The seat leakage classification of control valves complies with standard ANSI FCI 70-2 superseding ANSI B16.104.

| Leakage Class Designation | Maximum Leakage Allowable | Test Medium | Test Pressure | Testing Procedures Required for Establishing Rating |

| CLASS I | – | – | – | No test is required provided the user and supplier so agree. |

| CLASS II | 0.5% of rated capacity | Air or water at 50-125 F (10-52C) | 45-60 psig or max. operating differential whichever is lower | Pressure applied to valve inlet with outlet open to atmosphere or connected to a low head loss measuring device full normal closing thrust provided by the actuator. |

| CLASS III | 0.1% of rated capacity | Air or water at 50-125 F (10-52C) | 45-60 psig or max. operating differential whichever is lower | Pressure applied to valve inlet with outlet open to atmosphere or connected to a low head loss measuring device full normal closing thrust provided by the actuator. |

| CLASS IV | 0.01% of rated capacity | Air or water at 50-125 F (10-52C) | 45-60 psig or max. operating differential whichever is lower | Pressure applied to valve inlet with outlet open to atmosphere or connected to a low head loss measuring device full normal closing thrust provided by the actuator. |

| CLASS V | 0.0005 ml per minute of water per inch of port diameter per psi differential | Water at 50-125F (10-52C) | Max service pressure drop across valve plug, not to exceed ANSI body rating. | Pressure applied to valve inlet after filling entire body cavity and connected piping with water and stroking valve plug closed. Use net specified max actuator thrust, but no more, even if available during the test. Allow time for leakage flow to stabilize. |

| CLASS VI | Not to exceed amounts shown in the following table based on port diameter. | Air or nitrogen at 50-125 F (10-52C) | 50 psig or max rated differential pressure across valve plug whichever is lower. | The actuator should be adjusted to operating conditions specified with full normal closing thrust applied to the valve plug seat. Allow time for leakage flow to stabilize and use a suitable measuring device. |

Control Valve Seat Leakage Classifications

| NOMINAL PORT DIAMETER (INCHES) | NOMINAL PORT DIAMETER (MILLIMETERS) | LEAK RATE (ML PER MINUTE) | LEAK RATE (BUBBLES / MINUTE*) |

| 3 | 76 | 0.9 | 6 |

| 4 | 102 | 1.7 | 11 |

| 6 | 152 | 4 | 27 |

| 8 | 203 | 6.75 | 45 |

| 10 | 254 | 9 | 63 |

| 12 | 305 | 11.5 | 81 |

*Bubbles per minute as tabulated are a suggested alternative based on a suitable calibrated measuring device, in this case, a 0.25-inch OD X 0.032-inch wall tube submerged in water to a depth of from 1/8 to 1/4 inch. The tube end shall be cut square and smooth with no chamfers or burrs. The tube axis shall be perpendicular to the surface of the water. Other measuring devices may be constructed and the number of bubbles per minute may differ from those shown as long as they correctly indicate the flow in milliliters per minute.

ANSI FCI 70-2 pdf Free Download

Our file is for non-commercial use, only for study. So if you want it for commercial use, please buy it from Fluid Controls Institute, here is the link for your reference. To learn ANSI FCI 70-2 Control Valve Seat Leakage Standard just freely download it here.

If you are interested in more videos, please refer to this page.

Final Thought For ANSI FCI 70-2 Standard

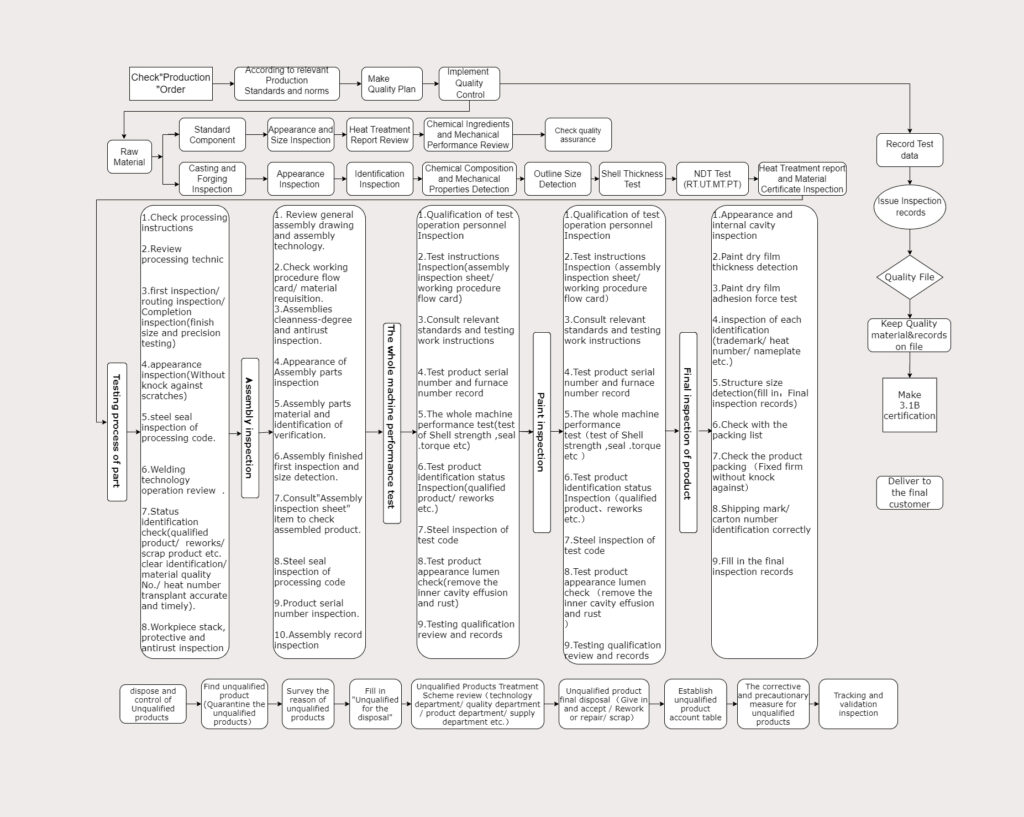

There are lots of standards for industrial valves, including design and manufacturing, inspection and test standards, face-to-face standards, connection standards, as well as material standards, etc. Basically, a reliable valve manufacturer has its own manufacturing procedure, to guarantee the quality of products. For example, the following is our factory manufacturing procedure.

If you are interested in more standards for industrial valves, please refer to this article.