Cavitation is the formation and collapse of vapor bubbles (cavities) in the liquid flow streams caused by changes in pressure and velocity. There are four primary negative side effects of uncontrolled cavitation in control valves: high noise, excessive vibration, material damage, and deterioration of flow effectiveness. Physical damage to valve trim is usually characterized by a pitted, rough appearance.

Cavitation in control valves occurs only with liquid flows—gases cannot cavitate.

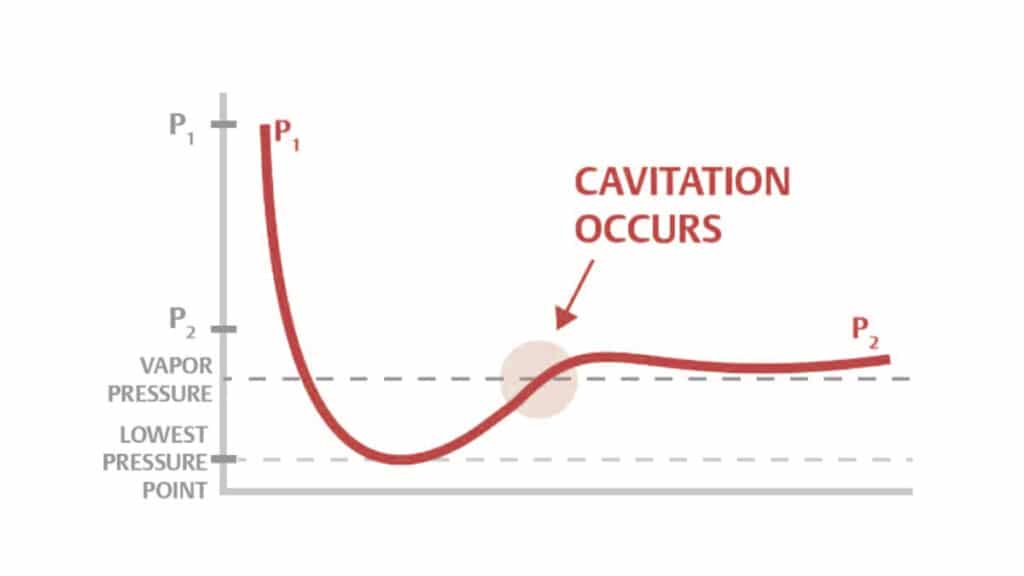

Vapor bubbles form if the liquid’s pressure falls to near the vapor pressure as the liquid passes through the control valve. Bubbles can suddenly collapse or implode as the pressure increases down line, producing cavitation.

Cavitation is one of the results of choked flow. It is the point at which increasing the pressure drop while maintaining a constant inlet pressure yields no further increase in flow rate.