Fire Safety Valves are critical safety devices designed to isolate flammable liquids and gases from extreme heat and open flames. When exposed to high temperatures, the fire safety valve closes to prevent flammable liquids from coming into contact with heat sources, whether in a fire or an overheated system. These hot shutoff valves are usually available in two configurations: Fire Ball Valves and butterfly valves.

The fire safety ball valve is designed to American Petroleum Institute (API) Standard 607. One of the characteristics of the fire safety ball valve is that it operates under operating conditions similar to ordinary valves. In case of fire, the resilient seat will burn off, but a secondary metal will come into play and allow the ball to seal against it. The valve also includes graphite body seals and packing to prevent external leakage.

A fire safety valve with a fusible connector includes a spring assembly with a clock and a trigger attached to the fusible connector. The connecting Rod keeps the valve open during normal operation by maintaining tension on the spring. When exposed to heat above a certain temperature, the connecting rod disconnects, releasing the Spring and closing the valve.

Fire Safety Valves are essential for all operations from building safety systems to process equipment. THINKTANK provides those fire safety valves to the following applications which have excellent performance.

- Main Generator and backup generator

- Diesel and natural gas fuel systems

- Biofuel processing plant

- Chemical manufacturing

- Oil and Gas refinery

- Storage containers and Utility tanks

- Schools, hospitals, offices, and other public facilities

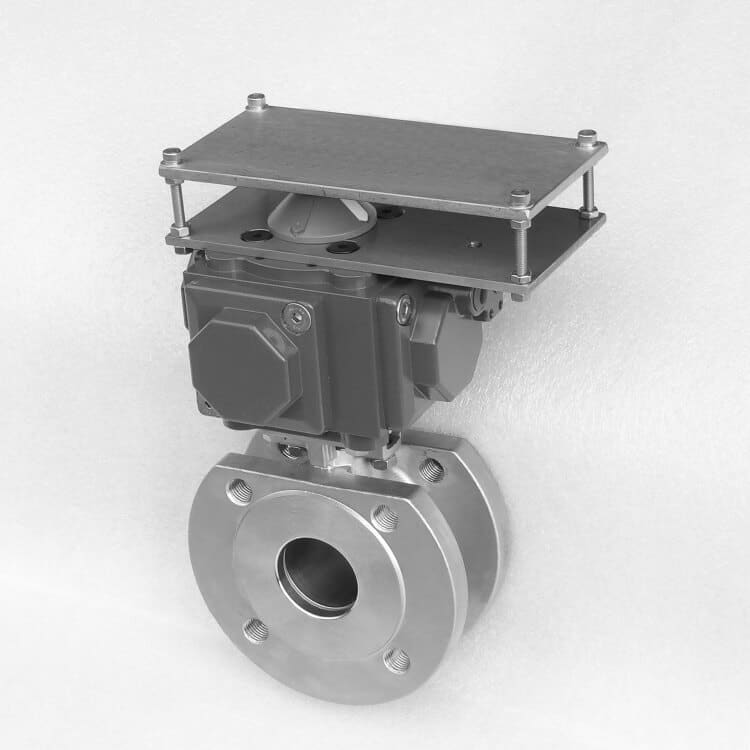

Fire Block Valve

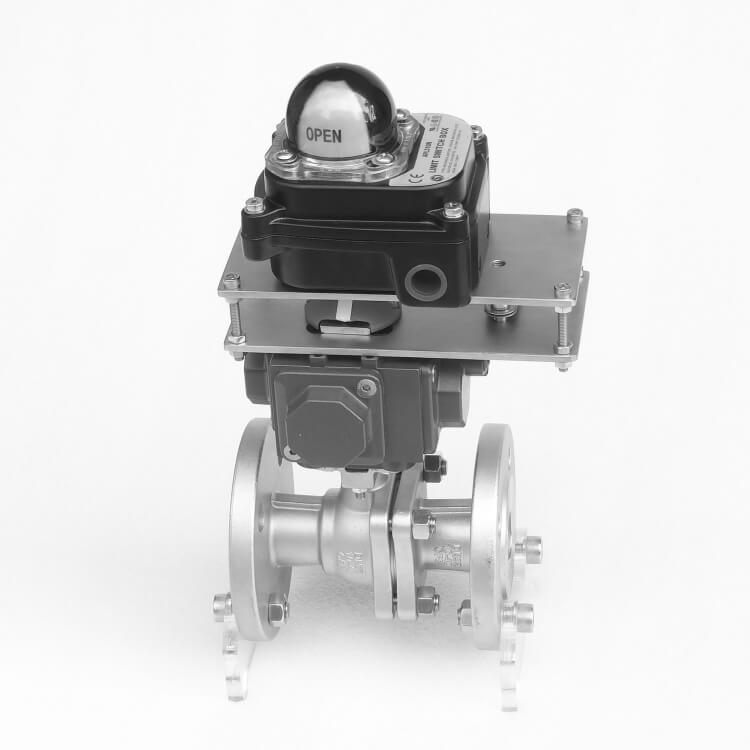

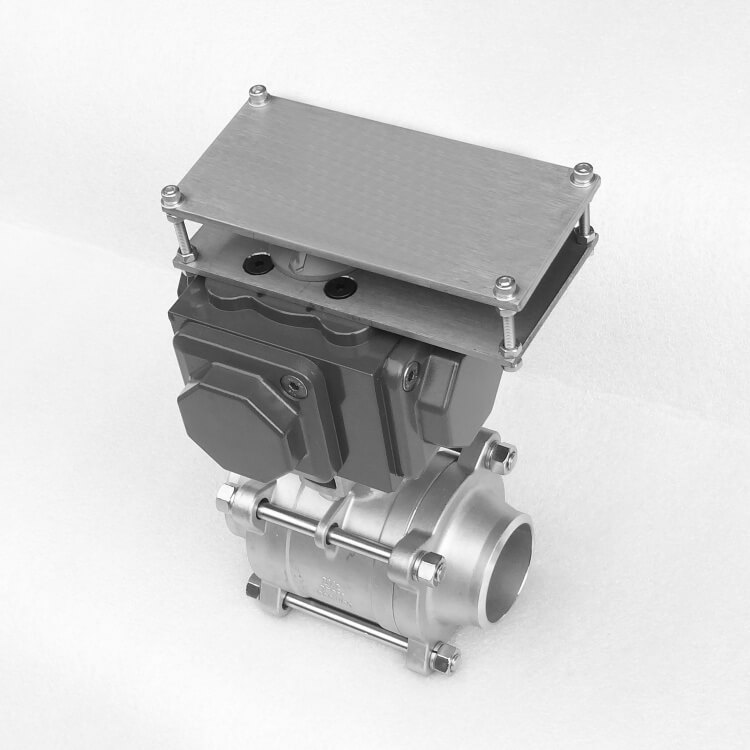

Fire Safe Ball Valve With Automatic Thermal Shut Off Device

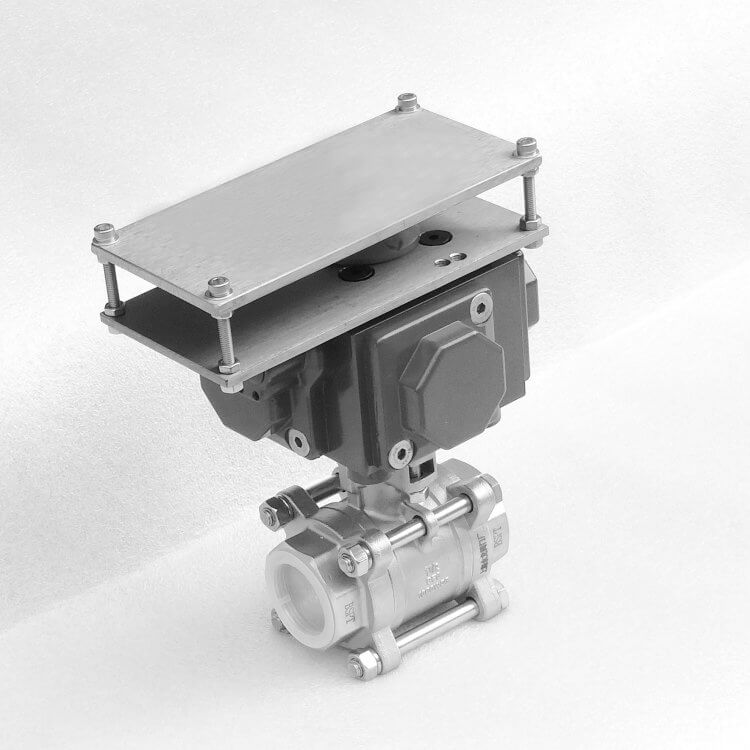

Fire Safe Valve

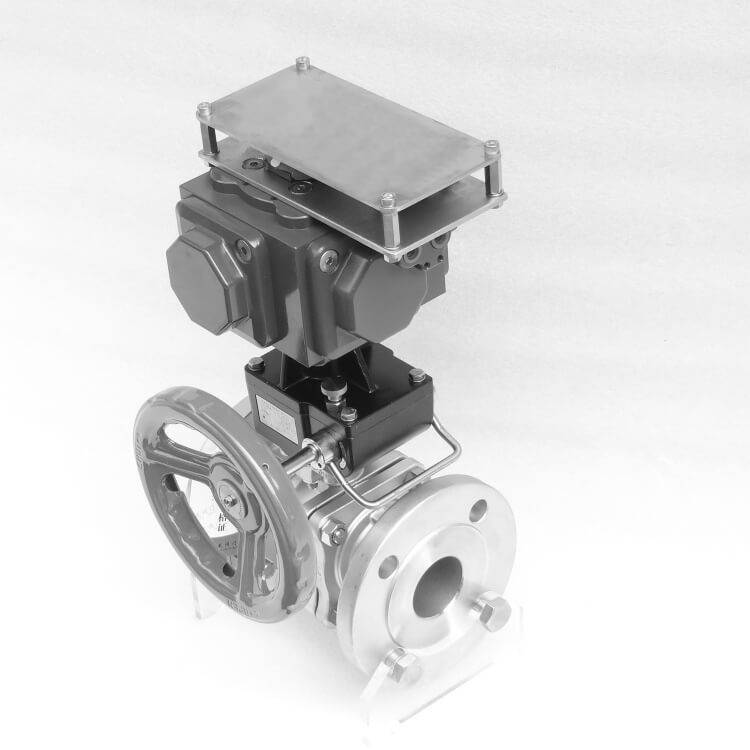

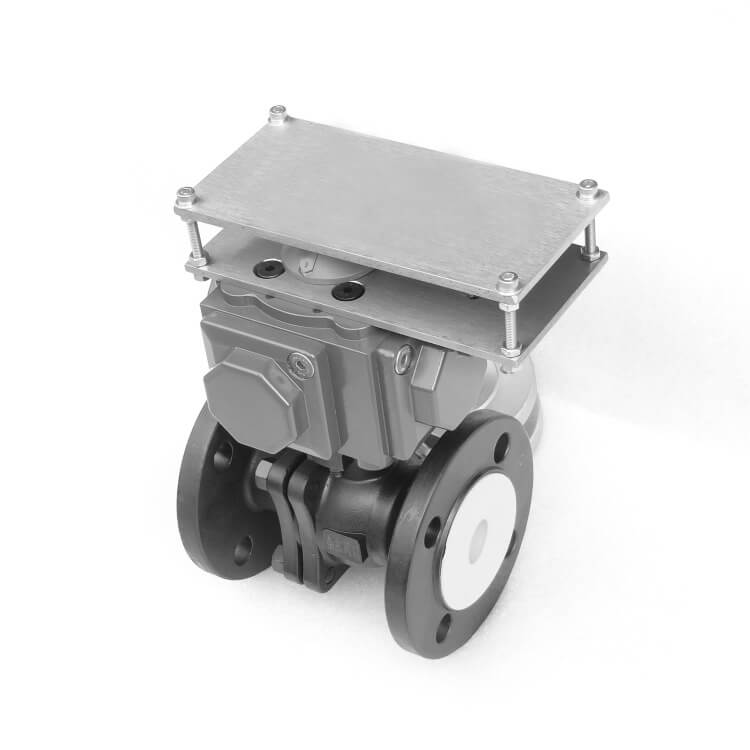

Fuse Valve For Fire Protection

Fusible Link Ball Valve

Fusible Link Valves

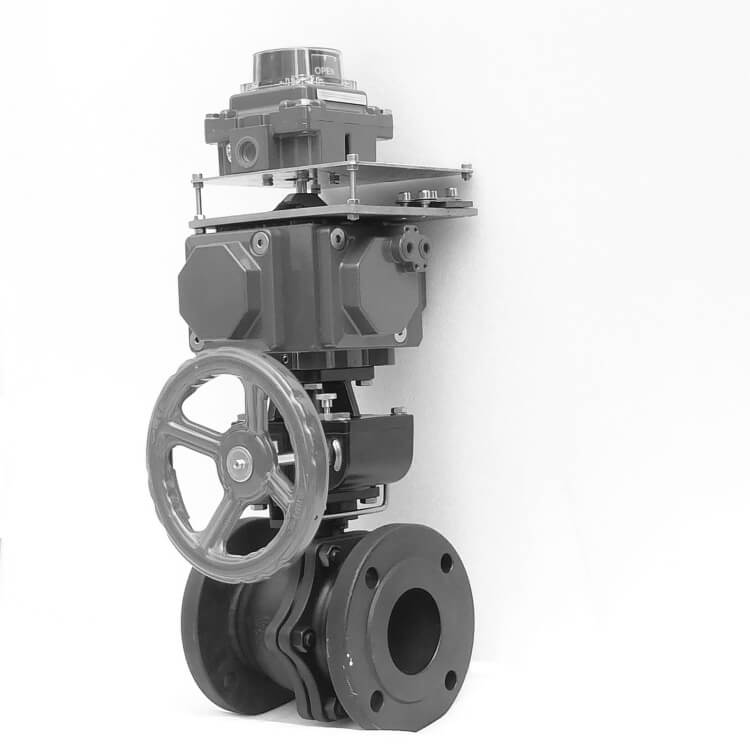

Methanol Emergency Shut Off Valve

Special Fuse Valve For Oil Tank Fire Protection