The mission of THINKTANK is to ensure that the valve is safe and reliable and to provide customers with 100% satisfactory products and services. The pursuit of safety and reliability of product performance is the mission of each of our employees. Our quality team is not one person or several people, but full participation. Every THINKTANK people is highly responsible for each product. It is our pursuit to make perfect products with noble character. The company has established a complete quality management system following ISO9001:2008. Product quality is effectively controlled from design, purchase, manufacturing, inspection, sales to after-sales service, ensuring that product performance parameters comply with customer technical requirements and relevant standards and specifications.

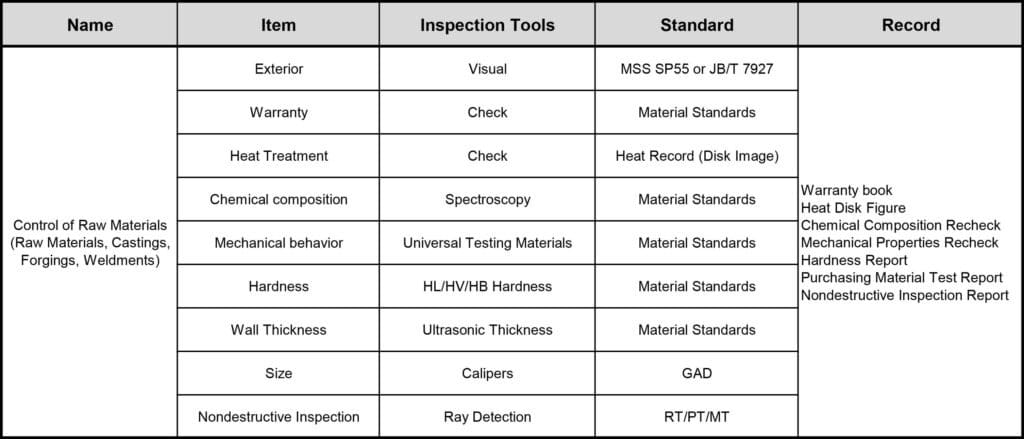

Raw Material

Casting Material

Dimension Inspection

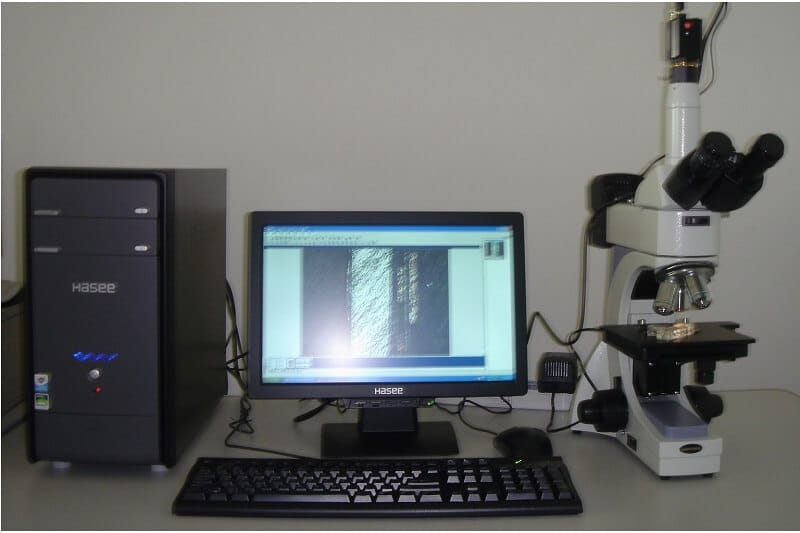

Metallographic Analysis

Raw Material Test

Size

Utultrasonic Testing

Ultrasonic Test

General Dimension Inspect

Test Thickness For Casting Valve Body

Manufacturing Process

Process control inspection is key to control the inherent quality of products, and it is also an important link for factories to reduce the production cost and ensure the delivery time. The main procedures of process inspection are first inspection, routine inspection, and final inspection. Ensure that every part is carefully manufactured by the staff and passed strict inspections, and the staff is highly responsible in each process. With advanced testing equipment and strict scientific management, the safety and reliability of the products are guaranteed.

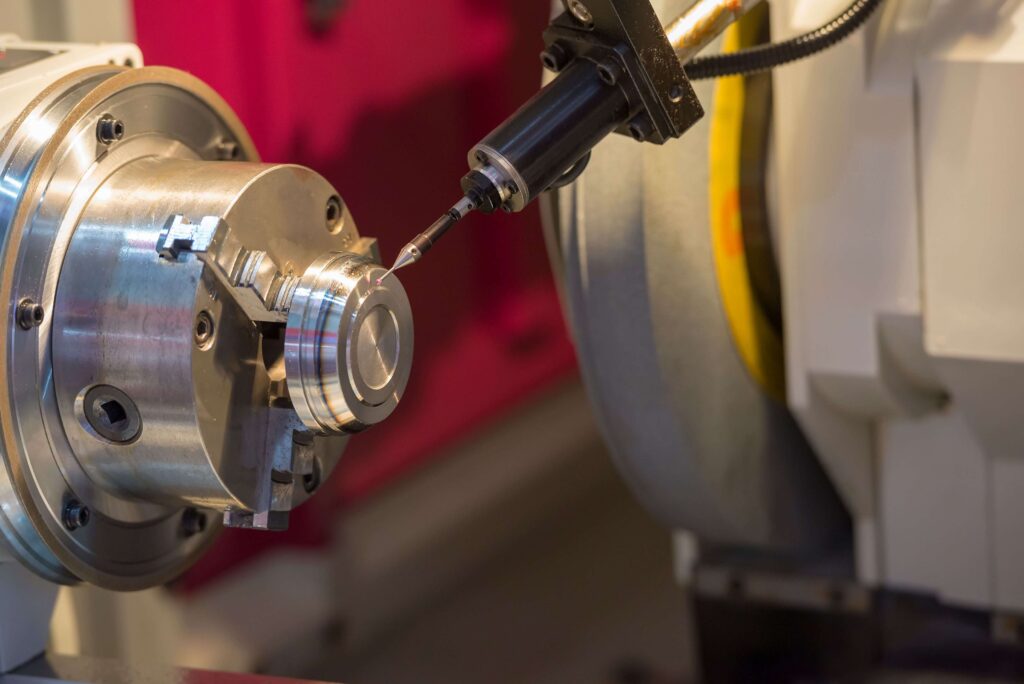

- Machining process and size control

- Precise machining process control

- Cryogenic Treatment

- Supersonic spray

- Post-welding heat treatment to distress

- Hydraulic Pressure Test

- Leakage Test

Assembly Inspection and Test

Assembly inspection is the most important quality control link before shipment of control valves. Testing and inspection are the verification methods to ensure product safety and reliability. Through various tests such as pressure test, valve life test, electrostatic test, electric spark test, fatigue test, flow test, etc., the products provided to customers are guaranteed to be safe and reliable.

Product Traceability Management

Through the tracking management of products and parts, fixed-point and partition management of raw materials, parts, finished products, etc.; keeping complete product quality files to provide customers with timely and effective data when repairing or replacing spare parts. Realize the traceability of products and key components, bringing great convenience and benefits to customers.

- Product serial number tracking management ERP

- Product serial number tracking management ERP

- Casting furnace number management

- Casting sample management

- Part barcode management

- After-sales service file management

- Product maintenance file management