As the Marketing Director at THINKTANK, I’m thrilled to share insights into the pivotal role that industrial valves play in the realm of process control, regardless of the medium—be it liquid, gas, slurry, or powder. Industrial valves are indispensable across a myriad of sectors. From sewage treatment to the refinement and processing of chemical raw materials, from managing steam in power plants to enhancing the processing of food and beverages, and from blending dyes in textile mills to transporting natural gas through pipelines, industrial valves are omnipresent across various industrial domains.

Take the petrochemical industry, for example. Here, indutrial valves are crucial for controlling the flow and pressure of volatile organic compounds, which is essential for ensuring safety, operational efficiency, and environmental compliance. The global industrial valve market is anticipated to exceed US$ 99.8 billion by 2028, growing at a compound annual growth rate (CAGR) of 4.4%[1]. The growing demand for industrial valves in the healthcare and pharmaceutical sectors, the establishment of global smart city networks, and the rapid deployment of connected networks to monitor valve conditions and predict system failures with intelligent wireless controls are among the key factors driving the growth of the industrial valve industry.

Why this article worth you to read

The Chinese industrial valve market exhibits tremendous growth potential and has made significant contributions to both domestic development and the global supply chain. This market expansion is driven by China’s robust industrial sectors, including petrochemicals, water treatment, and power generation. China’s commitment to infrastructure development, urbanization, and industrialization has led to an increased demand for high-quality industrial valves. Moreover, the technological support from foreign valve brands has accelerated the research and development of advanced valves, positioning Chinese industrial valves as key players in the global market. Additionally, the Chinese government’s focus on environmental sustainability and energy efficiency has spurred innovation in valve technology, enhancing its appeal to international markets.

Recognizing the critical role and complex dynamics of the Chinese industrial valve market, I’ve conducted extensive research for the “Top 10 Chinese Industrial Valve Manufacturers of 2024” report. This effort is not just aimed at keeping international brands informed about the latest developments in the Chinese industrial valve industry but also serves industrial contractors, engineering companies, valve buyers, wholesalers, and distributors. My hope is that this report will provide new insights to industry stakeholders, offering a rational data basis for quickly choosing the right supply chain, thereby saving a significant amount of time and effort.

Collaborating with China’s top industrial valve manufacturers ensures not only product quality but also exceptional and timely after-sales service, as proven by numerous projects and user experiences. This strategic alliance can enhance your company’s operational efficiency, ensure the purchased valves meet international standards, and leverage these manufacturers’ innovative capabilities to better adapt to market and on-site conditions. Thus, this report is a valuable resource for understanding and connecting with the upper echelons of the Chinese industrial valve manufacturing industry, helping you quickly establish strong partnership relations. So, please, take your time to read through it.

Market Overview

The growth of the Chinese industrial valve market is propelled by the country’s extensive industrial activities, spanning sectors such as petrochemicals, water treatment, power generation, textiles, pharmaceuticals, polysilicon, chemicals, and oil and gas. Rapid industrialization, a focus on energy efficiency, and continuous technological advancements have significantly contributed to this growth. Furthermore, despite challenges and fluctuations, globalization of trade has opened new avenues for Chinese manufacturers to expand their global market footprint.

Technological innovation, especially in smart and automated valve technologies, has had a significant impact on the market by enhancing operational efficiency and helping the industry meet stringent environmental regulations. Additionally, China’s environmental policies aimed at reducing industrial pollution and promoting sustainable practices have driven the adoption of advanced valve solutions that enable efficient resource use and reduce emissions.

While the post-pandemic era’s escalating frictions in China-U.S. trade relations, the withdrawal of foreign factories, and the weakness in China’s real estate sector have impacted the Chinese industrial valve market, the overall market still possesses strong growth capabilities and considerable potential for further expansion. This is supported by technological progress, stability in the industrial valve supply chain, environmental initiatives, and the dynamics of global trade.

This growth not only strengthens China’s importance in the global supply chain but also highlights its role as a key player in the future development of the industrial valve market.

The current state of the Chinese industrial valve market showcases significant growth and potential, reflecting China’s key role in the global manufacturing and industrial sectors. As of 2024, the global industrial valve market is estimated to be worth approximately $81.55 billion, with a forecasted compound annual growth rate (CAGR) of 4.2% from 2024 to 2034, reaching a value of $123.05 billion by 2034. [2]This growth trajectory highlights the increasing use of industrial valves in controlling the flow of materials across various sectors, underscoring the Chinese market’s contribution to global expansion.

The Key Factors driving the growth of the industrial valve market in China

Several key factors driving the growth of the industrial valve market in China include:

Infrastructure Development

China’s substantial investment in infrastructure, including the construction and upgrading of water treatment facilities, power plants, and chemical plants, has directly increased the demand for industrial valves.

Industrial Automation

The push towards industrial automation and the integration of Internet of Things (IoT) technology in manufacturing processes have led to increased demand for smart valves that offer better control, efficiency, and data analysis capabilities.

Sustainable Environmental and Energy Policies

Reducing environmental pollution and increasing energy efficiency have become priorities for China. The government has implemented policies aimed at reducing industrial pollution and promoting cleaner, more sustainable energy sources. This shift has elevated the adoption of advanced valve solutions capable of ensuring more efficient resource use and lower emissions, positioning the Chinese industrial valve market as a leader in environmentally sustainable manufacturing practices.

Impact of Technological Innovation

Technological innovations, particularly in smart and automated valve technologies, have had a profound impact on the market. These innovations include the development of valves with higher precision, durability, and the ability to monitor and control operations remotely. These advancements not only improve operational efficiency but also help industries meet strict environmental regulations by minimizing leaks and reducing waste.

International Trade Dynamics

The dynamics of international trade, including tensions and partnerships, also affect the Chinese industrial valve market. Although trade barriers can present challenges, China’s strategic trade alliances and its Belt and Road Initiative (BRI) are opening new markets for Chinese valve manufacturers. Furthermore, despite fluctuations in global trade policies, China’s role as a global manufacturing hub ensures its industrial valve market remains crucial to the international supply chain.

In summary, driven by infrastructure development, technological progress, environmental policies, and international trade dynamics, the Chinese industrial valve market exhibits strong growth characteristics. The market’s adaptability to these factors, combined with China’s key role in the global supply chain, positions it for continued expansion and significance in the coming years.

Top 10 Industrial Valve Manufacturers in China 2024

When analyzing China’s top 10 valve manufacturers, I will display each company’s position and strategic direction in the industry in five key aspects, including company profile (basic information, year of establishment, headquarters location), products and services (key products lines, special services, technical advantages), innovation and technology (innovative examples in product design, material use, intelligent manufacturing), market position (position in domestic and international markets, awards and certifications received), future prospects (company development strategy, future plans, adaptability to industry trends), etc.

NO 1. CHUANYI AUTOMATION [Revenue in 2023 Approximately US$1.02 Billion]

Chuanyi Company Profile

Chongqing Chuanyi Automation Co., Ltd. is a comprehensive enterprise integrating scientific research, manufacturing, sales, import and export trade, and investment. It stands as the largest and most comprehensive automation instrument manufacturing enterprise in China, with the broadest product range and strongest system integration capabilities. The company has been honored among China’s Top 100 Electronic Information Enterprises, Top 100 Machinery Industry Enterprises, Top 100 Electrical Industry Enterprises, and Top 50 Industrial Enterprises in Chongqing. Originally established in 1965 as part of the national initiative to build a third front, it was known as Sichuan Instrument General Factory before being renamed Chongqing Chuanyi General Factory Limited in 1999 and ultimately restructuring to Chongqing Chuanyi Automation Co., Ltd. in 2008.

Products and Services

Chongqing Chuanyi specializes in a diverse range of products spanning over a dozen major categories. These include industrial automation control systems and instruments, control software, analytical instruments and systems, building automation systems, electrical automation systems, electronic and instrumentation components, IT-specialized integrated circuits, functional materials, process tooling equipment, automotive/motorcycle parts and specialized vehicles, optical instruments, environmental testing equipment, and computerized fuel dispensers. The company is recognized as a high-tech enterprise by the Chongqing Science and Technology Commission.

Innovation and Technology

Chongqing Chuanyi has a strong focus on R&D, leading in the fields of process automation, intelligent measurement, and control system design and manufacturing. The company holds 61 patents, including 4 invention patents, with an additional 49 patents pending. It has completed numerous national and provincial-level projects, demonstrating its leadership in innovation within the automation instrument industry in China. The company’s predictive maintenance solutions, based on stress wave and current harmonic technology, showcase its innovative approach to comprehensive intelligent monitoring and diagnostic systems for the entire lifecycle of equipment.

Market Position

As a pioneer in the industry with a registered capital of 2.95 billion yuan, Chuanyi offers an expansive product range including temperature, pressure, flow, and level instruments, intelligent actuators, control valves, and industrial automation control instruments and devices. Chuanyi’s classic products and solutions in industrial automation instruments and systems have been instrumental in advancing the automation and intelligence of process devices. The company’s materials and components division develops and produces high-performance electrical contact materials, heating materials, temperature measurement materials, composite materials, and other specialized instrument materials, further solidifying its market position.

Future Outlook

Leveraging its status as a national-level R&D and manufacturing base for instruments, Chuanyi aims to focus on the R&D and industrialization of new-generation automation control systems, intelligent field instruments, engineering application software, and system integration. The company is set to continue its robust development of advanced scientific instruments, microelectronic devices, electronic functional materials, and competitively scaled automotive/motorcycle parts. By consolidating and expanding its traditional market domains such as electricity, metallurgy, and petrochemicals, and fostering new market areas in nuclear power, urban rail transit, automotive electronics, biomedical, environmental analysis instruments, and motion control devices, Chuanyi aspires to become a well-structured, efficient, technologically leading, scientifically managed, culturally advanced, and internationally competitive enterprise group with sustainable development capabilities.

NO 2. Neway Valve [Revenue in 2023 Approximately US$559 Million]

Neway Company Profile

Established in 2009, with its precursor originating in 2002, Neway Valve has committed itself to delivering comprehensive industrial valve solutions. Located in Suzhou, China, Neway has consistently focused on technological innovation and development in high-end casting production, low-emission control, fire safety, high temperature and pressure resistance, large-size products, ultra-low temperature technology, corrosion resistance, anti-sulfur technology, intelligent control, and safety valve technologies. Their position as a global supplier or strategic supplier to numerous energy companies worldwide speaks to their capability and trustworthiness.

Products and Services

Neway offers a wide array of valve products, including gate valves, globe valves, check valves, ball valves, butterfly valves, control valves, API6A valves, subsea valves, safety valves, and nuclear power valves, across more than 5,000 specifications. These products serve diverse industries such as oil and gas, chemicals, polysilicon, and power generation, illustrating Neway’s extensive reach and expertise. Recent years have seen breakthroughs in high-end fields like deep-sea and nuclear power valves, laying a solid foundation for increasing the market share of high-end products.

Innovation and Technology

Neway Valve stands at the forefront of the industry due to its emphasis on R&D, producing valves that lead in precision, durability, and capability for remote monitoring and control. Their investment in R&D and continuous breakthroughs in high-end product areas strengthen their industry competitiveness and contribute significantly to their technological leadership.

Market Position

As a domestic leader in the industrial valve sector, Neway’s continuous revenue growth and profitability recovery in 2022 highlight its robust position in the market. With a comprehensive growth rate of 13.41% from 2017-2021 and a net profit increase of 19.96% in Q1-Q3 2022, Neway demonstrates solid financial health and operational efficiency. Additionally, its global qualifications and approvals from energy companies underscore its respected status and commitment to quality and safety standards.

Future Outlook

Neway is poised for continued growth, with a clear strategy for development and market expansion. Their commitment to R&D and adapting to industry trends ensures their ongoing ability to meet market demands and maintain leadership in high-end product markets. Their significant shareholding by the actual controllers guarantees stable governance and strategic alignment.

With a continuous focus on technological innovation and market expansion, Neway Valve has become an important player in the global valve industry. With the 2023 revenue approximating $559 million, Neway will continue to leverage its advantages in design, manufacturing, and service to provide high-quality solutions to its customers, driving both the company’s and the industry’s development forward.

If you are interested in their annual report, you can read this post. [3](Chinese post)

NO 3. Suyan Valve [Revenue in 2023 Approximately US$419 Million]

Suyan Valve Company Profile

Founded in 1991, Jiangsu Suyan Valve Machinery Co., Ltd. is a comprehensive enterprise located in Binhai County, Jiangsu Province, focusing on scientific research development, production processing, and technical services. With a registered capital of 800 million yuan and total assets of 50 billion yuan, the company covers an area of 80 hectares and has a building area of 320,000 square meters, reflecting its massive production scale. It employs over 1,500 people, including 415 with college degrees or higher, 6 PhDs, and 25 postgraduates, showcasing the company’s strong technical capabilities.

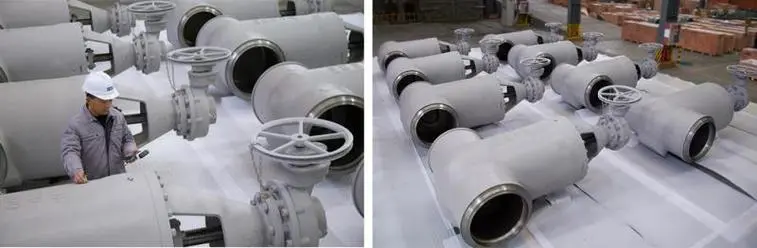

Products and Services

Jiangsu Suyan Valve Machinery Co., Ltd. offers comprehensive industrial valve solutions, with a product line that includes gate valves, ball valves, fully welded ball valves, and a variety of high, medium, and low-pressure valves. The company, with its deep cultivation in fields such as oil and natural gas, power stations, oceans, nuclear power, and LNG, provides customers with technically superior customized services.

Innovation and Technology

The company actively invests in technological innovation, boasting research and development platforms such as a national CNAS laboratory and a national-level post-doctoral scientific research workstation. It invests more than 4% of its annual sales revenue into R&D, has developed over 300 new products, and holds 376 effective patents, demonstrating its innovative capabilities in product design, material usage, and smart manufacturing.

Market Position

Suyan Valve holds a significant position in both domestic and international markets. Its products are distributed across large enterprises like PetroChina, Sinopec, and CNOOC, and are also exported to North America, the Middle East, and other regions. With a global market share of 10.5% and a domestic market share of 24%, the company demonstrates its industry-leading position. Additionally, the company has earned multiple honors and certifications for its technological innovations.

Future Outlook

In response to industry trends, Jiangsu Suyan Valve Machinery Co., Ltd. adheres to a product strategy of “high, large, difficult, new, and special,” committed to improving product quality and service levels, and strengthening its efforts to explore international markets. Through technological innovation and market expansion, the company aims to ensure its competitiveness and sustainable development capability in the future industrial valve market.

NO 4. Jiangsu Shentong Valve (Revenue in 2023 Approximately US$349 Million)

Shentong Company Profile

Jiangsu Shentong Valve Co., Ltd., located in Nanyang Town, Qidong City, Jiangsu Province, faces Shanghai across the river and is 105 km away from Shanghai Pudong Airport, offering convenient transportation. The company, with a registered capital of 208 million RMB, is recognized as a national high-tech enterprise, Jiangsu innovative enterprise, and a model for energy-saving and emission reduction. It also stands as a benchmark for standardized intellectual property management in Jiangsu. Jiangsu Shentong is a vice-chairman unit of the China Valve Industry Association, leads the butterfly valve working group of the National Valve Standardization Technical Committee, and is a member of multiple prestigious industry alliances, including those with Baosteel and Sinopec. The company holds licenses for the design and manufacture of civilian nuclear safety equipment and special equipment manufacturing licenses for pressure vessels and piping components. It has passed certifications such as API6D, API609 by the American Petroleum Institute, and ISO standards including ISO9001, ISO10012, ISO14001, and GB/T28001.

Products and Services

Jiangsu Shentong specializes in the research, development, production, and sales of new and specialized valves, holding 109 valid patents. Its main products include metallurgical special valves, nuclear power special valves, coal chemical industry special valves, natural gas transmission special valves, transportation vehicle special valves, supercritical special valves. These products are widely used in metallurgy, nuclear power, thermal power, coal chemical industry, oil and natural gas transportation, and refining. The “Shentong” and “Dieball” brands are particularly recognized in the metallurgical industry for their energy-saving and emission reduction systems, dominating the domestic market with a share of over 70% for nuclear power butterfly and ball valves.

Innovation and Technology

Shentong specializing in the research, development, production and sales of new special valves, it has 109 valid patents. It mainly produces 145 series of seven categories including butterfly valves, ball valves, gate valves, globe valves, check valves, regulating valves, and special valves. 2000 Products of multiple specifications, these products are widely used in metallurgy, nuclear power, thermal power, coal chemical industry, oil and natural gas gathering and transportation, petroleum refining and other fields. “Shentong” brand and “Butterfly Ball” brand metallurgical special valves are mainly used in blast furnace gas dry dust removal and gas recovery and other energy-saving and emission reduction systems in the metallurgical industry. The leading products have a domestic market share of more than 70%. The domestic market share of nuclear power butterfly valves and ball valve products reaches more than 90%.

Market Position

The company’s market position is defined by its strategic focus on metallurgy, nuclear power, and expanding into petrochemicals and serving the energy sector. Its products find extensive applications across various industrial fields, with metallurgy, nuclear power, and energy chemical industries being its core areas. Following national development policies and the transformation and upgrading paths of downstream industries, Jiangsu Shentong is continuously expanding into new areas like hydrogen energy, energy-saving services, military aerospace, etc., bringing continuous growth momentum to the company.

Future Outlook

Jiangsu Shentong has established itself as a significant player in the valve manufacturing industry through its emphasis on innovation, market expansion, and sustainable development. The company is well-positioned to capitalize on future growth opportunities in new energy sectors such as hydrogen, wind power, and semiconductors, demonstrating its adaptability to industry trends and commitment to technological advancements.

NO 5. SUFA (Revenue in 2023 Approximately US$279 Million)

SUFA Company Profile

Zhonghe Sufa Technology Industry Company Ltd, originally established as Suzhou Ironworks in 1952 and later known as Suzhou Valve Factory, is a technology-driven manufacturing enterprise specializing in the R&D, design, manufacturing, and sales of industrial valves. Listed on the Shenzhen Stock Exchange in 1997, it became the first publicly traded company in both China’s valve industry and within the China National Nuclear Corporation group. It boasts one of the most specialized industrial valve production bases in China’s valve industry, with a wide variety of products, comprehensive specifications, and high technical content. The company is also recognized for its complete certifications, advanced quality management, and testing capabilities. It currently has 10 subsidiaries and affiliated companies involved in valve manufacturing, testing, nuclear technology applications, and finance.

Products and Services

Committed to creating value for shareholders, employees, the corporation, and society, Zhonghe Sufa Technology Industry adheres to market-oriented and international strategies. It provides valve system solutions for industries such as oil and gas, refining, nuclear power, electricity, metallurgy, chemicals, shipbuilding, papermaking, and pharmaceuticals. It has gradually established three main target markets: nuclear engineering, petrochemicals, and public utilities, becoming a leading company in the nuclear power valve sector in China. It is the primary valve supplier for the country’s three major nuclear power groups, maintains strategic cooperation with the “Big Three” oil companies, and supplies valve products to large private petrochemical enterprises like Hengli Petrochemical and Zhejiang Petrochemical. Its “H” and “SUFA” valve product trademarks were awarded the “Top Ten Annual Brands of the World Market China (Valve) 2006,” enjoying a strong reputation and brand influence in the domestic valve industry.

Innovation and Technology

The company has been at the forefront of autonomous innovation in critical valve indigenization, successfully developing products like the main steam isolation valve that fill domestic gaps and are internationally advanced. These achievements have played a crucial role in ensuring the supply security, independence, and strength of the nuclear industry, oil, chemical, and thermal power sectors. Zhonghe Sufa is recognized as a leader in technological R&D and digitalization in China’s valve industry, designated by the National Development and Reform Commission as a technical support unit for third-generation nuclear power critical valves and recognized by the Jiangsu Provincial Department of Science and Technology as the Jiangsu Special Valve Engineering Technology Research Center. It was also selected as a Suzhou 5G application demonstration enterprise, winning the first prize in the Jiangsu region and the second prize in the national competition of the Ministry of Industry and Information Technology’s fifth “Bloom Cup” 5G application contest.

Market Position

Zhonghe Sufa was one of the first in the domestic valve industry to obtain the “API” certificate and the ISO9000 series quality certification issued by DNV, as well as the first to receive the European Community’s No. 001 “CE” certificate, leading the way in obtaining “Pressure Pipeline Valve Safety Registration” and “Import and Export Commodity Inspection Exemption” certificates. It has passed qualifications certifications from classification societies such as SBS, BV, DNV, and CCS, and possesses a nuclear pressure equipment design and manufacturing license granted by the National Nuclear Safety Administration.

Future Outlook

As a leading company in the domestic valve industry, Zhonghe Sufa plays significant roles in several industry associations. It is a member of the China Nuclear Instrument Industry Association, vice-chairman of the China General Machinery Industry Association, vice-chairman of the Valve Branch of the China General Machinery Industry Association, chairman of the Jiangsu Valve Industry Association, vice-chairman of the National Valve Standardization Technical Committee, and vice-chairman of the Jiangsu Quality Association.

NO 6. KOSO Control Engineering (Wuxi) (Revenue in 2023 Approximately US$251 Million)

KOSO(WUXI) Company Profile

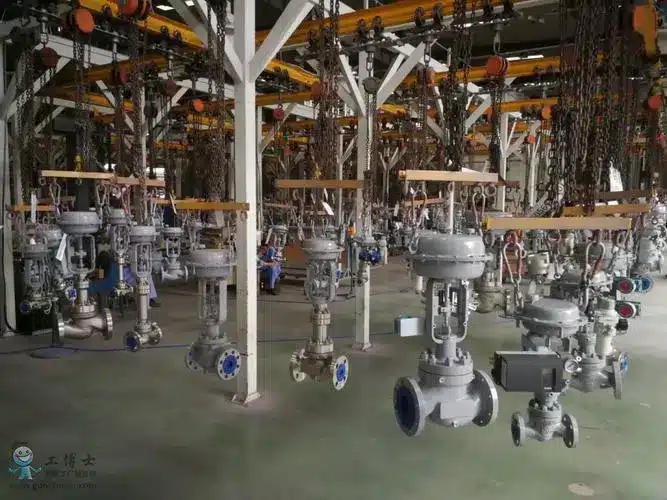

KOSO Control Engineering (Wuxi) Co., Ltd., a wholly-owned subsidiary of KOSO Co. Ltd. in Japan, was established in July 1993. Located by the picturesque Taihu Lake in Liyuan Economic and Technological Development Zone, Wuxi, the company spans over 70,000m^2 with a total investment of $20 million. KOSO Control Engineering (Wuxi) operates two facilities in Wuxi Li Lake Science and Technology Park and Wuxi Hudai Industrial Park, employing over 500 staff. Specializing in the manufacture and sales of KOSO brand control valves, actuators, and accessories, the company prides itself on a comprehensive manufacturing process from thermal and cold processing to assembly and testing, boasting an annual output of over 35,000 control valve sets and exporting quality components globally.

KOSO Control Engineering (Wuxi) carries the legacy of its Japanese parent company, leveraging “advanced technology,” “a complete product range,” “powerful sales,” and “meticulous service” as its pillars. The company has grown alongside China’s economic boom, responding swiftly to customer needs with perfect solutions, and evidences the miracles of China’s economic development.

Products and Services

The product lineup includes 200 series regulating ball valves, 300 series cutoff ball valves, 400 series parallel slide valves, 500 series spherical valves, 600 series butterfly valves, and 700 series high-performance butterfly valves, catering to metallurgy, petrochemicals, air separation, and venturing into nuclear power. KOSO Wuxi’s approach to manufacturing, focusing on importing key components while localizing others, guarantees high-quality products at competitive prices for various industries.

Innovation and Technology

KOSO’s commitment to innovation is evident in its products, such as the 500M series control valves known for their unique labyrinth sleeve structure that effectively eliminates cavitation and reduces noise in high differential pressure applications. The 710E/710C series of high-performance butterfly valves and the 400H series of high-pressure gate valves highlight KOSO’s innovative use of materials and designs for reliability and durability in harsh conditions. As a member of the Japanese Fieldbus Consortium, KOSO Wuxi benefits from advanced technology in electronic actuators and intelligent electro-hydraulic actuators under the 3700 and 3800 series, emphasizing precision and reliability.

Market Position

KOSO Control Engineering (Wuxi) has maintained its position in the domestic valve industry with continuous sales growth, achieving a sales figure of over 800 million RMB with ambitions to exceed 1 billion RMB by 2013. The company’s quality management system has been certified under ISO 9001, ISO 14000, and has received fire safety and pressure pipeline safety certifications, reflecting its strong market presence in China and ambition for international expansion.

Future Outlook

KOSO is strategically positioned for further growth, adapting to the fast-paced development of China’s economy and the valve industry. The company’s dedication to technological innovation, quality assurance, and customer service, coupled with a comprehensive product range and strong sales network, sets a solid foundation for future expansions and responding to the evolving industry trends.

KOSO Control Engineering (Wuxi)’s detailed approach to combining traditional craftsmanship with modern technology and services ensures it remains a leader in the valve manufacturing industry, both domestically and internationally.

NO 7. Zhejiang Lenor Flow Control Technology Co., Ltd. (Revenue in 2023 Approximately US$158 Million)

LINUO Company Profile

Zhejiang Lenor Flow Control Technology Co., Ltd. is a national high-tech enterprise dedicated to the R&D, production, and sales of fluid control equipment. Established in January 2003, Lenor was listed on the Growth Enterprise Market of the Shenzhen Stock Exchange in June 2020, under the stock abbreviation “Zhejiang Lenor” with the stock code “300838”.

Products and Services

Lenor’s key product lines include ball valves, V-type ball valves, butterfly valves, gate valves, and control valves, which are essential components in fluid conveyance systems with functions such as cut-off, regulation, diversion, backflow prevention, pressure stabilization, branching, and relief of overflow pressure. As a provider of control valve system solutions, Lenor designs and produces control valves catering to various industries and market needs, offering personalized, diverse, and systematic solutions for the chemical, petrochemical, and paper industries.

Innovation and Technology

In the era of industrial automation, Lenor’s control valves serve as crucial final control elements, adjusting process parameters like medium flow, pressure, temperature, and level. These valves are indispensable in smart manufacturing, reflecting Lenor’s commitment to technological innovation, including product design, material usage, and smart manufacturing. Leveraging its provincial-level enterprise research institute and industrial design center, Lenor follows a path of independent R&D and cooperation with research institutes and universities. This collaborative R&D model, oriented towards market demands, forms a standardized, efficient R&D system, ensuring continuous product development and optimization.

Market Position

Recognized as a national high-tech enterprise and awarded titles such as provincial-level high-tech enterprise R&D center, key high-tech enterprise under the National Torch Plan, Zhejiang Famous Brand Product, and specialized and innovative “Little Giant” enterprise, Lenor has established itself firmly in both domestic and international markets. These accolades attest to Lenor’s industry leadership, commitment to quality, and innovative capabilities.

Future Outlook

The company’s future looks promising, with a planned capacity not yet reaching its maximum, leaving room for expansion. Forecasting a yearly production value demand of 1.5 billion RMB, Lenor’s current factory planning and production capacity are expected to robustly support its development. With a reported revenue of 1.112 billion RMB for 2023, marking a 9.79% year-on-year increase, and a net profit estimated between 107 to 114 million RMB, reflecting a growth of 0.18% to 6.73%, Lenor’s financial performance underscores its strong market position and potential for future growth. The company’s strategic development, adaptation to industry trends, and future plans demonstrate its readiness to contribute significantly to the evolving demands of the industrial 4.0 and smart manufacturing landscape.

NO 8. YDF Valve (Revenue in 2023 Approximately US$139 Million)

YDF Valve Company Overview

Jiangsu Yandian Valve Co., Ltd., committed to providing high-quality industrial valve application solutions globally, creates value for its users. As a leading member of China’s valve manufacturing industry, Yandian Valve focuses on the innovative design of high-quality valves. Through continuous technological research and development and enhancement of its capabilities, it has become one of the most competitive leading manufacturers in the global valve sector!

Products and Services

Yandian Valve’s main products include ball valves, gate valves, globe valves, check valves, butterfly valves, and power station valves. The product range covers sizes from 1/2” to 60” (DN15 to DN1500) and pressure ratings from 150lb to 2500lb (PN16 to PN420). Materials include conventional carbon steel, stainless steel, duplex steel, and alloy steel (titanium alloy, Monel, Inconel, etc.). The products are designed to operate in temperatures ranging from -196℃ to 640℃ and fully comply with ASTM, ANSI, API, GB, BS, JIS, and DIN standards. YDF products are widely used in industries such as oil and gas, chemical, refining, power stations, shipbuilding, LNG, long-distance pipelines, storage tanks, marine platforms, and air chemical industries. YDF has obtained certifications including ISO9001, ISO14001, ISO45001, CE/PED, ATEX, TA Luft/ISO15848-1 low emission certificate, ABS, BV, DNV, CCS, SIL 3, CU-TR, TS, and CNAS (ISO 17025).

Innovation and Technology

YDF Valve extensively utilizes CNC machining centers, such as CNC lathes, CNC drilling machines, and machining centers. The factory is also equipped with large vertical lathes and drilling machines capable of processing valves up to 60 inches. Advanced machining equipment and CNC management systems ensure product quality and timely delivery. The factory employs three-coordinate measuring instruments to check the dimensions and precision of components.

Quality Management

YDF implements strict quality control from raw material inspection, through process inspection, to final inspection. The factory has a range of advanced testing instruments and equipment for various inspection control points, including spectral analysis, mechanical properties, non-destructive testing, and thickness testing. The special performance laboratory can conduct ultra-low temperature tests, vacuum tests, low leakage tests, high pressure and temperature tests, and other assessments. An independent cleaning room is available for valve degreasing and cleaning.

Test Center

The YDF special performance test laboratory can conduct ultra-low temperature tests, vacuum tests, low leakage tests, high-pressure gas tests, high-temperature tests, lifecycle cycle tests, and fire tests. It is equipped with liquid nitrogen tanks and a specialized valve degreasing cleaning room.

Market Position

YDF Valve holds a significant position in both domestic and international markets, supported by its wide range of certifications and awards. These acknowledgments not only validate YDF’s commitment to quality and innovation but also underscore its competitive edge in the industrial valve industry.

Future Outlook

YDF Valve is strategically positioned for future growth, with plans to continue its focus on technological innovation, market expansion, and adaptation to industry trends. Its dedication to research and development, coupled with its ability to meet the evolving needs of the industry, ensures that YDF Valve will remain a key player in the global valve manufacturing landscape.

NO 9. Harbin Power Station Valve (Revenue in 2023 Approximately US$82 Million)

Harbin Power Station Valve Company Overview

Harbin Power Station Valve Company, a subsidiary of Harbin Electric Corporation, stands as a prominent entity in the Chinese valve manufacturing landscape. Founded in 1954 and evolving from one of the 156 key projects constructed with Soviet assistance during China’s First Five-Year Plan, it has transitioned through several stages, including being a workshop within Harbin Boiler Factory, a valve manufacturing division, and a development department for power station valves, before adopting its current name in January 2008. Now, it’s an integral part of Harbin Electric Group Company Limited, marked by its transformation through mixed ownership reform completed at the end of 2020, making it the first mixed-ownership pilot enterprise within the Harbin Electric Group.

Products and Services

Harbin Power Station Valve specializes in designing and manufacturing a wide range of valves, water level measuring devices, and pressure reduction and temperature control equipment for thermal power, nuclear power, solar thermal, petrochemical, and military applications. The company’s product portfolio includes over 40 series and more than 3,000 varieties, featuring main products such as full-lift safety valves, molten salt safety valves, gate valves, globe valves, check valves, hydrostatic testing plug valves, and new type control valves. These products serve power plants and related enterprises across China and are exported to numerous countries, including Japan, India, Vietnam, Turkey, Indonesia, and Pakistan.

Innovation and Technology

Harbin Valve has undertaken and completed significant research and development tasks, including the localization of valves for 600MW supercritical thermal power units and the development and industrialization of major equipment for 1000MW ultra-supercritical thermal power units. As a leading participant in the national initiative for the localization of supercritical and ultra-supercritical key valves, the company has developed a variety of valve types that have passed technical evaluations organized by the National Energy Administration, holding nearly 70% market share in their application projects. The company’s full-lift safety valve has been awarded the Second Prize for Scientific and Technological Progress by the Ministry of Machinery Industry, along with several national patents and awards for other products.

Market Position

Harbin Valve is among the top valve manufacturers in China, especially noted for its leadership in the high-temperature, high-pressure thermal power valve sector. Its comprehensive ranking among the nearly ten thousand valve manufacturers nationwide underscores its leading position. The company has received numerous awards and certifications, highlighting its commitment to quality and innovation.

Future Outlook

Harbin Power Station Valve Company is dedicated to product safety, efficient management, continuous innovation, and enhancing customer satisfaction. It has embraced industry trends by focusing on talent development, technological innovation, and product upgrading to maintain its competitive edge. With the establishment of high-tech R&D centers and state-of-the-art testing facilities, Harbin Valve aims to strengthen its overall capabilities and contribute to the digital transformation of the power generation industry. The company’s future plans involve adhering to national strategies for technological advancement and industrial upgrading, positioning itself for sustained growth and innovation in the evolving global valve market.

Harbin Power Station Valve Company exemplifies the strength and innovation of Chinese manufacturing, with a clear vision for the future and a commitment to leading the industry forward.

NO 10. THINKTANK (Revenue in 2023 Approximately US$25 Million)

THINKTANK Valve is a rising family-owned business with its headquarters situated in Taiwan. Since its establishment in Shanghai in 2012, THINKTANK has rapidly emerged as a significant player in the valve manufacturing industry, with 90% of its business coming from international markets. This underscores its global orientation and the company’s commitment to serving a worldwide clientele.

Product and Services

THINKTANK specializes in a wide range of high-performance butterfly valves, ball valves, control valves, self-operated pressure regulating valves, breather valves, flame arresters, fusible link safety valves, pressure relief valves, pressure relief valves and more.

Young brand but advantage & Flexible Service

We have a clear market positioning and continuously upgrade our control valves and self-operated pressure regulating valves in sectors such as the chemical industry, seawater desalination, power generation, natural gas, storage tanks, and hydrogen energy. Importantly, as the market becomes more segmented, we actively expand into niche areas. For instance, in the storage tank industry, our breather valves, flame arresters, and fire safety valves have achieved ATEX and PED certifications, with some core components also receiving FM and UL certifications. THINKTANK, although a relatively new brand, diligently works in its areas of expertise, providing meticulous service to valve and instrument brands, engineering companies, contractors, and valve distributors. In the highly competitive valve market, THINKTANK has seen a steady annual increase in turnover, reaching over 25 million in annual turnover within just 12 years—an achievement we all take pride in.

Why Choose THINKTANK As a Reliable Industrial Valve Vendor

While our company may not surpass the larger, established companies in production scale or history, in our niche markets, we excel in rapidly responding to customer projects, offering technical support, business quotations, and exceptionally short delivery times, providing a significant advantage in all aspects for our customers.

1. Rapidly Responding

Benefit: This ensures that our customers receive prompt attention to their inquiries, issues, or orders. A quick response time significantly reduces downtime for process production relying on our products for the end-user’s operations, improving their efficiency and productivity.

2. Technical Support

Benefit: Technical support provides customers with expert advice and problem-solving for any issues they encounter with our products. This means less operational disruption and increased confidence in using our products, as help is always at hand to optimize performance or resolve challenges quickly. Also for new project, we provide expert sizing and selection for our customers, which means customer only focused on the commerical work without waste energy on technical issues.

3. Instant Commercial Offer

Benefit: Customers benefit from receiving immediate pricing and product availability information, enabling swift decision-making and planning. This efficiency in communication helps streamline the purchasing process, reducing the time from inquiry to order and allowing businesses to move forward without delay.

4. Exceptionally Short Delivery Time

Benefit: By ensuring products are delivered in the shortest time possible, we help customers meet their project deadlines and reduce the waiting time for essential components. This minimizes the risk of project delays, ensuring a smoother workflow and faster time to market for the end-users’ products or services.

5. Excellence in Service

Benefit: Excellence in service encompasses not just the quality of our products but also the customer experience from start to finish. This means personalized service, attention to detail, and a commitment to customer satisfaction. As a result, customers enjoy a seamless, hassle-free experience with reliable support, fostering loyalty and trust in our brand.

Moreover, for such B2B products as industrial valves, we offer satisfying after-sales service. Many of our clients are not the end-users, hence, require strong after-sales support from valve manufacturers. It’s well known that after-sales service for Chinese valves often disappoints, with issues of shirking responsibility or delays being common. THINKTANK has won long-term cooperation with many brands, largely because we solve problems for our clients, regardless of whose fault it is, actively assisting in their resolution. For us, the order is just the beginning; producing excellent, stable products is the foundation, but service is our core competitive strength.

Products and Services

For seawater desalination projects, we offer products such as duplex steel high-performance butterfly valves, duplex steel control valves, and fluorine-lined self-operating control valves.

For storage tank applications, our products include fire valves, breather valves, flame arresters, N2 Blanking Regulators, N2 pressure regulators, and N2 Pressure regulator exhaust pressure systems.

Looking forward, we aim to enhance the production process of valve castings, improve control technology and testing processes for valve fugitive emissions (low leakage), and upgrade fire valve technology, high-temperature and high-pressure technology, as well as corrosion and sulfur resistance technologies. Starting from the details, we listen to ongoing customer feedback to manufacture valves that truly meet their needs.

Concolusion

The above excellent valve manufacturers can help you quickly find your industrial valve supply chain, with good brand reputation endorsement, high-quality products and services, whether you are new to the valve industry or a rich experience in purchasing industrial valves, this information will give you a real comprehensive understanding of China’s valve industry market. Choose the right supplier for your project. If you have any other questions, please feel free to contact me.

Reference

[1] Markets and Markets for industrial valve market report

[2] Future market insights for industrial valve market report