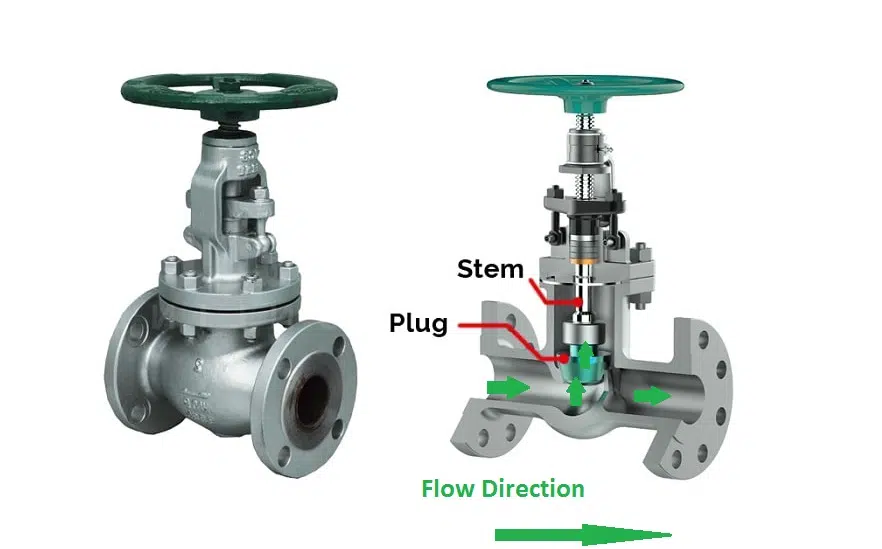

A globe valve is a highly efficient flow control device that is crucial for regulating the flow in a pipeline. Unlike ball valves, globe valves are known for their distinct structure, which includes a movable disc or plug and a stationary ring seat housed within a nearly spherical body.

How Does a Globe Valve Work?

Globe valves function by manipulating a movable plug, which is often referred to as a disc. This plug is connected to a stem and is operated through either manual rotation using a handwheel or automated means employing an actuator. The plug’s movement adjusts the flow of fluid passing through the valve. The design of the globe valve ensures that the seal between the disc and the seat is reliable, minimizing leaks.

In automated globe valves, smooth stems are utilized instead of threaded ones. The actuator, in this case, is responsible for moving the stem and regulating the valve. These valves are a staple in industries where precise control over flow rate is required.

Although traditionally globe valves were named for their spherical bodies, modern globe valves might not necessarily retain this shape. However, the term “globe valve” continues to be used due to the internal mechanisms that it possesses.

Different Configurations of Globe Valves

Globe valves are predominantly two-port valves, but three-port configurations are also available. The ports are openings in the valve body through which fluid flows. The two ports in standard globe valves might be straight across from each other or oriented at an angle, such as 90 degrees. When ports are arranged at an angle, these are known as angle globe valves.

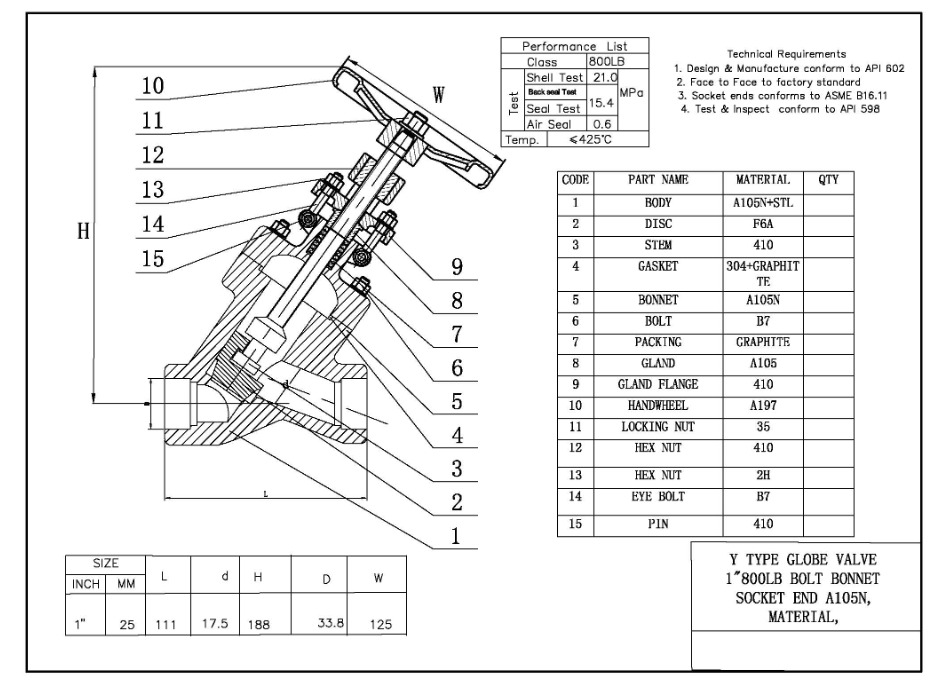

Angle globe valves are particularly beneficial for handling corrosive or high-viscosity fluids, which might solidify at room temperatures. This is because their design allows the fluid to drain off, preventing clogging or corrosion over time. Additionally, some globe valves possess a “Y” shaped body, which is advantageous for minimizing fluid clogging and corrosion in the long run.

Key Components of a Globe Valve

1. Body

The body of the globe valve is the primary pressure-containing structure. It is the most substantial part of the valve and contains all the internal parts that come into contact with the fluid being controlled. The body is connected to the bonnet, which assists in containing the fluid, gas, or slurry.

2. Bonnet

The bonnet provides a leakproof closure for the valve body. Different types of bonnets can be used in globe valves, including screw-in, union, or bolted bonnets.

3. Plug or Disc

This is the closure member of the valve. The plug is attached to the stem and can be moved up or down to control the flow of fluid through the valve.

4. Stem

The stem acts as a connector between the actuator and the plug. It transmits the actuation force from the actuator to the plug, allowing the valve to open or close.

5. Cage

The cage surrounds the plug and is located within the valve body. It is crucial for guiding the plug to the seat of the valve, ensuring a good shutoff, and also plays a significant role in determining the flow within the valve.

6. Seat

The seat ring provides a stable and uniform surface for the plug to create a leak-tight seal when the valve is closed. The seats can be screwed in or torqued.

Globe valves are versatile and play an essential role in various applications where flow needs to be accurately controlled. Their design and functionality make them particularly valuable for not just controlling the flow but also for regulating pressure.

Applications of Globe Valves

Globe valves are employed in a diverse range of industries due to their ability to provide precise throttling and reliable sealing. Some common applications include:

Chemical Processing

Globe valves are used to control the flow of chemicals through pipelines. Their tight sealing capabilities are crucial for ensuring that hazardous materials are handled safely.

Power Generation

In power plants, these valves are used to control the flow of steam and other fluids. Their precise control is critical for the efficient generation of power.

Water and Wastewater Treatment

They are used for throttling purposes in water treatment facilities to regulate the flow of water or other treatment chemicals through the system.

Oil and Gas Industry

Globe valves are used to control the flow of oil and gas in pipelines. Their robust design and tight sealing are critical in high-pressure environments.

HVAC Systems

These valves are often used in heating, ventilation, and air conditioning systems to control the flow and pressure of coolants or refrigerants.

Marine Applications

In ships and submarines, globe valves are used for managing the flow of fluids through the intricate network of pipes.

Food and Beverage Industry

Employed for regulating the flow of liquids during various stages of processing, ensuring product quality and safety.

Maintenance and Troubleshooting

Like all mechanical devices, globe valves require regular maintenance to ensure optimal performance. This includes checking for leaks, ensuring that the valve opens and closes properly, and replacing worn-out components.

When troubleshooting a globe valve, some common issues to look out for include:

Leakage

This can occur from the gland seal, the seat, or the body joints. Regular maintenance and replacement of gaskets and seals can mitigate this.

Stem Misalignment

This can cause the valve not to open or close properly. It’s important to ensure that the stem is properly aligned with the valve body.

Worn or Damaged Seats

This can cause the valve to not seal properly. Replacing or reconditioning the seat is often necessary.

Conclusion

Globe valves, with their versatile design and reliable performance, are an essential component in a multitude of industries. Understanding their functionality and components is fundamental to utilizing them effectively. Regular maintenance and vigilant troubleshooting practices are also key to ensuring their longevity and optimal performance. Whether it’s controlling the flow of water, steam, oil, or chemicals, globe valves prove to be indispensable in achieving precise control and safety in various applications.

THINKTANK is a reliable globe valve supplier for many renowned valve brands, should you have any questions just feel free to contact us.