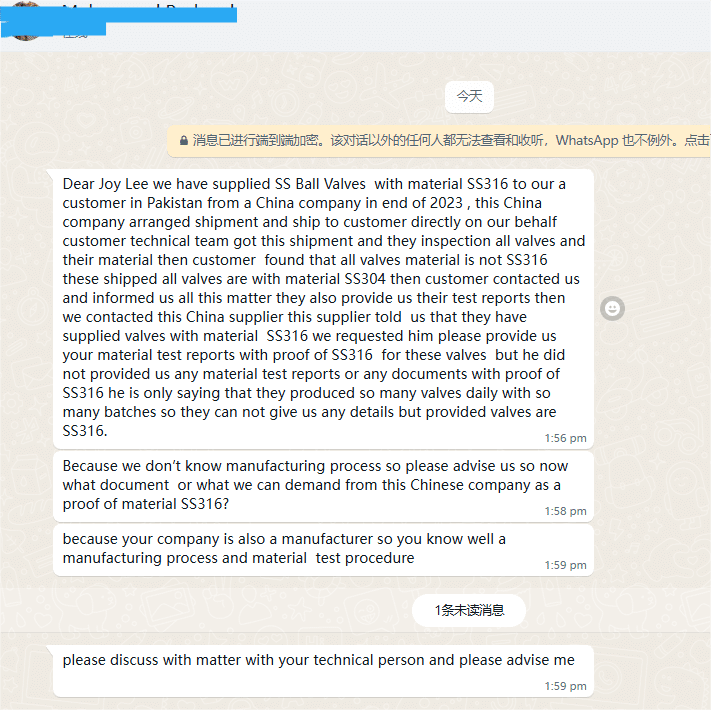

Today, one of our regular customers in Pakistan sent us a message that a large number of SS316 3PC Ball valves with threaded connections that he purchased from other Chinese valve vendor, were found to be of substandard quality by the end user, all of these valves are fail pass quality.

The end-user provided a test report that results show all the material was SS304, but the label was SS316. Our regular customer asked the Chinese supplier to provide a material report, but the sales refused to provide it, saying that the material was fine, and then refused to provide any certificates, test reports, production processes, etc.

usually, customers only see the price on the quotation, which is just the price. The same material, parameters, and technical requirements of the target, but I am sorry to say that the Chinese valve market is now really mixed. There are a hundred ways to save costs in valve wall thickness, internal component design, stem material, valve plug/ball material, body material, etc.

For example, according to the valve wall thickness, many manufacturers use the lower limit value required by the valve standard, which means that the strength of the valve cannot be guaranteed according to the safety factor of the maximum pressure.

There is also the body material. Unless the material is tested, we can’t tell with our naked eyes whether the valve meets the standard.

For threaded ball valves, the purchase volume is very large, and the general medium is water and steam, so users are not likely to really test whether the material of the valve meets the standard.

This time, the end user of our customer personally tested the material, indicating that the application conditions must be corrosive, so in order to ensure safe and reliable operation, a test was conducted.

Unfortunately, all valves in this batch did not pass. Such things are everywhere, which is also the main reason why our STONE 3PC ball valve has particularly lower sales performance, because very few customers really care about the material and wall thickness issues.

Our 3pc NPT ball valves are 30% heavy than others, and we pay special attention to the ratio of Cr, Ni, Mn, Mo for the material. We cannot compete with many cheating peers, and our costs are higher than their selling prices. We don’t feel regretful or annoyed at all. A real brand will be known over time, which is why STONE has been around for more than 30 years and still exists.

I am just angry because some Chinese valve suppliers have caused a bad reputation for Chinese brands, which has not only harmed the interests of customers, but also the interests of the entire Chinese valve industry.

Today I say this not to show off how good we are, but to let more buyers, bosses, or engineers who purchase Chinese valves know that they should not only care about the price, but also pay more attention to quality control when purchasing. Cheap is a one-time business, and in fact it is very expensive, not only wasting your money, but also damaging your brand and reputation.