If you’re sourcing knife gate valves for tough conditions—whether it’s slurry lines, chemical tanks, or wastewater systems—you know not all valves perform the same. At THINKTANK, we don’t just sell valves. We manufacture and ship them daily, built to spec, tested in-house, and ready for real-world applications.

Below is a recent shipment batch showcasing a variety of pneumatic knife gate valves—covering different sizes, body materials, and actuator setups.

What Knife Gate Valve We Shipped – Summary (First Quarter of 2025)

| Size | Pressure | Body Material | Gate | Packing | Actuation | Qty |

| 3″ | 150LB | A351 CF3M | SS | PTFE | Pneumatic | 90 |

| 4″ | 150LB | A351 CF3M | SS | PTFE | Pneumatic | 118 |

| 5″ | 150LB | 904L / 316L / Titanium Gr.12 | SS / Ti Gr.12 | PTFE | Pneumatic | 120 |

| 6″ | 150LB | WCB | SS304 | PTFE | Pneumatic | 120 |

| 8“ | 150LB | 904L / 316L / Titanium Gr.12 | SS / Ti Gr.12 | PTFE | Pneumatic | 180 |

| 10″ | 150LB | 316L | SS | PTFE | Pneumatic | 100 |

Each valve was manufacturing to meet specific material and operating condition requirements, we will do shell hydraulic pressure test, seat leakage pressure test and functional test before shipment.

MSS SP-81 Knife Gate Valve

If you’ve worked with knife gate valves in real systems—especially where you’ve got slurry, fiber, or solids in the line—you know reliability depends on build standard and sealing design.

That’s why we follow the MSS SP-81 standard for our valves. It’s not just a spec—it means full port flow, bi-directional sealing, and a compact, square body that fits tight spaces. The seat and packing are designed for low maintenance, even in abrasive or corrosive service.

There are many material options for your application, such as WCB, CF3M, 316L, 904L, and even Titanium Gr.12, depending on your process media. Whether it’s chemical, mining, wastewater, or pulp stock—we’ve built for it.

🔍 Key Points:

- True bi-directional flow – reduces stock variants

- Robust sealing – tight shutoff even with solids in the line

- Compact body – ideal for system retrofits or tight skids

- Corrosion-resistant materials – handles aggressive media

- Low maintenance – less downtime, easier servicing

🔧 Used In:

- Wastewater lines with solids

- Chemical dosing and drain systems

- Slurry transfer in mining

- Pulp & paper fiber lines

- Bulk powder and hopper isolation

If you’re designing a system or replacing failing valves, this is the kind of unit you want to install once—and not worry about later.

Why Engineers Choose THINKTANK Knife Gate Valves

- In-house machining and testing, from casting to final assembly

- Multiple body materials (WCB, CF3M, 316L, 904L, Titanium)

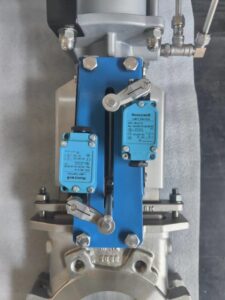

- Accessory integration: limit switches, solenoid valves, air filter regulators

- Standard and custom face-to-face dimensions (MSS SP-81 compliant)

- Quick response for repeat orders and project-specific BOMs

Knife Gate Valve Hydraulic/Shell Pressure Test

Knife Gate Valve Seat Leakage Pressure Test

Ready to Talk Specs?

Looking for a valve partner that understands project timelines and system demands?

Send us your specs—we’ll help you design the right knife gate valve for your application.