As an engineer at THINKTANK, I’m excited to share a recent case study showcasing how we provided a custom control valve solution to meet a client’s specific needs and optimize their system performance.

Client’s On-Site Situation and Problem

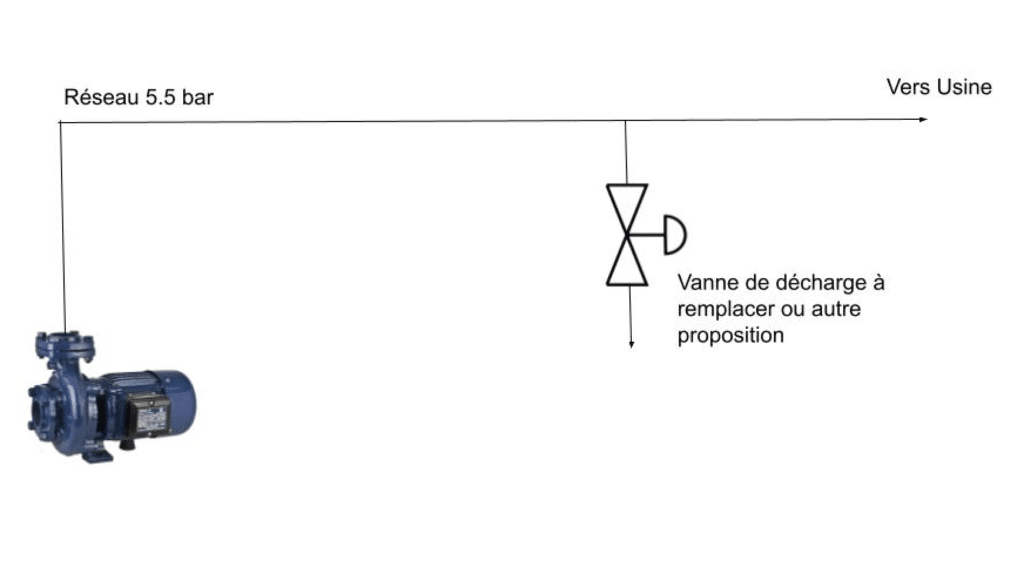

Our client approached us with an issue: their existing valve had an unacceptably long closing time of 30 seconds, which was affecting system efficiency. They required a new control valve that could meet the following specifications:

- Valve Diameter: DN125

- Valve Material: Stainless Steel

- Valve Type: Globe (preferred) or Butterfly

- Inlet Pressure: 5.5 bar

- Outlet Pressure: None (as it’s a discharge valve)

- Maximum Flow Rate: 110 m³/h

- Normal Flow Rate: 50 m³/h

- Minimum Flow Rate: 20 m³/h

- Working Medium: Water

- Fluid Temperature: Ambient

- Actuator Type: Electric

Client’s Requirement

The client requested a control valve with a reaction time of less than 30 seconds, or any alternative proposals that could improve the system’s response time.

Our Solution

To meet the client’s requirements, we proposed using an intelligent frequency-controlled electric actuator. This actuator can be adjusted to control the opening and closing time of the valve, allowing precise operation that meets the client’s 30-second closing time requirement.

We provided a comprehensive smart electric control valve solution, including:

- Intelligent Electric Actuator: The intelligent electric actuator offers precise control over response time, ensuring the valve closes within the required 30 seconds.

- Globe Type Control Valve: Given the client’s flow rate specifications, we recommended a globe type control valve, which is perfect solution for flow control. Assembly with the intelligent electric actuator, it ensures optimal flow control.

- Material and Durability: The valve was made of stainless steel as requested, ensuring long-term reliability and performance in water applications.

With this customized solution, we not only met the client’s technical requirements but also helped them improve system efficiency and reliability.

If you’re facing similar challenges or have specific valve requirements, feel free to reach out. We’re here to provide you with expert, customized solutions that deliver the best possible results.