What Is A Steam Trap Valve?

As explained in quoting the ANSI/FCI 69-1-1989 standard, a trap is an automatic valve that automatically drains condensate from steam to the outside of the valve body while maintaining tight contact with live steam, if necessary, allowing steam to flow at a controlled or adjusted rate. Most steam traps are capable of draining non-condensable gases while maintaining close contact with the steam.

In industry, steam is often used for heating or as a driving force for mechanical power. So the main function of a steam trap is used in such conditions to make sure that steam is not wasted.

Why Steam Trap Is Used In Piping?

Steam is created when water vaporizes into a gas. To make the vaporization process happen, the water molecules must be given enough energy to break the hydrogen bonds between the molecules, and this energy to convert the liquid into a gas is called “latent heat”.

The steam-based heating process uses latent heat and transfers it to a given product. When the work is complete, i.e., the steam has given up its latent heat, the steam condenses and becomes condensate. In other words, condensate does not have the ability to do work with steam. Therefore, if condensate is not removed as soon as possible, either in the steam transport piping or in the heat exchanger, the heating efficiency will be compromised.

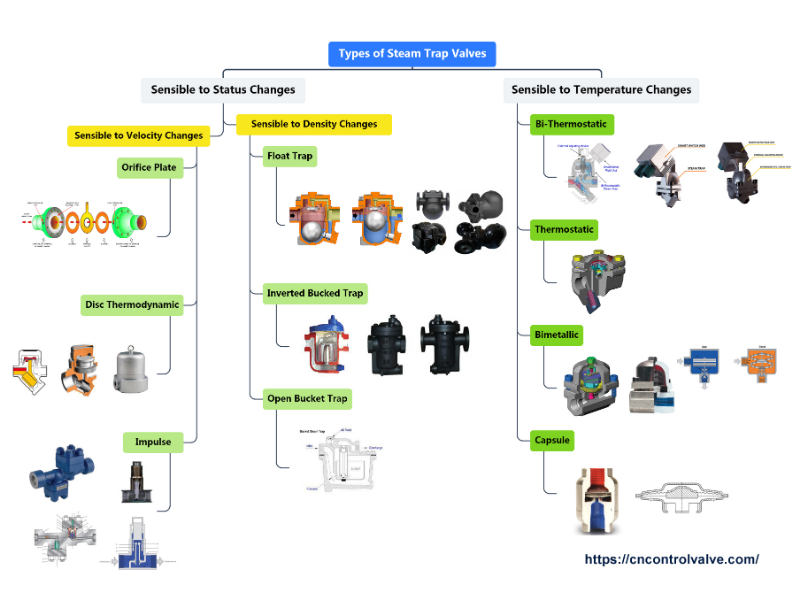

How Many Types Of Trap Valves Are There?

Steam traps are valves used in steam piping and equipment to automatically discharge condensate, air, and other non-condensable gases, and to prevent steam leakage. Based on the operating principle of steam traps, there are three types of steam traps as follows.

Mechanical Type Steam Trap | Classification of Steam Traps by Sensible to Density Changes

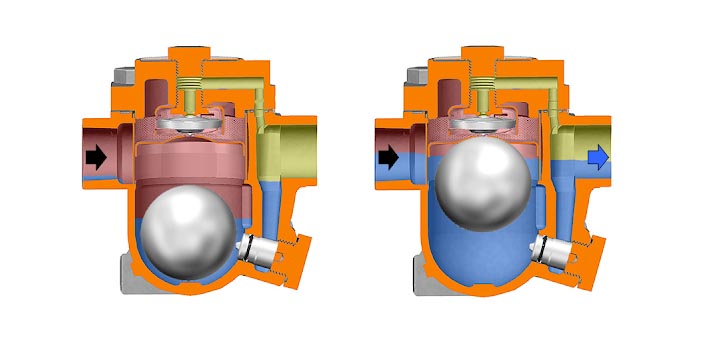

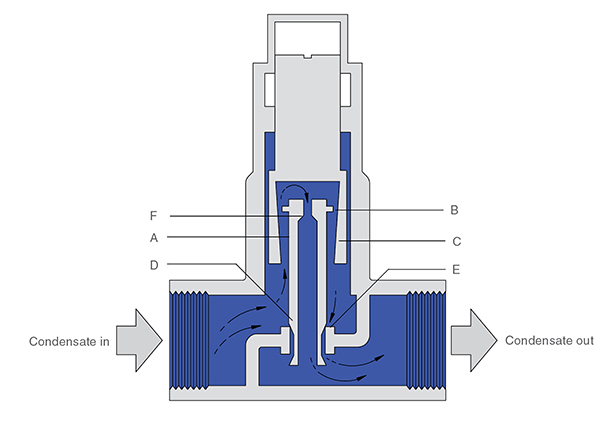

Mechanical type steam traps are operated by the change in condensate level in the steam trap.

1. Float Trap

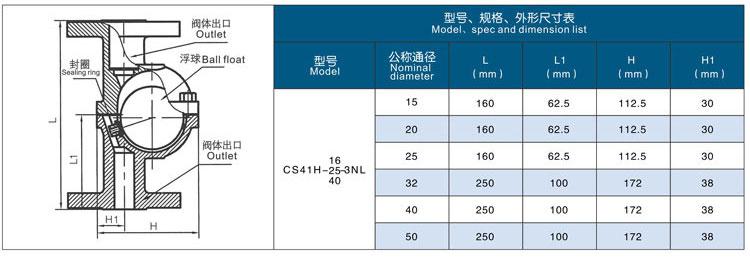

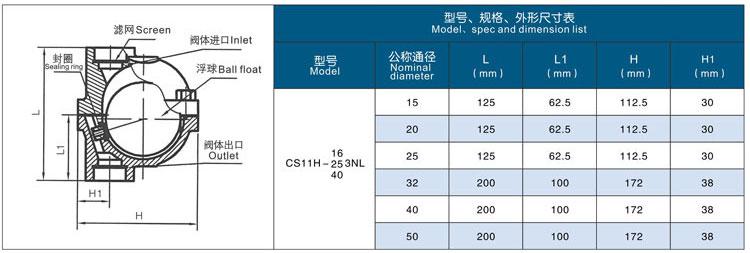

The CS41H Free Float trap is an automatic valve, especially for steam equipment with low pressure, low drainage, and high stability of temperature. The float steam trap is capable of discharging condensate from steam piping networks and heating equipment and preventing steam leakage. This product is widely used in petroleum, chemical, textile, printing and dyeing, pharmaceutical, pulp and paper, food, and other industries.

Features

- Ability to continuously drain stable performance, large capacity, low air leakage rate, and high back pressure rate.

- Stainless steel hollow free float is the main part of the valve, THINKTANK adopts stainless steel ground round float ball.

- All internal parts use stainless steel material which is corrosion resistant, wear-resistant, long service life.

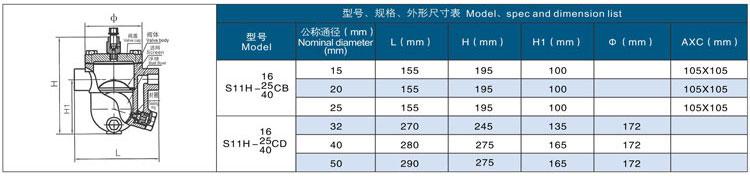

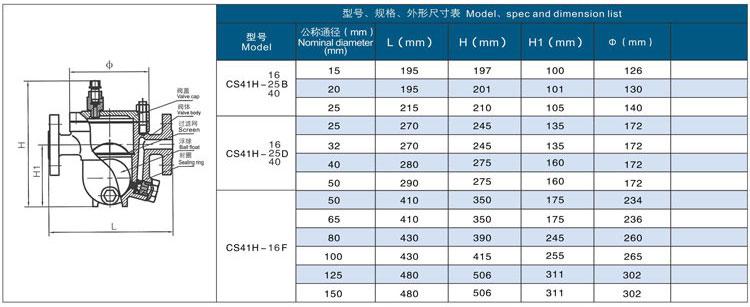

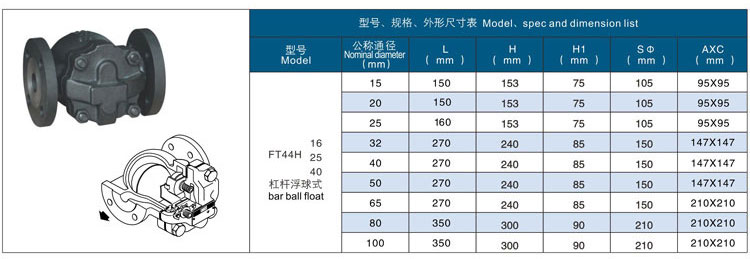

FT44H Lever Float Ball Steam Trap Dimensional Drawing

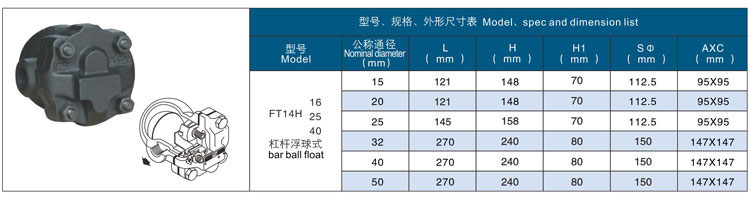

FT14H Lever Float Ball Steam Trap Dimensional Drawing

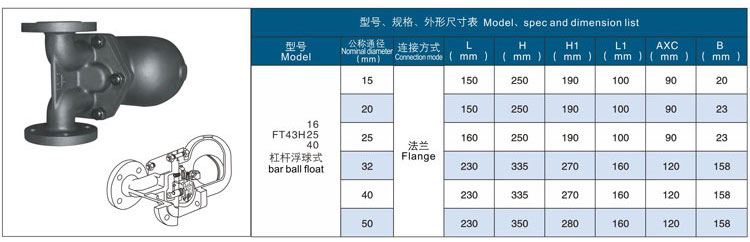

FT43H Lever Float Ball Steam Trap Dimensional Drawing

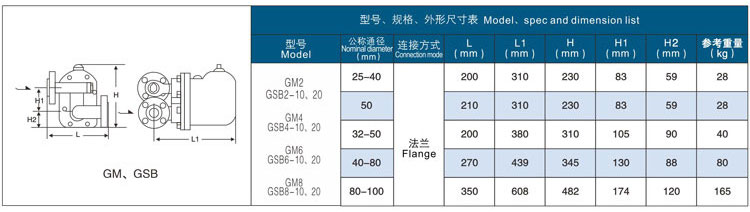

GM/GSB Lever Float Ball Steam Trap Dimensional Drawing

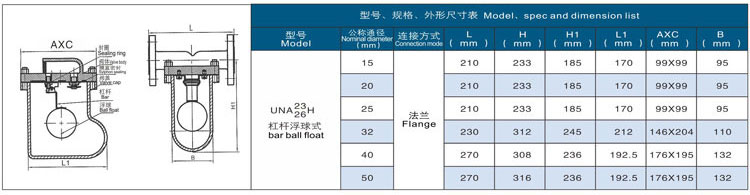

UNA23/26H Lever Float Ball Steam Trap Dimensional Drawing

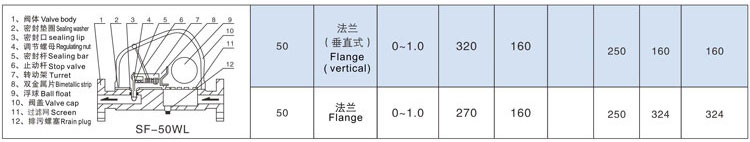

SF-50WL Lever Float Ball Steam Trap Dimensional Drawing

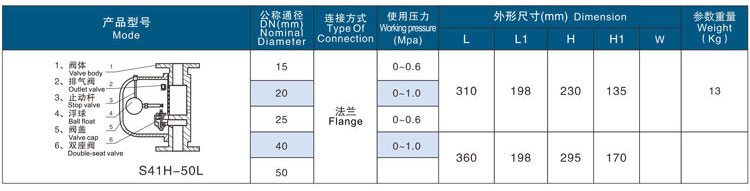

S41h-50L Lever Float Ball Steam Trap Dimensional Drawing

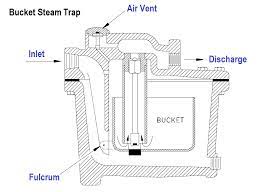

2. Inverted Bucket Trap

An inverted bucket trap is an inverted bucket that is level sensitive, with the bucket opening downward and connected to a lever to drive the disc to open and close the valve. The inverted bucket trap is capable of discharging air, is free of water shock, and has good dirt resistance.

The steam leakage rate is less than 3%, the back pressure rate is 75%, there are more connections, and the sensitivity is not as good as that of the free float type trap. Because inverted bucket traps rely on the upward floating force of steam to close the valve, they are not suitable for use when the differential pressure is less than 0.1 MPA.

Inverted Bucket Steam Trap Dimensions(mm)

| Model | 981-3 | 981 | 980 |

|---|---|---|---|

| Dimension | 15.20.25 | 15.20.25 | 15.20.25 |

| A | 100 | 100 | 100 |

| B | 190 | 190 | 190 |

| C | 127 | 127 | 127 |

| D | 100 | 100 | 100 |

| Bolt Qty | 6 | 6 | 6 |

| Max. Allowable Pressure and Temperature | 1.7MPa 232℃ | 1.7MPa 232℃ | 1.7MPa 232℃ |

| Max. Working Pressure | 1.7 | 1.7 | 1.7 |

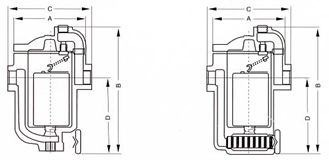

Other Model Inverted Bucket Steam Traps

3. Open Bucket Trap

An open bucket trap is an open bucket that is level sensitive, with the bucket opening upward.

Thermodynamic SteamTrap | Classification of Steam Traps by Sensible to Velocity Changes

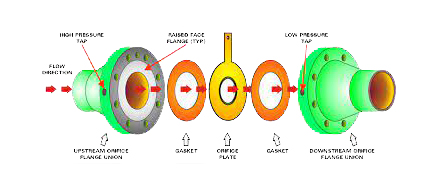

1. Orifice Plate Steam Trap

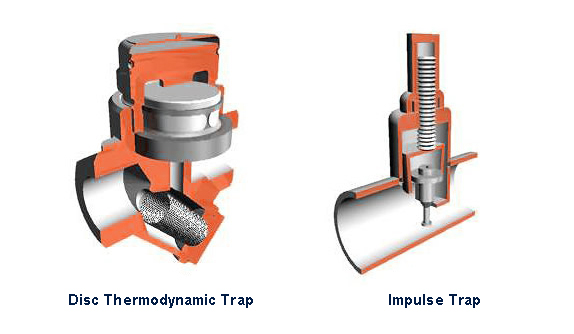

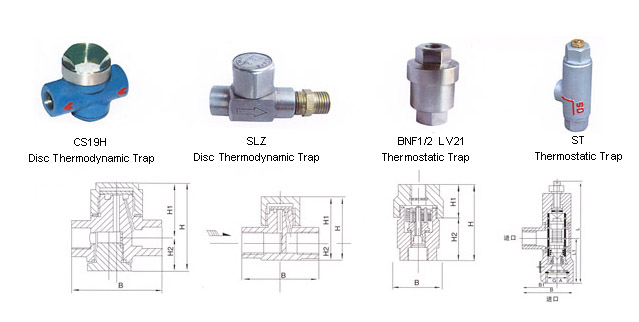

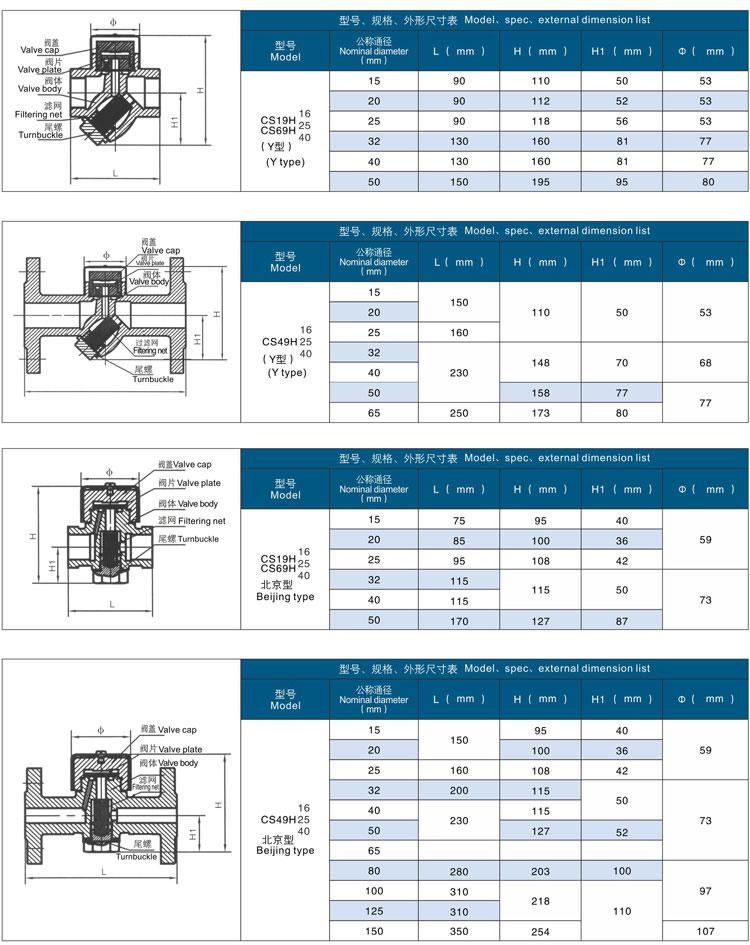

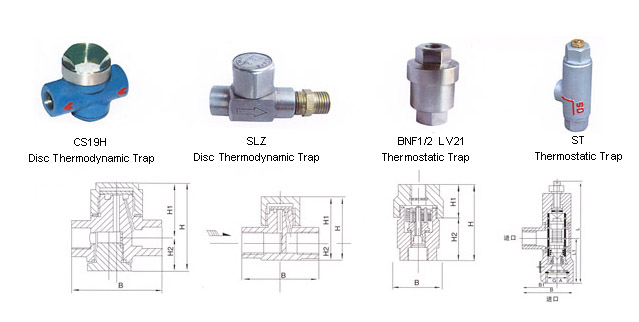

2. Disc Thermodynamic Trap

Discharge of Water(Kg/h) (Based on Differential Pressure MPa)

| Model | DN | 0.05MPa | 0.15MPa | 0.4MPa | 0.6MPa | 1MPa | 1.6MPa | 2.5MPa |

| CS19H-16C CS49H-16C | DN15 DN20 DN25 | 150 | 280 | 400 | 475 | 600 | 800 | |

| CS19H-16C CS49H-16C | DN32 DN40 DN50 | 550 | 650 | 900 | 1200 | 1700 | 2100 | |

| CS19H-25 CS49H-25 CS69H-25 | DN15 DN20 DN25 | 1717 | 1828 | 2536 | 2701 | 3202 | 3581 | |

| CS19H-25 CS49H-25 CS69H-25 | DN32 DN40 | 56 | 119 | 321 | 470 | 534 | ||

| CS19H-25 CS49H-25 CS69H-25 | DN50 | 1800 | 2050 | 2600 | 3000 | 3500 | 4300 | 5000 |

| CS19H-40 CS49H-40 CS69H-40 | DN15 DN20 DN25 | 56 | 119 | 321 | 470 | 534 | ||

| CS19H-25 CS49H-25 CS69H-25 | DN32 DN40 DN50 | 1800 | 2050 | 2600 | 3000 | 3500 | 4300 | 5000 |

Material List

| Body | Forged Steel |

|---|---|

| Cap | Stainless Steel |

| Bonnet | Forged Steel |

| Disc | Stainless Steel |

| Sealing | Stainless Steel |

| Model | DN | Connection | Max. Allowable Temp.℃ | Body Material | B | H | H1 | H2 |

| CS19W-16P | 6 | Threaded | 250℃ | 0Cr18Ni9 | 50 | 48 | 30 | 18 |

| CS19W-16P | 8 | Threaded | 250℃ | 0Cr18Ni9 | 50 | 48 | 30 | 18 |

| CS19W-16P | 10 | Threaded | 250℃ | 0Cr18Ni9 | 52 | 58 | 35 | 23 |

| SLZ Thermodynamic Steam Trap | 6 | Threaded | 250℃ | 0Cr18Ni9 | 40 | 33 | 24 | 9 |

| SLZ Thermodynamic Steam Trap | 8 | Threaded | 250℃ | 0Cr18Ni9 | 40 | 33 | 24 | 9 |

| SLZ Thermodynamic Steam Trap | 10 | Threaded | 250℃ | 0Cr18Ni9 | 52 | 37 | 26 | 11 |

| Model | DN | B | H | H1 | H2 |

| ST-16C Adjustable Thermostatic Trap | 15 | 62 | 162 | 95 | 67 |

| ST-16C Adjustable Thermostatic Trap | 20 | 68 | 162 | 95 | 67 |

| ST-16C Adjustable Thermostatic Trap | 25 | 75 | 168 | 93 | 75 |

| ST-16C Adjustable Thermostatic Trap | 32 | 80 | 175 | 100 | 80 |

| Model | BNF1 | BNF1 | BNF1 | BNF2 | BNF2 | BNF2 | |

| Connection | 1/2″Threaded Ends | 3/4″Threaded Ends | 1″Threaded Ends | 1/2″Threaded Ends | 3/4″Threaded Ends | 1″Threaded Ends | |

| Size | DN | 15 | 20 | 25 | 15 | 20 | 25 |

| Dimension(mm) | L | 100 | 105 | 105 | 100 | 105 | 105 |

| Dimension(mm) | W | 63 | 63 | 63 | 63 | 63 | 63 |

| Weight(Kg) | 0.8 | 0.9 | 0.9 | 0.8 | 0.9 | 0.9 |

3. Impulse Trap

Thermostatic Steam Trap | Classification of Steam Traps by Sensible to Temperature Changes

1. Bi-Thermostatic Steam Trap

2. Thermostatic Steam Trap

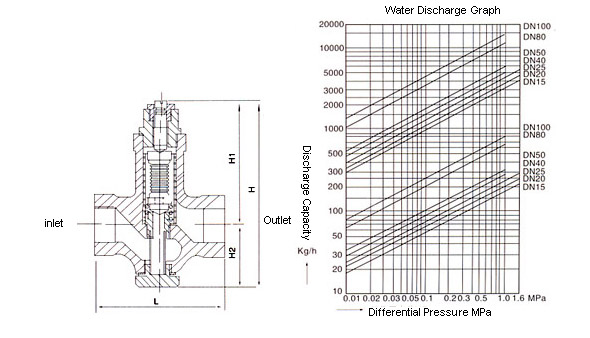

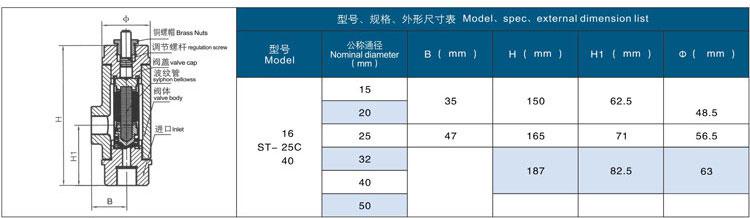

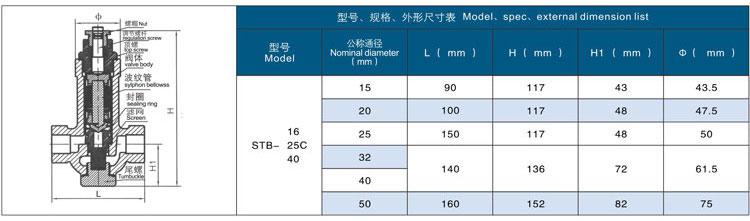

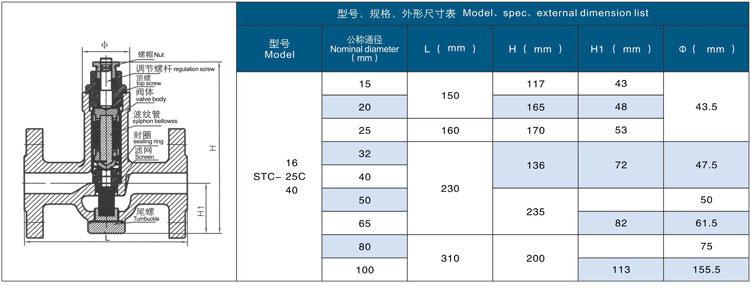

STC, STB, ST Series Adjustable Thermostatic Traps

Size: DN15 to DN100

Model: ST Series(Angle Type Threaded Ends), STB(Straight Type Threaded Ends), STC(Straight Type Flanged Ends)

Material: Cast Steel, Stainless Steel

Connection Type: Threaded Ends, Flanged Ends

Suitable Temperature: 80~450℃

Application: City construction, chemical industry, metallurgy industry, petroleum industry, pharmaceutical industry, food&beverage industry.

| Model-Size | Dimension | Dimension | Max. Drain(ton/hr) | Model-Size | Dimension | Dimension | Max. Drain(ton/hr) | Flange O.D. |

| L | H | L | H | |||||

| ST8-15 | 120 | 65 | 1.4 | STB16-15 | 90 | 150 | 3 | |

| ST8-20 | 120 | 65 | 3 | STB16-20 | 100 | 150 | 4 | |

| ST8-25 | 130 | 70 | 4 | STB16-25 | 120 | 165 | 5 | |

| ST16-15 | 120 | 65 | 3 | STB10-40 | 140 | 185 | 9 | |

| ST16-20 | 120 | 65 | 4 | STB10-50 | 160 | 195 | 11 | |

| ST16-25 | 130 | 70 | 5 | STC16-15 | 150 | 175 | 3 | 95 |

| ST16-40 | 145 | 85 | 9 | STC16-20 | 150 | 175 | 4 | 105 |

| ST16-50 | 145 | 95 | 11 | STC16-25 | 160 | 185 | 5 | 115 |

| STC10-40 | 230 | 255 | 9 | 145 | ||||

| STC10-50 | 230 | 255 | 11 | 160 | ||||

| STC10-80 | 310 | 285 | 18 | 195 | ||||

| STC10-100 | 310 | 355 | 22 | 215 |

Features of Adjustable Thermostatic Trap

STC series adjustable thermostatic trap is one of the products of thermostatic type. The temperature-sensitive element inside the valve is equipped with a temperature-sensitive mixture of a temperature-sensitive material, saturating agent, stabilizer, and filler, which is used to automatically close or open the valve by changing the state of thermal expansion and contraction in response to temperature. The temperature range for T condensate discharge is determined by selecting the appropriate specification, and then can be adjusted within this range with the adjusting screw as required.

BNF1(2)Lv21 Thermostatic Traps

Features

- BNF1(2)Lv21 thermostatic trap with steam or air insulation, not affected by ambient temperature, reduces operation frequency, and extends service life.

- Equipped with strainer for self drainage.

- The valve is sensitive and reliable and has a large drainage capacity.

Principle of Operation

Thermostatic traps use the thermodynamic properties of condensate to evaporate a second time when the condensate discharge is low. Only the viscosity and sealing aspects differ from the steam in driving the opening and closing elements.

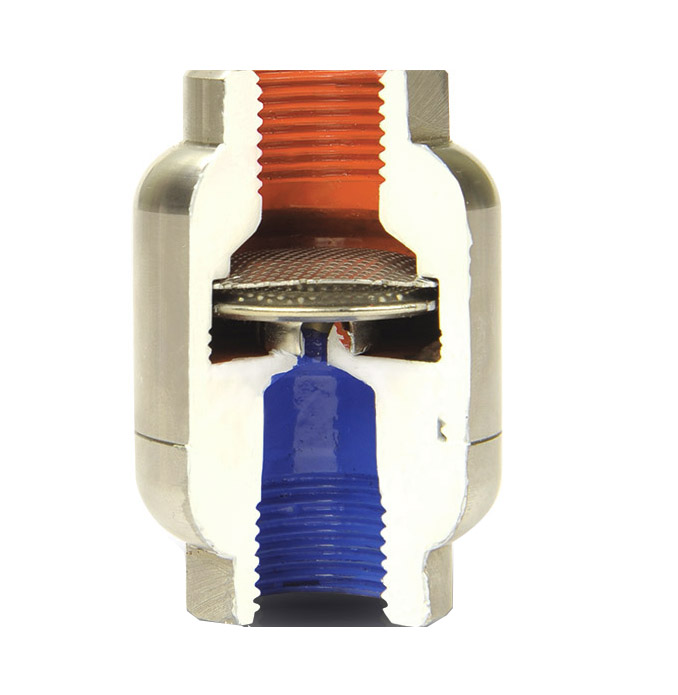

How Does A Thermostatic Steam Trap Work?

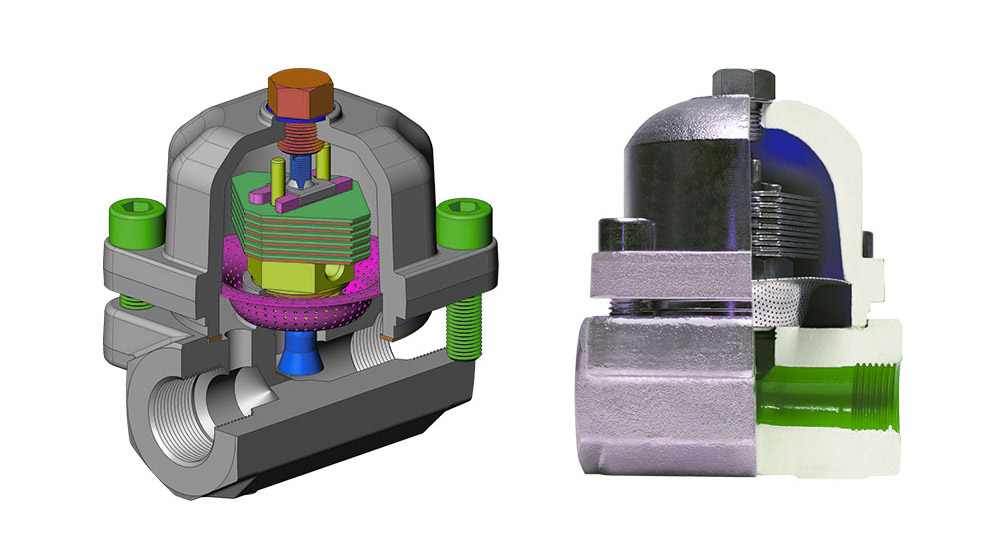

Thermostatic traps are based on the balance of steam pressure and the internal pressure of the thermostatic membrane capsule, which is filled with a special liquid whose saturation temperature is slightly lower than that of steam at any pressure.

In the start-up position, the steam trap opens fully to remove air and drain condensate. When the temperature reaches the pressure-dependent saturated steam level, the vaporization of the liquid inside the thermostatic capsule membrane generates a differential pressure that causes the orifice to close. As the condensate cools, the condensation of the liquid reduces the internal pressure of the membrane. The resultant differential pressure will benefit the external pressure that acts on the membrane by retracting and opening the orifice, which allows the condensate to drain and the cycle to continue.

| NO. | Advantages of Thermostatic Steam Trap |

| 1 | Maximum Efficiency: Benefit from the hidden energy of steam. |

| 2 | Easy Maintenance: In the event of any failure, only needs removing 4 bolts from the steam trap cover, without having to replace all steam traps. |

| 3 | Easy to Installation: Unlike thermodynamic steam traps (which can only be installed on horizontal lines), thermostatic steam traps can be installed horizontally, vertically, or at an angle on steam lines and are capable of operating at 100% efficiency. |

| 4 | Drain Air or Other Gases: Due to the action of the thermostatic capsule, thermostatic steam traps are enabled to drain air and other gases that cannot condense, to protect the system from water hammer. |

| 5 | Enhanced Discharge Capacity: Condensate discharge capacity can be improved by expanding the number of capsules that are used in the valve body design. The discharge capacity depends on the type and number of capsules, as well as the size of the steam trap. |

Disadvantage of Thermostatic Steam Trap

The fluid in the capsule is adjusted to the pressure of the saturated steam temperature, and at superheated temperatures, the capsule may become stuck and not function properly, so it is not suitable for ultra-high temperature steam.

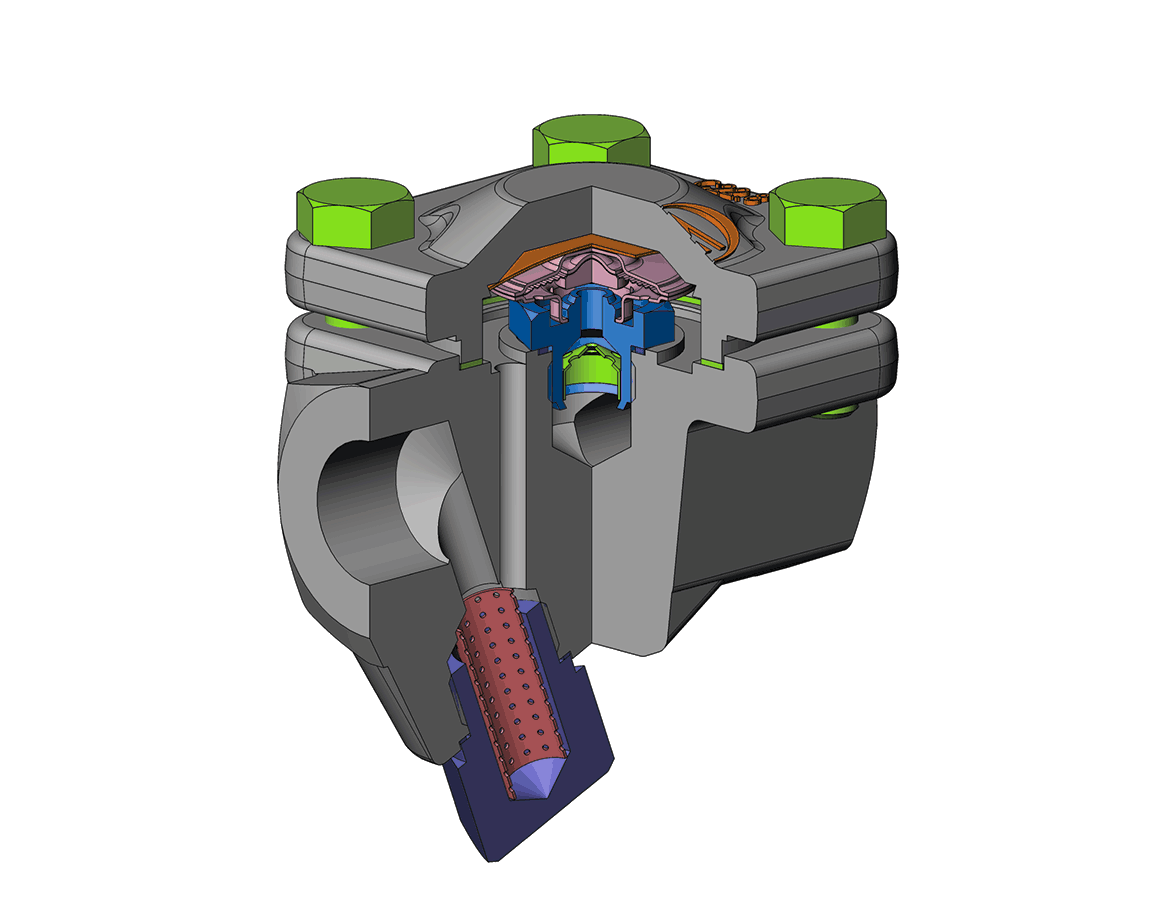

3. Bimetallic Steam Trap

The Bimetallic Steam Trap works by striking a balance between the opposing bi-metal force, which depends on temperature and attempts to close the discharge valve, and the steam force, which depends on pressure and tries to open the valve. The trap is calibrated so that the bi-metal force will prevail at saturated steam temperature while the force of pressure will prevail with under-cooled condensate and air and open the valve.

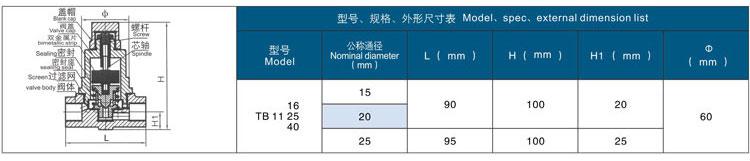

TB5,TB3,TB6,TB11 Series Bimetallic Steam Traps

The adjustable bimetal trap is operated by a bimetal temperature-sensing element that moves the valve plug to open and close. When the device is first started and low temperature condensate appears in the pipeline, the bimetal is spreading and the valve plug is in the open position under the spring force. When the condensate temperature is rising, the bimetal temperature-sensitive element starts to bend, and pushes the valve plug to the closed position. The trap closes completely before the condensate reaches saturation temperature. There is always high temperature condensate inlet of the valve, no steam leakage, and saves energy.

Application

TB5(3,6,11)F adjustable bimetal traps are used for steam mains, sub-cylinders, steam tracing lines, radiators, low-temperature heating tanks, crumb traps, etc.

Advantages of Adjustable Bimetallic Traps

- Free from water shock

- High-pressure resistance

- Small volume

- Lightweight

- Freeze-proof

- Automatically discharge air

- Can be installed in any position

- The back pressure rate is greater than 80%

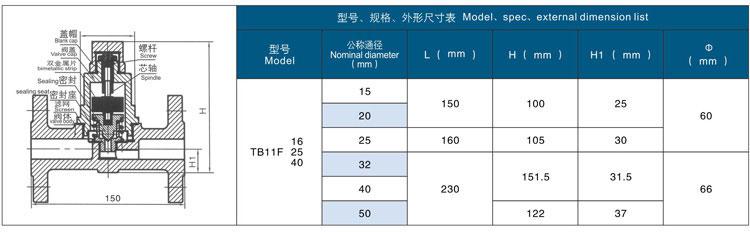

TB5(3,6,11)F Adjustable Bimetallic Trap

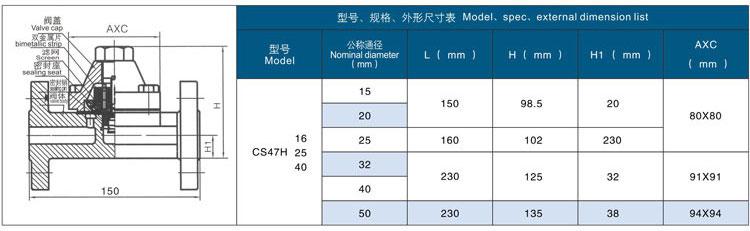

CS47H Adjustable Bimetallic Trap

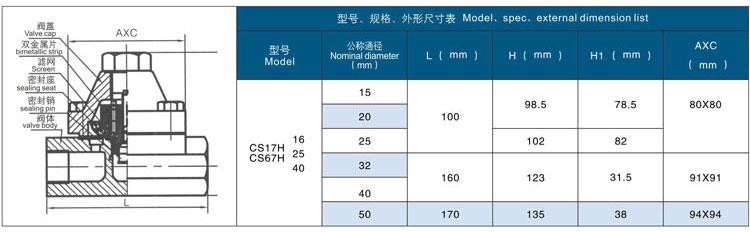

CS17H,CS67H Adjustable Bimetallic Traps

| Model | Size | Connection | Suitable Pressure | Max. Allowable | Adjustable | Body | ||||

| Nominal Diameter | Type | Range | Temperature | Temperature | Material | mm | ||||

| DN | (MPa) | ℃ | ℃ | L | H1 | H2 | W | |||

| TB6(CS17H-16C) | 15-20 | 1/2“~1” Threaded | 0.01~1.6 | 220 | 50~180 | A105 | 90 | 109 | 35 | 58 |

| TB6(CS17H-16C) | 25 | 1/2“~1” Threaded | 0.01~1.6 | 220 | 50~180 | A105 | 95 | 109 | 35 | 58 |

| TB6F(CS47H-16C) | 15-20 | Flanged | 0.01~1.6 | 220 | 50~180 | A105 | 150 | 109 | 35 | 58 |

| TB6F(CS47H-16C) | 25 | Flanged | 0.01~1.6 | 220 | 50~180 | A105 | 160 | 109 | 35 | 58 |

| TB6F(CS47H-16C) | 32-50 | Flanged | 0.01~1.6 | 220 | 50~180 | A105 | 230 | 109 | 35 | 58 |

| TB6W (CS67H-16C) | 15-20 | Sock welded | 0.01~1.6 | 220 | 50~180 | A105 | 90 | 109 | 35 | 58 |

| TB6W (CS67H-16C) | 25 | Sock welded | 0.01~1.6 | 220 | 50~180 | A105 | 95 | 109 | 35 | 58 |

| TB11 (CS17H-16C) | 15-20 | Threaded | 0.01~1.6 | 220 | 60~190 | A105 | 90 | 109 | 35 | 58 |

| TB11 (CS17H-16C) | 25 | 1/2“~1” Threaded | 0.01~1.6 | 220 | 60~190 | A105 | 95 | 109 | 35 | 58 |

| TB11F (CS47H-16C) | 15-20 | Flanged | 0.01~1.6 | 220 | 60~190 | A105 | 150 | 109 | 35 | 58 |

| TB11F (CS47H-16C) | 25 | Flanged | 0.01~1.6 | 220 | 60~190 | A105 | 160 | 109 | 35 | 58 |

| TB11F (CS47H-16C) | 32-50 | Flanged | 0.01~1.6 | 220 | 60~190 | A105 | 230 | 109 | 35 | 58 |

| TB3 (CS67H-16C) | 15-20 | Threaded | 0.01~1.6 | 350 | 50~190 | A105 | 90 | 85 | 23 | 54 |

| TB3 (CS67H-16C) | 25 | 1/2“~1” Threaded | 0.01~1.6 | 350 | 50~190 | A105 | 95 | 85 | 23 | 54 |

| TB3F (CS67H-16C) | 15-20 | Flanged | 0.01~1.6 | 350 | 50~190 | A105 | 150 | 85 | 23 | 54 |

| TB3F (CS67H-16C) | 25 | Flanged | 0.01~1.6 | 350 | 50~190 | A105 | 160 | 85 | 23 | 54 |

| TB3W (CS67H-16C) | 15-20 | Sock welded | 0.01~1.6 | 350 | 50~190 | A105 | 90 | 85 | 23 | 54 |

| TB3W (CS67H-16C) | 25 | Sock welded | 0.01~1.6 | 350 | 50~190 | A105 | 95 | 85 | 23 | 54 |

| TB5 (CS17H-21C) | 15-20 | Threaded | 0.01~2.1 | 350 | 50~200 | A105 | 90 | 85 | 23 | 54 |

| TB5 (CS17H-21C) | 25 | 1/2“~1” Threaded | 0.01~2.1 | 350 | 50~200 | A105 | 95 | 85 | 23 | 54 |

| TB5F (CS47H-21C) | 15-20 | Flange | 0.01~2.1 | 350 | 50~200 | A105 | 150 | 85 | 23 | 54 |

| TB5F (CS47H-21C) | 25 | Flange | 0.01~2.1 | 350 | 50~200 | A105 | 160 | 85 | 23 | 54 |

| TB5W (CS67H-21C) | 15-20 | Sock welded | 0.01~2.1 | 350 | 50~200 | A105 | 90 | 85 | 23 | 54 |

| TB5W (CS67H-21C) | 25 | Sock welded | 0.01~2.1 | 350 | 50~200 | A105 | 95 | 85 | 23 | 54 |

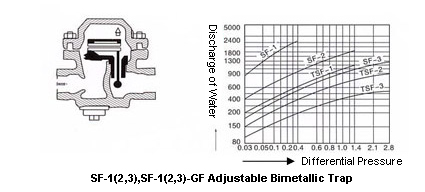

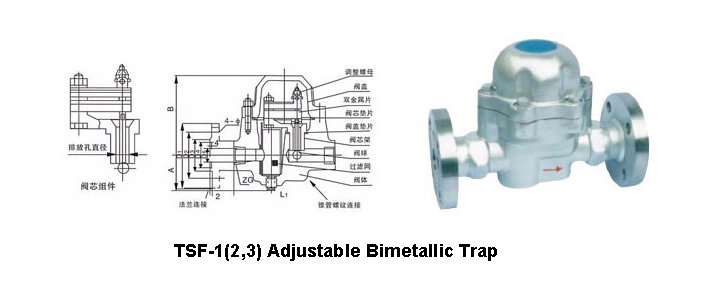

SF-1(2,3),SF-1(2,3)-GF Adjustable Bimetallic Trap

| Model | DN(mm) | L | H | D | D1 | D2 | b | f | Z-Φd |

| SF-1/2/3-GF | 15 | 230 | 180 | 95 | 65 | 45 | 14 | 2 | 4-Φ14 |

| SF-1/2/3-GF | 20 | 230 | 180 | 105 | 75 | 55 | 14 | 2 | 4-Φ14 |

| SF-1/2/3-GF | 25 | 230 | 185 | 115 | 85 | 65 | 14 | 2 | 4-Φ14 |

| SF-1/2/3-GF | 32 | 250 | 195 | 135 | 100 | 78 | 16 | 2 | 4-Φ18 |

| SF-1/2/3-GF | 40 | 250 | 200 | 145 | 110 | 85 | 16 | 3 | 4-Φ18 |

| SF-1/2/3-GF | 50 | 250 | 208 | 160 | 125 | 100 | 16 | 3 | 4-Φ18 |

| TSF-1/2/3-GF | 15 | 210 | 140 | 95 | 65 | 45 | 14 | 2 | 4-Φ14 |

| TSF-1/2/3-GF | 20 | 210 | 145 | 105 | 75 | 55 | 14 | 2 | 4-Φ14 |

| TSF-1/2/3-GF | 25 | 210 | 150 | 115 | 85 | 65 | 14 | 2 | 4-Φ14 |

TSF-1(2,3) Adjustable Bimetallic Trap

| Model | DN(mm) | L | H | H1 |

| TSF-1/2/3 | 15 | 110 | 130 | 35 |

| TSF-1/2/3 | 20 | 110 | 130 | 35 |

| TSF-1/2/3 | 25 | 110 | 130 | 35 |

| SF-1/2/3 | 15 | 155 | 170 | 45 |

| SF-1/2/3 | 20 | 155 | 170 | 45 |

| SF-1/2/3 | 25 | 155 | 170 | 45 |

How Does Bimetallic Steam Trap Work?

The primary parts of bimetallic steam traps are a conical end stem valve and a composite material made of two plates with differing expansion coefficients. Bimetal components are crushed due to the cold fluid, and the valve is open. During this phase, condensate, non-condensable gases, and air are released. Bimetallic plates expand in distinct ways as the hot condensate enters the system, pulling the valve toward the seat and causing it to cease discharging. The cycle resumes when cool condensate reenters the steam trap.

Pros of Bimetallic Steam Traps

| NO. | Advantages |

| 1 | Resistant to Water Hammer: Highly resistant to water hammer and corrosive condensate. |

| 2 | Resistant to Freeze: Not being affected by freezing. |

| 3 | High efficiency: Condensate discharge is lower than steam temperature. Possibility to adjust the bimetal plate to benefit from the hidden energy of the steam. |

| 4 | High-Temperature Condition: It Can be used in high-temperature and superheated steam lines. |

| 5 | Non Return function: The valve that is linked to the bimetallic plates serves as a check valve and prevents back pressure buildup in the system. |

| 6 | Easy Installation: Bimetallic thermostatic steam traps do not need to be fitted to the steam lines as horizontally to the x-axis, in contrast to thermodynamic steam traps. These steam traps are capable of operating at 100% efficiency and can be positioned horizontally, vertically, or at an angle to the steam flow. |

Cons of Bimetallic Steam Traps

| NO. | Advantages |

| 1 | Long reaction time. When condensate and steam temperatures are very close to each other, the response time of bimetal steam traps may be too long. Long response times for load and temperature changes may cause equipment or system failure. |

| 2 | Difficulty in the setting. Adjusting bimetal plate traps may be difficult, especially after valve maintenance. |

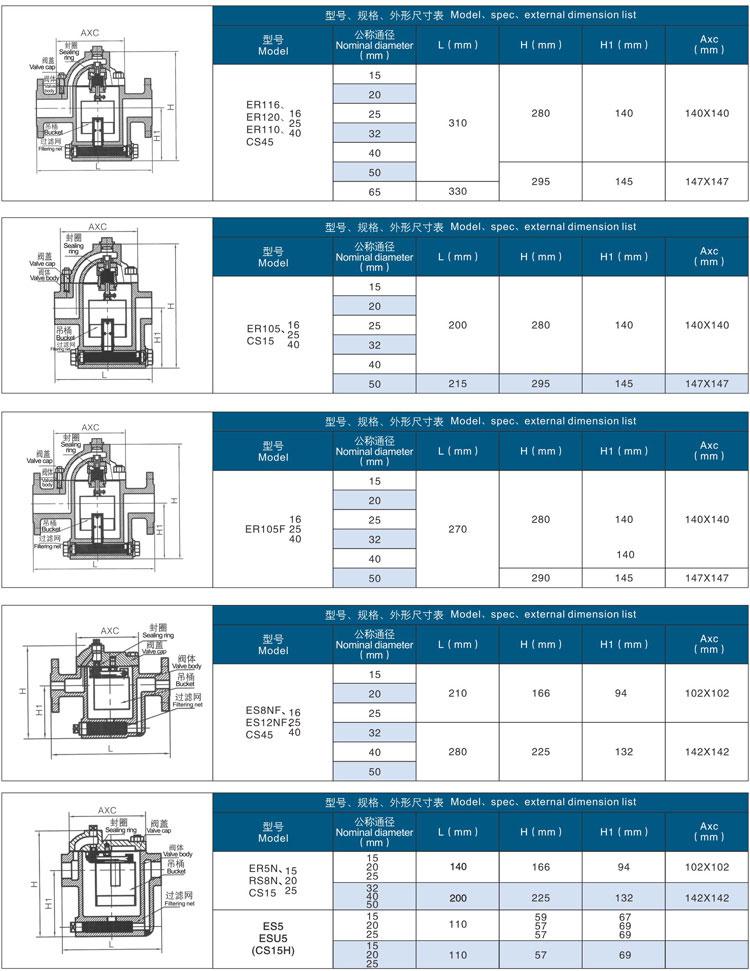

4. Thermostatic Capsule Steam Trap

Features, Types, and Applications of Thermostatic Capsule Steam Traps

The thermostatic capsules and all other internal parts are made of corrosion-resistant stainless steel. Hastelloy membranes even resist acidic condensate conditions very well. There are generally three different types of capsules for thermostatic capsule steam traps.

a. High-Temperature Capsule

Specially designed for applications that require the use of dry steam, such as the tire industry and the textile industry. These capsules discharge condensate at the relevant steam pressure 5°C below the saturated steam temperature.

b. Standard Temperature Capsule

Standard design for any application requiring the use of saturated steam. This capsule discharges condensate 10°C below the saturated steam temperature at the relevant steam pressure.

c. Low Temperature Capsule

Specifically designed for applications where steam is used for heating. At the relevant steam pressure, this condensate is discharged at a temperature 30°C below the saturated steam temperature and allows the equipment to use the enthalpy of hot condensate.

Installation Cautions for Steam Traps

Proper installation of steam traps has a direct impact on the safe operation of traps and the productivity of the equipment. The following are 19 common installation precautions.

- Be sure to purge the piping with steam to remove debris from the piping before installing the steam trap.

- A strainer should be installed in front of the trap to ensure that the steam trap is not blocked by debris in the piping, and the strainer should be cleaned regularly.

- On/off valve should be installed inlet and outlet the trap, in case to easy maintenance of steam trap at any time.

- The flow direction of condensate should be consistent with the trap installation arrow mark.

- Traps should be installed at the low point of the equipment outlet to discharge condensate in time, to avoid steam resistance in the piping.

- If there is no space to install a trap at the low part of the equipment, a backwater elbow (condensate lifting joint) should be added at the low position of the outlet to raise the condensate level before installing a trap to avoid steam resistance.

- The outlet pipe of the trap should not be immersed in water. (If it is immersed in water, drill a hole at the elbow to break the vacuum and prevent the sand from sucking back.

- Mechanical type traps should be installed horizontally.

- Do not install steam traps in series.

- Each unit should be installed with its own trap.

- Thermostatic type traps need to have more than one meter of non-insulated subcooling pipe in the inlet of the steam trap, and other types of traps should be installed as close to the equipment as possible.

- When you select traps for roller drying (with siphon type) equipment, please specify the trap should with an anti-vapor barrier device to avoid equipment vapor lock.

- If there is a condensate recovery outlet of the trap, the outlet pipe should be connected to the recovery pipeline to reduce back pressure and prevent backflow.

- If there is condensate recovery downstream of the trap, different pressure lines should be recovered separately.

- The condensate recovery main downstream of the trap should not be upward, which will increase the back pressure of the trap.

- The condensate downstream of the trap should be installed with a check valve before entering the recovery main to prevent the condensate backflow.

- To install traps on steam piping, the main piping should have a condensate collection well close to the radius of the main piping and then lead to the trap with a small pipe.

- If a mechanical trap is not used for a long time, remove the drain screw and drain the water from the valve to prevent freezing.

Though the trap is only a small valve in the entire steam system, it has a great impact on the normal operation of the system and the cost of the equipment, so routine maintenance and inspection are essential, and good operating conditions of the trap are necessary to ensure that the energy-saving effect is achieved.

In Conclusion

Steam traps provide the basic function of condensate drainage in a steam system. A typical steam system is probably a complex network, and a trap must be matched to a specific drainage application, and we need to consider the various operating principles of steam traps as well as the specific needs and conditions.

THINKTANK manufactures a wide range of steam traps, including inverted bucket traps, float, and thermostatic traps, controlled disc traps, and differential condensate controllers. Not only we can provide a quick quote, but also provide technical guidance on how to match the various types of traps and their benefits to your specific application needs.