What is Duckbill Check Valve?

Duckbill valves are generally made of natural rubber or neoprene with artificial fibers through special processing and are called duckbill check valves because they look like a duck’s beak with a flat front end.

The Functional of Duckbill Check Valve

In the process of working, when the internal pressure of the pipeline gradually increases, the outlet of the duckbill check valve will gradually expand and open, and the medium of the pipeline will be discharged at high speed, when there is no internal pressure, the outlet of the duckbill check valve will be closed by its material elasticity, also the external media can not through the outlet of the duckbill check valve reverse to pipeline. So the duckbill check valve prevents sewage backflow.

Classification of Duckbill Check Valves

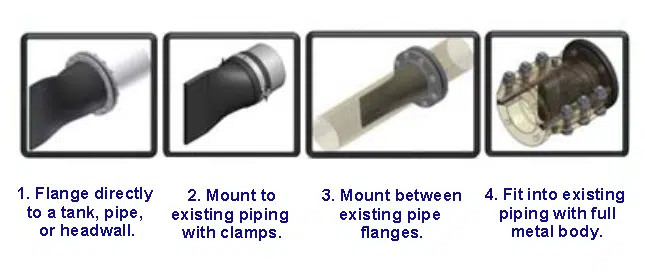

Based on connection type: Flange duckbill check valve, inline duckbill check valve, and clamp duckbill check valve

Based on material: Natural rubber duckbill check valve and neoprene duckbill check valve.

Advantages of Duckbill Check Valves

- Rubber duckbill check valves are cheaper than other check valves.

- Easy to install and maintain.

- Due to its special design and material, the duckbill check valve has lightweight, small in size, and easy to transport.

- All rubber construction can resist abrasive slurries.

- Special design and material can prevent backflow.

- Ultra-quiet operation with no water hammer.

- Available in size from 1” to 128”.

- Don’t cause warp or freeze

- It can quickly interchange with any flap type check valve.

Disadvantages of Duckbill Check Valves

- If rubber duckbill check valves are placed outdoors for a long time, easy to be damaged.

- Not high-temperature resistance, easy to accelerate aging.

- The outdoor sunlight and ozone will reduce the service life of the product.

- During the transportation process or the installation process, if workers did not deal well will cause surface damage.

Although the duckbill check valve has been used more and more in recent years, according to the characteristics of the product, the end-users should avoid bumping, sharp objects scratching, away from heat sources, and high temperatures in the use and storage process. In outdoor use, it should also be checked frequently.

Case Study:

Duckbill Check Valve Solves Irish Air’s Stormwater Runoff Challenges

Bombardier, one of the UK’s major aerospace companies, was founded in 1942 and is the world’s only equipment manufacturer to produce both aircraft and locomotives, making it the third-largest civil aircraft manufacturer in the world. The Belfast manufacturing facility is one of these plants and the project design required that at least half of the stormwater runoff from the roof of its 600,000 square foot facility would be discharged into the Cone Estuary via a 1.5-meter diameter concrete outfall pipe to avoid stormwater backflow and roof ponding.

Solution

Since the outfall pipe connects to the mouth of Conn’s Water and is needed to prevent river backflow into the drainage system during tides, this 1.5-meter diameter concrete outfall pipe needed a check valve with absolute backflow prevention. The 1.5m diameter concrete drainage pipe needed a check valve with absolute backflow prevention. We knew that the drainage pipe was laden with debris, mud, and silt, which could easily cause blockage of the drainage system, and through continuous communication and coordination with the end-user, we finally chose a duckbill valve as the ideal product to solve the problem perfectly. The duckbill valve is the ideal product to ensure the discharge of mud, silt, and debris and to prevent the backflow of river water.

Square Rubber Duckbill Check Valve

Model: SD-50 Series

Product Introduction

Installation method: SD-50 Series rubber duckbill check valve is integrated with a rubber flange, valve body, and duckbill. It can be with a gasket metal flange, and directly connected with the coupling flange. This duckbill check valve can be directly installed in the tank, pipeline, and weir. During installation, the flange of the duckbill check valve corresponds to the coupling flange to ensure absolute sealing after the coupling is tightened. In the installation process, the flange lip of the rubber drain check valve should not be touched. SD-50 series duckbill check valve is mainly used in sewage discharge systems, pump outlet lifting pumping stations, and submerged aeration systems.

SD-50 series duckbill check valve is of complete rubber structure, which has the advantages of corrosion resistance, long service life, and good backstop performance, and provides tight sealing, backflow prevention, backflow, and maintenance-free.

Applications

- Waterproof systems

- Sewage sludge

- Discharge systems

- Rainwater drainage

- Pump outlets

- Lift pump stations

- Sater discharge to a river or sea

- Stormwater outfall/overflow

- Submerged outfall diffuser

- Sewer interceptors

- Wet/dry wells

- Scrubber systems

- Land erosion

- Stagnant water

- Submerged aeration systems

- Salt and freshwater water (collection) basins

Main Features

1. The rubber flange and the valve body are integrated, which is extremely convenient to install.

2. The valve body is designed with complete rubber material, which will not cause siltation and stuff jamming, reducing maintenance costs and allowing solid particles to pass smoothly.

3. Opening pressure is small, usually the difference between the forward and reverse water level only needs to exceed 10mm to open the valve, and the pressure loss is small.

4. When the external pressure of the valve is greater than the pressure of the valve pipeline, the duckbill check valve will automatically close to prevent backflow. Usually, a 3m deep water application can reach zero leakage, in an 8m deep water application the valve can still work normally.

5. Working temperature: -20°C to 80°C

6. Suitable medium: raw water, seawater, sewage.

Inline Duckbill Check Valve

Model: ID-50 Series

Main Features

- Large size with welded body design

- Maintenance-free operation, no hinge restraint

- Can be installed in any position

- Can be closed properly in granular media conditions

Manufacturing & Design

1. Cast steel, cast iron valve body

2. Adopts Neoprene, Hypalon, Buna-N, EPDM, Viton, and natural rubber material used for duckbill.

3. The shell can be made of carbon steel and stainless steel.

4. The flange ends can meet various standards.

5. Special spraying painting is available.

Clamped Duckbill Check Valve

Model: CD-50 Series

The clamp-type duckbill check valve is suitable for corrugated pipes, steel pipes, PVC pipes, cement pipes, and other sewage pipes.

The clamp-type duckbill check valve is widely used in coast, beach, wharf, reservoir, municipal flooding, and sewage application. It’s kind of an environmentally friendly green valve. This duckbill check valve replaces the flapper check valve and completely solves the problem that the flapper is easily blocked by mud, silt, rocks, vegetation, and marine life.