Challenges in Mining Applications

In mining, metallurgy, and chemical industries, lime milk transportation presents significant technical challenges. Lime milk is not only highly abrasive but also contains a large number of unreacted limestone particles. Traditional valves often suffer from clogging, rapid wear, and frequent replacement, which leads to expensive downtime and lower process efficiency.

To solve this problem, THINKTANK has developed a heavy-duty angle control valve specifically designed for lime milk applications. This valve features optimized flow path design and advanced wear-resistant materials, which can ensuring long-term stable operation in harsh, high-solid-content environments.

Case Study: THINKTANK Angle Type Control Valve -Proven Success in Alkali Chemical Industry

Project Background

- Location: One of Alkali Industry 200,000 Tons Expansion Project

- Application: Lime milk flow control in the ammonia evaporation process

- Process Conditions:

- Medium: Lime milk slurry (main component: calcium hydroxide) with limestone particles

- Pipeline Diameter: DN100

- Inlet Pressure: 5 Bar

- Outlet Pressure: 4 Bar

- Flow Rate: 45 m³/h

Challenges with Previous Valves

During the initial plant construction, the engineering company selected an Fisher pneumatic diaphragm globe type control valve. At that time, the lime milk medium only contained small limestone particles (less than 0.5mm) because the engineering company replaced the filter screen frequently. However, after one year of operation, the valve trim and seat were severely eroded, and even the valve body showed wear. Eventually, the valve failed completely because the trim and seat were too damaged to seal tightly.

Because the Fisher valve was expensive and had a long lead time, the plant engineer tried several domestic control valve brands over the following years. Unfortunately, all of them failed within two months, including some well-known local brands.

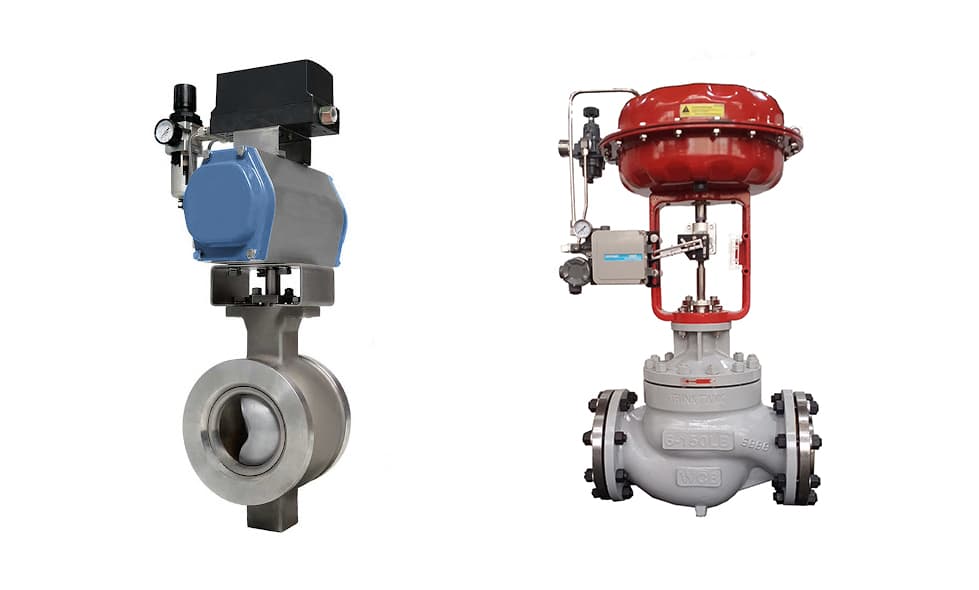

The following are valve type solutions provided by other domestic valve manufacturers and the problems encountered during their use.

Failed Valve Solutions

a. Pneumatic Diaphragm Globe Control Valve (with STL hardfacing on trim and seat)

- Issue: After 10 days, the valve became clogged, and the valve stem bent.

- Cause: Large limestone particles (1-2 cm) accumulated in the valve cage, which creating a blockage that restricted the movement of the plug. As the actuator continued to apply force, the plug remained stuck, increasing pressure on the valve stem. Eventually, the excessive force caused the stem to bend, leading to a complete failure of valve operation.

b. V-Ball Control Valve

- Issue: After one month, the valve leaked.

- Cause: Inspection showed that one side of the valve body and plug was eroded down to only 3mm thickness due to continuous particle impact. That’s why the valve can not tight to shutoff.

c. Fully Lined Ceramic Valve

- Issue: After one week, the valve failed.

- Cause: The ceramic liner cracked under impact from large solid particles, and the valve body suffered severe erosion.

What THINKTANK Engineer Team Do?

During discussions with the end-user, we carefully studied every detail of the process and control requirements. We also listened to the past experiences with different control valves, learning about their advantages and problems.

Step 1. Understanding Lime Milk

Lime milk is made by burning limestone to produce quicklime, which then reacts with water to form calcium hydroxide slurry. This slurry is alkaline and slightly corrosive. It also contains many unreacted limestone particles. These particles pass through a 5mm filter screen, but if the screen is damaged, larger limestone pieces can enter the next stage of the process. Our control valve will install in the pipeline after this filtration step.

Step 2. Choosing the Right Valve

Control valve selection must be based on actual working conditions and control needs. First, we analyzed the problems found in the previously used control valves.

Issues with Previous Valves

a. Pneumatic diaphragm globe type control valve

- These valves have an S-shaped flow path, which makes it hard for solid particles to pass through smoothly.

- Solid particles hit the valve trim and body, causing serious wear and damage.

- If large particles cannot pass through the cage, they get stuck and block the valve, stopping the plug from moving.

b. V-ball control valve or eccentric rotary valve

- Solid particles constantly hit one side of the valve body and plug.

- Over time, this fast erosion weakens the valve trim and body, which leading to internal leakage.

c. Fully lined ceramic valve

- Ceramic has high hardness and strong resistance to wear.

- However, if large solid particles hit the ceramic plug with actuator force, the ceramic will crack, and the valve will be useless.

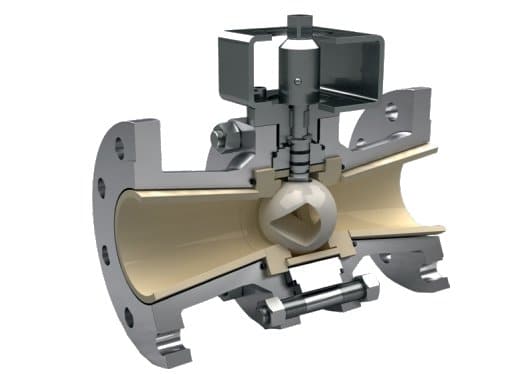

THINKTANK’s Solution: Angle Control Valve for Lime Milk

From these failures, we saw that the key to success is choosing the right valve type. THINKTANK has developed a special angle control valve designed specifically for lime milk applications.

Here are 6 reasons why our THINKTANK angle control valve stands out for lime milk.

1. Optimized Flow Path: Anti-Clogging & Self-Cleaning to Protect Valve Trim

One of the biggest challenges in mining applications is particle accumulation and erosion. THINKTANK’s angle control valve is engineered to solve this problem.

- Flow path(Flow to close: high-in, low out) ensures smooth media flow through the valve, preventing sediment buildup and blockage.

- Self-cleaning function: As the medium passes through the valve seat, the flow velocity changes from low to high and back to low. This design prevents solids from settling inside the valve, keeping it free from clogging.

Why this is important

- If a flow to open direction (low-in, high-out) is used, the valve trim and seat would be directly exposed to the full impact of the fluid, leading to faster erosion and more severe clogging issues.

With this design, maintenance frequency is significantly reduced, and the valve remains operational for a much longer period compared to conventional designs.

2. Anti-Erosion Valve Seat: High-Wear-Resistant Materials & Self-Centering Design

Standard valve trims and seats often fail due to severe erosion from solid particles. THINKTANK’s angle control valve has a breakthrough solution.

- STL hard alloy overlay: The valve seat and plug are fully overlaid with STL (cobalt-based alloy), providing superior erosion resistance and extending valve life.

- Self-centering seat & plug design: Unlike traditional valves that may suffer from misalignment, THINKTANK’s design ensures the valve plug and seat remain perfectly aligned, achieving Class V shutoff even after extended use.

- Snap-in seat structure: Unlike welded or threaded seats, this modular seat design allows for quick and easy replacement, reducing downtime by over 60%.

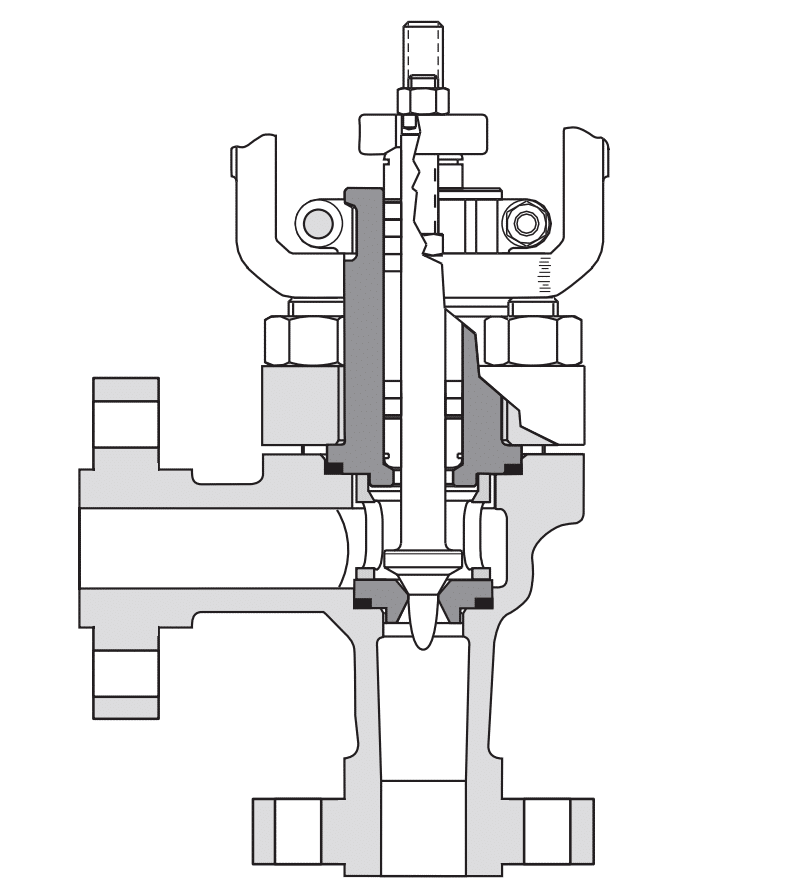

3. Oversized One-Piece Valve Stem: Eliminating Bending & Deformation Risks

In high-velocity and high-abrasion environments, the strength of the valve stem is crucial.

- THINKTANK’s one-piece valve plug and stem eliminates weak points at connection joints, reducing the risk of breakage.

- The valve stem diameter is 3-4 times larger than traditional designs, providing superior resistance against bending forces.

- Dual-guided design keeps the stem moving smoothly, even under high-pressure differentials, preventing side-load wear and failure.

This design significantly enhances durability, making the valve ideal for mining, metallurgy, and chemical process industries.

4. Special Valve Cage Design: Maximizing Wear Resistance & Flow Efficiency

Traditional control valve cages often create flow turbulence and become blockage points for solids. THINKTANK’s angle control valve is specifically engineered to avoid these problems.

- Optimized flow guide structure: The valve cage not only secures the seat but also guides the fluid direction, reducing local high-velocity erosion.

- Enlarged cage holes: Unlike conventional designs that easily clog, THINKTANK’s valve allows for 1-3cm solid particles to pass through, preventing operational failures.

- 10mm thick special stainless steel cage: Standard valve cages are 4-6mm thick, but THINKTANK’s reinforced cage offers significantly higher wear and corrosion resistance, ensuring long-term performance in high-solid-content slurries.

5. High-Thrust Actuator: Eliminating Clogging & Blockages

Lime milk solids can cause valve plug movement issues. Traditional diaphragm actuators often lack the force needed to clear minor blockages. THINKTANK’s valve actuator solves this problem completely.

- Equipped with a double-acting cylinder actuator, providing 4-5 times the thrust of diaphragm actuators. Even if solid particles get lodged between the plug and seat, the actuator force crushes them easily, ensuring continuous operation.

- The high-thrust design also enables faster response times and precise flow control, improving automation and system efficiency.

6. Reinforced Valve Body: Enhanced Erosion Resistance & Longer Lifespan

In mining lime milk applications, the valve body itself is also subject to extreme wear. Even if the trim is highly resistant, a weak valve body will lead to premature failure. THINKTANK has addressed this issue with an upgraded body design.

- Thickened valve body structure, increasing wall thickness by 30-50%, significantly improving erosion resistance.

- Special wear-resistant alloy coating, further enhancing the body’s durability.

- Modular construction, allowing individual components to be replaced rather than the entire valve, reducing maintenance costs.

Why Do Mining/Engineering Companies/Valve Brand Prefer THINKTANK’s Angle Control Valve?

- Extended Service Life – Lasts 3 times longer than traditional control valves, reducing replacement frequency.

- Minimal Downtime – Quick-replacement design cuts maintenance time by over 60%, improving operational efficiency.

- Superior Wear Resistance – Trim, seat, and body materials engineered to withstand high-solid-content media.

- Perfect for Harsh Mining Conditions – Designed specifically for high-abrasion, high-solid-content slurries, ensuring long-term performance.

THINKTANK’s angle control valve has been successfully deployed in multiple mining operations, and earning high praise from our customers. If you’re looking for a long-lasting, low-maintenance control valve for lime milk, slurries, and high-solid-content applications, THINKTANK is your best choice!