What are Ceramic Valves

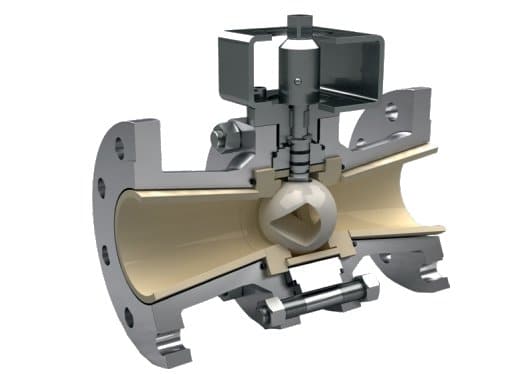

Ceramic valves are typically designed for the inner valve parts which touch with the medium, and these parts are made from ceramic materials. For example, in a ceramic ball valve, the ball is select ceramic material, the valve body is lined with ceramic, or ceramic is coated onto the metal ball, plug or disc. These valves have perfect performance in wear resistance, high-temperature resistance, and corrosion resistance.

Ceramic valves are used in highly demanding services including slurry, erosive, corrosive, and scaling applications. These valves are known for their excellent corrosion and wear resistance. They are essential in environments like power plants, mining, and chemical processing where they provide reliable shut-off for pipelines conveying particulate media.

There are many types of ceramic valves and many manufacturers. In this post, we will focus on the top 10 ceramic valve manufacturers in the world for reference by engineers or experts of engineering companies, valve service companies of power plants, dry ore and powder material conveying equipment in mining industry, dry powder conveying and discharging equipment in the cement industry, flour conveying systems in flour mills, and other engineers of conveying systems that come into meet with high-abrasive media such as powders or solid particles.

Top 10 Ceramic Valves Manufacturers

There are several manufacturers who specialize in produce high-quality ceramic valves. Some of the leading names include Bray, Fujkin, Flowserve, Neles™, Samson, Caldera Engineering, NGK CHEMITECH, Azbil Corporation, NIL-COR, and THINKTANK.

1. Bray(USA)

A global leader in fluid control solutions, Bray specializes in the design, manufacture, and distribution of high-performance ceramic valves, catering to a wide range of industrial applications.

2. Fujkin(Japan)

Renowned for its precision technologies, Fujikin offers advanced ceramic valves that are widely used in semiconductor manufacturing, biotechnology, and other high-tech industries.

3. Flowserve(USA)

A major player in the flow control industry, Flowserve provides engineered and pre-engineered ceramic valve solutions for complex and critical applications across various sectors.

4. Neles™/Valmet (Finland)

Known for its innovative approach, Neles™ delivers reliable valve technologies, including ceramic valves, that are designed to improve process efficiency and safety in industrial environments.

5. Samson(Gemany)

With a focus on automation and control processes, Samson produces a range of high-quality ceramic valves that meet the stringent demands of process industries.

6. Caldera Engineering(USA)

Specializing in severe service applications, Caldera Engineering offers ceramic valves that excel in handling high-pressure, high-temperature, and corrosive environments.

7. NGK CHEMITECH(Japan)

A part of the NGK Group, NGK CHEMITECH provides ceramic valve solutions that are engineered for durability and precision, particularly in chemical and industrial processes.

8. Azbil Corporation(Japan)

Azbil is committed to creating advanced automation solutions, including ceramic valves that optimize operational efficiencies and contribute to energy savings in various industries.

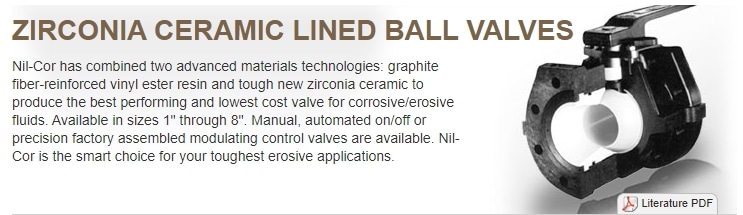

9. NIL-COR(USA)

NIL-COR is a pioneer in the development of composite and ceramic valves, offering lightweight, corrosion-resistant options that are ideal for industrial applications where metal valves fall short.

10. THINKTANK(China)

Compared with the above 9 ceramic valve companies, THINKTANK may be the youngest and newest brand in this field. We have nearly 13 years of experience in the field of ceramic valves and have become a recognized brand in the field of industrial valves. Based in China, THINKTANK is an expert in control valve solutions, producing ceramic valves that are essential for industries dealing with high-abrasion and corrosive media.

FAQs Ceramic Valves

What are Ceramic Valves Used For

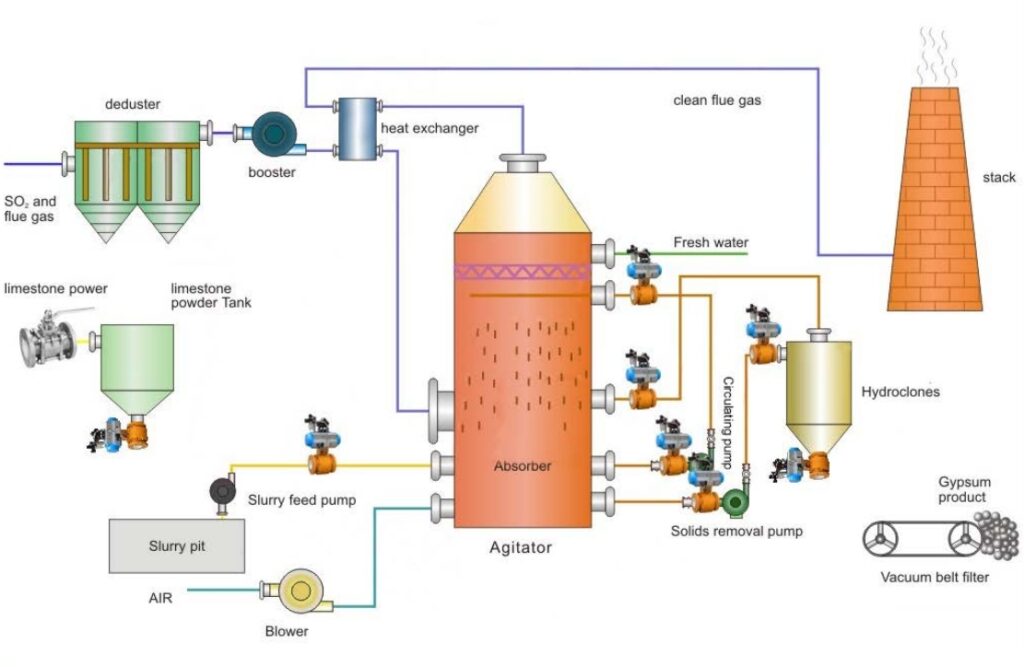

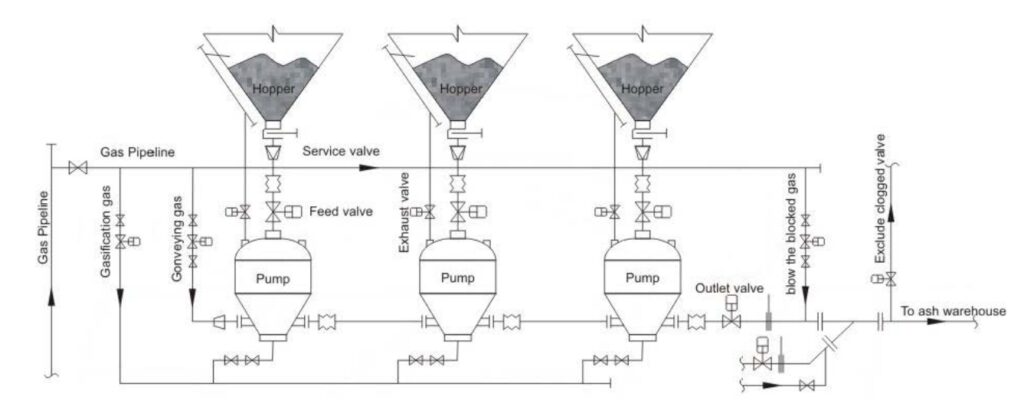

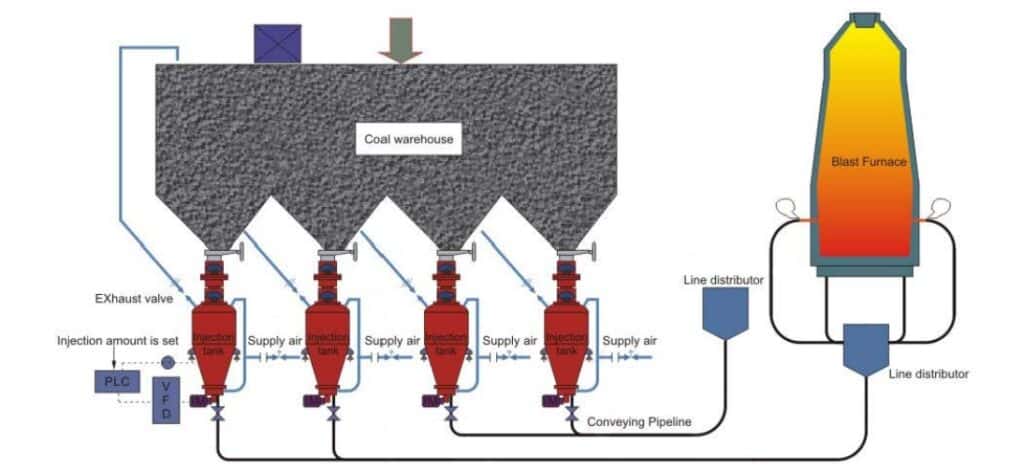

Ceramic valves are mainly used in industrial fields such as power plant, petroleum, chemical industry, metallurgy, mining, sewage treatment, etc., especially in the face of severe service, such as high wear, strong corrosion, high temperature, high pressure, etc.

Ceramic valves can meet the use environment of high wear and strong corrosion. Although the first purchase cost is higher than metal valves, but its performance and service cycle life are far superior to other similar metal valves.

What are the ceramic materials

To meet the stringent demands of modern industries, ceramic valves are manufactured using a variety of ceramic materials, each possessing unique properties.

Alumina Ceramic

Alumina Ceramic is the most commonly used ceramic material, available in various purities ranging from porous 76% refractory material to 99.9% high-purity grades. While lower purity alumina is a relatively low-cost alternative, its hardness and corrosion resistance are significantly lower compared to high-purity alumina. In addition to alumina, zirconia, silicon carbide, and silicon nitride are also widely used in ceramic valves for their distinct characteristics.

- 99.5% Alumina

99.5% alumina is the standard material used in ceramic valves. It offers exceptional corrosion resistance and hardness and does not undergo radioactive degradation, making it ideal for various corrosive applications. It remains stable at extremely high temperatures, suitable for environments exceeding 1000°F.

- 99.9% Alumina

99.9% alumina is one of the purest forms of alumina available. Compared to 99.5% alumina, it has finer particle size, more uniform structure, and fewer binding materials. This significantly enhances its corrosion and wear resistance, making it suitable for the most demanding applications while maintaining a relatively low purchase cost.

Silicon Nitride

Silicon nitride exhibits outstanding thermal shock resistance and high strength at elevated temperatures, surpassing other ceramics. Initially developed for components in internal combustion engines, turbines, and diesel engine glow plugs, it is now an ideal material for ceramic valves. Silicon nitride remains highly stable at high temperatures, making it suitable for use with molten metals.

Silicon Carbide

Silicon carbide’s hardness is second only to diamond and boron carbide, making it 95% harder than standard alumina. It features high thermal conductivity, excellent thermal shock resistance, and strength durability at extreme temperatures. Silicon carbide boasts the highest corrosion resistance among all fine ceramic materials and is one of the few materials resistant to hydrofluoric acid (HF), making it the ultimate choice for ceramic materials.

Zirconia

Zirconia has the highest strength and toughness of all engineering ceramics at room temperature. However, its corrosion resistance is inferior, and it is more susceptible to impact and friction wear. Therefore, zirconia is primarily used in applications requiring high torque and/or high pressure.

Applications of Ceramic Valves

Ceramic valves are used in a variety of applications due to their durability and efficiency. In power plants, they handle dry ash systems and other particulate media with ease, ensuring reliable shut-off and control. In the mining industry, ceramic valves manage slurry and abrasive materials, offering a long-lasting solution to wear and tear. The chemical industry benefits from ceramic valves’ resistance to corrosive substances, making them ideal for handling aggressive media. Additionally, these valves are used in the papermaking industry to manage slurry and other challenging materials.

Benefits of Ceramic Valves

The primary benefits of ceramic valves include their exceptional wear resistance, corrosion resistance, and long-term durability. These valves are designed to withstand harsh environments and demanding applications, which means you don’t have to replace them as often or maintain them as frequently. They seal well, so you can shut them off and not have leaks. They don’t wear out, and they don’t break. They provide a low total cost of ownership, which means they’re a cost-effective solution for industrial applications.

Conclusion

Ceramic valves are indispensable in various industries due to their durability and efficiency. Whether you need to control slurry in mining or handle corrosive materials in a chemical plant, ceramic valves will do the job and give you the best value over time. In the next article, we will talk about the types of common ceramic valves used in different working conditions. If you have any questions, please do not hesitate to contact us for free consultation.