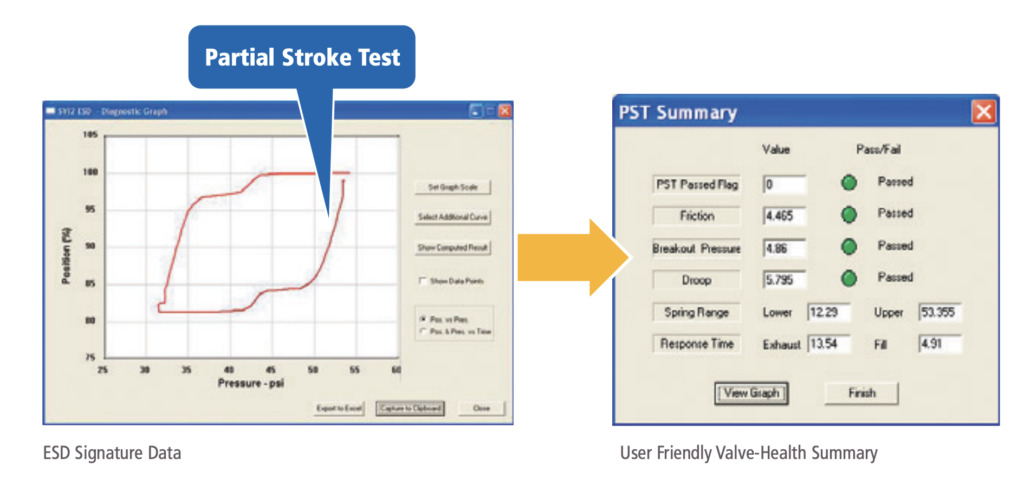

“PST” in the context of control systems, particularly valve control systems, typically refers to a “Partial Stroke Test.” ESD stands for “Emergency Shutdown,” and an ESD control valve is designed to shut down the process in the event of an emergency to prevent catastrophic failures or incidents.

Why Partial Stroke Test Is so important

- Safety: Ensuring the ESD valve functions correctly is crucial for the safety of the plant, its personnel, and the surrounding environment.

- Reduced Process Interruption: A full stroke test of the valve would necessitate a complete shutdown of the process, which could be time-consuming and costly. A PST, on the other hand, allows for testing the valve’s functionality with minimal disruption to the process.

- Early Detection of Issues: Regular PSTs can help detect potential problems early on, reducing the likelihood of unexpected failures.

To ensure safety and correct operation, ESD valves and their associated testing mechanisms, like PSTs, are often governed by strict regulations and standards in the process industries.

1. Introduction of ESD and PST

1.1 Brief overview of ESD valves and their significance in process industries

Emergency Shutdown (ESD) valves are critical safety components used in various process industries, including oil and gas, petrochemicals, and pharmaceuticals, among others. Their primary role is to halt the flow of a process fluid—be it gas, liquid, or a combination of both—during specific abnormal conditions, thus preventing potential hazards. By doing so, they ensure that systems operate within safe parameters and reduce the risk of catastrophic events like explosions, leaks, or other hazardous releases. In essence, an ESD valve acts as a safeguard, allowing operators to bring systems to a safe state during emergencies.

1.2 The importance of valve testing for safety and reliability

Regular testing of ESD valves is crucial to ascertain their functionality and reliability. Given that these valves stand as the last line of defense against potential industrial disasters, ensuring they operate flawlessly is of paramount importance. Over time, valves may develop issues due to wear and tear, corrosion, or component failures. Without regular testing, such problems can go undetected, leading to valve malfunctions when they are most needed. By testing these valves, industries can not only maintain operational integrity but also uphold safety standards, protecting both human lives and the environment. Moreover, regular testing also extends the lifespan of the valves, ensuring longevity and cost savings in the long run.

1.3 Introducing the concept of Partial Stroke Testing (PST)

While it’s essential to test ESD valves, shutting down the entire process to conduct a full stroke test can be both time-consuming and expensive. This is where Partial Stroke Testing (PST) comes into play. PST is a diagnostic procedure designed to check the functionality of an ESD valve without necessitating a full shutdown of the process. Instead of the valve going through its full range of motion, a PST involves moving the valve partially to verify its operability. This ensures that the valve will function correctly during an emergency while minimizing disruptions to the ongoing process. With the help of PST, industries can strike a balance between maintaining safety standards and ensuring uninterrupted operations.

2. ESD Valves

Emergency Shutdown (ESD) valves are integral components in many industrial systems, acting as vital safety barriers in various processes. Their primary role is to control the flow of substances, ensuring that in the event of an irregularity or emergency, they can quickly shut down a system or isolate a particular segment to prevent potential hazards.

What is ESD Control Valve

ESD control valve refers to the terminal control component-actuator/control valve with a certain SIL level used in emergency shutdown systems. For ESD control valves, the normal working state is static. During normal production in the process flow, the valve is open or closed for a long time. According to the safety monitoring situation, for safety purposes, the valve will act when it is needed, and it will not act if it is not required. Control Valves need to be safe, reliable and available. How to determine the status or fault before the safe action of the ESD control valve is required, which involves the safety and cost of the system, as well as maintaining the SIL level, which leads to the “Partial Stroke Test (PST)” of the ESD control valve.

The PST function only allows the ESD control valve to complete a small stroke action (can be set by the user, such as 10% or less) without affecting the normal production of the user, and obtain relevant information from it for test analysis to determine safety availability and status. This solves the problem of long-term static equipment thermal standby and online monitoring, ensures the safety performance of ESD control valves, and avoids long periods of uncertainty or inspections that could only be caused by unplanned shutdown inspections or annual shutdown maintenance tests. The test cost is high and bypass installation is avoided. The ESD valve positioner with PST function can enable the SIS loop to reduce the number of equipment and maintain and extend the required failure probability PFD (SIL level) through PST periodic inspection.

When the ESD control valve does not have digital applications and is not an on-site intelligent device, it is basically a combination of a shut-off valve plus a solenoid valve and a valve position switch. The implementation of PST is very inconvenient. In the early days of PST, a pneumatic switching panel was set up on site, or a mechanical stroke limit method was adopted, or a stop valve was added to the bypass line of the FSD control valve pipeline design for offline testing, which was complex and costly, and basically had no feedback information. Later, PST can be executed by the SIS/ESD system, which takes up a lot of resources. However, only the solenoid valve action and valve position switch feedback signals can be monitored, and no more information is provided for system analysis.

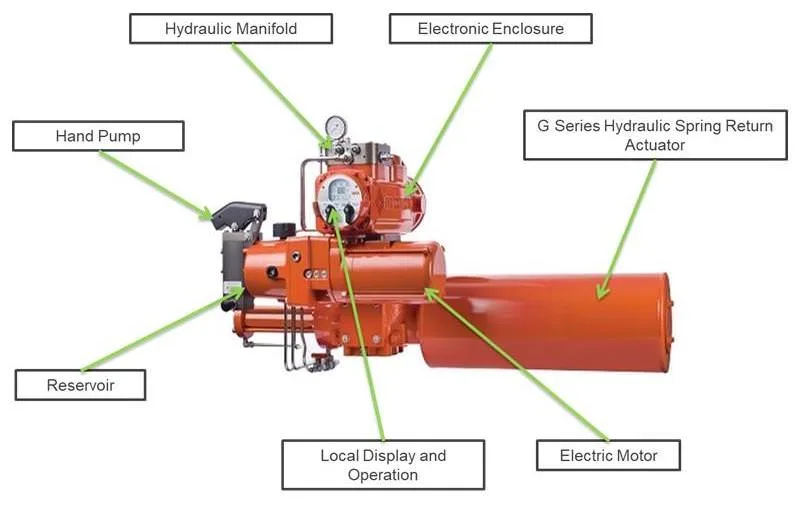

With the introduction of digital valve positioners and the development of control valve diagnostic technology, digital solutions have been used for terminal control components in SIS/ESD systems, whether they are cut-off control valves with switching actions or control valves that regulate fluid flow. Become a consensus within the industry. For the sake of safety functions, cost reduction and operability, users and manufacturers began to transfer PST functions to digitally applied ESD control valves.

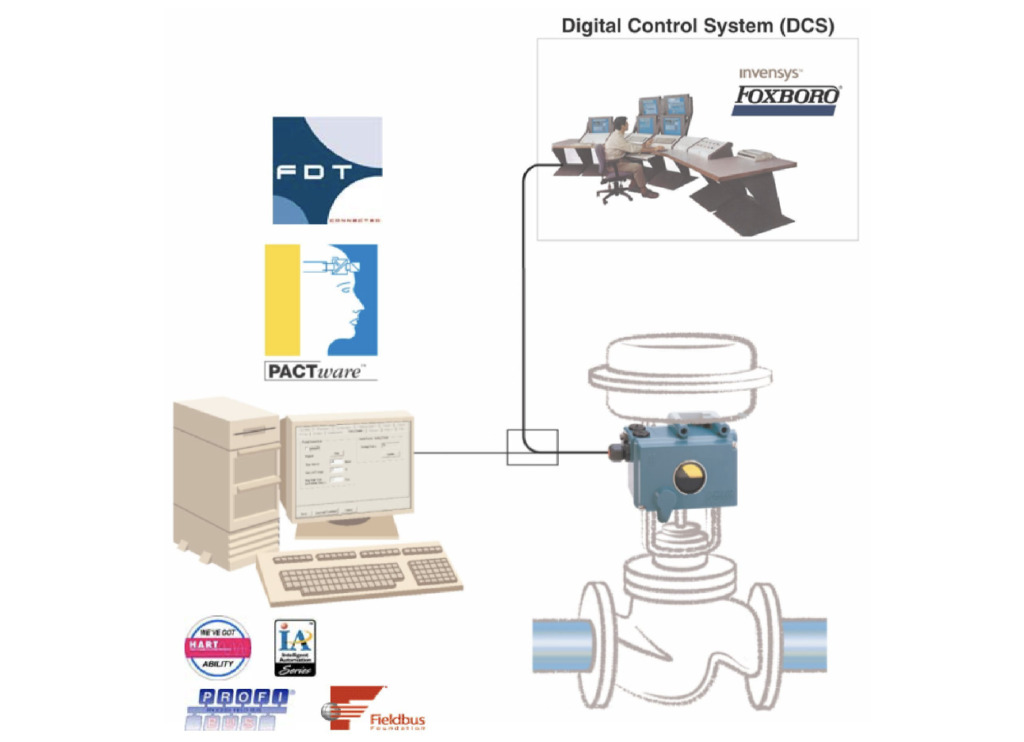

The firmware expansion of the digital valve positioner enhances the PST function and handles SIS signals and corresponding information processing, monitors and diagnoses information to communicate to the upper system, and supports open FDT/DTM and EDDL, which can be integrated into more systems.

Digital valve positioners equipped with PST functions and diagnostic functions and certified by SIL are also called ESD valve positioners. At this time, PST and its ESD valve positioner are important features of ESD control valves, and have therefore become an important component in implementing functional safety in SIS/ESD systems, and have been widely used in key industries such as petroleum and petrochemicals.

Although ESD valve positioners from different manufacturers have many differences in design structures, working principles, component functions, etc., their PST functions are basically the same. They all simultaneously measure valve position (stroke), given signal, Set point deviation, output control signal, time value, etc.

The analysis parameters include overshoot, dead zone, T63, T98 rise time and response time relative to the amplitude change. In terms of communication, the system uses HART technology (4~20mADC+HART or 24VDC+HART) or bus technology (FF or PROFIBUS-PA) to obtain conventional information and self-diagnostic information about the performance of the control valve in the ESD valve positioner. Digital status or alarm signals can also be connected.

The ESD valve positioner can set an automatic test cycle or manually start the test for PST, and can choose to perform a step response test or a ramp function test. In order to ensure test safety, during the PST test, when the valve position exceeds the control limit, the output control signal exceeds the allowable value, the valve stroke deviation exceeds the ESD allowable value, or the test times out, the test will be immediately terminated and canceled, interrupt processing will be performed, and an alarm message will be issued. , return to the original state. It can also be set to interrupt the test caused by air source failure or excessive friction, or to cancel the test manually.

ESD valve positioner with PST function

There are many digital valve positioners on the market, but ESD valve positioners with PST function and SIL certification are still very limited. They are all well-known international brands. Here are the end-users are familiar with are:

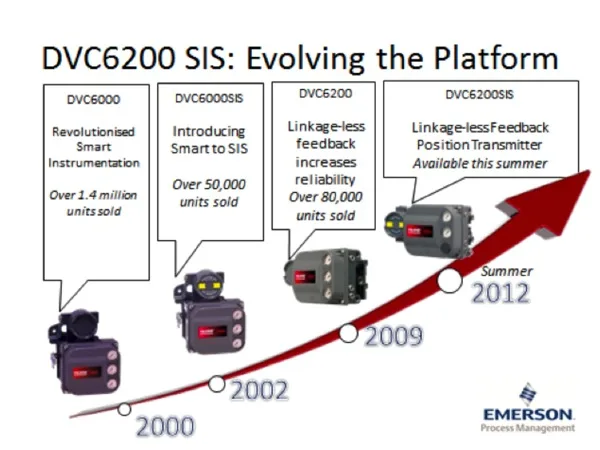

1. Emerson-Fisher’s DVC6000SIS model | HART communication, SIL3, intrinsically safe/explosionproof

Fisher can perform offline/online upgrades on the DVC6000 base model and download SIS (ESD) level software. SAMSON has ESD software pre-installed in the 3730-3 shipped after October 2007. You only need to purchase an activation code to activate the ESD function.

2. NETSO-neles’ VG800 series and RCI | HART communication, SIL3, intrinsically safe/explosionproof

VG800 is a safety system intelligent component dedicated to ESD switch control valves. It cannot perform positioning adjustment and control the switching action of the built-in solenoid valve. It requires an external dedicated RCI module for HART communication, signal detection and status monitoring.

3. SAMSON’s 3730-3ESD type | HART communication, STL4 (solenoid valve function), intrinsic safety

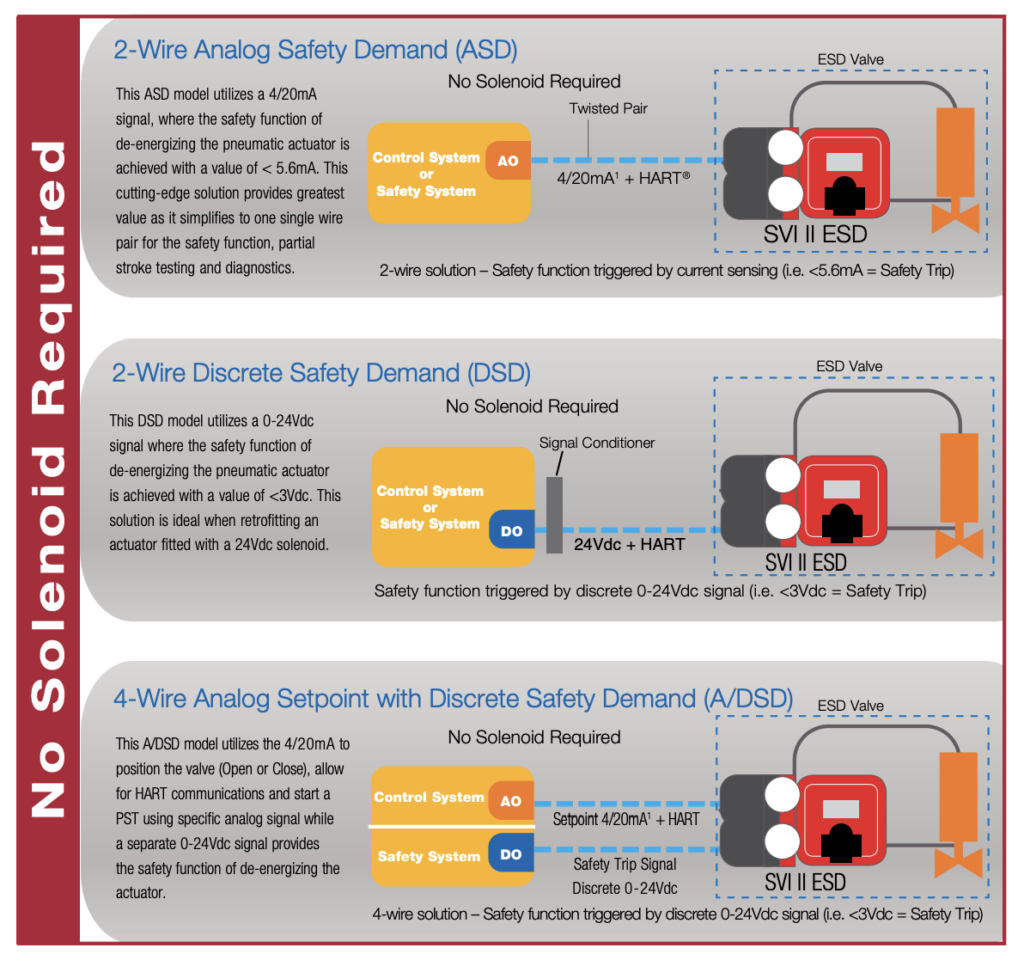

The 3730-3ESD housing can integrate a low-power solenoid valve (certified to SIL4) and an inductive valve position switch (in addition to soft contacts), and the corresponding cables are also led to the positioner terminals. DVC600OSIS can be equipped with external solenoid valves and valve position switches. It has current input and voltage input. It has four-wire (point-to-point)/two-wire (multi-point) connection methods. When the second wire is 24VDC, it may need to be equipped with a line resistance modulator, or it may be preset internally. Install a small solenoid valve and connect the second line 24VDC to the junction box. SVIIIIESD has multiple sensors. There are 2 D0, 1 DI and 1 PV inputs. Optional 2-wire analog ASD type, 2-wire digital DSD type or Four-wire analog/digital hybrid A/DSD type (3 types corresponding to different circuit boards).

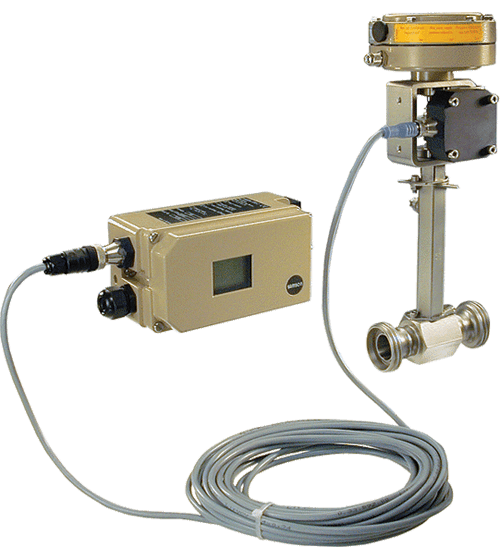

4. DRESS-Masoneilan’s SVIIESD | HART communication, SIL3, intrinsically safe/explosionproof

5. SRD991/960 of INVENSYS-Foxboro-Eckardt | HART or bus, SIL3

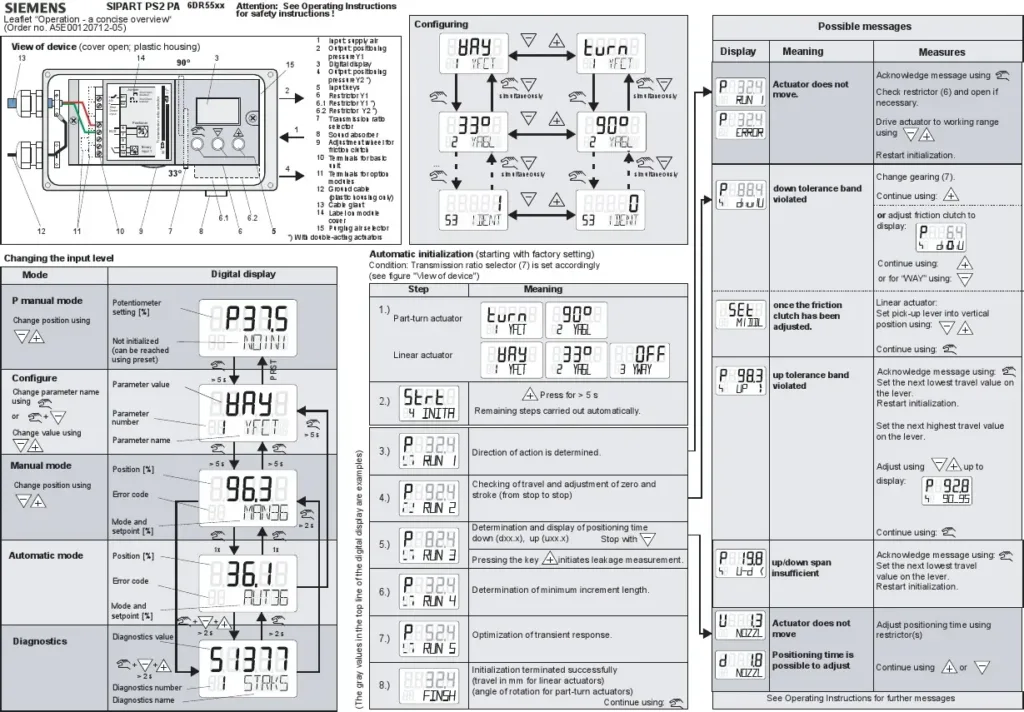

6. STENENS’ SIPARTPS2 | HART or bus, SIL2, intrinsically safe/explosionproof.

DVC6000SIS, SVIIESD, 3730-3ESD, SRD991/960, and SIPARTPS2 all have firmware expanded ESD functions on top of their basic digital valve positioners to perform PST and valve position control functions (including custom switching characteristics), and performance diagnosis and information processing, supporting HART communication or fieldbus, and its structure and principle are generally used for basic valve positioners.

- VG800 is powered and communicated by the RCI module installed in the control room, and the RCI module then obtains the valve status signal to the SIS.

- DVC6O0OSIS uses AMSvalveLink for monitoring and diagnosis, supports DD and EDDL, and can integrate the valveLink operating plug-in into other manufacturers’ control systems/safety systems (such as plugging into Yokogawa’s PRM), but does not support FDT/DTM open platforms.

- SVIIESD uses ValVue2ESD software, integrated into the SIS as a plug-in. The 3730-3ESD supports the integration and use of EDDL and FDT/DTM in process control systems.

- SANSON’s TROVIS-VTEW monitoring interface. SRD991/960 uses VALcare.

- SIPARTPS2 enters Siemens Security Integration.

- The VG800 uses the NelesValvguard security system.

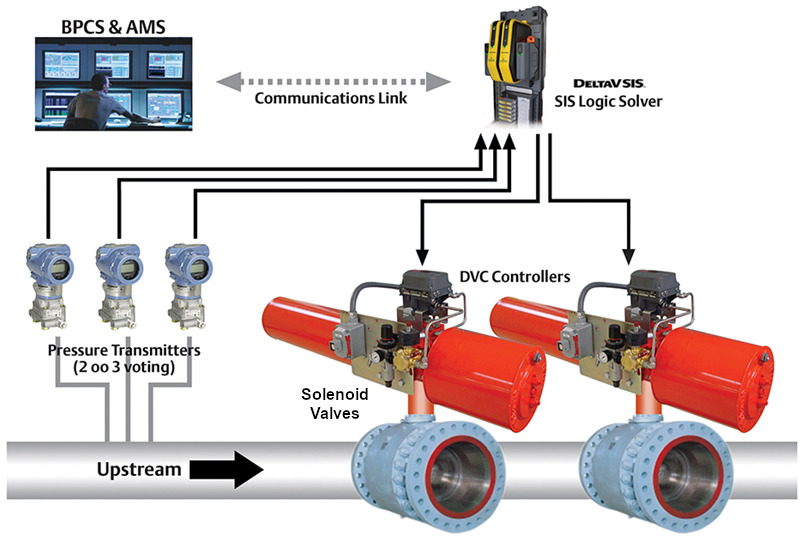

Most of the currently applied ESD valve positioners are based on HART communication. The application process is: the SIS/ESD system uses digital signal output (24VDC) to trigger the solenoid valve action to cut off or give an emptying signal to the pneumatic actuator or use the ESD valve positioner to automatically The defined switching characteristics make the control valve act, or an analog signal (4~20mADC) is used to place the ESD control valve in a specific valve position. The valve position signal is connected to the SIS, and the safety barrier or RCI module is connected to the HART multi-channel collector. Communicate with the host computer or DCS via HART to collect ESD control valve information for monitoring and diagnosis. Similar to above for bus communication.

The model number of DVC6000SIS is SIS instead of ESD. It can be seen that it is emphasized that its application range is wider than that of ESD. Considering that SIS is mainly a logic controller and also has DCS analog control, DVC6000SIS has two input signals to choose from, and the wiring is divided into two-wire and four-wire connections. Furthermore, external solenoid valves are considered. The input signal is 4-20mADC current, which is called point-to-point mode. It is mostly in the case of four-wire connection. The external solenoid valve is a single 24VDC. The input signal is 24VDC voltage, which is called multidrop mode. It is mostly in the second-wire connection situation, with an external solenoid valve and DVC6000SIS sharing the signal, or 24VDC without an external solenoid valve. Both conditions must be determined before application and set on the DIP switches on the printed circuit board.

The solenoid valve is connected to the air pipeline from the valve positioner to the pneumatic actuator, or a small solenoid valve is pre-integrated inside to receive the interlock action signal of the SIS system and evacuate the signal pressure of the actuator. When two-wire connection is used for multi-point applications, the valve positioner and solenoid valve are connected in parallel.

Since the loop line resistance varies depending on the actual site, a line resistance modulator (LC340 type) must be used to ensure the necessary 24VDC. The type with internal pre-installed solenoid valve connects the second line 24VDC directly to the junction box of DVC6000SIS. The four-wire connection point-to-point form is wired separately.

The valve positioner uses a 4-20mADC current loop, and then uses a safety barrier to isolate and extract the HART signal. The solenoid valve uses 24VDC action. An LCP100 field operation panel with buttons and indicator lights is also available, allowing users to start PST on site. DVC6000 was launched earlier and does not have local display and local configuration operation buttons, making on-site monitoring operations somewhat inconvenient.

2.1 Definition and primary function

An ESD valve is defined as a type of safety valve that provides automatic shutdown of system processes in emergency situations. Its primary function is to ensure the safety of the plant and its operations by preventing the escalation of events that could lead to equipment damage or pose risks to human safety and the environment. When a potentially dangerous condition is detected, either by manual intervention or through automatic detection systems, the ESD valve is activated, stopping the flow of materials, isolating equipment, or venting harmful substances.

2.2 Common scenarios where ESD valves are employed

ESD valves are employed in a variety of scenarios across different industries:

Oil and Gas Production

To prevent over-pressurization of pipelines or equipment and to stop the flow of hydrocarbons in the event of leaks or breaks.

Chemical Plants

To contain and prevent the release of toxic or hazardous chemicals during process upsets.

Power Plants

For shutting down turbines or fuel supplies in cases of malfunctions or anomalies.

Pharmaceutical Manufacturing

To halt processes if contamination or other anomalies are detected.

Refineries

To isolate sections of the plant if hazardous conditions, such as fires or leaks, arise.

LNG Terminals

To prevent unintended releases during the loading and unloading of liquified natural gas.

2.3 Why is testing necessary for ESD valves

ESD valves play a pivotal role in the safety protocols of many industrial processes. Their reliable and effective operation is paramount in preventing potential catastrophes.

2.4 Potential risks of valve malfunctions.

Valve malfunctions can lead to a myriad of issues:

- Uncontrolled Release: A malfunctioning valve could fail to close, leading to the uncontrolled release of hazardous substances, which poses environmental and health risks.

- System Overpressure: If a valve doesn’t open or vent when required, it can result in system overpressure, which could lead to equipment rupture and potential explosions.

- Process Disruption: An improperly functioning valve can disrupt the entire industrial process, leading to downtime, loss of product, and significant financial impacts.

2.5 Case studies of incidents resulting from valve failures

Case 1. Bhopal Gas Tragedy (1984)

One of the world’s worst industrial disasters occurred in Bhopal, India, when methyl isocyanate gas and other chemicals leaked from a pesticide plant. Malfunctioning safety systems, including valves and vent scrubbers, were among the factors contributing to the catastrophe, leading to thousands of deaths and severe long-term health impacts for many survivors.

Case 2. Deepwater Horizon Oil Spill (2010)

The explosion and subsequent sinking of the Deepwater Horizon oil rig in the Gulf of Mexico resulted in one of the largest environmental disasters in U.S. history. Failures in the blowout preventer, a form of an ESD valve, were critical in the chain of events that led to the spill.

These incidents highlight the importance of regularly testing and maintaining ESD valves to their safety function and ensure their proper functionality in critical situations.

3. Understanding Partial Stroke Testing (PST)

Partial Stroke Testing (PST) serves as a critical tool in the maintenance and assurance of ESD valve functionality. While a full shutdown can be disruptive and time-consuming, PST offers a way to verify valve performance without halting the entire process.

3.1 Definition and primary objectives of PST

Partial Stroke Testing, commonly referred to as PST, is a diagnostic procedure used to assess the operability of an ESD valve without fully actuating it. Instead of the valve going through its entire range of motion as in a full-stroke test, a PST partially moves the valve to ensure it can initiate its emergency function. The primary objectives of PST are:

- Operability Verification: Confirming that the ESD valve can move and isn’t seized or stuck in its position.

- Functional Assessment: Ensuring that the valve’s actuation system (whether pneumatic, hydraulic, or electric) is in working condition.

- Early Problem Detection: Identifying potential issues before they escalate into major problems or system failures.

3.2 How PST differs from full-stroke tests

While both PST and full-stroke tests aim to validate the functionality of ESD valves, they differ in their execution and scope:

- Range of Movement: PST only moves the valve partially, typically between 10% to 20% of its full range, whereas a full-stroke test involves actuating the valve through its entire range of motion.

- Operational Impact: Full-stroke tests often require a system or process shutdown to safely assess the valve’s performance, resulting in potential downtime. PST, on the other hand, is designed to minimize process disruption by testing the valve’s functionality during ongoing operations.

- Frequency: Due to its less intrusive nature, PST can be conducted more frequently than full-stroke tests. This regularity ensures continuous monitoring and early detection of potential issues.

3.3 Benefits of PST

Partial Stroke Testing offers numerous advantages, making it a preferred method for many industries when verifying the operability of ESD valves.

3.3.1 Reduced process interruption

PST is designed to be minimally invasive, allowing industries to verify the health of their ESD valves without stopping their operations. This ensures that production targets are met, operational costs are minimized, and overall system efficiency is maintained.

3.3.2 Early detection of issues

With the ability to be conducted more frequently than full-stroke tests, PST serves as a regular health check for ESD valves. This frequent testing allows for the timely identification of wear and tear, anomalies, or potential malfunctions, ensuring that corrective actions can be taken before minor issues escalate into major problems.

3.3.3 Ensuring continuous safety without total shutdown

Safety is paramount in any industrial process. PST offers a balance between safety integrity function, ensuring that ESD valves are ready to perform in emergency scenarios while negating the need for a total system shutdown. This means industries can maintain the highest safety standards without compromising on productivity.

4. PST Procedures and Protocols

To ensure the effectiveness and safety of a Partial Stroke Test (PST), it’s vital to follow standardized procedures and protocols. Proper preparation, execution, and post-test evaluations are key to obtaining reliable results and maintaining the operational integrity of the system.

4.1 Pre-test preparations and safety precautions

Before conducting a PST, it’s essential to take some preparatory steps and observe safety precautions:

- Notification: Inform relevant personnel, including control room operators and on-site technicians, about the scheduled PST to avoid confusion or unintentional interference.

- Safety Gear: Ensure technicians are equipped with the necessary personal protective equipment (PPE), including safety goggles, gloves, and ear protection if required.

- System Monitoring: Ensure that all monitoring systems are operational, allowing for real-time tracking of valve positions and system pressures during the test.

- Backup Plans: Have contingency plans in place for any unforeseen circumstances or unexpected results during the test.

4.2 Step-by-step guide to conducting a PST

- Initiation: Start the PST software or control module, selecting the specific valve to be tested.

- Baseline Reading: Record the initial valve position and system parameters. This provides a reference for comparison after the test.

- Partial Actuation: Actuate the valve to the predetermined partial position, typically between 10% to 20% of its full range.

- Monitor Movement: Observe and record the valve’s movement to ensure it corresponds to the expected partial actuation without any unexpected behaviors.

- Return to Original Position: Once the PST is complete, ensure the valve returns to its original position and that system parameters stabilize.

- System Check: Confirm that there are no alarms or anomalies in the control system related to the valve’s position or other related parameters.

4.3 Post-test evaluations and documentation

After conducting the PST, it’s imperative to evaluate the results and maintain proper documentation:

- Compare Data: Cross-reference the data recorded during the test with baseline readings to identify any discrepancies or deviations.

- Document Findings: Maintain a detailed record of the test, including date, time, valve details, test results, and any anomalies or issues observed.

- Recommendations: If the PST reveals any potential issues or areas of concern, provide actionable recommendations for maintenance or further inspection.

- Update Maintenance Logs: Ensure that maintenance logs for the specific ESD valve are updated with the latest PST results.

4.4 Frequency of PST – Best practices and industry standards

The frequency of PST largely depends on the industry, the specific application of the ESD valve, and the associated risks. However, some general guidelines include:

- High-Risk Systems: For systems where the potential consequences of a valve malfunction are severe, conducting PST quarterly or even monthly might be recommended.

- Moderate-Risk Systems: For systems with moderate associated risks, semi-annual or annual PST might be sufficient.

- Regulatory Compliance: Always adhere to local, regional, and industry-specific regulations and standards. Some industries may have mandated PST frequencies to ensure safety and compliance.

- Manufacturer Recommendations: Often, the valve manufacturer provides guidelines on recommended testing frequencies based on the design and expected lifespan of the valve.

It’s always a good practice to consult with industry experts, or you can freely to contact our THINKTANK’s engineers or regulatory bodies to determine the most appropriate PST frequency for a specific application.

5. Challenges and Considerations in PST

Partial Stroke Testing (PST) plays an instrumental role in ensuring the functionality of ESD valves without shutting down an entire system. However, as with any diagnostic procedure, PST comes with inherent challenges and requires careful considerations to ensure its efficacy and safety.

5.1 Potential risks during PST

Several risks might emerge during a PST:

- Incomplete Return: After partial actuation, there’s a risk that the valve might not return to its original position, potentially causing operational issues.

- Stress on Components: Repeated partial movements can introduce unusual stress patterns on the valve components, which may not be designed for such operations, leading to premature wear.

- False Positives/Negatives: There’s always a risk that a PST might indicate a valve is working correctly when it isn’t, or vice-versa.

- System Disruptions: Even though PST is meant to be minimally invasive, in some sensitive systems, even a slight change in valve position might disrupt the process flow or dynamics.

5.2 Overcoming common challenges

Addressing the inherent challenges of PST requires meticulous planning and strategies:

- Regular Maintenance: To counteract the stress on valve components due to repeated PSTs, it’s crucial to have a more frequent maintenance and inspection schedule.

- Advanced Diagnostic Tools: Using advanced diagnostic tools can help in providing a more accurate picture of the valve’s health, reducing chances of false positives or negatives.

- PST Training: Ensure that personnel conducting PSTs are well-trained and aware of potential pitfalls and risks, ensuring they can take corrective actions swiftly if something goes amiss.

- System Monitoring: Continuous monitoring of the system can help in early detection of any disruptions or anomalies caused due to PST.

5.3 Factors influencing the accuracy and reliability of PST

Ensuring accurate and reliable PST results depends on various factors:

- Equipment Calibration: Regularly calibrate PST equipment to ensure they provide accurate readings.

- Valve History: A valve that has been frequently or recently maintained or has a history of issues might respond differently during a PST.

- Operator Expertise: The reliability of PST results can heavily depend on the operator’s expertise and experience. Any oversight or misjudgment can lead to inaccurate results.

- Environmental Conditions: The ambient conditions, such as temperature, humidity, and potential contaminants, can influence valve behavior and thus the outcomes of a PST.

- Frequency of Tests: Conducting PSTs too frequently might introduce wear, while doing them rarely might miss out on capturing potential issues in time.

6. Integrating PST with Modern Technology

In today’s rapidly evolving technological landscape, integrating modern technology with traditional procedures such as Partial Stroke Testing (PST) can reap significant rewards. With the fusion of automation, IoT, and other technological advancements, PST becomes more efficient, accurate, and aligned with the demands of modern industries.

6.1 The role of automation in PST

Automation plays a pivotal role in enhancing the efficiency and reliability of PST:

- Consistency: Automated PST systems ensure that the tests are conducted consistently every time, eliminating human errors or variations.

- Scheduling: With automation, PSTs can be scheduled during optimal times, ensuring minimal disruption and maximum effectiveness.

- Real-time Analysis: Automated systems can analyze the test results in real-time, providing instant feedback on the valve’s condition and performance.

- Integration with Control Systems: Modern automated PST systems can be seamlessly integrated with plant control systems, enabling a cohesive and unified approach to valve management.

6.2 Benefits of integrating IoT (Internet of Things) with ESD valve testing

The integration of IoT brings a new dimension to ESD valve testing:

- Remote Monitoring: IoT-enabled ESD valves can be monitored from anywhere, offering convenience and real-time insights.

- Predictive Maintenance: With continuous data collection and analysis, IoT systems can predict potential valve failures or maintenance needs before they become critical.

- Enhanced Data Collection: IoT devices can collect a plethora of data, providing a more comprehensive view of the valve’s performance over time.

- Safety Improvements: IoT can trigger alarms or notifications in case of anomalies during PST, ensuring immediate attention and resolution.

6.3 Case studies showcasing the success of technology-integrated PST

Case Study 1: A Leading Petrochemical Plant

By integrating automated PST systems, the plant saw a 20% increase in the early detection of potential valve issues, leading to reduced downtime and increased operational efficiency. The system, coupled with IoT, allowed for real-time monitoring, and electronic control systems leading to a safer work environment and timely maintenance schedules.

Case Study 2: A Global Pharmaceutical Manufacturer

To ensure the utmost quality and safety, the manufacturer integrated IoT with their ESD valves. The continuous data collection and analysis provided insights that led to a 15% reduction in maintenance costs. Automated PSTs ensured that production was rarely interrupted, leading to consistent product output and quality.

Case Study 3: A Renowned Food Processing Unit

Food safety being paramount, the processing unit incorporated automated PSTs into their system. This not only streamlined their testing procedures but also reduced the chances of contamination. With IoT in place, the unit’s engineers could monitor the valves remotely, ensuring optimal operation at all times.

7. Regulatory and Compliance Landscape

Ensuring the proper functioning and safety of ESD valves is not just a matter of best practices—it’s often a legal and regulatory imperative. Comprehending the regulatory landscape is essential for plants and industries to avoid legal repercussions, maintain reputation, and most importantly, ensure safety.

7.1 Global standards governing PST and ESD valve operations

Several international standards and guidelines offer insights and rules on PST and ESD valve operations:

- IEC 61511: This is a standard for Safety Instrumented Systems for the Process Industry Sector, which includes details related to PST.

- ISA 84 (ISA 84.00.01-2004): Also known as the Functional Safety of Safety Instrumented Systems, it is a key standard in the process industry, including specifications related to ESD valves and PST.

- API 6D: This specification from the American Petroleum Institute is for pipeline valves and includes provisions relevant to ESD valves.

- Other Regional Standards: Many countries have local or regional standards that might have specific requirements, and it’s essential for industries operating in those regions to be aware of and comply with these standards.

7.2 Periodic audits and certifications

Regular audits and certifications are imperative to ensure ongoing compliance:

- Internal Audits: Conducting regular internal checks helps in identifying potential non-compliance issues before they become problematic. It ensures that the systems are always operating within the stipulated guidelines.

- Third-party Audits: Getting an external entity to assess the operations provides an unbiased view of the plant’s adherence to standards. It also offers credibility to the company’s claims of compliance.

- Certifications: Acquiring certifications from recognized bodies indicates that the facility or system meets specific standards. Not only does it offer an assurance of quality and safety, but it can also provide a competitive edge in the market.

- Training and Updates: Regulations and standards might evolve over time. Regular training sessions for personnel and timely updates to systems ensure that the facility remains compliant even as standards change.

8. Conclusion

Safety, in industries where ESD valves are deployed, is not a mere checkbox but a cardinal requirement. PST, in its capacity, serves as a reliable method ensuring that ESD valves function as intended during critical moments. By facilitating a balance between comprehensive testing and operational continuity, PST offers a pragmatic approach to safety system valves. It ensures that potential valve malfunctions are identified and addressed timely, thereby safeguarding both human lives and valuable assets.

In an age where technology integrates itself seamlessly into virtually every facet of industry operations, the realm of ESD valve testing is no exception. The augmentation of PST with modern technological tools, ranging from automation to the Internet of Things (IoT), exemplifies a future where testing is not only more efficient but also more insightful. As we move forward, it becomes imperative for industries to keep pace with these advancements, ensuring that their functional safety systems and protocols are not only compliant with present regulations but are also future-ready.

To conclude, while the landscape of ESD valve testing, driven by technology and regulations, is ever-evolving, the core principle remains steadfast: the unwavering commitment to safety and functionality. Embracing advancements, understanding regulations, and upholding the principles of safety will undoubtedly steer industries towards a future where operations are both efficient and secure. As a trustworthy control valve manufacturer, We THINKTANK welcomes EPCs, engineering companies, valve dealers and brand owners to cooperate with us to create optimal safe fluid solutions.

9. References

- International Electrotechnical Commission (IEC). (2018). Safety Instrumented Systems for the Process Industry Sector – IEC 61511. IEC Standard. Geneva, Switzerland: IEC.

- International Society of Automation (ISA). (2004). Functional Safety of Safety Instrumented Systems – ISA 84.00.01-2004. Research Triangle Park, NC: ISA.

- American Petroleum Institute (API). (2016). Specification for Pipeline Valves – API 6D. 24th Edition. Washington, D.C.: API.

- Smith, J. A., & Anderson, D. R. (2019). Advancements in Emergency Shutdown Valve Technologies. Journal of Process Safety, 45(3), 284-292.

- Roberts, L. (2020). The Role of Automation in Safety Valve Testing: A Comparative Analysis. Industrial Automation Review, 52(1), 17-23.

- Patel, H., & Kumar, A. (2018). IoT in Industrial Safety: Applications and Implications. International Journal of IoT Research, 12(2), 45-59.

- Fernandez, R. (2017). Safety Compliance in Petrochemical Industries: A Review of Regulations and Best Practices. Journal of Petrochemical Safety, 33(4), 320-329.

- Johnson, M. L., & Wilkins, S. P. (2019). Partial Stroke Testing: Benefits, Challenges, and Future Directions. Valve World Magazine, 27(5), 45-50.

- Rodriguez, P., & Kim, J. H. (2020). The Impact of Technological Advancements on Safety Valve Testing Procedures. Process Safety Progress, 39(2), 123-130.