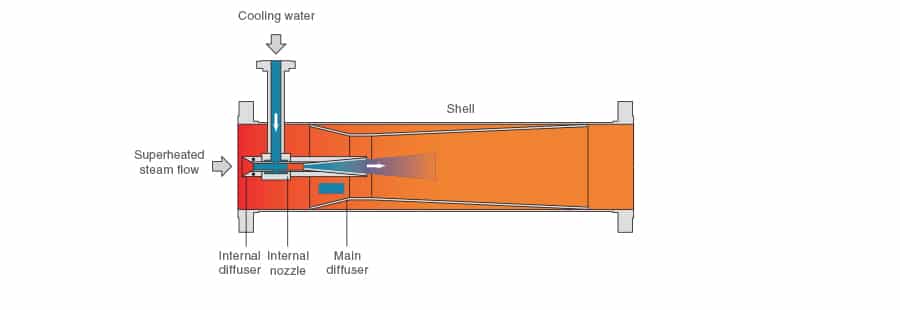

The Venturi desuperheater adopts restrictive measures in the superheated steam pipeline to form a high-speed and turbulent area where cooling water is injected. This helps to establish close contact between steam and cooling water, thereby increasing the efficiency of the desuperheating process.

What Is Desuperheating?

Desuperheating is the process of reducing the superheat temperature or returning superheated steam to its saturated condition. The majority of desuperheaters that are employed to return the system to a saturated condition produce discharge temperatures that are close to saturation, usually within 3°C of the saturation temperature.

An attemporator controls the steam temperature while a desuperheater removes whatever superheat there is in steam and reduces the temperature to a point at or nearly at saturation temperature.

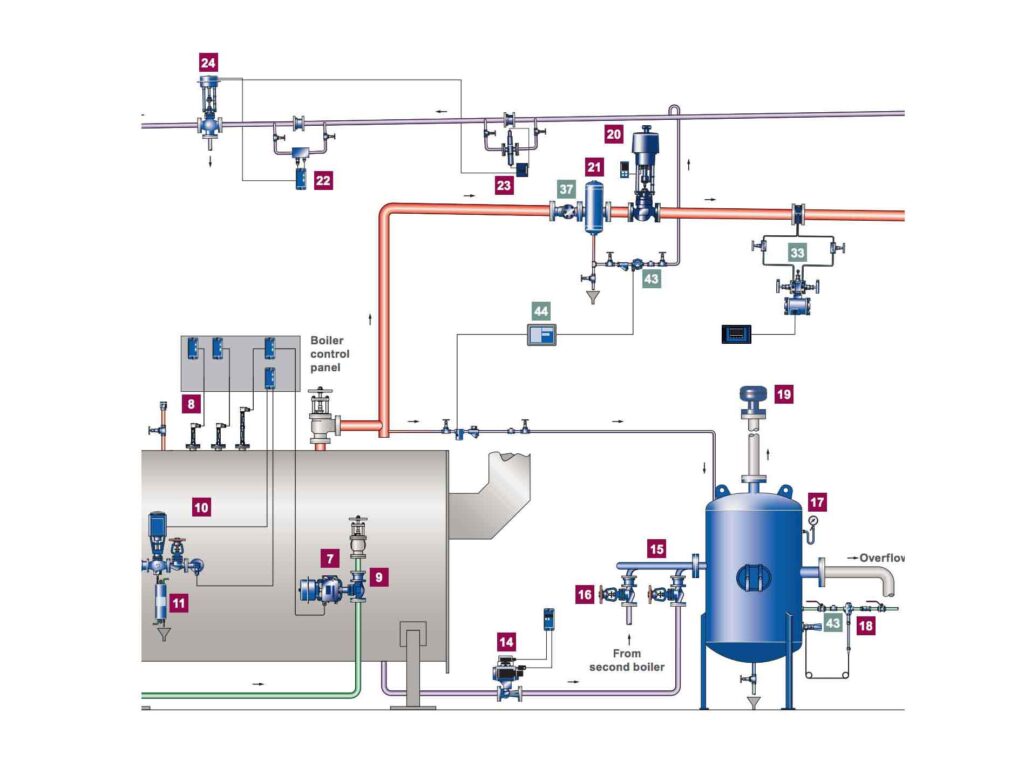

Attemporators are generally found in and/or associated with boiler steam, in zones where too high of a temperature affects something downstream of that point. An attemporator might be used between superheater zones in a multi-zone superheater boiler or in a re-heater zone to control reheater outlet temperature.

Desuperheaters are generally found in steam lines away from the boiler or boiler outlet piping where there is a downstream use for saturated steam.

Desuperheated steam is generally controlled to 5F – 10F above saturation (depending on the sophistication of the device) because if the temperature is controlled at saturation when it goes below the saturation line into the moisture region, the temperature controller cannot detect this.

What Is The Purpose Of Steam Desuperheating?

A regulated amount of water is injected into the superheated steam using a desuperheater mechanism. Evaporative cooling from the water injected into the superheated steam lowers the temperature of the steam, allowing for more effective utilization of the steam downstream.

What Exactly Is A Desuperheater Valve?

In order to reduce the temperature of superheated steam, a desuperheater injects a precise and predetermined amount of water into a steam flow. This could effectively transport heat or be used in other industrial applications to ensure that expensive issues like protracted startup and shutdown periods are avoided.

Final Thoughts

Steam is a complex and professional question around for valve selection, it’s very important to know your steam conditions, and if possible inform everything you know about your application, so the valve manufacturer will based on the process parameters sizing and select the right control valves for you. It ensures the accuracy, response time, service time and flow capacity, temperature, or pressure you need.

Meanwhile, if you are interested in further knowledge about steam or control valves, we recommend you to read the following posts.