The Spring Return Electric Actuator is a critical device for ensuring safety in high-risk environments such as tunnels, subways, marine applications, and other areas where rapid automatic control of equipment is critical. In this article, we will look at the technical principles, product features, and various application scenarios for this device.

What is a Spring Return Electric Actuator

A Spring Return Electric Actuator is an automatic resetting actuator that is designed to automatically return equipment to a preset safe position (either fully open or fully closed) in the event of a power failure by using its internal spring storage mechanism. It’s a reliable, fail-safe solution in emergency situations where you need to respond quickly to protect equipment and people.

Technical Principles and Features

Operating Principle

The Spring Return Electric Actuator uses an internal spring storage mechanism for resetting. During normal operation, the motor drives the actuator to open the equipment while storing energy in the spring. When power is lost, the stored spring energy is instantly released, driving the actuator back to the safe position. This design is perfect for 90° rotating devices such as ball valves, butterfly dampers, fire dampers, and smoke exhaust valves where you need to respond quickly in an emergency.

8 Key Advantages Features For Spring-Return Electric Actuator

The spring-return electric actuator consists of three main parts: the drive unit, the energy storage unit, and the energy locking unit. These three parts together form a complete transmission chain. In addition, there is an optional manual operation device that allows you to manually set the equipment to the desired position and lock it in place.

1. Compact Structure

The Spring Return Electric Actuator has a compact structure, which means it doesn’t take up much space. This makes it ideal for installations where space is tight, giving you flexibility in a variety of high-demand environments.

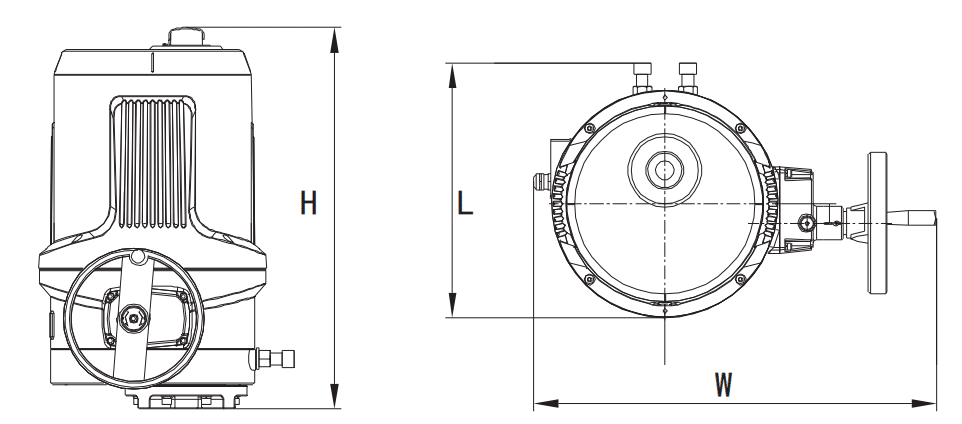

spring return electric actuator dimension

| Mode | Torque (N·m) | H (mm) | L (mm) | W (mm) | Weight *(Kg) |

| TTS-R1 | 50 | 485 | 309 | 587 | 35 |

| TTS-R2 | 150 | 485 | 309 | 587 | 38 |

| TTS-R3 | 300 | 532 | 332 | 607 | 55 |

| TTS-R4 | 500 | 564 | 410 | 652 | 80 |

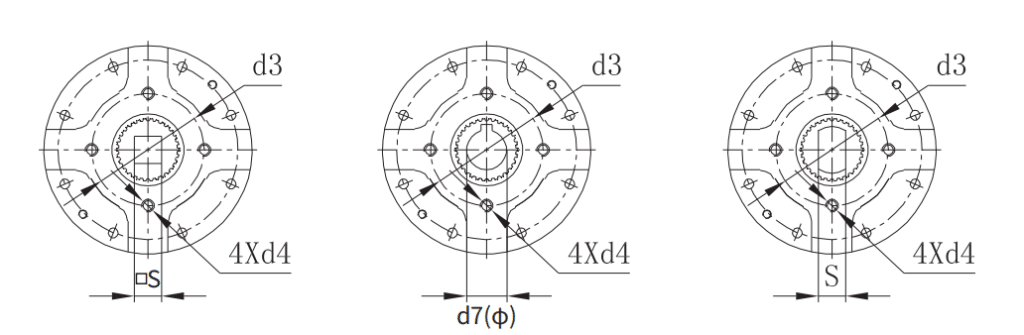

| Mode | ISO5211 Flange | d3 | d4 | □S | d7(⌀) | S | Axial Extension l5 |

| TTS-R1 | F07 | 70 | M8 | 11/14/17/22 | 14/18/22 | 11/14/17/22 | 38 |

| F10 | 102 | M10 | |||||

| TTS-R2 | F07 | 70 | M8 | 17/19/22 | 18/22 | 17/19/22 | 38 |

| F10 | 102 | M10 | |||||

| TTS-R3 | F10 | 102 | M10 | 19/22 | 22/25* | 19/22 | 38 |

| F14 | 140 | M16 | |||||

| TTS-R4 | F12 | 125 | M12 | 22/27 | 28/36 | 22/27 | 55 |

| F14 | 140 | M16 |

Spring Return Electric Actuator Specification

| Mode | TTS-R1 | TTS-R2 | TTS-R3 | TTS-R4 |

| Torque | 50 | 150 | 300 | 500 |

| Power (W) | 30/15 | 40/30 | 90/70 | 180/120 |

| Voltage | AC220 V; Optional: AC24V; AC110V | |||

| Frequency (Hz) | 50/60 | |||

| Work Duty | S2-15min | |||

| Operation Time (S) | 27*/54 | 27*/54 | 28*/56 | 26*/51 |

| Spring Return Time (S) | ≤10 | ≤10 | ≤10 | ≤10 |

| Life Cycle (cycles) | 20000 | 20000 | 10000 | 9000 |

| Output Flange (ISO5211) | F07/F10 | F07/F10 | F10/F14 | F12/F14 |

| Operation Temperature | -30°C ~ 65°C | |||

| Relative Humidity (25°C) | ≤95% | |||

| Ingress Protection | IP67 | |||

| Manual Handwheel | Optional | |||

| Manual Operation | Power-off operation with locking device | |||

| Fail-safe Direction | Default clockwise (CW); optional counterclockwise (CCW), to be specified in the order | |||

| Stop in Midstream | Electromagnetic brake control | |||

| Cable Connector | 2* NPT3/4 | |||

| Lubrication | Grease | |||

| Limit Switch | 2 sets for each direction, one of which is used as a feedback signal | |||

| On/Off Signal | 2/3 Position | |||

| Mechanical Stop | Adjustable mechanical stop in each direction of switching | |||

| Color | Default red top cover and black body | |||

2. Safety and Maintenance

The actuator is maintenance-free and designed for long-term, trouble-free operation. The spring efficiently drives the full 90° stroke, allowing for rapid valve closing (or opening) in emergencies, which is critical for fire protection and smoke evacuation systems.

3. Position Detection

With a simple, reliable travel limit switch, the actuator provides precise position detection. It has a 3D indicator for switch positions that you can see from multiple angles, giving you real-time feedback and making it easier to see what’s going on.

4. Operational Safety

The actuator is designed to be the most reliable in emergency situations. It uses a mechanical solution to safely open or close valves as required. With an internal energy storage mechanism, the spring return operation requires no manual intervention, so the device resets itself to the safe position.

5. Safety Integrity Level (SIL)

This Spring Return Electric Actuator meets SIL2/3 standards for safety integrity, making it suitable for applications that require high safety standards. It’s also maintenance-free, which means you don’t have to worry about it, and it won’t let you down when you need it most.

6. Replaceable Connecting Components

The mounted flange and drive couplings of actuator are designed according to ISO5211 standards, which means you have various options. This makes it easy to use in a lot of different configurations and installations, making the actuator more versatile.

7. Fire-Resistant Heat Shield (Customizable)

An optional fire-resistant heat shield is available, which allows the actuator to meet the strict requirements for fire and smoke extraction valves. This shield can withstand 150°C for up to 1.5 hours or 280°C for 1 hour, so you can use it in extreme conditions.

8. Explosion-Proof Certification

The spring return fail safe electric actuator is certified for explosive atmospheres and carries Ex db IIB/IIC T4/T6 ratings, which means you can use it in hazardous areas where safety is critical. This explosion-proof capability expands the range of applications for the actuator and meets the requirements of industries that handle flammable materials.

Application Scenarios

1. Tunnel and Subway Ventilation Systems

In confined spaces such as tunnels and subways, ventilation systems must reset automatically in case of power loss to ensure smoke evacuation during fires or other emergencies. The Spring Return Electric Actuator quickly returns smoke exhaust valves to the safe position when power is lost, which is critical to protect both the ventilation and smoke extraction systems. Thereby protecting personal safety or causing greater losses.

2. Chemical Equipment and Refineries

In chemical processing environments, you need to be able to shut off the flow of fluids quickly in an emergency, such like lost power of electric/motorized valves. The Spring Return Electric Actuator can quickly shut off the flow of fluids during an accident, which can prevent spills and more damage from happening.

3. Oil and Natural Gas Storage and Production

The Spring Return Electric Actuator is critical to operational safety because it provides rapid emergency shut-off in cases of power loss or system failure.

4. Firefighting Systems

In firefighting and fire protection systems, the Spring Return Electric Actuator is an essential component, especially in applications where immediate response and reliability are critical to safety. Fire protection systems are installed in high-risk areas such as factories, tunnels, and large public buildings where smoke and fire control is necessary for safe evacuation.

Commonly Used Spring Return Electric Actuated Valves

The Spring Return Electric Actuator is used in a wide variety of valves to provide fail-safe protection.

Here are three common fail safe/spring return electric actuated valves.

1. Spring Return Electric Actuated Ball Valve

Spring Return Electric Actuated ball valves are known for their excellent sealing and ease of use. A Ball Valve is perfect for applications that require quick on/off control. When you combine it with a Spring Return Electric Actuator, you can quickly isolate fluid paths in emergencies. This makes it ideal for the oil, gas, and chemical industries, especially in hazardous areas where you need high reliability.

2. Spring Return Electric Actuated Butterfly Valve

Butterfly Valves are compact and have low flow resistance, so they are suitable for pipelines that require large flow control. When you combine it with a Spring Return Electric Actuator, it can quickly return to a fully open or fully closed position in emergencies. This makes it ideal for smoke evacuation in tunnel and subway ventilation systems. It saves space, and it provides efficient control and safety protection.

3. Spring Return Electric Actuated Damper Valve

Electric Butterfly Damper Valves are ideal for ventilation systems and are commonly used in HVAC systems, tunnel smoke extraction, and marine ventilation systems. With the fail-safe feature of the Spring Return Electric Actuator, it can automatically adjust the ventilation volume or fully isolate the ductwork in emergencies, ensuring personnel safety during a fire or smoke leak. This configuration is especially suitable for high-temperature environments where you need reliable auto-switch control. It also supports the option of a fire-resistant shield for additional safety.

Frequently Asked Questions

1. What does a Spring Return Electric Actuator do?

A Spring Return Electric Actuator automatically releases stored spring energy to return the equipment to a safe position (such as fully open or closed) when power is lost. This makes it ideal for high-risk applications that require quick emergency operation.

2. What is the difference between a Spring Return and a Non-Spring Return electric Actuator?

A Non-Spring Return Electric Actuator stays in its last position when power is lost, while a Spring Return Electric Actuator automatically returns to a safe position, using spring force to enhance fail-safe functionality.

3. What is the purpose of an Electric Actuator?

An electric actuator converts electrical energy into kinetic energy to automatically opening valves or dampers, improving process control efficiency and safety.

4. How is a Spring Return Electric Actuator different from a regular actuator?

Unlike standard electric actuators, a Spring Return Electric Actuator can automatically reset to a safe position when power is lost, making it essential for emergency response situations where you need equipment and pipeline isolation or fully opening.

Conclusion

With its high-efficiency fail-safe features, the Spring Return Electric Actuator is widely used in high-risk industries such as tunnels, marine, and subway applications, providing critical protection in emergencies. It is the right choice for engineers who need reliable performance in demanding safety applications.

At THINKTANK, we have extensive experience in applications involving spring return electric actuated valves. We have worked on many critical projects, including fire protection systems for data centers, ventilation systems for tunnels and subway infrastructure, and fire protection solutions for storage tanks. Our track record in these high-stakes environments demonstrates our commitment to delivering reliable and robust solutions that meet the stringent safety and performance demands of our clients.

With our deep industry knowledge and technical capabilities, THINKTANK is the partner you can trust to implement effective spring return electric actuator solutions in any project that requires fail-safe performance and top-tier safety standards. Feel free to contact us, Let us help you ensure safety and reliability in your operations.