In industrial, water and wastewater applications both, swing check valves play a pivotal role in controlling the flow of liquids and gases. This article provides an all-encompassing guide to swing check valves, design , functionality, and maintainance to ensure longevity and performance.

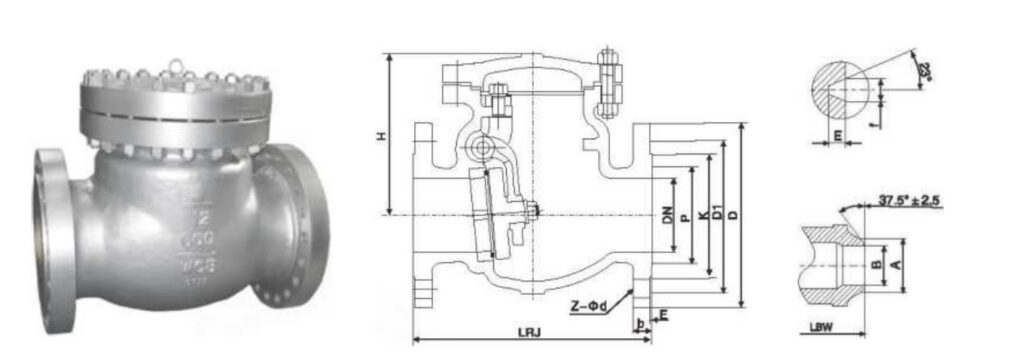

Design of Swing Check Valves

Swing check valves typically consist of a valve body, a disc, and a hinge. The disc swings on the hinge – in the forward flow, it moves away allowing fluid to pass, and in the backflow, it swings back onto the seat, effectively creating a seal.

Materials and Composition

Swing check valves are generally made from durable materials like bronze, cast iron, carbon steel, stainless steel, or PVC. These materials are meticulously selected to ensure resistance to corrosion, high pressure, and temperature fluctuations.

Swing Check Valve Animation

Structure and Components

A typical swing check valve consists of a valve body, a disc, and a hinge. The disc is pivotal, as it opens when the fluid flows in a forward direction and closes to the reverse flow and prevent backflow. The hinge is what keeps the disc attached, allowing it to swing either to an open or closed position.

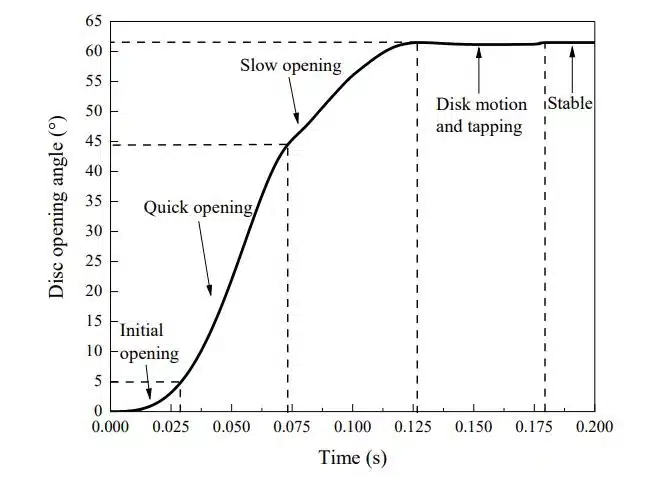

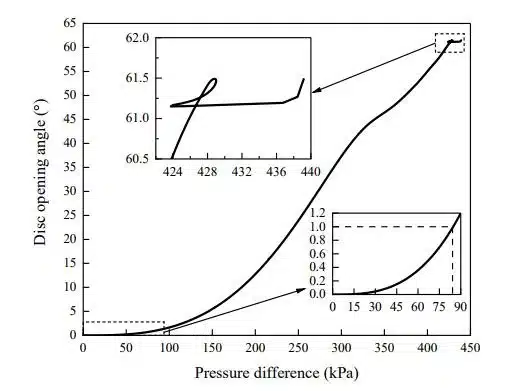

Velocity distributions under different mass flow rates For Swing Check Valve

The velocity distributions on the symmetry plane of the swing check valve are displayed below when the valve opening is 4%. Upon water vapor passing through the valve seat, a high-speed jet is observed, as indicated, with the maximum velocity reaching approximately 12 times the inlet velocity. This results in a high Mach number. Additionally, a distinct vortex is observed at the bottom of the swing check valve, which is attributed to the presence of the high-speed jet. At the top of the swing check valve, where the cross-sectional area is smaller compared to the bottom, water vapor flows along the surface of the valve disc due to the valve’s structural configuration. Figure 4 illustrates the velocity distributions at various mass flow rates, specifically highlighting instances where significant variations are observed. It is evident that the influence of the high-speed jet becomes more prominent as the mass flow rate increases.

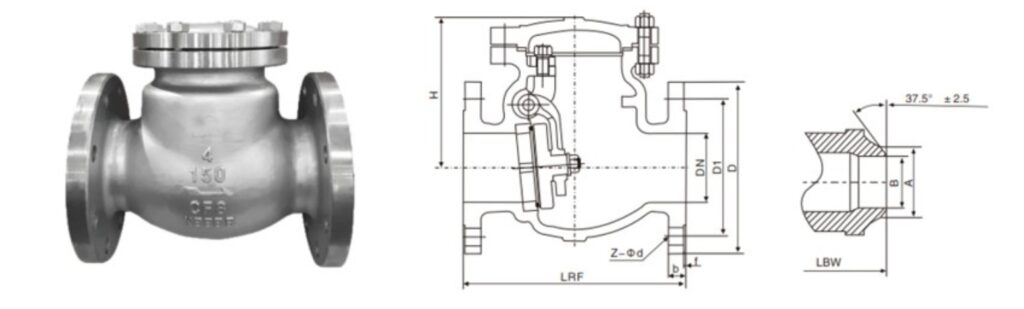

API 594 swing check valve dimensions

API 594 is a standard set by the American Petroleum Institute (API) that specifies the requirements and dimensions for check valves, including swing check valves, which are used in the petroleum and natural gas industries.

The API 594 standard covers two types of check valves:

- Type A: This type includes swing check valves and tilting disc check valves.

- Type B: This type covers piston check valves and ball check valves.

So for swing check valves, It is API 594 Type A standard.

The dimensions specified in API 594 for swing check valves include face-to-face dimensions, which are critical for installation, as well as dimensions of other parts like the valve body, valve disc side, and hinge pins.

Face-to-face dimensions are important as they tell you how much space the valve will take up along the pipe, ensuring compatibility with the pipeline it’s being installed in. For example, a typical 6-inch swing check valve complying with API 594 may have a face-to-face dimension of around 292 mm (or around 11.5 inches), but this can vary.

It’s important to note that there are multiple dimensions and specifications within API 594, and these can also change. Since swing check valves come in various sizes and pressure ratings, the dimensions will vary accordingly.

For the most accurate and up-to-date information on API 594 swing check valve dimensions, I recommend consulting the latest version of the API 594 standard or contact THINKTANK who specializes in API-compliant valves. We are a professional swing check valve manufacturer based in China, specialize in the production of various industrial valves, including swing check valves. It’s important to conduct due diligence and research when choosing a manufacturer, to ensure the products meet the standards and specifications required for your particular application. Our engineers and valve specialists can provide valuable insights on the specific dimensions required for your application.

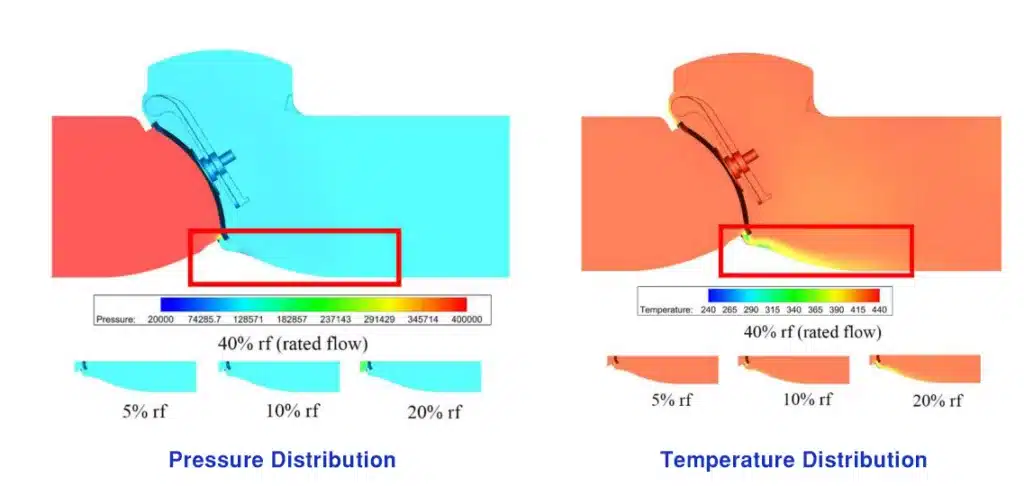

distribution of pressure and temperature at different mass flow rates For swing check valve

The following image shows the distribution of pressure and temperature at different mass flow rates.

When the mass flow rate is below 10% of the rated flow, the pressure variation is minimal, resulting in a negligible temperature difference. However, as the mass flow rate increases, a significant pressure difference becomes evident, with the maximum pressure difference reaching 0.4 MPa at a flow rate of 40% of the rated flow.

Analyzing the temperature distributions, it is apparent that there is a notable temperature variation at higher mass flow rates, with the maximum temperature difference reaching 200 K.

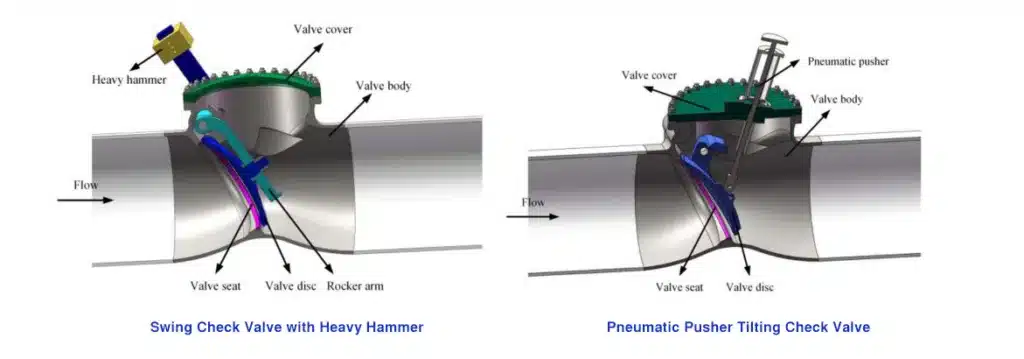

hydraulic swing check valve

Hydraulic swing check valves are composed of several key components, including the valve body, valve seat, valve disc, valve cover, and heavy hammer.

In terms of the pipe lengths associated with hydraulic swing check valves, the upstream pipe length is typically designated as 4D, indicating that it should be four times the nominal diameter of the valve. Similarly, the downstream pipe length is typically specified as 10D, meaning it should be ten times the nominal diameter of the valve. These pipe length ratios help ensure proper flow dynamics and optimal performance of the swing check valve in the hydraulic system.

Swing check valve standard

Swing check valves are subject to various standards that dictate their design, dimensions, material specifications, testing, and marking. The selection of a standard depends on the industry and the specific application. Some of the widely recognized international and industry standards for swing check valves include:

- API 6D: Issued by the American Petroleum Institute, this standard covers the design, manufacturing, and testing of valves primarily used in the oil and gas industry.

- API 594: Also from the American Petroleum Institute, this standard covers design and dimensions specifically for check valves, including swing check types.

- ASME B16.34: Issued by the American Society of Mechanical Engineers, this standard covers the pressure and temperature ratings, dimensions, tolerances, and materials for flanged, threaded, and welding end valves, including swing check valves.

- MSS SP-71: Developed by the Manufacturers Standardization Society, this standard covers iron swing check valves.

- BS 1868: A British Standard which specifies requirements for swing check and tilting disc check valves made of steel, used for oil and gas applications.

- ISO 15761: This International Organization for Standardization standard specifies requirements for steel check valves, including swing check valves, for petroleum, petrochemical, and allied industries.

- DIN 3202: A German standard specifying face-to-face dimensions for swing check valves.

When selecting a swing check valve, it is important to choose one that adheres to the standards applicable to your industry and region. It is also critical to understand the specifications of the system in which the valve will be installed, such as pressure, temperature, and fluid compatibility, to ensure that the valve will perform effectively and safely.

Operation of Swing Check Valves

Flow Direction

Swing check valves are self-actuating. The pressure of the fluid passing through the valve forces the disc to swing away from the valve seat, allowing flow. When the flow ceases or reverses, the spring or disc returns to its seat, preventing backflow.

Pressure Drop and Flow Rate

It’s important to understand that the full swing check valve operation can create pressure drop in the system due to the swinging motion of the disc. This pressure drop must be accounted for in system design to ensure that adequate pressure is maintained for proper functioning.

Applications

Swing check valves are widely used across various industries including petrochemical, pharmaceutical, water treatment, and food processing. They are particularly useful in systems where it is necessary to prevent backflow, such as in pumping applications or in systems with varying pressures upstream flow through.

Swing Check Valve HS Code

As of my last knowledge update in September 2021, the Harmonized System (HS) code for a swing check valve would likely fall under the category of taps, valves, and similar appliances. Please note that HS codes can change, so you should verify the most current code with a relevant authority or through an updated resource in your nation.

Typically, swing check valves could fall under the following HS code:

8481.30 – Check valves

This code is used for international trade and classifies the swing check valve under a broader category of taps, cocks, valves, and similar appliances for pipes, boiler shells, tanks, vats, or the like, including pressure-reducing valves and thermostatically controlled valves.

However, as HS codes can be detailed and specific, and there may be updates or changes, I would recommend consulting a customs specialist or using an updated tariff schedule to confirm the current HS code for swing check valves in your country or the country you are exporting to.

horizontal check valve

In fluid control systems, swing check valves are crucial components used to prevent backflow. Their installation can be either horizontal or in vertical position, depending on the system’s requirements. In this article, we will focus on the vertical installation of swing check valves and its significance.

The Need for Vertical Installation

Vertical installation of swing check valves is usually preferred when space is limited or the pipeline is vertically oriented. Additionally, in some applications, a vertical installation may facilitate better flowing fluid dynamics within the system.

Gravity Assistance

In a vertical installation, gravity can assist in the closing of the valve. This is particularly useful in low flow systems where the weight of the fluid might not have sufficient force to fully close the valve.

Swing check valve installation guide

Installing a swing check valve properly is crucial for its optimal operation and for ensuring the safety and integrity of the piping system. Below is a general installation guide for swing check valves. Please note that you should always consult the manufacturer’s instructions and relevant regulations, and ensure that personnel are qualified for the installation.

- Inspection and Preparation:

- Check the valve to ensure it is free of damage and that it meets specifications.

- Ensure that the pipeline where the valve will be installed is clean and free from debris.

- Confirm that the valve is compatible with the fluid it will control and that it meets the required pressure and temperature ratings.

- Orientation:

- Swing check valves should be installed in the correct orientation for proper operation. Typically, swing check valves are installed in horizontal pipe runs, but some can be installed in vertical pipe runs with upward flow.

- Ensure that the valve’s hinge pin is oriented horizontally to allow the disc to swing freely.

- Positioning:

Position the valve in the location where it will be installed. Ensure that the flow arrow on the valve body matches the direction of flow in the pipeline.

- Installation:

- If the pipeline is existing, ensure it is depressurized and drained.

- Use appropriate gaskets between the valve flanges and the pipeline flanges.

- Insert the valve between the flanges, ensuring proper alignment.

- Install the flange bolts. Tighten the bolts in a crisscross pattern to ensure even pressure.

- If using a threaded swing check valve, apply thread sealant and screw the valve into place, making sure not to over-tighten.

- Testing and Inspection:

- Once the valve is installed, gradually pressurize the system.

- Check for leaks around the flanges and repair if necessary.

- Confirm that the valve operates correctly by observing the flow through the system. The valve should allow flow in one direction and prevent backflow.

- Maintenance:

- Keep records of the installation.

- Develop a maintenance schedule according to the manufacturer’s recommendations.

Safety Notes:

- Always use personal protective equipment (PPE) during installation.

- Follow all local codes and standards.

- If you are not experienced or trained in valve installation, consider hiring a qualified professional.

Maintenance of Swing Check Valves

Routine Inspection

To ensure the longevity and performance of swing check valves, it is essential to perform regular inspections. This includes checking for leaks, ensuring that the hinge pin is not damaged, and that the disc swings freely.

Cleaning and Lubrication

Over time, debris can accumulate in the valve, affecting its operation. It is crucial to periodically clean the valve and apply suitable lubrication to the hinge to ensure smooth operation.

Replacing Worn Out Parts

In the event that parts of the valve become worn out or damaged, they must be replaced promptly to avoid valve failure. This includes replacing the disc or the hinge pin if they become excessively worn.

Testing

Regular testing of the valve under operating conditions is essential to ensure that it is functioning correctly. This might include pressure testing to ensure that the valve is sealing properly under cracking pressure and that there is no leakage.

Conclusion

Swing check valves are an indispensable component in many industrial applications. Understanding the design aspects, operational principles, and maintenance procedures is vital for those who utilize these valves in their systems. Regular inspection, cleaning, and timely replacement of parts are crucial in ensuring their longevity and optimal performance.

We, at THINKTANK, take pride in being a reliable supplier of swing check valves. Our commitment to quality and precision sets us apart. We manufacture swing check valves that conform to international standards and meet the stringent requirements of various industries. Each valve undergoes rigorous testing to ensure optimal performance and long-lasting durability in diverse industrial applications. By employing advanced manufacturing techniques and utilizing high-quality materials, we deliver reliable swing check valves that offer efficient fluid control, effectively prevent backflow, and contribute to the overall reliability and safety of fluid systems. With our expertise and unwavering dedication to customer satisfaction, we have earned a reputation as a trusted supplier of dependable swing check valves. Contact us today and you will have no worries in your valve business.