The GZT644TC Pneumatic Ceramic Twin Disc Gate Valve is equipped with a ceramic liner inside the body, contributing to its exceptional performance in dry ash conveying systems and hopper pumps. This type of valve is especially well-suited for high-abrasion industries, such as mining, papermaking, chemicals, etc. The valve’s ability to withstand high levels of wear and tear makes it a valuable asset in these demanding fields. Moreover, it’s designed to function efficiently at temperatures up to 200℃, further emphasizing its versatility and robustness in various industrial applications.

Specification For GZT644TC Pneumatic Ceramic Double Disc Gate Valve

- Product Name: Pneumatic Ceramic Double Disc Gate Valve

- Model: GZT644TC

- Size: 2″ ~ 36″

- Nominal Pressure: PN10/16, ANSI Class 150LB/300LB

- Design and Manufacture: GB/T 12224, ASME B16.34

- Face-to-Face Dimension: Manufacturer’s Standard, ASME B16.5 & B16.47

- Flange Dimension: JB/T 79.1, ANSI B16.5, DIN 2543, JIS B2020

- Inspection and Test: GB/T 9092, ASME B16.34

- Material Standard: GB/T 12229 for Carbon Steel, GB/T 12230 for Stainless Steel

Structural Features

Cylinder Actuator

Utilizes a cylinder to drive the gate up and down, resulting in fast opening/closing.

Double Gates

These adopt floating connections to provide reliable one-way seals. The floating connection helps distribute friction evenly, increasing service life.

Anti-Wear Ceramics

Sealing surfaces are lined with anti-wear ceramics, offering excellent resistance to abrasion.

Compact Design

Easy for transportation, installation, and maintenance.

Working Principle

The cylinder drives the gate to move downwards via the stem, engaging the sealing surfaces of the gate and body, thereby closing the valve. The reverse movement makes the valve open.

Main Parts and Materials

| Body | CF8 /A216Gr. WCB |

| Disc | CF8 / A216Gr. WCB/Ceramic |

| Bonnet | CF8 /A216Gr. WCB |

| Bonnet Gasket | Graphite |

| Packing | Graphite |

| Gland | ASTM A276 304 |

| Yoke | ASTM A216 WCB |

| Outside Screw Rod | ASTM A276 304 |

| Seat | RTFE/Ceramic |

| Seat Ring | ASTM A276 304 |

| Seat Ring Seal | Flexible Graphite |

| Seat Ring Gasket | PTFE |

| Handwheel | Iron Steel |

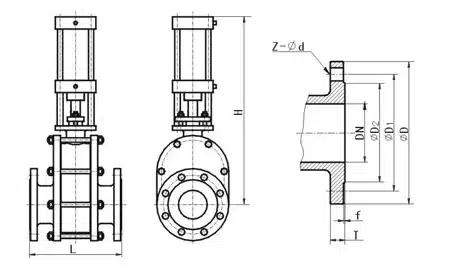

Main Dimensions

| DN | PN | L | D | D1 | C | H | n-Φd |

| 50 | 10 | 200 | 160 | 125 | 16 | 520 | 4-Φ18 |

| 65 | 220 | 180 | 145 | 18 | 595 | 4-Φ18 | |

| 80 | 240 | 195 | 160 | 20 | 635 | 8-Φ18 | |

| 100 | 280 | 215 | 180 | 20 | 630 | 8-Φ18 | |

| 125 | 300 | 245 | 210 | 22 | 715 | 8-Φ18 | |

| 150 | 320 | 280 | 240 | 24 | 840 | 8-Φ23 | |

| 175 | 320 | 310 | 270 | 26 | 885 | 8-Φ23 | |

| 200 | 350 | 335 | 295 | 26 | 1155 | 8-Φ23 | |

| 250 | 400 | 405 | 350 | 30 | 1400 | 8-Φ23 | |

| 300 | 450 | 460 | 400 | 30 | 1800 | 12-Φ23 |

Installation, Use & Maintenance

Before Installation

Clean the valve and remove any defects that may have occurred during transportation.

Checking

Ensure that the marks and nameplate on the valve align with operating requirements.

Installation Direction

This valve can be installed on pipelines at any angle.

Operation

The valve should be either fully open or fully closed when in use. Using it as a throttle valve may result in faster wear.

Long-Term Storage

Store in a dry, ventilated room with periodic checks to prevent rust.

Transportation

Avoid knocking during transportation to prevent damage.

If your application includes dry ash conveying systems and hopper pumps, high abrasive industries, mining, Pulp and paper industry, and chemical, please feel free to contact a THINKTANK representative, our pneumatic ceramic double disc gate valves are capable of high-temperature operation and are especially suitable for applications in granular media.