Design and Selection of Check Valves

Check Valve Types

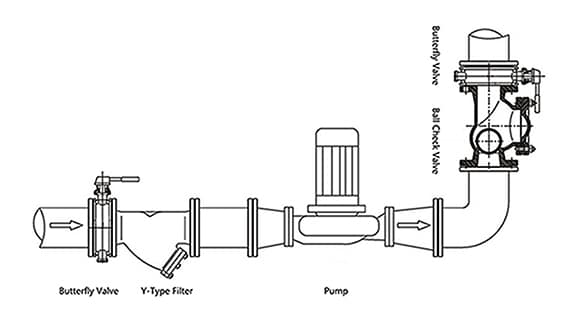

Ball Check Valve (Lift)

The ball check valve is simple and compact and commonly used on small water or wastewater pumps where the economy is important. A ball check valve consists of a threaded or flanged body with internal features that guide a rubber‐coated ball in and out of the seat as the flow goes forward and reverse.

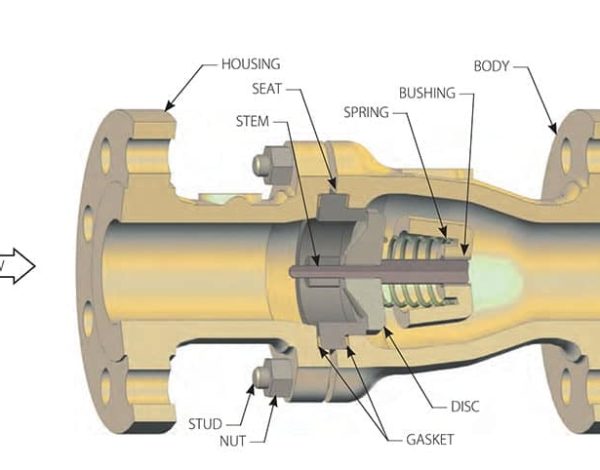

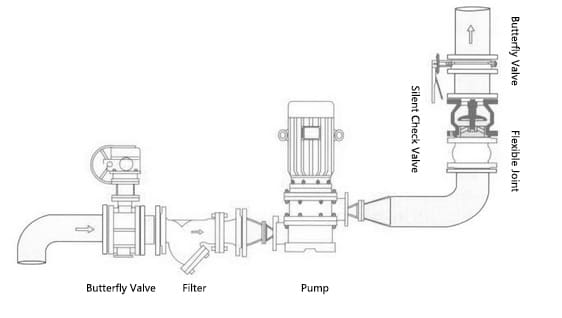

Silent Check Valve (Lift)

The silent check valve is suitable for water supply and drainage pipelines. The valve disc is guided by the central axis at both ends of the inlet and outlet, and it can be opened and closed flexibly. It can be installed horizontally or vertically. The valve disc is spring-loaded, and its quick closing can effectively reduce the water hammer pressure, with good sealing performance and no noise when closing. It has the advantages of small size, lightweight, low fluid resistance, fatigue resistance, and long service life.

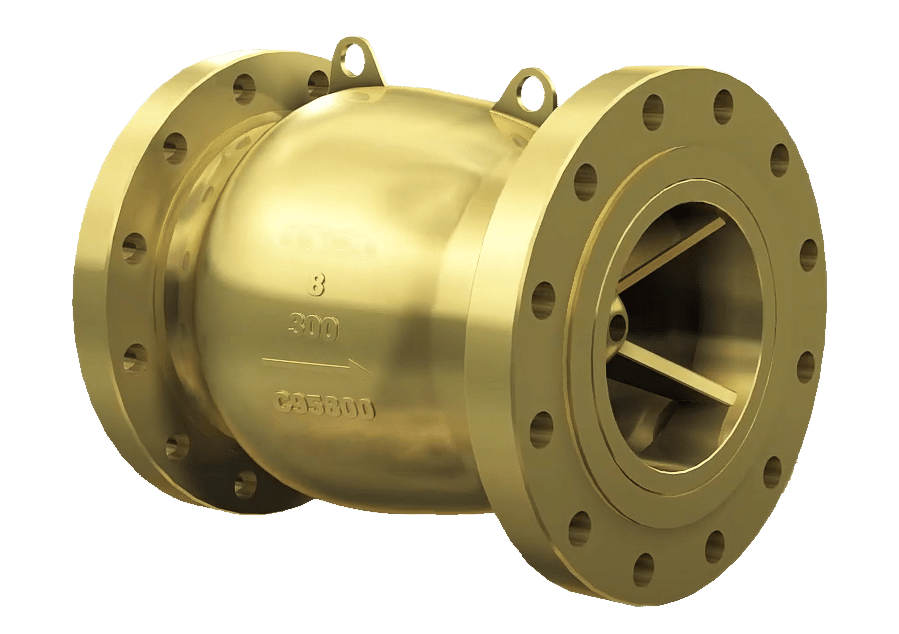

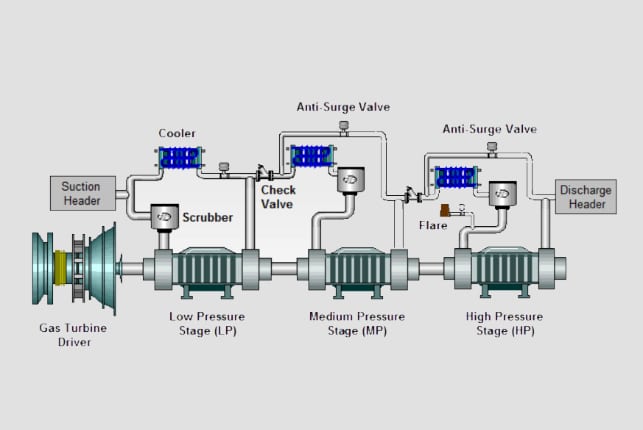

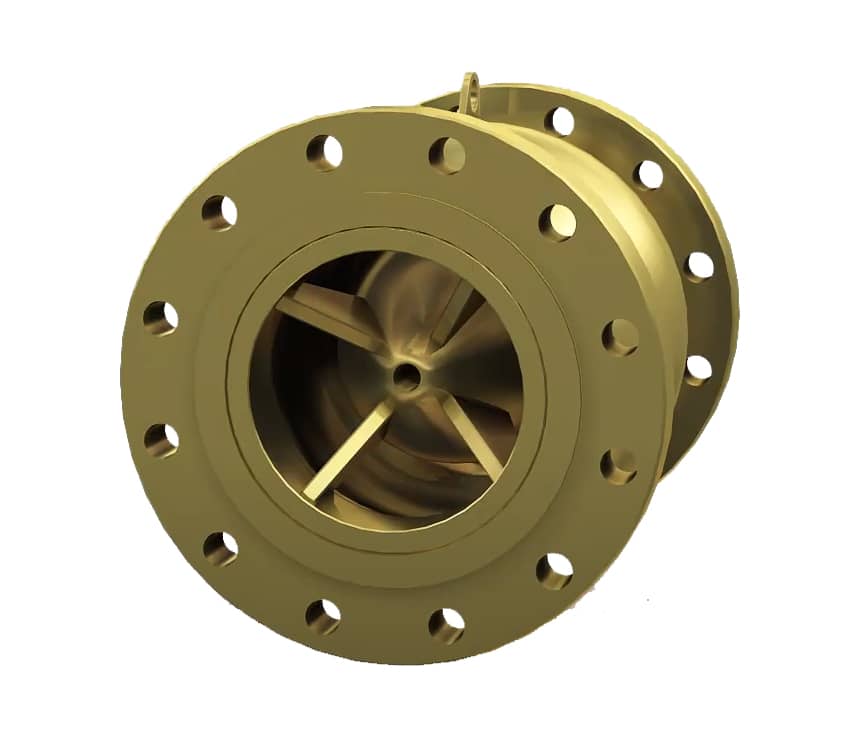

Nozzle Check Valve (Lift)

The axial flow check valve is a high-performance check valve designed in accordance with API 6D and ASME B16.34. In addition to the function of a general check valve, it also uses superb sealing technology to make the valve zero leakage. Unique Venturi inner streamlined flow channel design has the advantages of small flow resistance, good flow state, fast response to medium pressure changes, and small size. It is the preferred valve for general industrial use and pipeline use and is especially suitable for oil pump outlets and natural gas compressor outlets.

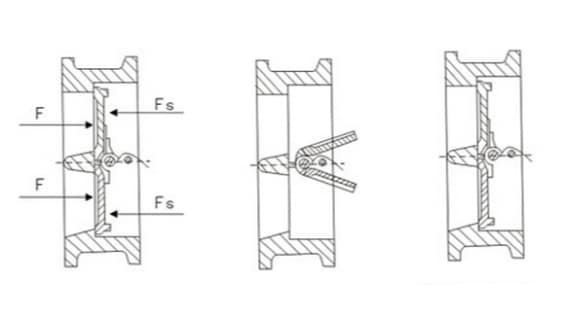

Dual Plate Check Valve (Swing)

The dual plate check valve has two spring-loaded butterfly valve disc, which are assemble on the shaft of the disc through hole. Compared with the single disc swing check valve of the same size, this structure also reduces the disc weight by 50%. Due to the spring load, this valve responds quickly to reverse flow.

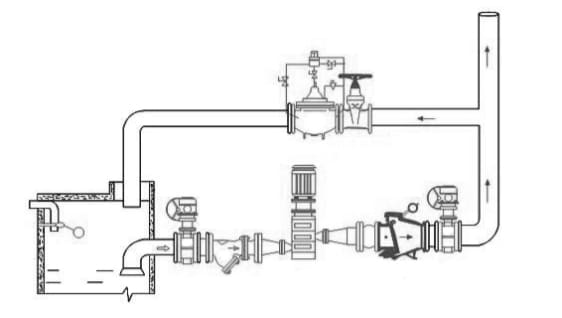

Traditional Swing Check Valve with Lever and Weight

The heavy hammer check valve is mainly used in the water supply system. It is installed vertically in the pipeline. It depends on the pressure difference in the system and the weight of the valve flap to realize the lifting, automatically preventing the backflow of medium water and ensuring the normal operation of the pipeline.

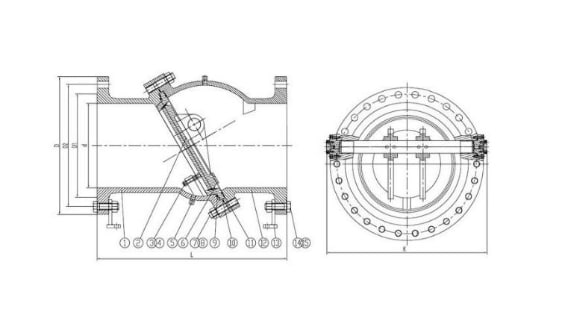

Tilted Disc Check Valve

The seat sealing surface of the tilting disc check valve is a part of the oblique cone. The sealing line formed between the seat and the disc is an approximately elliptical curve. The angle between the plane of the curve and the centerline of the valve flow path is 60 degrees; The long axis center of the approximate elliptical sealing line forms an angular eccentricity with the cone axis, that is, the second eccentric included angle between the axis of the cone where the valve seat sealing surface is and the centerline of the valve body flow channel is 15 degrees to 20 degrees