As the food and beverage industry evolves, manufacturers continue to make strides toward ensuring safe and hygienic production methods. Using sanitary control valves is one of the most critical components of creating clean or sterile processing and safe food products.

These valves are designed to prevent contamination by reducing or eliminating dead space, minimizing crevices, and reducing the risk of bacterial growth. In this post, we will explore the purpose of sanitary control valves and the benefits they offer to various industries that rely on them.

What are Sanitary control valves?

Sanitary control valves are specifically designed valves used in the food and beverage industry to regulate the flow of fluids and liquids such as water, beer, dairy products, juices, etc. They are critical components of process systems that must meet high standards of hygiene and cleanliness.

Material

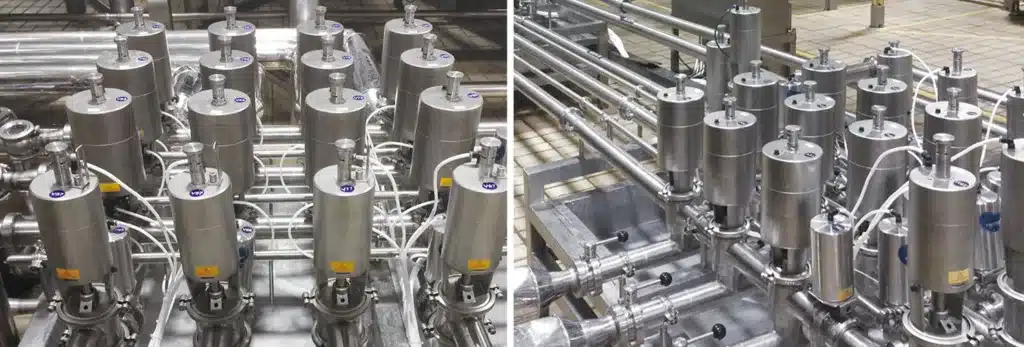

The valves are usually made of high-grade stainless steel. This ensures they are resistant to the corrosive effects of food and beverage products, cleaning and sterilizing agents. Stainless steel also facilitates easy cleaning, thereby ensuring high hygiene standards.

Design

They are designed in such a way as to prevent any accumulation of the product, dirt, or bacteria. This is often achieved through a smooth, streamlined design with no unnecessary corners or crevices where particles could get trapped.

Cleaning

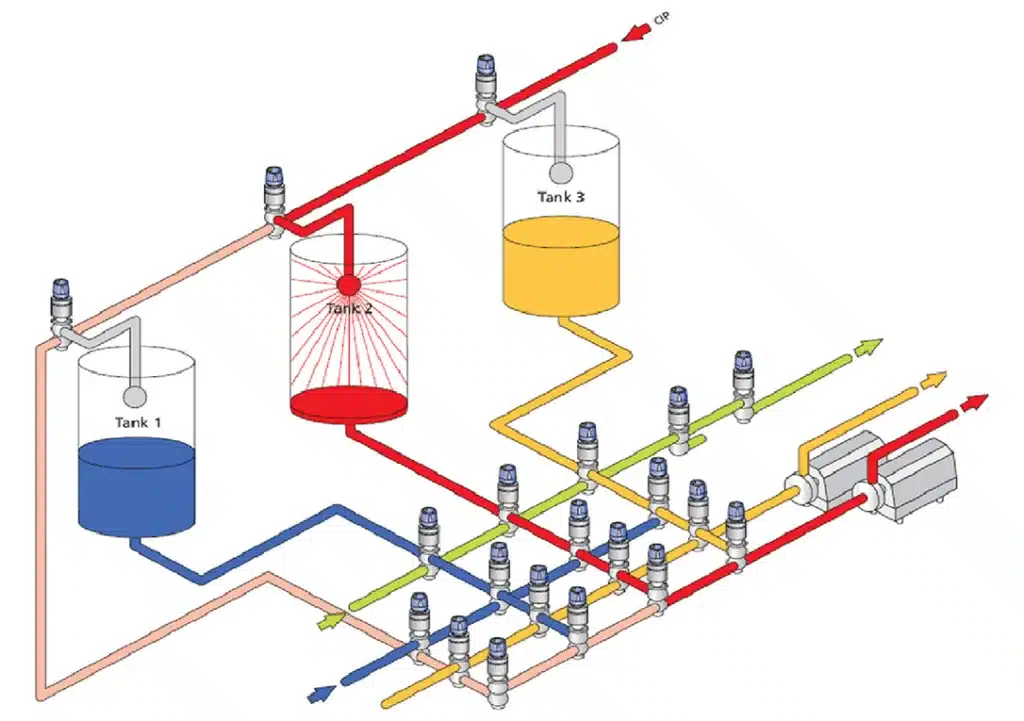

Sanitary control valves are designed to be easily cleaned, either manually or through a process called Clean-in-Place (CIP). CIP is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters, and associated fittings, without disassembly.

Regulation

These valves control the flow of fluid through the equipment by opening, closing, or partially obstructing various passageways. This is done either manually or by automated machinery.

Standards Compliance

Sanitary valves are built to meet specific sanitary standards such as the Food and Drug Administration (FDA) standards in the United States or the European Hygienic Engineering & Design Group (EHEDG) guidelines in Europe. These regulations ensure that the equipment used in food and beverage production is safe and hygienic.

Sealing

The valves have excellent sealing properties to prevent any leakage, which could lead to contamination.

Temperature Resistance

Since food and beverage processing often involves heat, these valves are built to withstand high temperatures without deforming or losing functionality.

The primary function of Sanitary Valves

Sanitary control valves come in different shapes and sizes, and every industry has unique requirements that must be met. However, the primary function of sanitary valves is to regulate fluid flow while preventing contaminants from entering the system.

Depending on the application, sanitary valves can come in the form of gate, globe, diaphragm, butterfly valve, and ball valves. These valves are specifically designed to be cleaned and to avoid bacterial growth within the system.

Hygiene-oriented industries, such as food and beverage, pharmaceutical, medical, dairy, and chemical equipment, utilize sanitary control valves to maintain the quality, purity, and cleanliness of their products.

For example, in the food industry, such sanitary ball valves are used in food processing, sugar production, dairy, beer brewing, and wine production. These valves help maintain the industry’s reputation by ensuring that food products meet high hygiene standards.

Benefits of Using Sanitary Valves

a. Reduction of maintenance costs

One of the significant benefits of using sanitary control valves is the reduction of maintenance costs. Due to their clean design, sanitary control valves are easy to clean and sanitize without requiring special equipment. They are constructed with materials that can withstand sanitization methods such as autoclaving, chemical cleaning, and disinfection. In essence, these valves are designed with the best practices in mind.

b. Regulating flow rates

Another essential factor that makes sanitary valves critical is their ability to regulate flow rates. In food processing, for instance, precise regulation of flow ensures consistent quality and flavor and results in uniformity in the finished product.

Sanitary flow control valves are designed to provide accurate control of fluid flow under varying pressure and temperature conditions, which allows for efficient product production.

c. Reduce the risk of contamination

Sanitary control valves are specially designed to reduce the risk of contamination during the manufacturing process. These valves do this by eliminating the dead space, minimizing crevices, and reducing the chances of bacterial growth within the system.

The closures of sanitary valves are also designed to be easily disassembled, cleaned, and sanitized, making them ideal for industries that require frequent cleaning activities.

d. Excellent flexibility

Lastly, sanitary valves offer excellent flexibility. They can be customized to meet specific needs and be made from various materials such as stainless steel and exotic alloys.

Sanitary valves can also be designed to handle various gases or fluids at a range of temperatures, pressures, and flow rates. This versatility makes them an essential component in every industry where hygiene is a critical concern.

Conclusion

In conclusion, sanitary control valves are purpose-built solutions that play a pivotal role in providing clean, safe, and efficient production methods. Their ability to reduce the risk of contamination, regulate flow rates, and flexibility make them an invaluable tool in various industries. Manufacturers can invest in these valves with the confidence that they are investing in a safer, more efficient, and uniform production process.

THINKTANK is a professional supplier of sanitary control valves, based in Taiwan of China. With an emphasis on high-quality production and exceptional customer service, we offer a comprehensive range of sanitary control valves that are suitable for a variety of applications in the food and beverage industry.

Each valve is carefully designed and manufactured to meet the highest standards of hygiene, durability, and efficiency. Made from high-grade stainless steel, THINKTANK’s sanitary control valves resist the corrosive effects of food and beverage products and cleaning agents, making them ideal for any food processing operation.

Furthermore, these valves are designed for easy cleaning, with seamless surfaces that prevent the build-up of bacteria or product residue. This design allows for Clean-in-Place (CIP) processes, further facilitating the maintenance and cleanliness of your systems.

Adhering to global standards, THINKTANK’s sanitary control valves are compliant with regulations such as those imposed by the Food and Drug Administration (FDA) and the European Hygienic Engineering & Design Group (EHEDG). This ensures the safety and hygienic processing of food and beverages.

As an industry leader, We THINKTANK not only provides robust, reliable, and hygienic solutions for the food and beverage sector but also offers unparalleled customer support and expert advice. This makes THINKTANK your go-to partner for sanitary control valves in China and beyond. Please do not hesitate to contact us if you have any questions.