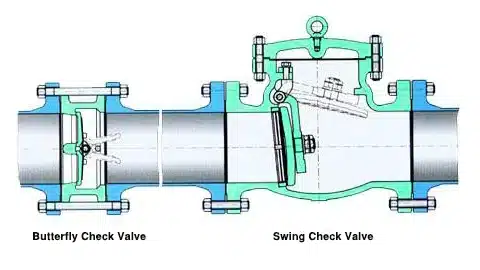

The butterfly check valve is often called a dual plate check valve or swing check valve. It’s designed to prevent backflow in systems, operating automatically to allow flow in one direction and preventing reverse flow.

What are Butterfly Check Valves

Butterfly check valves, also known as dual-plate check valves or swing check valves, are a specific type of valve in the larger category of non-return or check valves. They play a crucial role in many fluid systems by preventing backflow, which is the undesirable reversal of the flow of fluid.

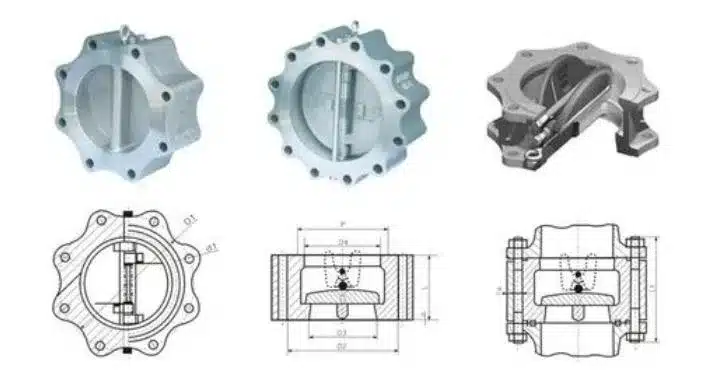

The ‘butterfly’ in the name comes from the design of the valve, which typically consists of two semi-circular plates or ‘discs’. These plates are hinged down the middle and mounted within the pipeline. When fluid flows in the forward direction, it pushes the two semi-circular plates open, allowing the fluid to pass. When the flow stops or attempts to reverse, the pressure drops, causing the two semi-circular plates to swing back together, effectively blocking the pipe and stopping the fluid from flowing backward. This mechanism operates automatically, driven by the dynamics of the fluid flow itself.

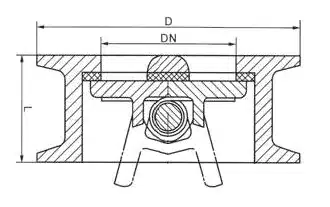

| Size | 150LB | 300LB | 600LB | |||

| inch | L | D | L | D | L | D |

| 2 | 60 | 103 | 60 | 110 | 60 | 110 |

| 21/2 | 67 | 122 | 67 | 129 | 67 | 129 |

| 3 | 73 | 135 | 73 | 148 | 73 | 148 |

| 4 | 73 | 173 | 73 | 180 | 79 | 192 |

| 5 | 86 | 196 | 86 | 215 | 105 | 240 |

| 6 | 98 | 222 | 98 | 250 | 136 | 265 |

| 8 | 127 | 279 | 127 | 307 | 165 | 319 |

| 10 | 146 | 339 | 146 | 361 | 213 | 399 |

| 12 | 181 | 409 | 181 | 422 | 229 | 456 |

| 14 | 184 | 450 | 222 | 485 | – | – |

| 16 | 191 | 514 | 232 | 539 | – | – |

| 18 | 203 | 549 | – | – | – | – |

| 20 | 219 | 606 | – | – | – | – |

| 24 | 222 | 717 | – | – | – | – |

| Size | PN1.0 | PN1.6 | PN2.5 | PN4.0 | PN6.4 | PN10.0 | ||||||

| L | D | L | D | L | D | L | D | L | D | L | D | |

| DN50 | 60 | 109 | 60 | 109 | 60 | 109 | 60 | 109 | 60 | 115 | 60 | 122 |

| DN65 | 67 | 129 | 67 | 129 | 67 | 129 | 67 | 129 | 67 | 140 | 67 | 147 |

| DN80 | 73 | 144 | 73 | 144 | 73 | 144 | 73 | 144 | 76 | 150 | 73 | 157 |

| DN100 | 73 | 164 | 73 | 164 | 73 | 170 | 73 | 170 | 79 | 177 | 79 | 183 |

| DN125 | 86 | 194 | 86 | 194 | 86 | 197 | 86 | 197 | 105 | 213 | 105 | 220 |

| DN150 | 98 | 220 | 98 | 220 | 98 | 227 | 98 | 227 | 136 | 250 | 136 | 260 |

| DN200 | 127 | 275 | 127 | 275 | 127 | 287 | 127 | 293 | 165 | 313 | 165 | 324 |

| DN250 | 146 | 330 | 146 | 332 | 146 | 343 | 146 | 355 | 213 | 364 | 213 | 394 |

| DN300 | 181 | 380 | 181 | 387 | 181 | 403 | 184 | 450 | 229 | 424 | 229 | 458 |

| DN350 | 184 | 440 | 184 | 447 | 184 | 460 | 222 | 478 | – | – | – | – |

| DN400 | 191 | 492 | 191 | 498 | 191 | 518 | 232 | 549 | – | – | – | – |

| DN450 | 203 | 542 | 203 | 558 | 203 | 568 | – | – | – | – | – | – |

| DN500 | 219 | 597 | 219 | 620 | 219 | 624 | – | – | – | – | – | – |

| DN600 | 222 | 698 | 222 | 734 | 222 | 734 | – | – | – | – | – | – |

Purpose and Role of Butterfly Check Valves in Preventing Backflow in Fluid Systems

The primary purpose of butterfly check valves, like all check valves, is to ensure unidirectional flow of fluids in a system. They prevent the backward flow or backflow of fluids, which is critical in many fluid systems to maintain efficiency, protect equipment, and avoid potential disasters.

Maintaining Efficiency

In many fluid systems, it’s crucial to maintain a steady, unidirectional flow. Reversals in flow can create inefficiencies, increase wear and tear on equipment, and in some cases, cause system failures. Butterfly check valves ensure that fluids continue to move in the intended direction, even when the pressure changes, thereby maintaining the system’s overall efficiency.

Protecting Equipment

Backflow can cause significant damage to equipment that’s designed to handle fluid moving in one direction only. For example, pumps and compressors could be damaged by backflow. By preventing backflow, butterfly check valves help to extend the lifespan of these and other pieces of equipment.

Preventing Contamination

In systems where different fluids might interact, backflow can lead to contamination. This is particularly crucial in industries like water treatment, food and beverage production, and pharmaceutical manufacturing. In these cases, butterfly check valves help ensure product integrity by preventing fluid mixing.

Avoiding Potential Disasters

In certain systems, like those dealing with hazardous materials, backflow could potentially lead to a dangerous situation. By ensuring unidirectional flow, butterfly check valves play a role in preventing such disasters.

Working Principle of Butterfly Check Valves

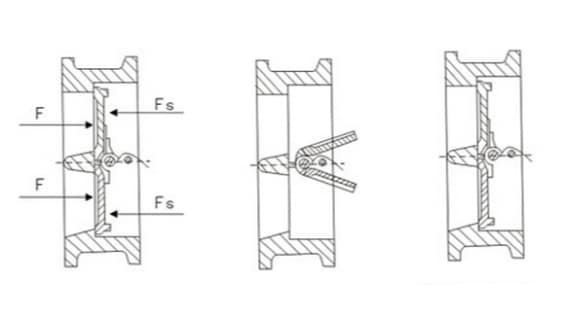

The butterfly check valve, also known as a dual plate check valve, has a unique yet simple mechanism that is designed to allow flow in one direction while preventing backflow. Here’s a step-by-step breakdown of how this mechanism works:

Forward Flow

When there is forward pressure in the pipeline (i.e., the fluid is flowing in the intended direction), this pressure pushes against the two semi-circular ‘butterfly’ plates, which are hinged in the center of the valve. The plates swing open around the hinge, like a pair of double doors, allowing the fluid to pass through.

No Flow or Reverse Flow

When the fluid flow stops or attempts to reverse, the pressure against the plates drops. The plates, due to the hinge mechanism, swing back to their original closed position. In some designs, a spring mechanism may assist in closing the plates. This effectively blocks the pipe and stops the fluid from flowing backward.

Sealing

To prevent any leakage, butterfly check valves often have a resilient seat that provides a tight seal when the plates close. The interaction between the ‘butterfly’ plates and the seat ensures that there is no backward leakage, even when there is pressure from reverse flow.

Automatic Operation

The entire operation of the butterfly check valve is automatic, driven by the dynamics of the fluid flow itself. There is no need for an external power source or manual operation, making butterfly check valves a highly efficient and low-maintenance option for preventing backflow in fluid systems.

This mechanism combines simplicity with efficiency, providing reliable backflow prevention with a low-pressure drop and a compact design. This makes butterfly check valves a popular choice for a wide variety of applications across many industries.

Industries and Systems Where Butterfly Check Valves are Used

Butterfly check valves are versatile and can be found in a wide range of industries and systems due to their ability to prevent backflow efficiently. Here are a few examples:

Water and Wastewater Treatment

In water treatment plants, butterfly check valves are often used in pumping systems to prevent the backflow of water. They ensure that treated water doesn’t flow back into the treatment system, maintaining the integrity and efficiency of the treatment process.

Oil and Gas Industry

Butterfly check valves are integral to pipeline systems in the oil and gas industry. They prevent the reverse flow of oil or gas, thereby protecting pumps and other components of piping system that could be damaged by backflow.

Power Generation

Power plants, especially those that utilize steam (such as nuclear and coal-fired plants), use butterfly check valves in their piping systems to control the direction of fluid and prevent backflow of steam, which is crucial for safe and efficient operation.

Chemical Industry

In chemical processing plants, butterfly check valves are used to prevent the backflow of chemicals, thus ensuring the safety and efficiency of chemical reactions and preventing potential contamination or hazardous situations.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, butterfly check valves can be used to ensure that air and coolant flows in the correct direction, improving the efficiency of the system.

Real-World Examples of Applications

New York City Water Supply System

One of the largest water supply systems in the world, this system uses various types of valves, including butterfly check valves, to control and direct the flow of water throughout the city. These valves are crucial to preventing backflow and ensuring that the water supply is safe and reliable.

Gulf of Mexico Oil Platforms

Oil platforms in the Gulf of Mexico and other oil-rich regions around the world use butterfly check valves in their complex pipeline systems to prevent the backflow of oil. This ensures the efficient and safe extraction and transportation of oil.

These examples highlight the importance and versatility of butterfly check valves. Regardless of the industry or application, these valves play a crucial role in ensuring fluid flows in the correct direction, improving efficiency, and preventing potential damage or hazards.

Advantages of Using Butterfly Check Valves

Compact Design

Butterfly check valves, with their dual plate configuration, have a shorter face-to-face dimension compared to other check valves, making them compact and easy to install in limited space.

Lower Pressure Drop

Due to their design, butterfly check valves tend to have a lower pressure drop across the whole valve body when open, leading to more efficient fluid flow.

Quick Response to Flow Reversal

The lightweight dual plates of the butterfly check valve respond quickly to changes in flow direction, providing prompt backflow prevention.

Versatility

Butterfly check valves are suitable for a wide range of applications and can handle different types of fluids, including liquids, gases, and semi-liquids.

Durability

The robust design and use of resilient materials in butterfly check valves make them highly durable, with the ability to withstand demanding operational conditions.

Comparison with Other Types of Non-Return Valves

| Item | Butterfly Check Valve | Swing Check Valve | Lift Check Valve | Piston Check Valve | Ball Check Valve |

| Design | Compact, dual plates | Single, swinging disc | Piston or ball lifted by flow | Piston with dashpot | Ball lifted by flow |

| Pressure Drop | Low | Moderate-High | Moderate | Low-Moderate | Moderate |

| Response to Flow Reversal | Quick | Slower than butterfly valve | Moderate | Slow (regulated by dashpot) | Moderate |

| Maintenance | Low | Moderate-High | High | Moderate-High | Moderate |

| Cost | Generally lower | Moderate-High | High | Moderate-High | Moderate |

Please note that the selection of a non-return valve type depends on several factors, such as the nature of the fluid, the operating pressure and temperature, installation space, and specific system requirements. It’s always recommended to consult with a valve professional to select the appropriate valve type for each unique application.

Important Factors to Consider When Choosing Butterfly Check Valves for Various Applications.

Type of Fluid

The nature of the fluid (liquid, gas, or semi-liquid), its temperature, and its corrosive or abrasive properties can influence the choice of material for the butterfly check valve. Some materials may be more suited to specific types of fluids to ensure long-term performance and durability.

Operating Pressure and Temperature

The operational conditions in the system, such as the pressure and temperature, will influence the choice of butterfly check valve material. Certain materials and designs can better withstand high pressures and temperatures.

Desired Level of Leak Tightness

The desired level of leak tightness for butterfly check valves, like any other valve, will largely depend on the specific application. However, as a general rule, butterfly check valves should ideally provide a tight seal to prevent backflow when in the closed position.

Installation Space

Butterfly check valves are known for their compact design face dimensions, making them suitable for systems where space is limited. However, the specific dimensions of the installation space should still be considered when selecting a valve.

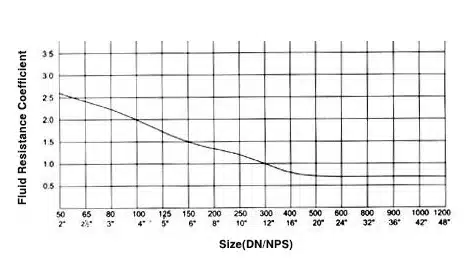

Flow Characteristics

The expected flow rate, pressure drop, and frequency of flow reversal can affect the performance of the valve. For systems with frequent flow reversals, a butterfly check valve with a low cracking pressure might be advantageous.

| DN/mm | NPS/inch | Fluid resistance coefficient when the valve is fully open | Water flow coefficient with valve fully open at room temperature | Direction of Flow of Fluids | |||

| Kv(m3/h) | Cv(U.S) | Cv(U.K) | ↑ | → | |||

| Opening pressure approximation KPa | |||||||

| DN50 | 2“ | 2.6 | 63 | 74 | 62 | 2 | 1 |

| DN65 | 21/2” | 2.4 | 109 | 128 | 107 | 2 | 1 |

| DN80 | 3” | 2.3 | 172 | 201 | 169 | 2 | 1 |

| DN100 | 4” | 2 | 289 | 338 | 283 | 2 | 1 |

| DN125 | 5” | 1.8 | 476 | 557 | 466 | 2 | 1 |

| DN150 | 6” | 1.5 | 750 | 878 | 735 | 2 | 1 |

| DN200 | 8” | 1.3 | 1432 | 1675 | 1403 | 2 | 1 |

| DN250 | 10” | 1.2 | 2330 | 2726 | 2283 | 2 | 1 |

| DN300 | 12” | 1 | 3676 | 4301 | 3602 | 2 | 1 |

| DN350 | 14” | 0.9 | 5274 | 6171 | 5169 | 2 | 1 |

| DN400 | 16” | 0.8 | 7306 | 8548 | 7160 | 3 | 1 |

| DN450 | 18” | 0.8 | 9246 | 10818 | 9061 | 3 | 1 |

| DN500 | 20” | 0.8 | 11415 | 13356 | 11187 | 3 | 1 |

| DN600 | 24” | 0.7 | 17573 | 20560 | 17222 | 3 | 1 |

| DN700 | 28” | 0.7 | 23919 | 27985 | 23441 | 4 | 1 |

| DN750 | 30” | 0.7 | 27458 | 32126 | 26909 | 4 | 1 |

| DN800 | 32” | 0.7 | 31241 | 36552 | 30616 | 4 | 1 |

| DN900 | 36” | 0.7 | 39539 | 46261 | 38748 | 4 | 1 |

| DN1000 | 40” | 0.7 | 48814 | 57112 | 47838 | 4 | 1 |

| DN1050 | 42” | 0.7 | 53817 | 62966 | 52741 | 4 | 1 |

| DN1200 | 48” | 0.7 | 70292 | 82242 | 68886 | 4 | 1 |

Industry Standards and Regulations

Depending on the industry and the region, there may be standards, specifications and regulations that dictate the use of certain types of valves or specific materials. Always ensure that the chosen valve complies with these regulations.

Maintenance and Cost

Consider the ease of maintenance and the total cost of ownership, including initial costs and potential future maintenance costs. Butterfly check valves are generally low maintenance and cost-effective, but individual models may vary.

Valve Quality

Ensure that the valve is sourced from a well-tested and reputable manufacturer and meets quality standards. The performance and lifespan of the valve can significantly impact the overall efficiency and safety of the system.

By considering these factors, you can choose a butterfly check valve that is best suited to your specific application, thereby ensuring optimal performance and durability.

Conclusion

Butterfly check valves, with their dual-plate design, compactness, and quick response to flow reversal, have found widespread applications across industries including water treatment, oil and gas, power generation, chemical industries, and HVAC systems.

Whether it’s maintaining the efficiency of a system by ensuring a steady, unidirectional flow or preventing potential equipment damage and contamination, the benefits of using butterfly check valves are undeniable. Their comparison with other types of non-return valves highlights their advantages in terms of design, pressure drop, flow reversal response, maintenance, and cost.

However, when selecting a butterfly check valve for a specific application, important factors such as the type of fluid, operating pressure and its temperature range, installation space, flow characteristics, industry standards, and regulations, maintenance and cost, and valve quality should be considered.

As a reliable manufacturer and supplier in the valve industry, THINKTANK provides high-quality butterfly check valves designed to meet these diverse requirements. Our valves are recognized for their smooth surfaces and durable construction, designed to withstand varying operational conditions. We’re proud to serve many international well-known brands, providing OEM services that meet specific operational needs. With a reputation built on quality, innovation, and customer satisfaction, THINKTANK is a trusted partner for all your butterfly check valve needs.