A swivel flange is a uniquely designed pipe connector widely used in industrial applications that require high precision and efficiency. Its 360° rotational capability simplifies installation and alignment, making it an indispensable choice for engineers and procurement managers.

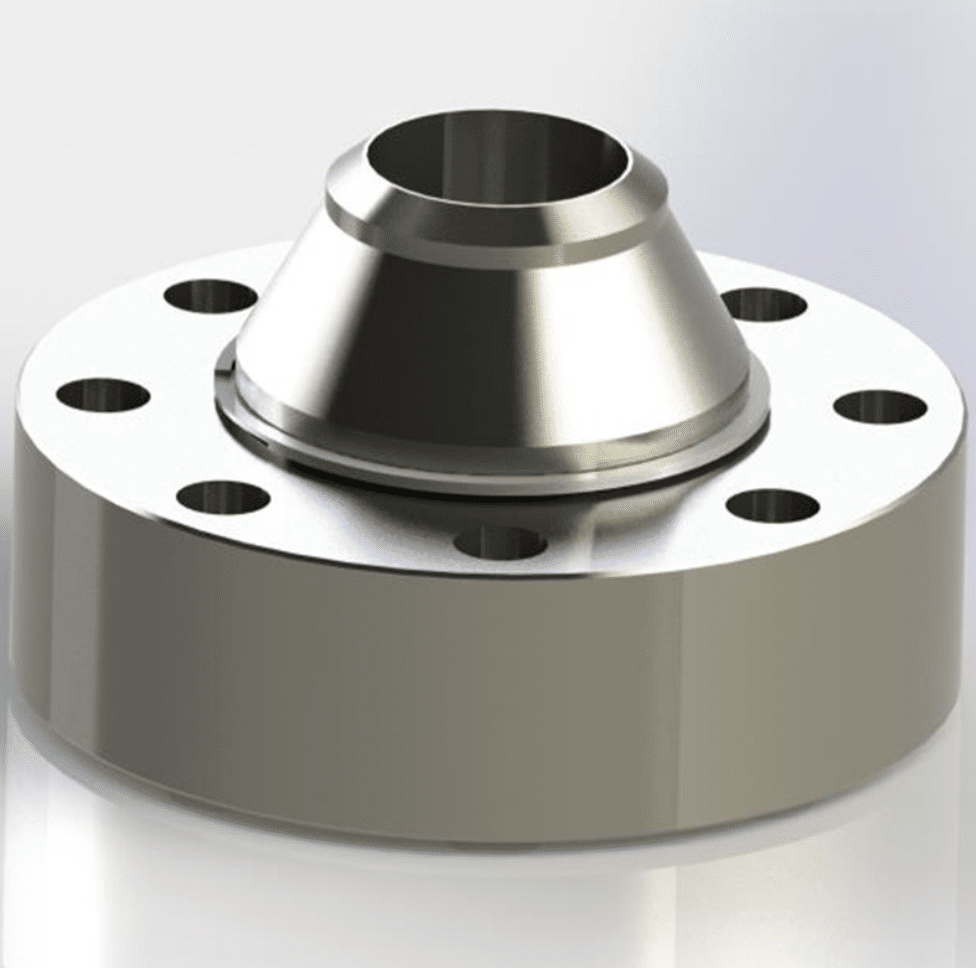

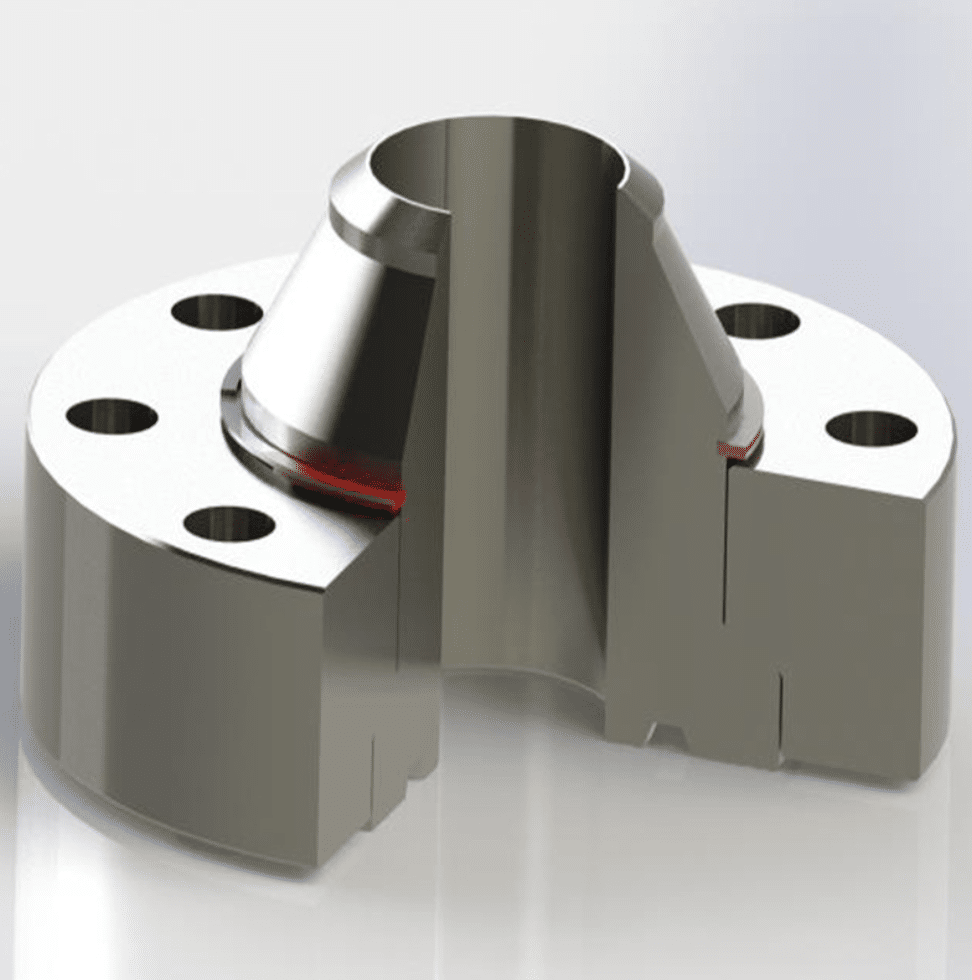

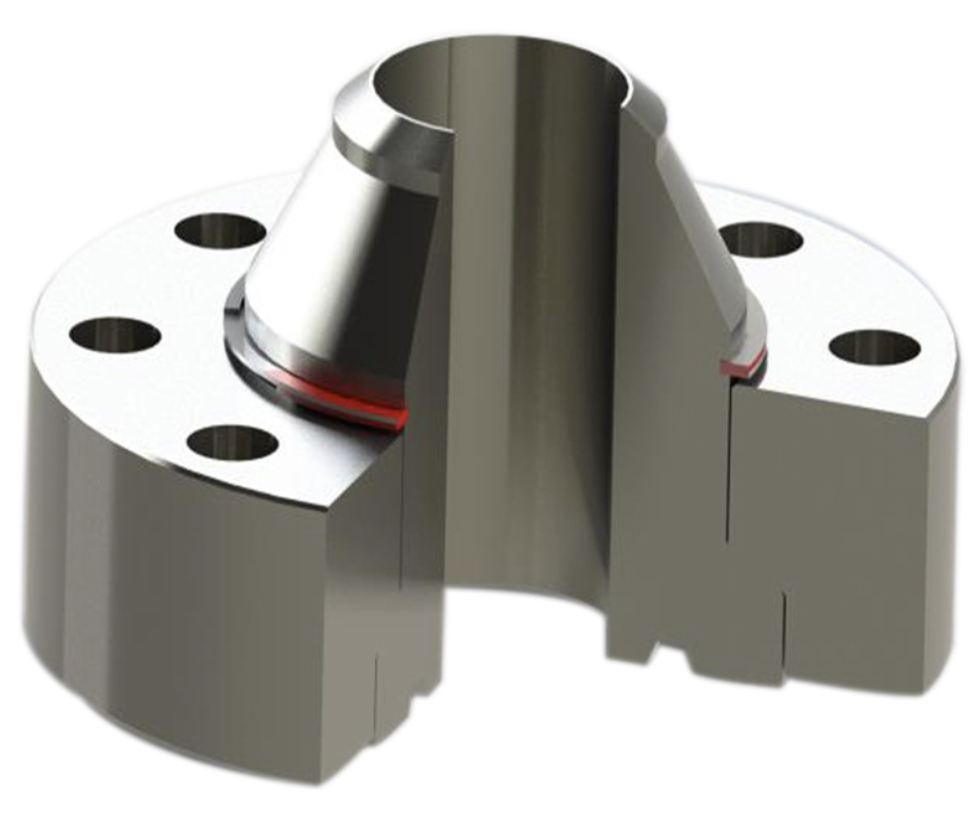

A swivel flange is a special weld neck flange consisting of an inner ring and an outer ring that allows 360° rotation. This design simplifies bolt-hole alignment, reduces installation time, and ensures efficient pipe connections. It is ideal for offshore, industrial, and high-dynamic load applications due to its versatility and reliability.

In this article, we will delve deeper into the advantages, applications, and key technical specifications of swivel flanges.

1. What is a Swivel Flange?

Swivel Flange is a split-type flange assembly comprising a forged outer ring, a heavy forged welding hub, and a gasket. The inner weld-neck hub is designed to rotate freely during installation, enabling quick and precise alignment of bolt holes when connecting to a weld neck (WN) flange or other flange types. This innovative design is particularly beneficial in applications where accurate bolt-hole alignment is crucial.

The outer ring is secured in position by a retainer ring, allowing the flange assembly to rotate independently around the hub. This feature simplifies and accelerates the process of aligning bolt holes between two joining flanges, making swivel flanges a practical solution for offshore piping. They are widely used in subsea installations, where challenging conditions often make bolt-hole alignment difficult and time-consuming.

We provide high-quality swivel flanges with FAST delivery time. Available in materials such as ASTM A105/N and A694 grades (F42, F46, F52, F60, F65, etc.) and also Duplex SS(UNS S31803 material.

2. Key Advantages of a Swivel Flange

Swivel flanges offer a range of benefits, including:

Quick Alignment

The 360° rotational feature eliminates the hassle of manually adjusting pipe connections, significantly reducing alignment time.

Ease of Installation

Even in constrained or complex spaces, swivel flanges streamline the installation process, enhancing efficiency.

Cost Savings

By minimizing installation time and effort, swivel flanges indirectly reduce labor costs and project timelines.

Corrosion Resistance

Many swivel flanges are made from materials like stainless steel, super duplex, or copper-nickel, ensuring durability in harsh environments such as chemical plants or offshore installations.

3. Applications of Swivel Flanges

The unique characteristics of swivel flanges make them suitable for a variety of industries, such as:

Offshore and Subsea Operations

Ideal for challenging marine environments, especially in subsea installations.

Chemical Engineering

Reliable in handling corrosive substances and complex chemical processes.

Onshore Oil & Gas

Ensures secure connections in pipelines for oil and gas distribution.

Paper Mills

Suitable for systems requiring precision and durability in pulp and paper processing.

Fertilizer Plants

Designed for use in high-pressure systems within fertilizer manufacturing.

Environmental Engineering

Applied in water treatment, waste management, and pollution control systems.

Power Plants

Critical for piping systems in thermal, hydro, and nuclear power projects.

Mining Industry

Handles high-dynamic loads in mineral extraction and processing.

Shipbuilding and Shipyards

Essential for marine-grade piping in ship construction and repair.

Mechanical Manufacturing

Versatile in various industrial machinery and mechanical systems.

Food and Pharmaceutical Industries

Ensures hygienic and precise operations in food processing and medicine production.

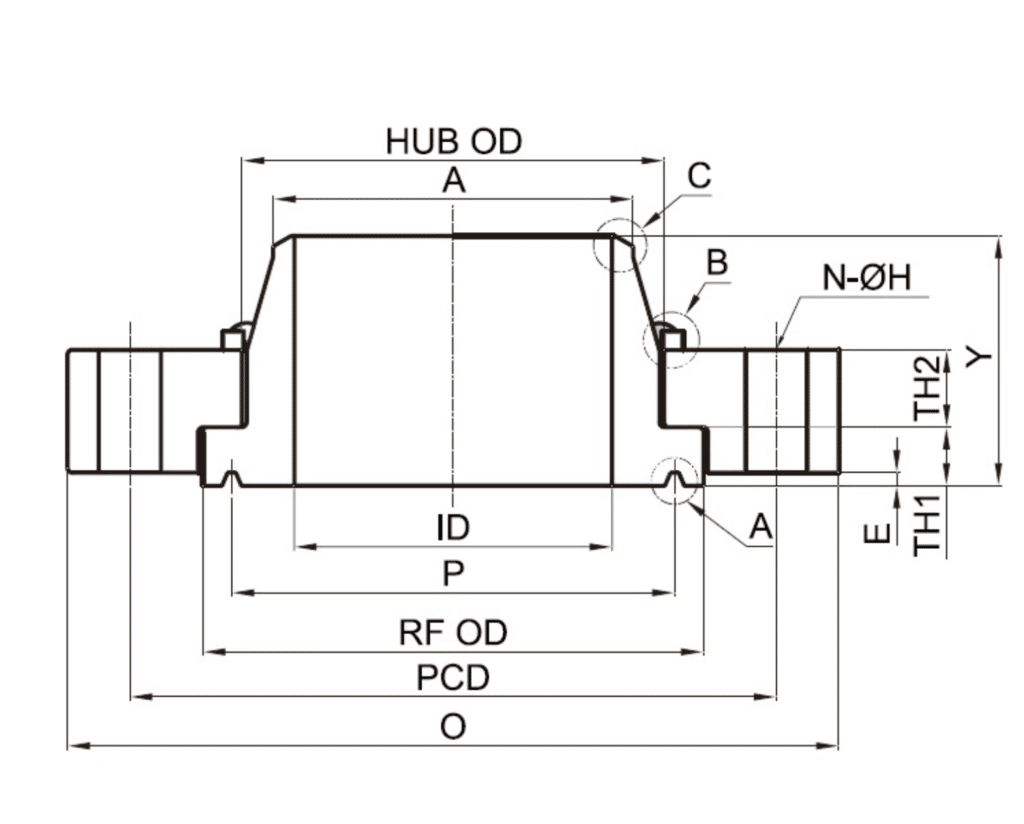

4. Technical Specifications of Swivel Flanges

| Nominal Dia. Of Flange | OD Of Flange | Dia of Bolt Circle | Dia. of Raised Face | P | TH1 | TH2 | Y | Dia. of Hub A | HUB OD | Radius R | F | E | Hole Dia H | Number of Bolt | RING NO | R1 |

| 8 | 483 | 394 | 308 | 269.88 | 60.5 | 66.6 | 197 | 219.1 | 243.8 | 6 | 16.66 | 11.13 | 44.5 | 12 | 50 | 1.5 |

| 10 | 585 | 483 | 373 | 323.85 | 71.2 | 78.3 | 233 | 273.1 | 303.6 | 6 | 16.66 | 11.13 | 50.8 | 12 | 54 | 1.5 |

| 12 | 675 | 572 | 486 | 381 | 82.1 | 82.1 | 282 | 323.9 | 386 | 6 | 23.01 | 14.27 | 54 | 16 | 58 | 1.5 |

| 14 | 750 | 635 | 543 | 419.1 | 89.6 | 88.3 | 311 | 355.6 | 438.9 | 6 | 26.97 | 15.88 | 60.3 | 16 | 63 | 2.3 |

| 16 | 825 | 705 | 606 | 469.9 | 99.8 | 96.7 | 344 | 406.4 | 496.1 | 6 | 30.18 | 17.48 | 66.7 | 16 | 67 | 2.3 |

| 18 | 915 | 775 | 670 | 533.4 | 110.4 | 107.3 | 373 | 457.2 | 545.9 | 6 | 30.18 | 17.48 | 73 | 16 | 71 | 2.3 |

| 20 | 985 | 832 | 721 | 584.2 | 121.2 | 117.1 | 402 | 508 | 587.7 | 6 | 33.32 | 17.48 | 79.4 | 16 | 75 | 2.3 |

| 24 | 1170 | 991 | 867 | 692.15 | 140.1 | 131.6 | 483 | 609.6 | 723 | 6 | 36.53 | 20.62 | 92.1 | 16 | 79 | 2.3 |

Conclusion

Swivel flanges are efficient, reliable, and versatile, which is why they’re the preferred choice for industrial pipe connections. Whether you’re working on an offshore project, in a dynamic environment, or in a corrosive environment, you’ll find that their performance and design are perfect to you as an engineer or procurement manager.