In the world of water treatment and chemical processing, it’s important to control lime dosing accurately. Getting the pH right and avoiding lime blockages can be difficult. Enter the lime dosing valve. It’s a solution that makes dosing lime easier and better.

What is a Lime Dosing Valve

A lime dosing valve is a special valve used to control the amount of lime you add to a water treatment system. It makes sure you dose lime accurately to adjust PH levels, prevent lime blockages, and keep your system water quality right where you want it.

How Does a Lime Dosing Valve Work

A lime dosing valve operates by precisely regulating the flow of lime slurry into a water system, ensuring that the correct amount of lime is delivered to achieve the desired water chemistry. Here’s a detailed explanation of its working mechanism:

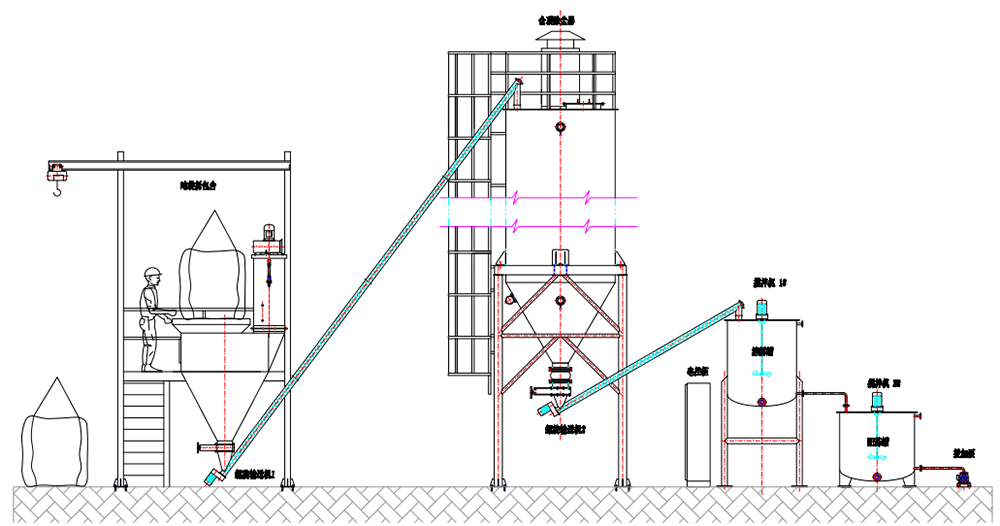

Continuous Circulation

To keep the lime slurry from settling and hardening, we use a lime ring main system. This system pumps the lime slurry around a closed loop all the time. This keeps the mixture consistent and prevents any particles from settling at the bottom or clogging up the works.

Take-Off Line Integration

Inside this circulating system, we put a Tee-piece. This Tee-piece is called a take-off line. It comes off the main loop and takes some of the lime slurry to the dosing valve. The take-off line is what gives us a controlled and manageable flow of lime slurry, which is critical for accurate dosing.

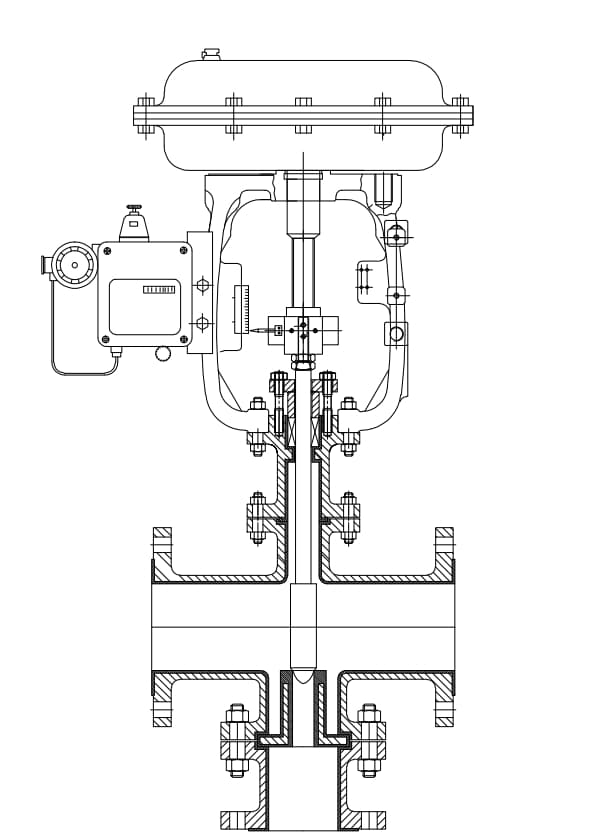

Dart Valve Control

The core of the lime dosing system is the dart valve. This type of valve is designed to give you very fine control over fluid flow. By adjusting the position of the dart inside the valve, you can control the flow rate of the lime slurry very accurately. The dart valve allows for both fine and coarse adjustments, so you can tailor the lime dosing to meet the specific requirements of your water treatment process.

Benefits of Lime Dosing Valves

- Precision Control: The dart valve allows you to control the flow of lime slurry very accurately, so you can dose exactly what you need.

- Preventing Settling: The continuous circulation in the lime ring main keeps the slurry from settling and hardening, so you don’t have to worry about consistency or blockages.

- Versatility: You can use lime dosing valves in a variety of different water treatment processes, from neutralizing acidic waters to removing heavy metals and other contaminants.

- Automation Compatibility: You can integrate these valves with automated control systems that allow you to make real-time adjustments based on water quality measurements.

Features of Lime Dosing Valves

Lime dosing valves are designed to give you superior performance, reliability, and ease of maintenance in tough water treatment environments. Here are the key features of these valves:

Self-Flushing

The self-flushing design makes sure any leftover lime slurry is continuously flushed out, so you don’t have to worry about blockages or inconsistent performance.

Compact Design

The lime dosing valve is compact, which makes it great for installations where you don’t have a lot of space, but you still need a valve that performs well.

Removable Bonnet and Bottom for Easy Maintenance

The valve has a removable bonnet, so you can do maintenance on it without having to take the valve body out of the process line. This feature minimizes downtime and maintenance costs.

Anti-Rotation Device

The valve has an anti-rotation device to keep the valve stable and accurate during operation. This device prevents the valve from moving when you don’t want it to, which could mess up your dosing.

Stroke Indication

The valve has a stroke indicator, which gives you a visual reference for where the valve is. This feature helps you monitor and adjust the valve to make sure you’re dosing accurately.

Standard Mainline Pipe Sizes

Lime dosing valves come in a range of standard mainline pipe sizes, typically from 50 mm to 400 mm. This range covers most installation requirements and flow rates.

Materials of Construction

Valve Body

- Mild Steel: Provides a good, strong, and cost-effective option for the valve body.

Lining Options

- Rubber: Offers good flexibility and resistance to abrasion.

- Ceramics: Provides excellent resistance to wear and corrosion, which is great for harsh environments.

- Polyurethane: Combines flexibility with durability and is suitable for a range of applications.

Coating

- Two-Coat Phenoline Painted Body: Gives you good protection against corrosion and chemical attack.

Valve Shaft and Positioner Mounting

- Stainless Steel: Provides excellent strength and corrosion resistance for the valve shaft and positioner mounting, which ensures long-term reliability.

Plug and Seat

- Polyurethane Coated: Gives you good durability and a tight seal to prevent leakage.

Options

Control or On/Off Operation

Valves can be set up for control applications where you need to regulate the flow very precisely, or for simple on/off operation.

Flange and Drilling

There are lots of different flange and drilling options available to match different pipeline standards and installation requirements.

Positioner

- Smart Positioner(HART, Profibus)– This gives you advanced control and communication capabilities.

- Electro-Pneumatic Positioner(4-20mA) – This allows you to control the valve very precisely using standard industrial signals.

- Pneumatic-Pneumatic Positioner (20-100kPa) – This gives you reliable pneumatic control for a wide range of applications.

Actuator

- Bias Spring Fail Closed – Ensures the valve closes automatically in the event of a failure.

- Fail Safe – Maintains the valve’s last position upon failure.

- Double Acting Actuator – This gives you strong control for both opening and closing actions.

Applications

Rock-Lime Dosing

Perfect for rock-lime dosing applications where you need to dose lime slurry accurately and reliably.

PH Control

Used in pH control applications to adjust the alkalinity and acidity of water, ensuring the water chemistry is right for different industrial processes.

Summary

Lime dosing valves play a critical role in modern water treatment systems. By providing precise control over lime addition, they help maintain optimal pH levels, prevent blockages, and improve overall water quality. Investing in a high-quality lime dosing valve can lead to more efficient and reliable water treatment operations. Also you if you interested in pinch valves, just click this article for “pinch-valves-manufacturer“.

For more information on lime dosing valves and systems, Please feel free to contact THINKTANK‘s representative for a free consultation.