At THINKTANK, we specialize in providing tailored valve solutions that enhance the safety and efficiency of industrial systems. One of our clients recently approached us with a critical issue involving hydrogen gas regulation in their process. They required a control system that could prevent damage caused by rapid depressurization due to valve failure. We developed a solution using our PCV-XXX and associated components to meet their needs. Below is a detailed overview of the system and how we addressed the challenge.

Client’s Requirements and Problem

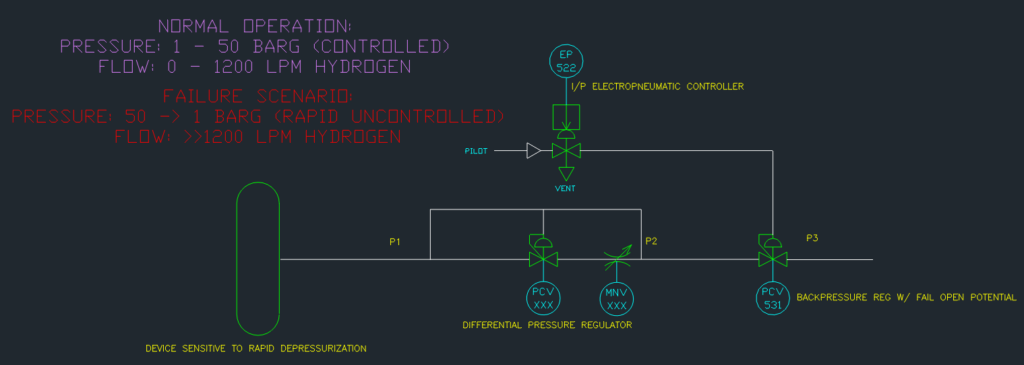

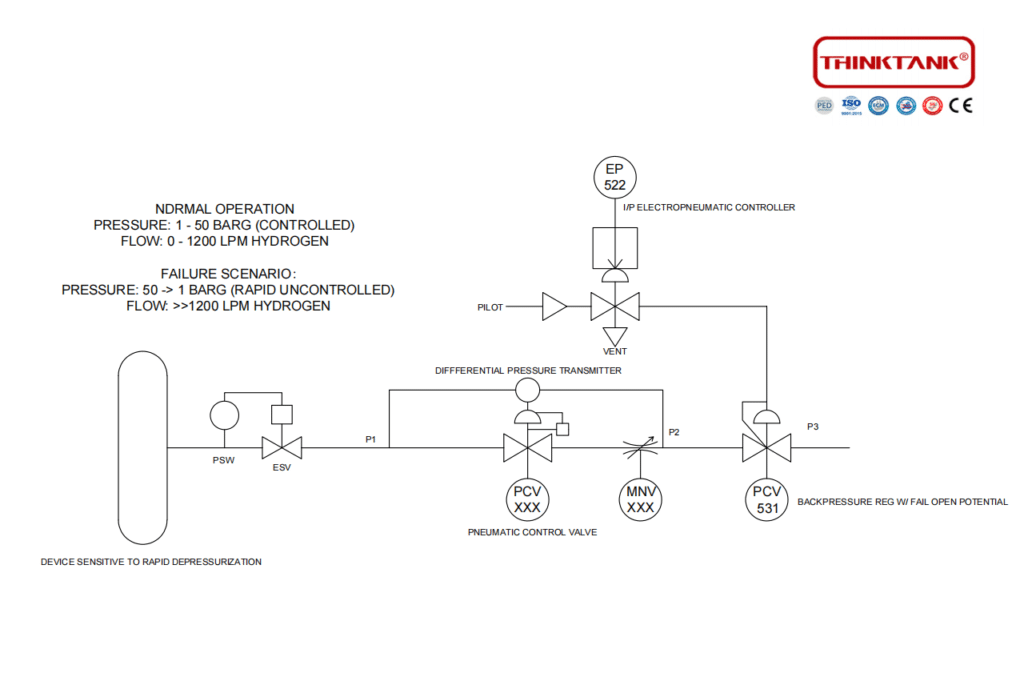

The client operates a hydrogen system that requires precise flow and pressure control for safe operation. They requested a solution that could maintain a pressure differential of 0.5 barg between two points (P1 and P2) and support flow rates between 0 and 1200 LPM. The pressure before the valve (P1) ranges from 1 to 50 barg, while the pressure after the valve (P2) should ideally be between P1 – 0.2 to 0.5 barg. However, in the event of a system failure, specifically the failure of the PCV-531 valve, they were concerned about rapid depressurization that could cause significant damage.

THINKTANK’s Solution

To protect against pressure loss and maintain system integrity, we proposed a solution that combines a differential pressure regulator with automatic response features in the event of failure. Here’s how our solution works:

1. Design Objectives

Ensure controlled operation under normal conditions, maintaining a pressure differential of 0.5 barg between P1 and P2, with a flow rate of 0-1200 LPM.

In case of system failure (e.g., abnormal pressure loss), automatically adjust the PCV-XXX opening to prevent a rapid pressure drop on the P1 side and protect the equipment.

Provide emergency shut-off protection to prevent pressure loss if P1 drops below 25 barg, ensuring the safety of the storage tank.

2. Equipment & Functions

2.1 Pressure Switch (PSW)

- Set Pressure: 25 barg (Set by End-User)

- Function: When P1 drops below 25 barg, the PSW sends a signal to trigger immediate closure of the ESV, cutting off the pipeline flow and preventing sudden pressure loss in the equipment.

- Installation Location: At the storage tank outlet, near the ESV.

2.2 Emergency Shutoff Valve (ESV)

- Type: Energized to Close (ESD – Energized Shut Down)

- Function:When PSW is triggered (P1 drops below 25 barg), the PSW sends a signal, and the ESV immediately closes, cutting off downstream flow to prevent further pressure loss.

- Under normal conditions (P1 ≥ 25 barg), the ESV remains open, allowing fluid to flow.

- The ESV only closes upon receiving a PSW trigger signal; it does not close due to power loss, ensuring proper operation.

2.3 Pneumatic Control Valve (PCV-XXX)

Control Method: Regulates based on the pressure differential between P1 and P2

Set Pressure Differential: 0.5 barg

Control Logic:

- When P1-P2 = 0.5 barg, PCV-XXX maintains the current opening, keeping the flow stable.

- When P1-P2 > 0.5 barg, PCV-XXX increases the opening, releasing pressure and lowering P1-side pressure.

- When P1-P2 < 0.5 barg, PCV-XXX reduces the opening, decreasing flow and maintaining P1-side pressure.

2.4 Differential Pressure Transmitter (DPT)

Monitoring Points: P1 and P2

Set Value: 0.5 barg

Function:

- Monitors the pressure differential (P1-P2) and determines the opening of PCV-XXX.

- When P1-P2 exceeds 0.5 barg, the PCV-XXX opening increases;

- when P1-P2 drops below 0.5 barg, the PCV-XXX opening decreases.

How This Solution Works

During normal operation, the system maintains a stable flow and pressure, ensuring that the pressure differential between P1 and P2 stays within safe limits. However, in the event of a failure, such as the PCV-531 malfunctioning, our solution automatically adjusts the valve opening to prevent rapid depressurization. If P1 drops below the critical 25 barg threshold, the PSW triggers the ESV to close, preventing further damage and ensuring the safety of the system.

Conclusion

THINKTANK’s custom solution combines our PCV-XXX, PSW, and ESV to ensure safe, reliable operation and protection against rapid pressure loss. By using advanced control and monitoring technology, we were able to meet the client’s requirements and provide them with a system that safeguards their equipment and enhances operational reliability.

If you’re facing similar challenges or need customized valve solutions, feel free to reach out. We’re here to help you optimize your system’s performance and ensure its safety and efficiency.