Description

Electric Globe Control Valves: Essential for Industrial Automation

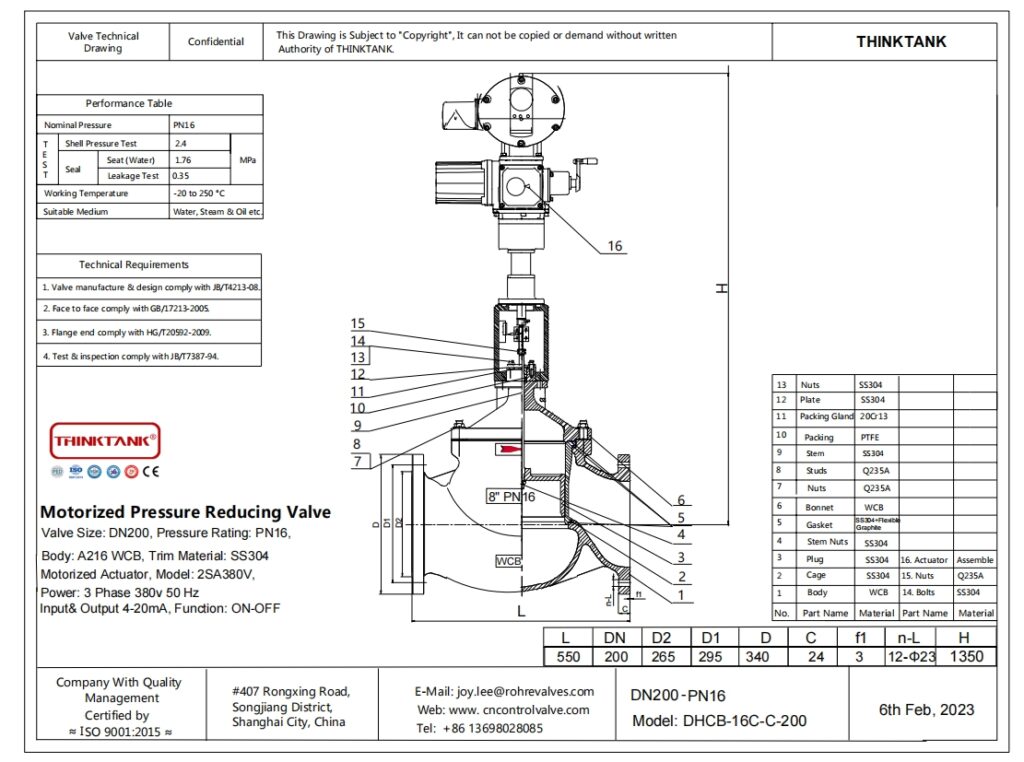

Product Name: Electric Globe Control Valve

Design Standard: ANSI/ISA 75.01.01 & ASME B16.34

Face to Face Standard: ASME B16.10

Flange Standard: ASME B16.5

Electric control valves are critical components in industrial automation, extensively used across various sectors including oil, chemicals, power generation, and pharmaceuticals. THINKTANK experts offer detailed guidance on model parameters and operational condition selection to assist you in choosing and utilizing the best electric control valves for your needs.

Model Parameters of Electric Control Valves

Model Description

The model number of an electric control valve typically comprises letters and numbers, indicating the manufacturer, function, connection type, and drive mode. For instance, the model “TT-EHCB/100C” signifies a THINKTANK brand electric control valve, where ‘E’ stands for Electric, ‘HCB’ denotes a control valve series, ‘100’ indicates a nominal diameter of DN100mm, and ‘C’ specifies the use of Carbon Steel in the valve body.

Temperature & Pressure Range of Body Material

| Temperature ℃ | Class150 | Class300 | Class600 | |||||||||||||||||||||||||||||||||||||||||||||

| LCB | WCB A105 |

WC6 F11 |

F304 CF8 |

F316 CF8M |

LCB | WCB A105 |

WC6 F11 |

F304 CF8 |

F316 CF8M |

LCB | WCB A105 |

WC6 F11 |

F304 CF8 |

F316 CF8M |

||||||||||||||||||||||||||||||||||

| -196~38 | – | – | – | 1.90 | 1.90 | – | – | – | 4.95 | 4.95 | – | – | – | 9.91 | 9.92 | |||||||||||||||||||||||||||||||||

| -45~38 | 1.84 | – | – | 1.90 | 1.90 | 4.78 | – | 4.95 | 4.95 | 9.57 | – | 9.91 | 9.92 | |||||||||||||||||||||||||||||||||||

| -5~38 | 1.84 | 1.96 | 1.99 | 1.90 | 1.90 | 4.78 | 5.10 | 5.16 | 4.95 | 4.95 | 9.57 | 10.2 | 10.32 | 9.91 | 9.92 | |||||||||||||||||||||||||||||||||

| ~50 | 1.81 | 1.92 | 1.92 | 1.84 | 1.84 | 4.72 | 5.00 | 5.16 | 4.77 | 4.80 | 9.46 | 10.1 | 10.32 | 9.56 | 9.62 | |||||||||||||||||||||||||||||||||

| ~100 | 1.72 | 1.76 | 1.76 | 1.56 | 1.61 | 4.51 | 4.63 | 5.14 | 4.08 | 4.21 | 9.02 | 9.27 | 10.29 | 8.17 | 8.43 | |||||||||||||||||||||||||||||||||

| ~150 | 1.57 | 1.57 | 1.57 | 1.39 | 1.47 | 4.40 | 4.51 | 5.01 | 3.62 | 3.85 | 8.78 | 9.04 | 10.03 | 7.26 | 7.69 | |||||||||||||||||||||||||||||||||

| ~200 | 1.40 | 1.40 | 1.40 | 1.25 | 1.37 | 4.26 | 4.38 | 4.88 | 3.27 | 3.56 | 8.54 | 8.75 | 9.75 | 6.54 | 7.12 | |||||||||||||||||||||||||||||||||

| ~250 | 1.20 | 1.20 | 1.20 | 1.16 | 1.20 | 4.05 | 4.16 | 4.62 | 3.04 | 3.34 | 8.11 | 8.33 | 9.26 | 6.10 | 6.67 | |||||||||||||||||||||||||||||||||

| ~300 | 1.01 | 1.01 | 1.01 | 1.01 | 1.01 | 3.76 | 3.87 | 4.23 | 2.91 | 3.15 | 7.54 | 7.74 | 8.48 | 5.80 | 6.32 | |||||||||||||||||||||||||||||||||

| ~350 | 0.84 | 0.84 | 0.84 | 0.84 | 0.84 | 3.59 | 3.69 | 4.01 | 2.81 | 3.03 | 7.18 | 7.38 | 8.04 | 5.60 | 6.07 | |||||||||||||||||||||||||||||||||

| ~375 | – | 0.73 | 0.73 | 0.73 | 0.73 | – | 3.64 | 3.88 | 2.77 | 2.96 | – | 7.28 | 7.75 | 5.54 | 5.93 | |||||||||||||||||||||||||||||||||

| ~400 | – | 0.64 | 0.64 | 0.64 | 0.64 | – | 3.44 | 3.65 | 2.74 | 2.91 | 6.89 | 7.31 | 5.48 | 5.81 | ||||||||||||||||||||||||||||||||||

| ~425 | – | 0.55 | 0.55 | 0.55 | 0.55 | – | 2.88 | 3.44 | 2.71 | 2.87 | 5.74 | 6.91 | 5.42 | 5.72 | ||||||||||||||||||||||||||||||||||

| ~450 | – | 0.47 | 0.47 | 0.47 | 0.47 | – | 1.99 | 3.08 | 2.68 | 2.81 | 4.00 | 6.17 | 5.37 | 5.61 | ||||||||||||||||||||||||||||||||||

| ~475 | – | 0.37 | 0.37 | 0.37 | 0.37 | – | 1.35 | 2.58 | 2.65 | 2.73 | 2.70 | 5.17 | 5.30 | 5.46 | ||||||||||||||||||||||||||||||||||

| ~500 | – | 0.28 | 0.28 | 0.28 | 0.28 | – | 0.88 | 2.02 | 2.60 | 2.67 | 1.75 | 4.04 | 5.20 | 5.37 | ||||||||||||||||||||||||||||||||||

| ~525 | – | 0.18 | 0.18 | 0.18 | 0.18 | – | 0.51 | 1.53 | 2.19 | 2.57 | – | 1.03 | 3.07 | 4.77 | 5.15 | |||||||||||||||||||||||||||||||||

| ~550 | – | – | – | – | – | – | – | 1.20 | 2.00 | 2.40 | 2.40 | 4.00 | 4.60 | |||||||||||||||||||||||||||||||||||

| ~566 | – | – | – | – | – | – | – | 1.00 | 1.90 | 2.20 | 2.00 | 3.80 | 4.50 | |||||||||||||||||||||||||||||||||||

| Temperature℃ | Class900 | Class1500 | Class2500 | |||||||||||||||||||||||||||||||||||||||||||||

| LCB | WCB A105 |

WC6 F11 |

F304 CF8 |

F316 CF8M |

LCB | WCB A105 |

WC6 F11 |

F304 CF8 |

F316 CF8M |

LCB | WCB A105 |

WC6 F11 |

F304 CF8 |

F316 CF8M |

||||||||||||||||||||||||||||||||||

| – 196~38 | – | – | – | 14.88 | 14.88 | – | – | – | 24.79 | 24.79 | – | – | – | 41.34 | 41.34 | |||||||||||||||||||||||||||||||||

| -45~38 | 14.35 | – | – | 14.88 | 14.88 | 23.92 | – | – | 24.79 | 24.79 | 39.87 | – | – | 41.34 | 41.34 | |||||||||||||||||||||||||||||||||

| -5~38 | 14.35 | 15.31 | 15.50 | 14.88 | 14.88 | 23.92 | 25.51 | 25.84 | 24.79 | 24.79 | 39.87 | 42.52 | 43.07 | 41.34 | 41.34 | |||||||||||||||||||||||||||||||||

| ~50 | 14.18 | 15.01 | 15.33 | 14.34 | 14.43 | 23.64 | 25.02 | 25.55 | 23.90 | 24.04 | 39.40 | 41.70 | 42.59 | 39.84 | 40.07 | |||||||||||||||||||||||||||||||||

| ~100 | 13.52 | 13.90 | 14.62 | 12.25 | 12.65 | 22.53 | 23.16 | 24.36 | 20.42 | 21.09 | 37.56 | 38.62 | 40.61 | 34.01 | 35.14 | |||||||||||||||||||||||||||||||||

| ~ 150 | 13.18 | 13.56 | 13.90 | 10.89 | 11.54 | 21.96 | 22.60 | 23.18 | 18.16 | 19.24 | 36.60 | 37.66 | 38.61 | 30.26 | 32.07 | |||||||||||||||||||||||||||||||||

| ~200 | 12.79 | 13.14 | 13.63 | 9.82 | 10.69 | 21.32 | 21.89 | 22.73 | 16.37 | 17.83 | 35.53 | 36.50 | 37.88 | 27.28 | 29.71 | |||||||||||||||||||||||||||||||||

| ~250 | 12.17 | 12.51 | 13.33 | 9.15 | 10.02 | 20.28 | 20.84 | 22.22 | 15.26 | 16.68 | 33.80 | 34.75 | 37.03 | 25.43 | 27.80 | |||||||||||||||||||||||||||||||||

| ~300 | 11.30 | 11.61 | 12.72 | 8.71 | 9.49 | 18.84 | 19.36 | 21.20 | 14.52 | 15.80 | 31.40 | 32.26 | 35.33 | 24.20 | 26.34 | |||||||||||||||||||||||||||||||||

| ~350 | 10.78 | 11.08 | 12.06 | 8.42 | 9.12 | 17.96 | 18.46 | 20.11 | 14.02 | 15.20 | 29.95 | 30.78 | 33.51 | 23.36 | 25.36 | |||||||||||||||||||||||||||||||||

| ~375 | – | 10.94 | 11.63 | 8.32 | 8.91 | – | 18.22 | 19.38 | 13.86 | 14.84 | – | 30.37 | 32.32 | 23.12 | 24.74 | |||||||||||||||||||||||||||||||||

| ~400 | – | 10.34 | 10.98 | 8.23 | 8.72 | – | 17.24 | 18.28 | 13.72 | 14.55 | – | 28.73 | 30.47 | 22.87 | 24.25 | |||||||||||||||||||||||||||||||||

| ~425 | – | 8.62 | 10.53 | 8.14 | 8.59 | – | 14.37 | 17.54 | 13.57 | 14.32 | – | 23.94 | 29.23 | 22.63 | 23.87 | |||||||||||||||||||||||||||||||||

| ~450 | – | 6.01 | 10.13 | 8.06 | 8.42 | – | 10.02 | 16.89 | 13.42 | 14.03 | – | 16.68 | 28.16 | 22.37 | 22.79 | |||||||||||||||||||||||||||||||||

| ~475 | – | 4.06 | 9.50 | 7.97 | 8.20 | – | 6.76 | 15.82 | 13.27 | 13.67 | – | 11.28 | 26.36 | 22.13 | 22.34 | |||||||||||||||||||||||||||||||||

| ~500 | – | – | 8.33 | 7.81 | 8.05 | – | – | 13.89 | 13.02 | 13.40 | – | – | 23.15 | 21.71 | 21.47 | |||||||||||||||||||||||||||||||||

| ~525 | – | – | 6.08 | 7.15 | 7.73 | – | – | 10.12 | 11.94 | 12.89 | – | – | 16.88 | 19.88 | 20.79 | |||||||||||||||||||||||||||||||||

| ~550 | – | – | 3.83 | 6.54 | 7.49 | – | – | 6.38 | 10.91 | 12.48 | – | – | 10.63 | 18.17 | 17.85 | |||||||||||||||||||||||||||||||||

| ~575 | – | – | 2.55 | 6.02 | 7.22 | – | – | 4.24 | 10.04 | 12.04 | – | – | 7.08 | 16.72 | 15.20 | |||||||||||||||||||||||||||||||||

| ~600 | – | – | 1.75 | 5.01 | 6.43 | – | – | 2.94 | 8.35 | 10.71 | – | – | 7.90 | 13.92 | 17.85 | |||||||||||||||||||||||||||||||||

| ~625 | – | – | – | 3.92 | 5.48 | – | – | – | 6.54 | 9.12 | – | – | – | 10.89 | 15.20 | |||||||||||||||||||||||||||||||||

| ~650 | – | – | – | 3.16 | 4.23 | – | – | – | 5.25 | 7.06 | – | – | – | 8.75 | 11.76 | |||||||||||||||||||||||||||||||||

| ~675 | – | – | – | 2.33 | 3.78 | – | – | – | 3.88 | 6.31 | – | – | – | 6.45 | 10.53 | |||||||||||||||||||||||||||||||||

Key Parameters

- Main parameters include nominal diameter, flow coefficient, adjustable range, drive mode, power supply voltage, and protection grade:

- Nominal Diameter: This is the inlet and outlet diameter of the electric control valve, determining its flow capacity. Choose a suitable nominal diameter based on actual needs.

- Flow Coefficient: A measure of the valve’s flow capacity, which is related to the nominal diameter. A higher flow coefficient indicates a stronger flow capacity.

- Adjustable Range: An important performance index of the valve, indicating the range of flow it can control within its rated stroke. A larger adjustable range means broader control capabilities.

- Drive Mode: Includes mechanical electric, smart, or digital electric actuator. Select based on actual needs and site conditions.

- Power Supply Voltage: Common voltages include AC220V, 380V, or DC24V. Consider site power conditions when choosing.

- Protection Grade: Indicates the valve’s dust and water resistance, essential for suitability in harsh environments.

Cv Rate and Valve Travel

Class150~600, PN16~110

| Size | 32 | 40 | 50 | 65 | 80 | 100 | 125 | |||||||||||||||||||||||||||||||||||||||||

| Seat | 32 | 40 | 50 | 65 | 80 | 100 | 125 | |||||||||||||||||||||||||||||||||||||||||

| Rated Cv |

EQ% | 11 | 17 | 11 | 17 | 24 | 17 | 24 | 44 | 24 | 44 | 68 | 44 | 68 | 99 | 68 | 99 | 175 | 99 | |||||||||||||||||||||||||||||

| Linear% | 11 | 17 | 11 | 17 | 24 | 17 | 24 | 44 | 24 | 44 | 68 | 44 | 68 | 99 | 68 | 99 | 175 | 99 | ||||||||||||||||||||||||||||||

| Travel(mm) | 25 | 38 | 50 | |||||||||||||||||||||||||||||||||||||||||||||

| Size | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | ||||||||||||||||||||||||||||||||||||

| Seat | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | ||||||||||||||||||||||||||||||||||||

| Rated Cv |

EQ% | 175 | 275 | 175 | 275 | 360 | 275 | 360 | 650 | 1050 | 1200 | 1700 | 1800 | 2500 | 3540 | 4180 | 4650 | 5850 | ||||||||||||||||||||||||||||

| Linear% | 175 | 275 | 175 | 275 | 360 | 275 | 360 | 650 | 1350 | 1560 | 2120 | 2750 | 3300 | 4650 | 5500 | 5850 | 6700 | |||||||||||||||||||||||||||||

| Travel(mm) | 50 | 75 | 100 | 120 | 150 | 200 | 280 | |||||||||||||||||||||||||||||||||||||||

Class900~ 1500, PN150~260

| Size | 32 | 40 | 50 | 65 | 80 | 100 | ||||||||||||||||||||||||||||||||||||||||||

| Seat | 32 | 40 | 50 | 65 | 80 | 100 | ||||||||||||||||||||||||||||||||||||||||||

| Rated Cv |

EQ% | 12 | 17 | 12 | 17 | 25 | 17 | 25 | 50 | 25 | 50 | 80 | 50 | 80 | 110 | 80 | 110 | |||||||||||||||||||||||||||||||

| Linear% | 12 | 20 | 12 | 20 | 30 | 20 | 30 | 60 | 30 | 60 | 90 | 60 | 90 | 140 | 90 | 140 | ||||||||||||||||||||||||||||||||

| Travel(mm) | 25 | 38 | ||||||||||||||||||||||||||||||||||||||||||||||

| Size | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | |||||||||||||||||||||||||||||||||||||

| Seat | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | |||||||||||||||||||||||||||||||||||||

| Rated Cv |

EQ% | 180 | 110 | 180 | 275 | 180 | 275 | 360 | 275 | 360 | 650 | 1000 | 1440 | 2040 | 2500 | 3100 | ||||||||||||||||||||||||||||||

| Linear% | 200 | 140 | 200 | 330 | 200 | 330 | 480 | 330 | 480 | 700 | 1050 | 1500 | 2040 | 2650 | – | |||||||||||||||||||||||||||||||

| Travel(mm) | 38 | 50 | 75 | 100 | 120 | 175 | ||||||||||||||||||||||||||||||||||||||||

Class2500

| Size | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | ||||||||||||||||||||||||||||||||||||||

| Seat | 32 | 40 | 50 | 55 | 55 | 85 | 125 | 130 | 150 | ||||||||||||||||||||||||||||||||||||||

| Rated Cv |

EQ% | 12 | 12 | 17 | 12 | 17 | 30 | 17 | 30 | 50 | 30 | 50 | 80 | 50 | 80 | 125 | 80 | 125 | 180 | 125 | 180 | 265 | 180 | 265 | 470 | ||||||||||||||||||||||

| Linear% | 12 | 12 | 20 | 12 | 20 | 42 | 20 | 42 | 60 | 42 | 60 | 90 | 60 | 90 | 150 | 90 | 125 | 200 | 125 | 200 | 330 | 200 | 330 | 520 | |||||||||||||||||||||||

| Travel(mm) | 25 | 38 | 50 | 75 | |||||||||||||||||||||||||||||||||||||||||||

Globe Control Valve Face to Face Dimension (mm)

| DN | A | ||||||||||||||||||||||||||||||||||||||||||||||

| Class 150 RF JIS 10K FF RF PN16 RF |

JIS 16K RF | Class 300 RF JIS 20K RF JIS 30K RF PN40 |

Class 600 RF JIS 40K RF PN63 |

JIS 16K | JIS 20K | JIS 30K | JIS 40K | ||||||||||||||||||||||||||||||||||||||||

| 32 | 190 | – | 205 | 210 | – | – | – | – | |||||||||||||||||||||||||||||||||||||||

| 40 | 222 | 231 | 235 | 251 | 235 | 236 | 248 | 251 | |||||||||||||||||||||||||||||||||||||||

| 50 | 254 | 263 | 267 | 286 | 265 | 267 | 276 | 286 | |||||||||||||||||||||||||||||||||||||||

| 65 | 276 | 288 | 292 | 311 | 290 | 292 | 303 | 311 | |||||||||||||||||||||||||||||||||||||||

| 80 | 298 | 313 | 317 | 337 | 310 | 317 | 326 | 337 | |||||||||||||||||||||||||||||||||||||||

| 100 | 352 | 364 | 368 | 394 | 360 | 368 | 379 | 394 | |||||||||||||||||||||||||||||||||||||||

| 125 | 403 | – | 425 | 457 | – | 425 | – | 457 | |||||||||||||||||||||||||||||||||||||||

| 150 | 451 | 465 | 473 | 508 | 475 | 473 | 486 | 508 | |||||||||||||||||||||||||||||||||||||||

| 200 | 543 | 560 | 568 | 610 | 570 | 568 | 580 | 610 | |||||||||||||||||||||||||||||||||||||||

| 250 | 673 | – | 708 | 752 | – | – | – | – | |||||||||||||||||||||||||||||||||||||||

| 300 | 737 | – | 775 | 819 | – | – | – | – | |||||||||||||||||||||||||||||||||||||||

| 350 | 889 | – | 927 | 972 | – | – | – | – | |||||||||||||||||||||||||||||||||||||||

| 400 | 1016 | – | 1057 | 1108 | – | – | – | – | |||||||||||||||||||||||||||||||||||||||

| 450 | 1140 | – | 1181 | 1239 | – | – | – | – | |||||||||||||||||||||||||||||||||||||||

| 500 | 1267 | – | 1397 | 1499 | – | – | – | – | |||||||||||||||||||||||||||||||||||||||

| 600 | 1556 | – | 1576 | 1676 | – | – | – | – | |||||||||||||||||||||||||||||||||||||||

| DN | A | ||||||||||||||||||||||||||||||||||||||||||||||

| Class 150 RJ |

Class 300 RJ |

Class 600 RJ |

Class 300 | Class 600 | Class 150 SW、BW |

Class 150、600 SW、BW |

|||||||||||||||||||||||||||||||||||||||||

| 32 | 235 | 248 | 251 | 244 | 248 | 251 | 251 | ||||||||||||||||||||||||||||||||||||||||

| 40 | 235 | 248 | 251 | 244 | 248 | 251 | 251 | ||||||||||||||||||||||||||||||||||||||||

| 50 | 267 | 283 | 289 | 276 | 283 | 286 | 286 | ||||||||||||||||||||||||||||||||||||||||

| 65 | 289 | 308 | 314 | 302 | 308 | 311 | 311 | ||||||||||||||||||||||||||||||||||||||||

| 80 | 311 | 333 | 340 | 327 | 333 | 337 | 337 | ||||||||||||||||||||||||||||||||||||||||

| 100 | 365 | 384 | 397 | 378 | 391 | 394 | 394 | ||||||||||||||||||||||||||||||||||||||||

| 150 | 464 | 489 | 511 | 483 | 505 | 473 | 508 | ||||||||||||||||||||||||||||||||||||||||

| 200 | 556 | 584 | 613 | 578 | 606 | 568 | 610 | ||||||||||||||||||||||||||||||||||||||||

| DN | A | ||||||||||||||||||||||||||||||||||||||||||||||

| JIS63K | Class 900 | Class 1500 | Class 2500 | ||||||||||||||||||||||||||||||||||||||||||||

| RF | RF(SW,BW) | RJ | RF(SW,BW) | RJ | RF(SW,BW) | RJ | |||||||||||||||||||||||||||||||||||||||||

| 40 | 323 | 333 | 333 | 333 | 333 | 358 | 361 | ||||||||||||||||||||||||||||||||||||||||

| 50 | 354 | 375 | 378 | 375 | 378 | 400 | 403 | ||||||||||||||||||||||||||||||||||||||||

| 80 | 431 | 440 | 443 | 460 | 463 | 498 | 504 | ||||||||||||||||||||||||||||||||||||||||

| 100 | 496 | 510 | 513 | 530 | 533 | 575 | 585 | ||||||||||||||||||||||||||||||||||||||||

| 150 | 699 | 715 | 718 | 770 | 776 | 820 | 833 | ||||||||||||||||||||||||||||||||||||||||

| 200 | 895 | 915 | 918 | 972 | 982 | 1020 | 1036 | ||||||||||||||||||||||||||||||||||||||||

| 250 | – | 1137 | 1140 | 1327 | 1336 | – | – | ||||||||||||||||||||||||||||||||||||||||

| 300 | – | 1311 | 1314 | 1400 | 1416 | – | – | ||||||||||||||||||||||||||||||||||||||||

| 350 | – | – | – | 1526 | 1526 | – | – | ||||||||||||||||||||||||||||||||||||||||

| 400 | – | 1520 | 1520 | – | – | – | – | ||||||||||||||||||||||||||||||||||||||||

| 450 | – | – | – | 1720 | 1720 | – | – | ||||||||||||||||||||||||||||||||||||||||

Selection Based on Operational Conditions

When selecting an electric control valve, consider the operating conditions such as medium type, working pressure, and temperature:

- Medium Type: The type of medium greatly affects the performance and structure of the valve. Corrosive media require corrosion-resistant materials or protective measures.

- Working Pressure: Influences the performance and lifespan of the valve. High pressures necessitate high-strength materials and structures.

- Working Temperature: Affects the materials and sealing performance of the valve. High temperatures require materials and seals that can withstand the heat.

Electric Actuator Basics

- Power Supply: Options DC24V, AC220V, AC380V.

- Input Control Signal: Typically 4-20MA or DC1-5V.

- Feedback Control Signal: Usually DC4-20MA (load resistance under 500 ohms).

Electric control valves receive signals from automation control systems (e.g., 4~20mA) to adjust the valve and control parameters such as flow, temperature, and pressure, enabling automated adjustment.

Flow Characteristics and Selection

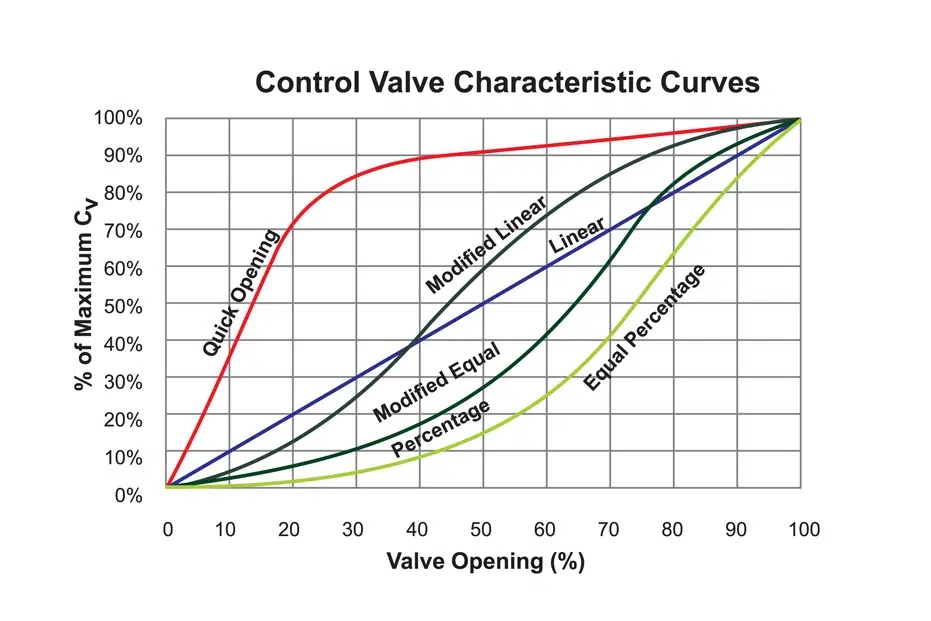

Flow characteristics of electric control valves include linear, equal percentage, and parabolic options, each suitable for different applications based on required control precision and stability.

Equal Percentage Characteristics

The relative stroke and flow of the equal percentage characteristic are not linear. This occurs because the flow change at any stroke point is proportional to the flow at that point, and the percentage change in flow remains consistent. As a result, when the flow is small, the change is minimal; when the flow is large, the change is significant, providing the same precision of adjustment at different openings.

Linear Characteristics

The relationship between the relative stroke and flow for linear characteristics is linear. The flow change caused by any unit change in stroke is constant. This means that large flows result in minor relative changes, and small flows result in significant relative changes.

Parabolic/Modified Characteristics

THINKTANK offers expert selection advice and free technical support and consultation services. Contact us to optimize your industrial processes with reliable, efficient control solutions.