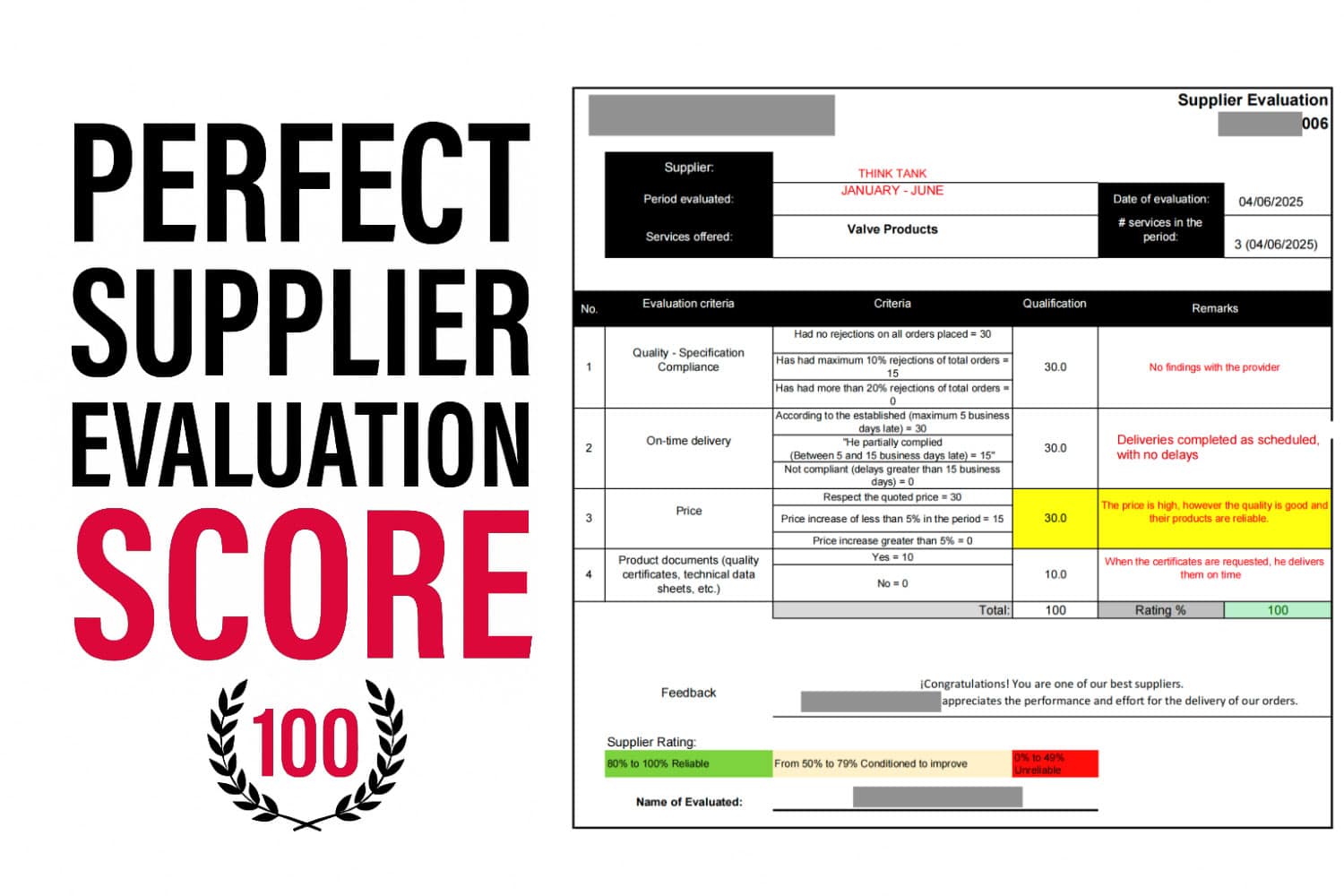

THINKTANK Earns Perfect Score in Supplier Evaluation — Empowering Client Brands as a Trusted Industrial Control Valve Supplier

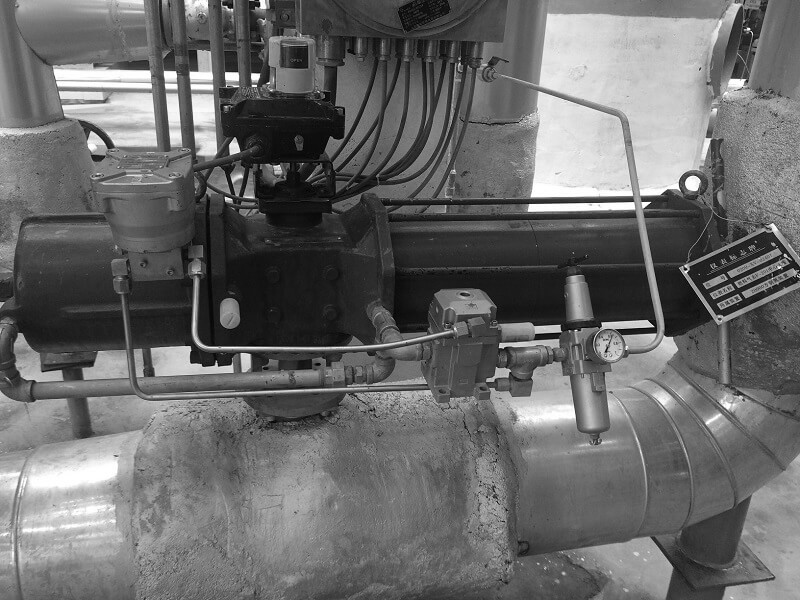

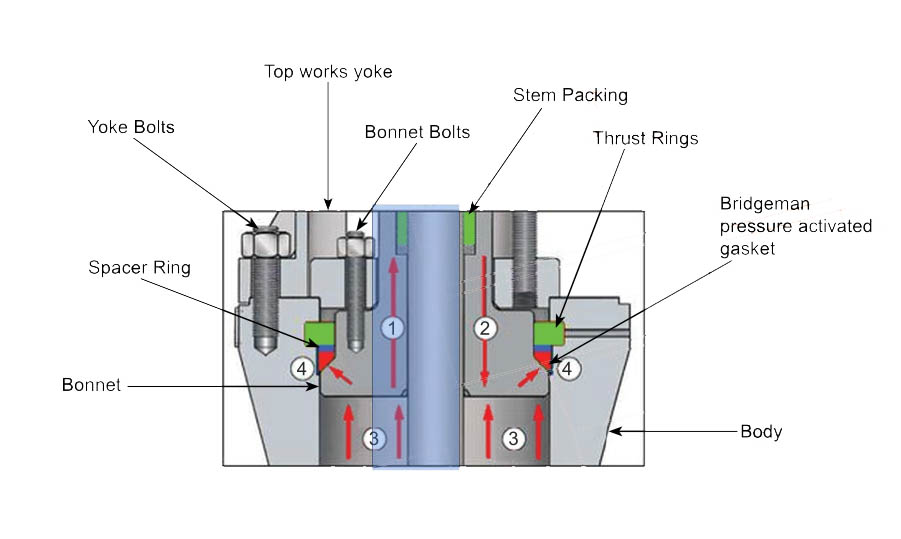

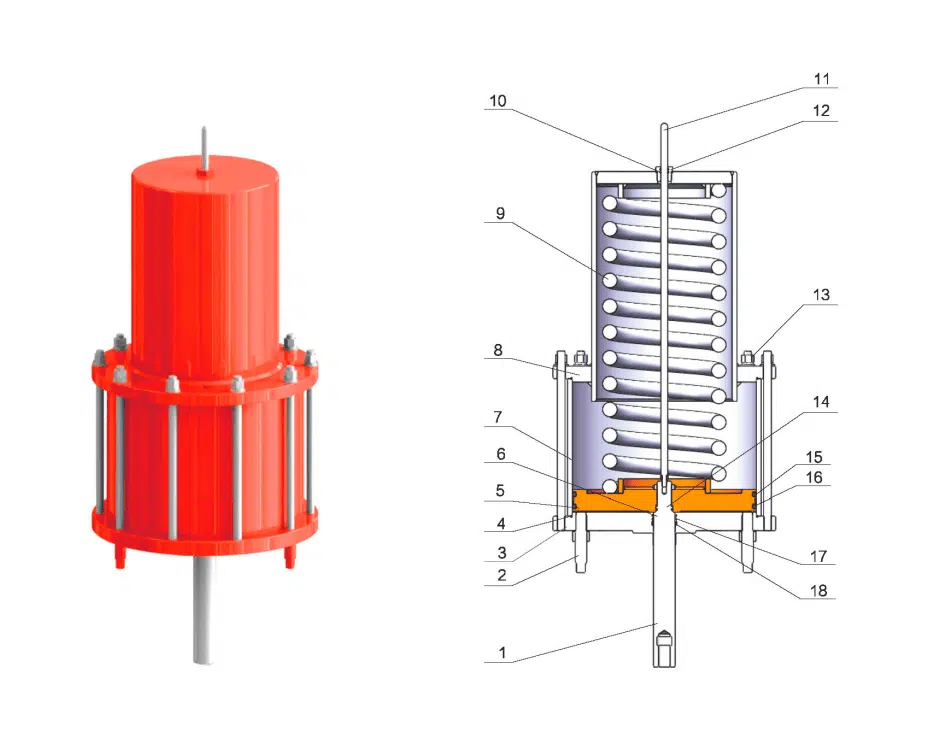

On June 4th, 2025, we received a supplier evaluation form from one of our long-standing OEM clients. The evaluation covered our performance for the first half of the year (January to June 2025) and assessed our capabilities across four categories: product quality, on-time delivery, pricing, and documentation support. We are