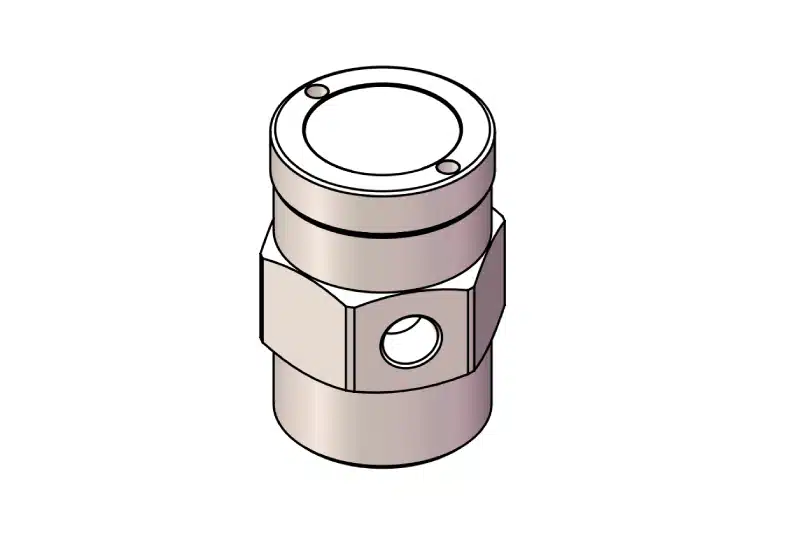

VB14 Vacuum Breaker Description

VB14 is a small special vacuum breakers used in condensing vapour/steam or liquid systems, and it made of Brass material, and the maximum operating pressure for saturated steam service reach 14barg(203psig).

VB21 Vacuum Breaker Description

VB21 is a small special vacuum breakers used in condensing vapour/steam or liquid systems, and it made of Stainless Steel material, and the maximum operating pressure for saturated steam service reach 21barg(304psig).

VB14 and VB21 Size: 1/2″ (DN15),1/8″(DN6)

VB14 and VB21 Connection: NPT, BSP

The Difference Between VB14 with VB21 Vacuum Breaker

VB14 Material List

| NO. | Part | Material |

| 1 | Cap | Brass |

| 2 | Valve | Stainless Steel |

| 3 | Valve Seat | Stainless Steel |

| 4 | Body | Brass |

| 5 | Gasket | Stainless Steel |

VB21 Material List

| NO. | Part | Material |

| 1 | Cap | Stainless Steel |

| 2 | Valve | Stainless Steel |

| 3 | Valve Seat | Stainless Steel |

| 4 | Body | Stainless Steel |

| 5 | Gasket | Stainless Steel |

VB14 and VB21 Installation and Maintenance Instructions

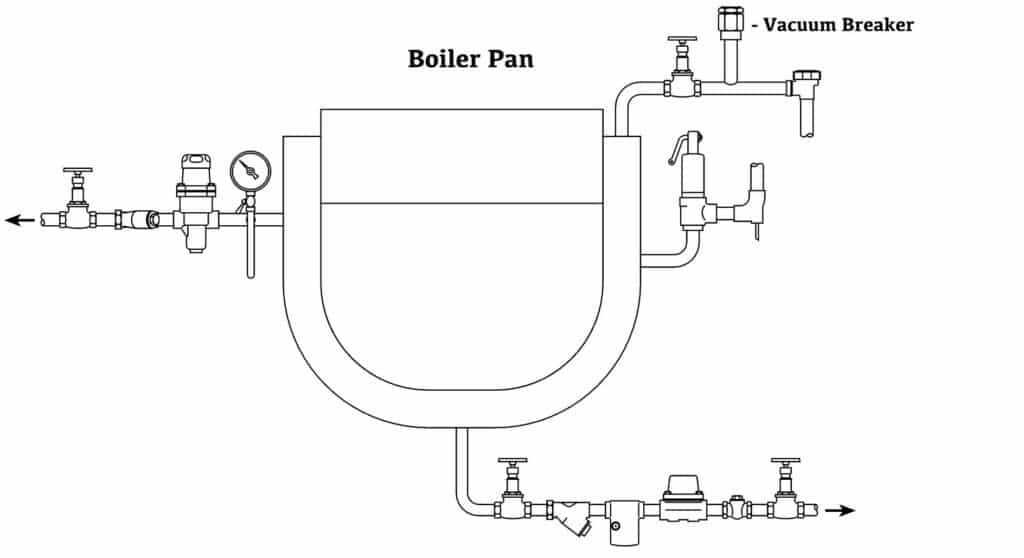

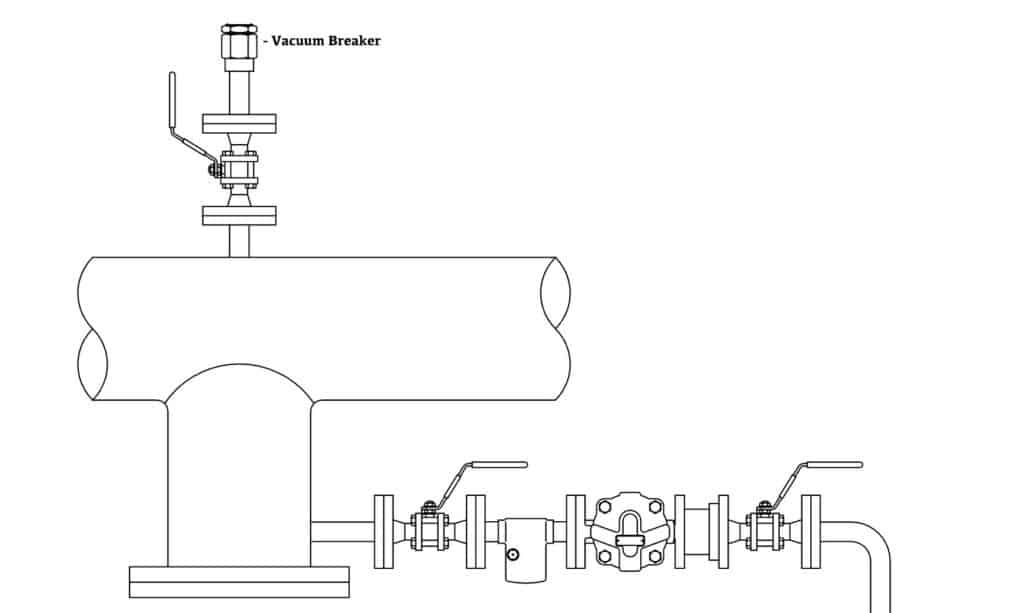

The VB14 and VB21 vacuum breaker must be installed in a vertical position with the system connection at the bottom. On steam systems, install the vacuum breaker at the highest point in the system where it will not get flooded with condensate.

Safety Information

Safe operation of the unit is guaranteed only if it is properly installed, commissioned, and maintained by a qualified person in accordance with the operating instructions. It is also essential to follow general installation and safety guidelines for pipeline and plant construction, including the correct use of tools and safety equipment.

Isolation

Before closing isolating valves, assess whether doing so could pose risks to other parts of the system or personnel. Potential dangers include isolating vents, protective devices, or alarms. Always close isolation valves gradually to avoid system shocks.

Pressure

Before performing any maintenance, consider what is currently or has previously been in the pipeline. Ensure that any pressure is isolated and safely vented to atmospheric pressure before starting maintenance. Do not assume the system is depressurised, even if a pressure gauge shows zero.

Temperature

Allow sufficient time for the system temperature to normalize after isolation to avoid burns. Consider the need for protective clothing, including safety glasses, before proceeding.

Following the Installation and Maintenance Instructions, nameplate, and Technical Information Sheet, confirm that the product is appropriate for the intended application. Before starting any installation, review the above ‘Safety Information’.

VB14 and VB21 Installation Guide

Step 1. Verify Valve Specification

Verify the materials, pressure, and temperature ratings, ensuring they do not exceed the maximum allowable limits. If the product’s maximum operating limit is lower than the system’s, make sure a safety device is in place to prevent overpressurization.

Step 2. Check Flow Direction

Ensure the correct installation orientation and confirm the direction of fluid flow.

Step 3. Remove Protective Covers

Remove protective covers from all connections and peel off any protective films from nameplates, especially before installing on steam or high-temperature applications.

Step 4. Vertical installation

Install the equipment vertically, with the system connection at the bottom.

Note: If the equipment discharges to the atmosphere, ensure the discharge location is safe, as the fluid may reach temperatures of 100°C (212°F).

Vacuum Breaker Commissioning and Operation

After installation or maintenance, verify that the system is operating correctly. Perform tests on all alarms and protective devices to ensure proper functionality.

The VB14 and VB21 vacuum breaker valves are designed to protect steam and process equipment from vacuum while allowing condensate to be efficiently drained from pipes and storage vessels. The valves have a Kv of 0.52 and require a differential pressure of 4.6 mmHg to open.

Normal Operation

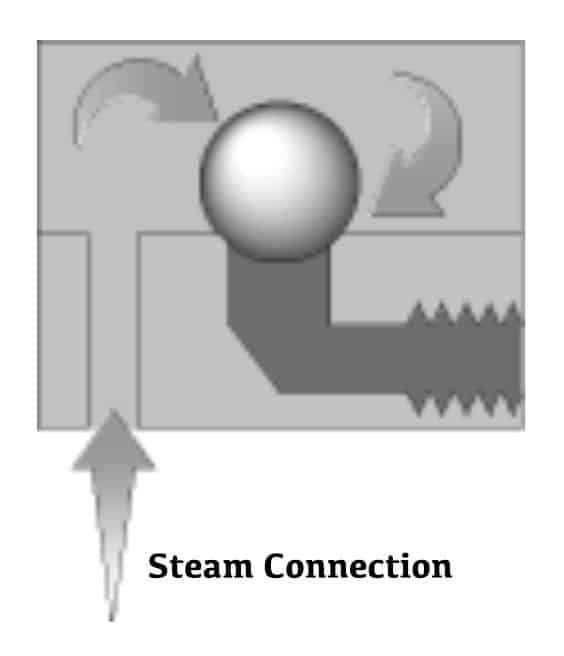

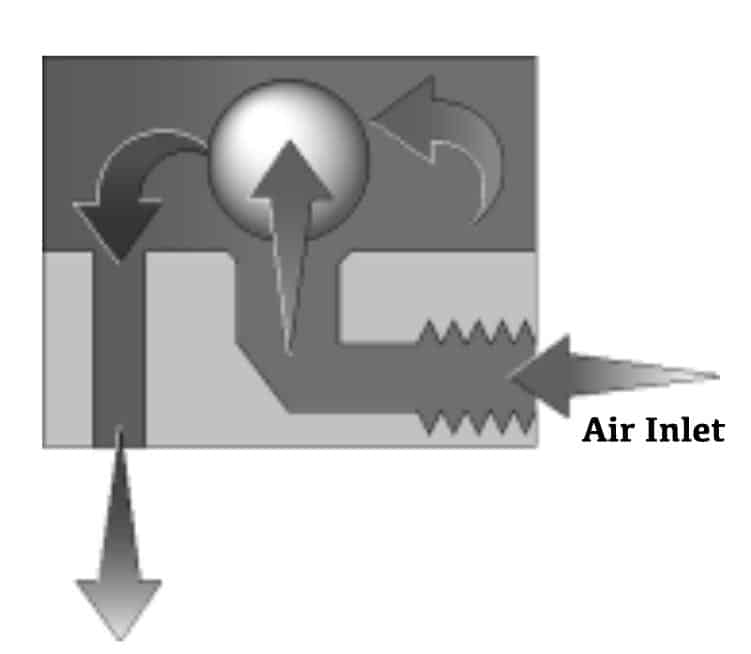

During normal operation, the precision-ground stainless steel vacuum breaker valve is seated tight and shuts off.

Cooling

As the system cools, the steam condenses, which reduces the pressure. The valve stays seated until the pressure in the upper chamber drops below the air inlet pressure (which is typically atmospheric pressure).

At the Point of Vacuum

When a vacuum is about to form, the valve instantly lifts off its seat, allowing air to enter through the upper chamber, which prevents the vacuum from forming.

Contact THINKTANK’s representative if you have any questions, and also free drawing is available.