What are self-operated pressure regulators?

The self-actuating pressure regulators are designed to maintain the adjustable setpoint of the pressure reducing system. It can be controlled upstream pressure or downstream pressure and is self-actuating, so no additional auxiliary energy sources such as electricity or air are required. THINKTANK’s ZZY series of self-operating pressure regulators are easy to operate and set up, and these are probably the most cost-effective pressure control valves available.

SPECIFICATIONS

Valve Body

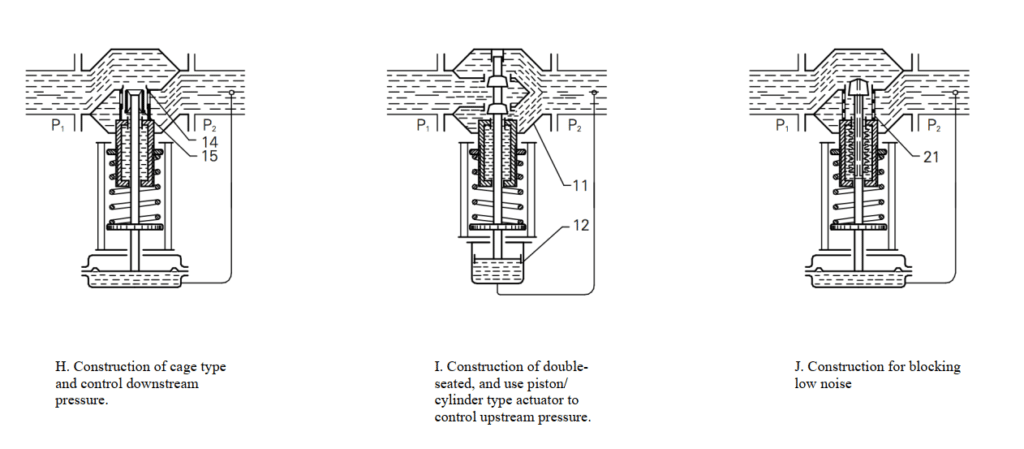

Plug Type Single-Seated(ZZYP), Cage Type(ZZYM), Double-Seated(ZZYN)

Action Type Control Upstream Pressure(B Type) and Control Downstream Pressure(K Type)

Nominal Diamter DN15mm ~ 300mm(1/2’’ ~ 16’’)

Flow Characteristic Quick Open

Adjusting Accuracy ±3 ~ 10%

Working Temperature ≤350

Pressure Reduction Rate Max. 10, Min. 1.25

Trim Material Standard Material, Working Temperature, Pressure Range and Leakage Information, Please Refer

to Sheet 1 and Figure 1.

Nominal Pressure PN1.6MPa, 4.0MPa, 6.3MPa, 10.0MPa, Class 150, 300, 600.

Connection Type Flanged Ends, Welded Ends, and Threaded Ends.

Body & Bonnet Material WCB, WC9, CF8, CF8M

Actuator Type Diaphragm, Piston/Cylinder, Bellows

Packing PTFE, Flexible Graphite

Adjusting Pressure Range(kPa)

15~50, 40~80, 60~100, 80~140, 120~180, 160~220, 200~260, 240~300, 280~350, 330~400, 380~450, 430~500,

480~560, 540~620, 600~700, 680~800, 780~900, 880~1000, 950~1100, 1080~1250, 1230~1400, 1380~1550,

1530~1800, 1780~2000, 1980~2300, 2280~2500

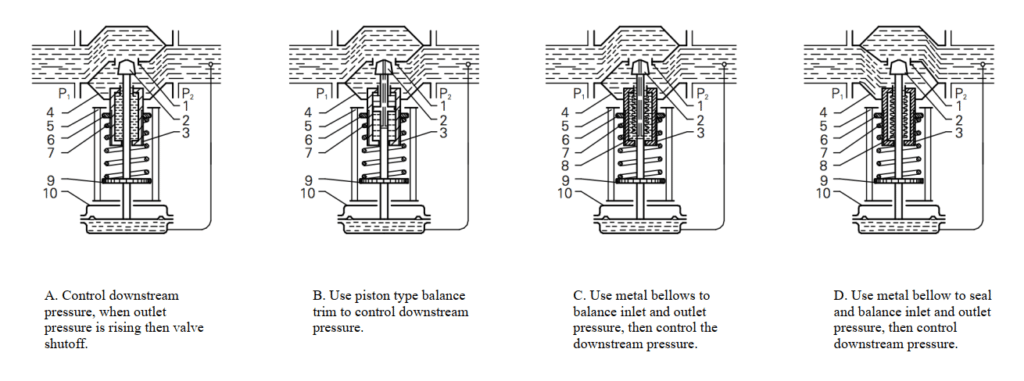

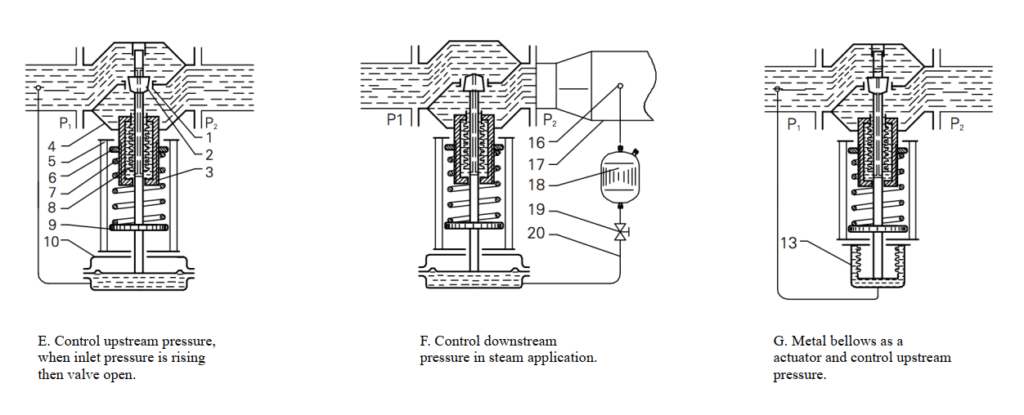

Construction Type

How to operate self-operated pressure regulators? How it works?

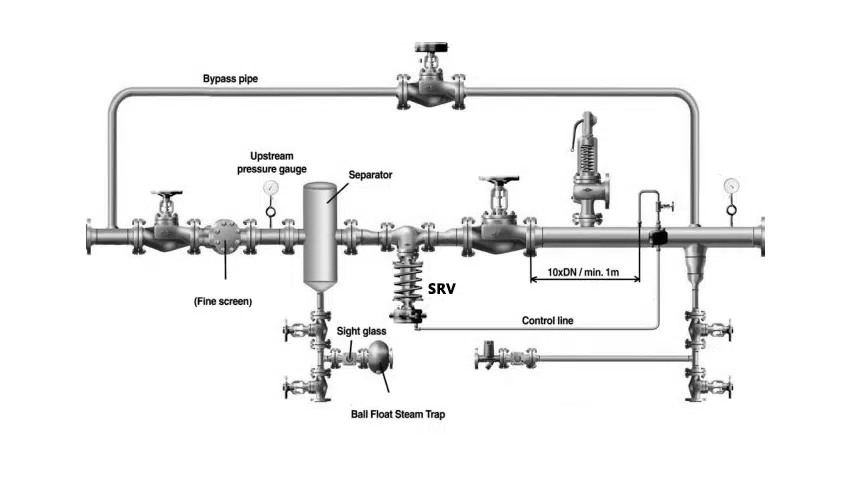

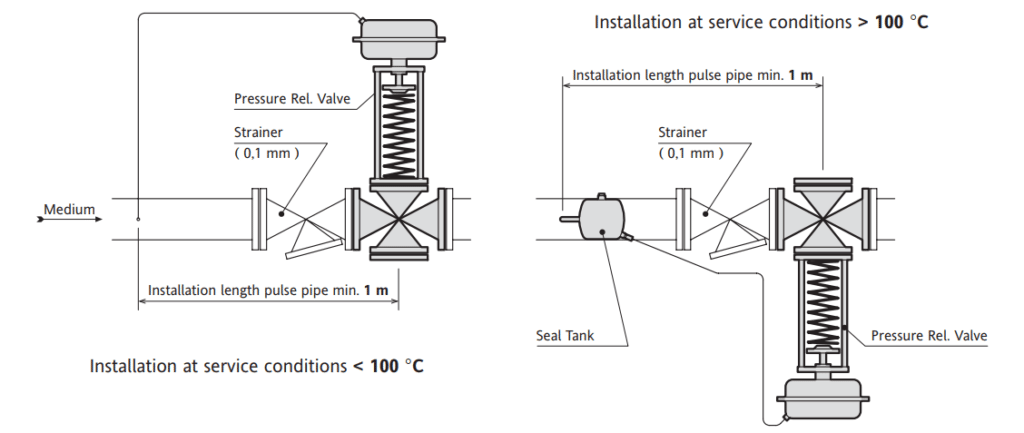

Here are some physical requirements you should know before the installation of the pressure regulator.

- Self-operated pressure regulators are used primarily for steam, non-flammable vapors, and gases.

- Pressure range-ability: 1:10

- When the work at steam or vapor which a service temperature of over 100°C, it’s necessary to use a sealed tank to protect the diaphragm of the self actuator against overheating.

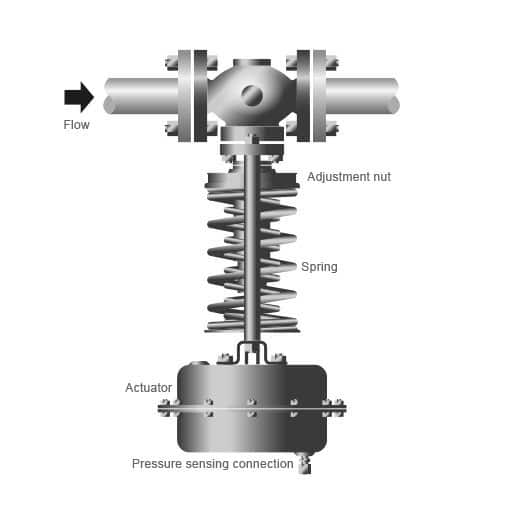

Now we know the self-operated pressure regulators are driving by the medium energy without any auxiliary energy. But how it works? Let’s learn deep of this regulator. For example, controlled downstream pressure application.

The downstream pressure acts on the actuator diaphragm through the control line, where it is converted into a force that reacts to the spring force.

Through adjustment, the preload force of the spring can be changed so that the two forces are in equilibrium under the required downstream pressure. The steam discharge capacity will cause the corresponding displacement of the valve plug until the equilibrium state is re-established.

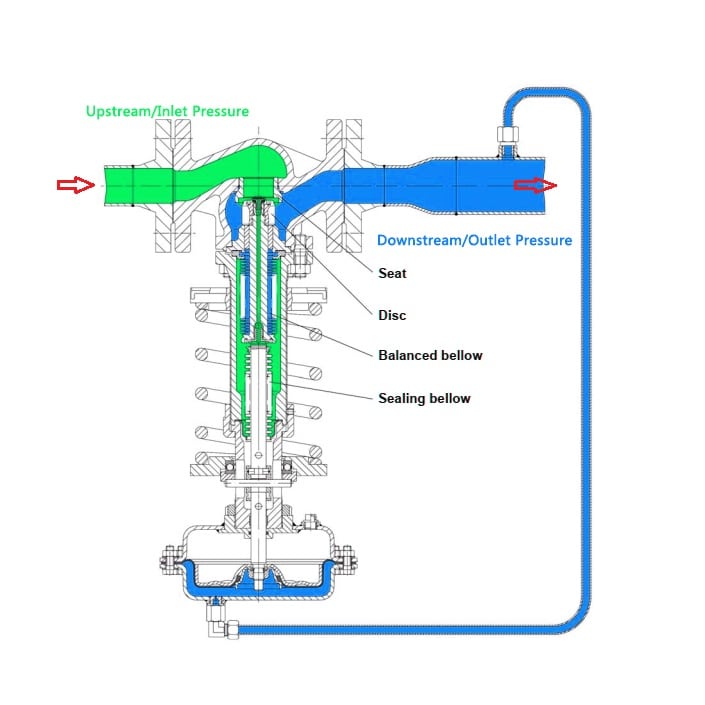

The two stainless steel bellows of the pressure reducer can be seen in above figure.

One is for the purpose of sealing the main shaft from the outside, and the other below is a pressure relief element, which is used to ensure equal force on the valve plug. For this purpose, upstream pressure is applied to the outside of the bellows from the inside through the hole in the valve plug. The inside of the bellows is connected to the downstream pressure through an orifice. Since the effective area of the bellows is the same as the valve seat area, the pressure difference can be compensated, so that the pressure regulator is basically not affected by upstream pressure fluctuations. In automatic process engineering applications, pressure regulators are classified as proportional controllers. The characteristic of such a controller is that the control deviation from the set value is permanent depending on the following factors: spring preload, nominal diameter, and P2/P1 ratio.

What’s the difference of pilot-operated valves & direct acting valves?

Most self-operated pressure regulators currently available can be divided into the following two main types:

- Direct-acting pressure control valves

- Pilot-acting pressure control valves

A direct-operated regulator is the first choice unless the flow or accuracy requirements cannot be satisfied.

Direct-acting pressure control valves can also be used in water, seawater, steam, because the actuator force is provided by the pressure acting on the actuator diaphragm instead of the bellows.

Therefore, they will cause the upstream or downstream pressure to change with the change of the medium flow rate. Careful consideration should be given when selecting and determining the valve size.

Pilot-operated pressure control valve works by balancing the downstream pressure between the pressure sensing tube and the pressure regulating control spring. This moves the pilot valve to adjust the control pressure. The control pressure transmitted through the pilot valve is proportional to the opening of the pilot valve and is guided to the lower side of the main valve diaphragm through the control pipe.

Pilot-operated pressure regulator VS. direct-operated pressure regulator

Accuracy

The accuracy of the pilot-operated regulator is much higher than that of the direct-acting regulator. Generally, direct-acting regulators need to deviate from the set point by 20%-40%, while pilot-operated regulators need 1%-5%.

Response time

The direct-acting regulator has the fastest response speed, because the change in upstream pressure causes the diaphragm to move directly related to the plug stroke. The pilot-operated regulator is subject to the same events, but the load pressure must be changed before the main valve can be repositioned. The loaded pilot valve is a bit faster than the unloaded pilot valve, because the main valve diaphragm can sense the outlet pressure, so that the main valve provides a good start for changes in outlet pressure.

Capacity

The pilot-operated regulator can provide a larger size and therefore a larger capacity. Due to its excellent accuracy, the flow capacity of basically all pilot-type regulators can be used, while the effective flow rate of direct-type regulators is limited due to excessive droop.

Minimum differential pressure required

There is no minimum differential pressure requirement for direct-operated pressure regulator. Regardless of the pressure difference, they can continue to controlling, but the pilot regulator needs to require a pressure difference between its inlet and outlet in order to open the main valve. The unloading pilot valve has a small diaphragm and requires a higher pressure difference to fully open the main valve.

Cost of Maintenance

The direct-acting regulator is the simplest and most compact type of regulator, so it is the least expensive and easiest to maintain. The unloading pilot valve is the next least costly, because their main valve is simple in design, combining the diaphragm and the valve plug into one component, the protective cover.

Direct-operated regulators are the least complex and most compact of the regulator styles making them the least expensive and easiest to maintain.

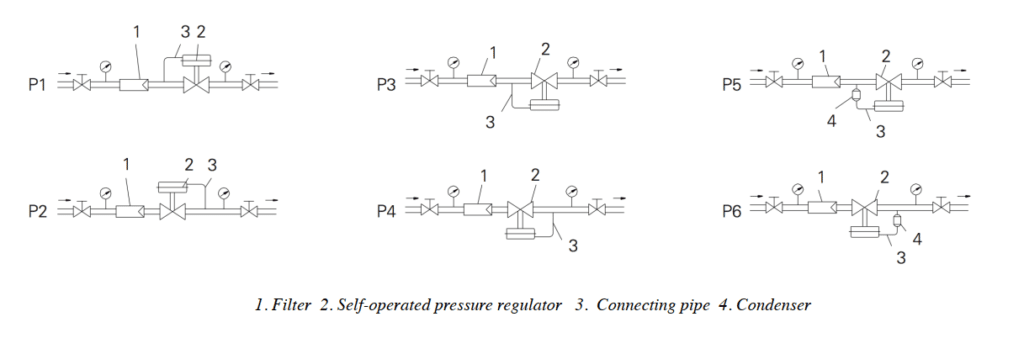

Practical System of Steam Pressure Reducing Station

system reqirements

Keywords of self-operated pressure regulators

There are many terms that can be expressed as pressure regulators. Here we give examples of several terms commonly used by customers。

- Direct-acting pressure reducing valves

- Direct-operated regulators

- Pilot-operated pressure reducing valves

- Pilot-operated regulators

- Self-acting pressure control valves

- Self-operated regulator

- Self-actuated pressure control valves

- Large pressure reducing regulator

- Pressure reducing regulator valve

For more information, please contact our representative to assistant you. Or, you can email direct via <[email protected]>