At THINKTANK, we often get asked by project engineers and system designers:

“Can Pressure Seal Bonnet technology be applied to control valves for high-pressure conditions?”

It’s a valid question—especially when you’re working with high-temperature steam or critical hydrocarbon services.

Over the past 30 years in valve manufacturing, we’ve worked with various industries where high-pressure valves are essential. But when it comes to control valves, the story is a bit different.

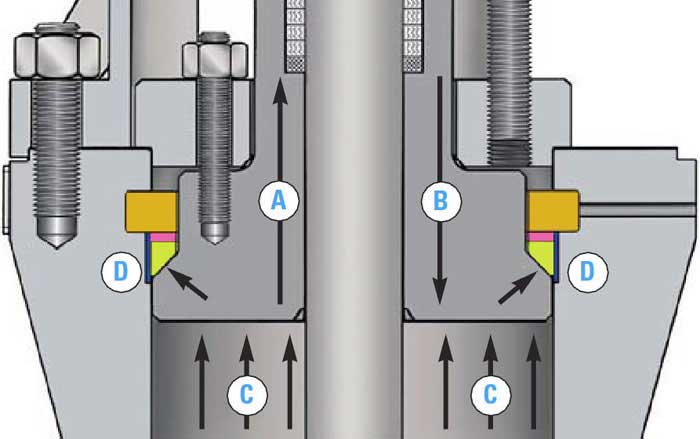

- A/B – Bonnet tendency to move up or down as pressure changes

- C – System pressure

- D – Sealing forces due to pressure

Pressure Seal vs. Bolted Bonnet – What’s the Real Difference?

Let’s start with a quick comparison.

Pressure Seal Bonnet

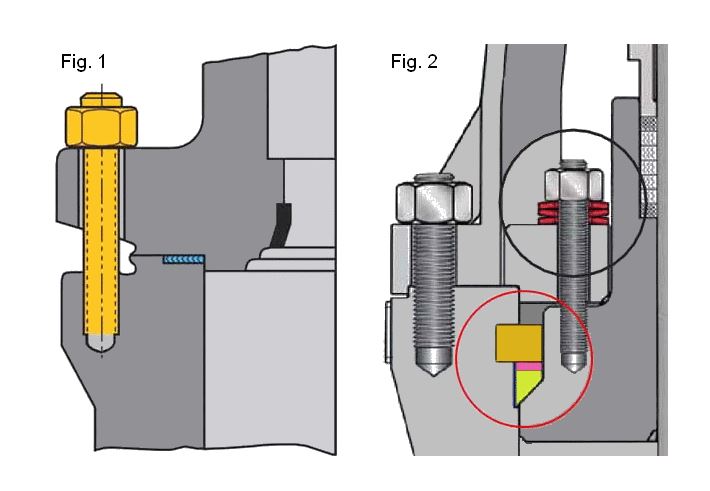

Pressure seal valves uses internal pressure to assist in sealing. The bonnet is inserted into the valve body and held by a segmented thrust ring. As pressure rises, it pushes the bonnet upwards to compress the gasket tighter. This makes the structure compact and lighter, suitable for ANSI Class 900 and above, commonly found in boilers, thermal oil systems, and main steam lines.

Pressure seal construction is adopted for valves used in high-pressure service, typically in excess of 170 bar. The unique feature of the pressure seal bonnet is that the body–bonnet joint seal improves as internal pressure increases—unlike other designs where higher pressure can increase the risk of leakage at the joint. The higher the internal pressure, the greater the sealing force.

Easy dismantling is made possible by dropping the bonnet assembly into the body cavity and driving out the four-segment thrust rings using a push pin. Relying on relatively simple design principles, pressure seal valves have proven their effectiveness in demanding fossil fuel and combined-cycle steam isolation applications. As system designers push boiler, HRSG, and piping pressure/temperature boundaries, pressure seal valves remain a reliable solution.

They are typically available in sizes from 2″ to 24″ and ASME B16.34 pressure classes from 600 to 2500. Some manufacturers even offer custom options for larger diameters or higher pressure ratings.

Pressure seal valves come in a wide variety of materials such as A105 forged and WCB cast steel, F22/WC9, F11/WC6 alloy grades, and stainless F316/F316H forged and cast materials designed to withstand temperatures above 500°C.

The pressure seal design concept originated in the mid-1900s when increasing system demands in power plants drove valve manufacturers to find alternatives to traditional bolted bonnet joints. Aside from offering improved sealing integrity, pressure seal valves also weigh significantly less than their bolted bonnet counterparts.

Bolted Bonnet

Traditional flange-to-flange design using bolts and gaskets. Sealing depends entirely on bolt preload. It’s easy to maintain and works well under low to medium pressure—most common in ANSI Class 150 to 600 systems.

Now, if pressure seal bonnets are so great under high pressure, why don’t we use them in control valves?

We Tried—And Here’s Why It Doesn’t Work

At THINKTANK, we actually explored the idea. We considered applying pressure seal bonnet structures to our high-pressure control valve designs and even carried out finite element analysis (FEA) to validate the mechanical feasibility.

The result? A series of technical challenges that made the design unviable. The structure couldn’t ensure precise alignment between internal components like plugs and seats. The momentary clearance before pressure builds up causes potential shifts, which can impact control performance.

And we’re not alone. To this day, even top brands like FISHER and Masoneilan haven’t adopted pressure seal bonnets for their control valves. One major reason is cost—integrating such a design significantly increases manufacturing complexity and overall pricing. Add to that the fact that high-pressure control valve applications are relatively rare, and it becomes clear why the market hasn’t moved in that direction.

Practical Reasons Control Valves Stick to Bolted Bonnet Designs

1. Pressure Range Compatibility

Most control valves operate in ANSI 600 or below. There’s simply no need to overengineer with a pressure-assisted seal when a bolted bonnet can do the job reliably and cost-effectively.

2. Stability During Variable Operation

Control valves often operate across wide pressure ranges—including low pressure or even vacuum. Pressure seal structures rely on internal pressure to maintain sealing. At low pressures, that sealing becomes unreliable, requiring preload compensation that increases stem friction and affects responsiveness.

3. Structural Alignment

Unlike isolation valves, control valves have precision internals that need rigid structural stability. Bolted bonnets offer consistent compression and alignment from the moment of installation. Pressure seal bonnets may introduce micro-movements that compromise internal alignment.

4. Frequent Actuation Stress

Control valves are in constant motion. This cyclic stress can lead to accelerated wear on pressure seal gaskets and thrust rings. On the other hand, bolted bonnets with dual packing systems handle repetitive movement better and offer more predictable performance.

5. Better Alternatives Exist

For demanding applications, THINKTANK and other manufacturers use advanced sealing systems like bellows seals or multi-stage packing with grease injection. These are specifically designed for stem sealing under high pressure—not bonnet sealing—and provide reliable emission control without overcomplicating the structure.

THINKTANK Solution: Multi-Packing Group Sealing

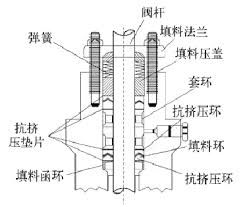

To meet high-pressure application needs, we use a multilayer packing structure. It includes:

- Two sets of PTFE packing rings

- A central metal bushing (which can act as a lantern ring)

- Top and bottom O-rings for elastic sealing

This setup offers redundant sealing layers and can even integrate a monitoring or grease injection port. It delivers tight stem sealing, excellent chemical resistance, and ease of maintenance—all without the structural complexity of a pressure seal bonnet.

Final Thought

While pressure seal bonnets offer excellent performance in many high-pressure isolation valve applications, they’re not the best fit for control valves. The unique demands of modulating service—like alignment, responsiveness, and frequent actuation—make bolted bonnets a more reliable and practical choice.

If you’re evaluating valve options for a high-pressure system and want input based on real engineering experience, feel free to reach out. Our team at THINKTANK is here to help you make the right call—based on field results, not just theory.