What is Pneumatic Diaphragm Single-Seat Control Valve?

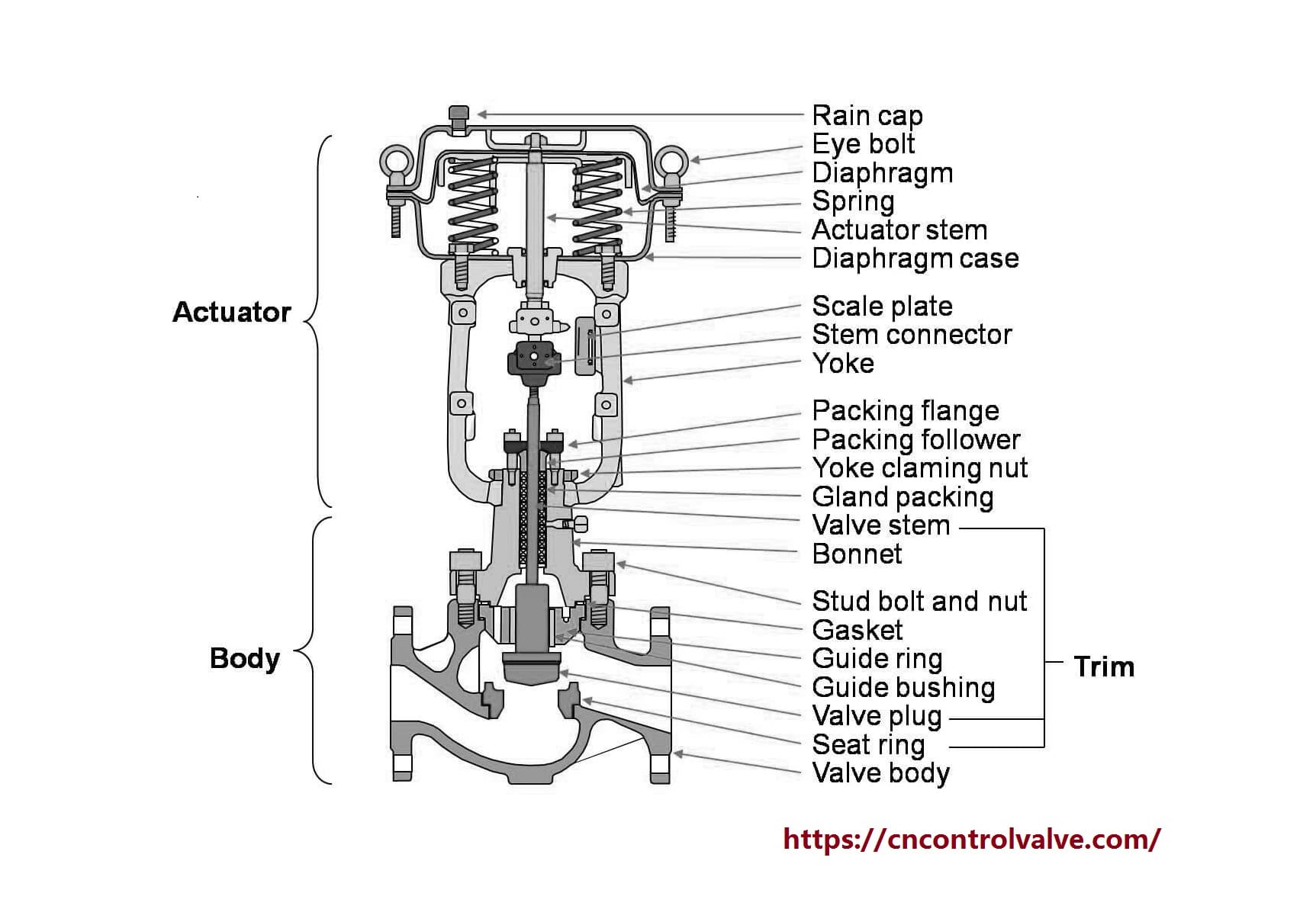

The pneumatic diaphragm single-seat control valve is to take the compressed air as the power source, acting on the diaphragm and then pushing the stem to control the globe valves.

Usually, it will be complete with a valve positioner, converter, solenoid valve, and other accessories to drive the control valves, to achieve on-off or proportional regulation, which depends on the control signal of the industrial automation control system to adjust the pipe medium.

The control valve has the following characteristics: small size, lightweight, high performance, large capacity, and the general regulating valve IEC standards. It is suitable for the general fluid medium and process conditions of the production process system. The utility model is composed of a pneumatic multi-spring film actuator and a low flow resistance single-seat valve. The new actuator has a high degree, lightweight, simple installation and calibration, compact structure, smooth flow passage, and large flow coefficient.

With industrial automation development, the control valve is used more and more widely as the final actuator of the Automatic Control System. The quality and safety of production are directly related to the application of the control valve. Among all kinds of control valves, the pneumatic diaphragm control valve is widely used as a control valve with a simple structure, convenient use and maintenance, and intrinsic safety characteristic.

6 Main Performance Characteristics Of The Pneumatic Diaphragm Single-Seat Control Valve

- The pneumatic diaphragm control valve features a top-guided single-seat, compact structure, fewer parts, and easy maintenance.

- The metal-to-metal control valve is suitable for many kinds of applications and reaches the IV class leakage standard, soft seal structure valve core reaches the VI class leakage standard.

- The valve body is designed as a low flow resistance channel with the same cross-section according to the fluid mechanic’s principle, and the rated flow coefficient is increased by 30%.

- The adjustable range is large; the inherent adjustable ratio is 50. The actuator adopts a multi-spring structure. The height is reduced by 30%, and the weight is reduced by 30%.

- Bellows seal type control valve, the stem movement to form a complete seal, stop the leakage of fluid.

- Globe-type control valve with an insulation jacket, used for fluid cooling easy crystallization, and solidification caused by blocking occasions.

Download Catalogs

Final Thoughts

In this post, we have learned the main performance characteristics of single-seat control valves. There are lots of materials, pressure, accessories, characteristics, functional, and split pressure control of control valves, so if you are interested in more knowledge, please just click the following posts.