In the past 5 years, we made our HPR/HPH series axial piston pumps as OEM products for a well-known brand. These pumps have been successful in many industries because they are so advanced and work so well. Over the years, we have participated in many projects, and win the trust from system companies.

Now that our confidentiality agreement has expired and we are no longer limited to exclusive sales to brand owners, we can now offer these high-performance pumps to the public.

The HPR/HPH series axial piston pumps can serve as an alternative to Danfoss PAH pumps. These pumps offer similar performance characteristics and are suitable for high-pressure applications such as reverse osmosis, ultra-pure water systems, and industrial water treatment, which are also key markets for Danfoss PAH pumps.

Here’s how the HPR/HPH series compares as a viable alternative:

Key Features and Advantages as a Danfoss PAH Alternative

1. High Pressure Handling

Both HPR/HPH pumps and Danfoss PAH pumps are designed to handle high-pressure environments. They typically operate in ranges up to 160 bar or more.

Like Danfoss PAH pumps, the HPR/HPH series is designed for applications such as reverse osmosis systems. This makes them perfect for industrial water treatment.

2. Corrosion Resistance

Just like Danfoss PAH pumps, the HPR/HPH series uses high-quality materials like ASTM 316L and ASF2205, which are very corrosion resistant. This means they last a long time, even when you’re handling seawater or other aggressive fluids, just like Danfoss pumps.

3. Ultra-Pure Water Applications

The HPR/HPH pumps are designed so there is no lubricating oil contamination, just like Danfoss PAH pumps. This makes them perfect for ultra-pure water systems because you don’t have to worry about cross-contamination.

4. Low Pulsation and High Efficiency

The HPR/HPH pumps have a multi-piston design that minimizes pulsation, so you get a nice, steady flow rate and high efficiency, just like Danfoss PAH pumps, which are known for their smooth operation and efficiency.

5. Compact and Durable Design

Both pump series are known for their compactness and durability, allowing for easy integration into various industrial setups where space might be limited but high performance is required.

6. Customizable for Different Fluids

Both HPR/HPH and Danfoss PAH pumps can be customized for different water qualities (tap water, seawater, etc.), with seals and materials adjusted for various fluid types. This flexibility makes the HPR/HPH a strong alternative for Danfoss PAH in diverse applications like firefighting, dust suppression, and oil and gas operations.

Performance Specifications Comparison (General)

| Feature | HPR/HPH Series | Danfoss PAH Series |

|---|---|---|

| Max Pressure (Bar) | 160 | 160+ |

| Flow Rate (L/min at 1500 rpm) | 11 – 142.5 | Similar (varies by model) |

| Operating Temperature (°C) | 2°C to 50°C | 2°C to 50°C |

| Corrosion Resistance | ASTM 316L / ASF2205 | 316L stainless steel |

| Pulsation | Minimized | Low Pulsation |

| Applications | Reverse osmosis, ultra-pure water, seawater | Reverse osmosis, seawater |

Working Principle of Axial Piston Pumps

Axial piston pumps are positive displacement pumps that work by using multiple pistons that move back and forth inside a cylinder block to suck in and push out fluid. These pistons are arranged parallel to the central axis of the pump. When the shaft turns, the swashplate tilts, which pushes the pistons in a linear motion, creating a pressure difference inside the pump chambers.

Axial Piston Pumps High Pressure Pump PR/HPH Series

- HPR/H 08 ~ 12.5

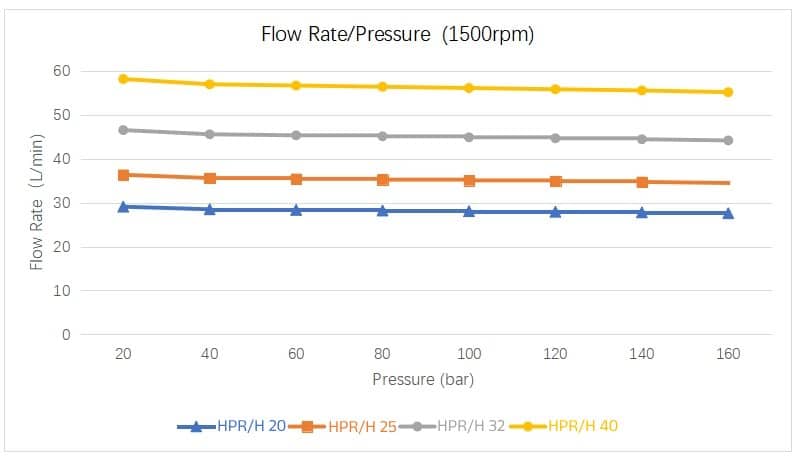

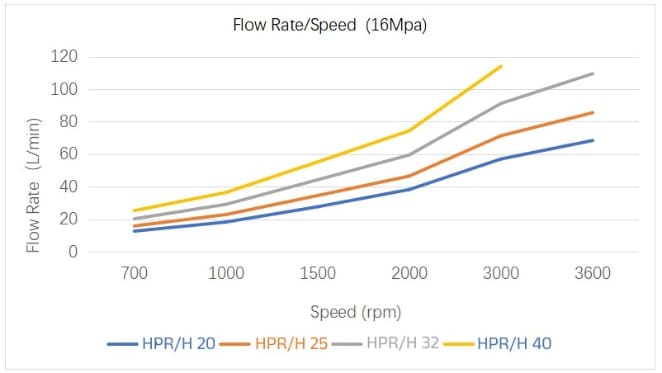

- HPR/H 20 ~ 40

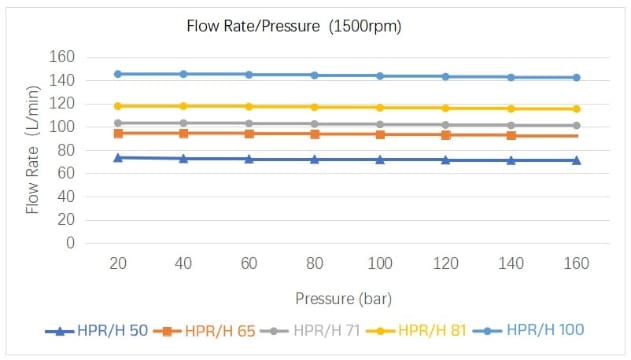

- HPR/H 50 ~ 100

Application

HPR/HPH pumps can be used in the following applications

- Zero wastewater discharge

- High-pressure atomization humidification system

- Fire extinguishing system

- High-pressure flushing and cleaning process

- Fixed and mobile water hydraulic system

Advanced Technology

The HPR/HPH series pumps are completely oil-free clean systems, using water as the sole coolant and lubricant, eliminating the potential risk of cross-contamination between oil and water. Originating from advanced British pump technology, the HPR/HPH high-pressure water pumps deliver superior performance.

- Ultra-clean technology with no lubricating oil, preventing cross-contamination

- Compact design for easy assembly, disassembly, and maintenance

- Excellent corrosion resistance

- Multi-plunger design minimizes pulsation

- Widely used in various ultrapure water treatment applications

- Longer service life resulting in ultra-low operating costs

- Outstanding stability

Axial Piston Pumps Working Conditons – HPR/HPH Series

a. Operating Ambient Temperature Range: -30 to +60°C

If the ambient temperature exceeds this range or the motor installation is above 1000 meters in altitude, the motor’s output power may decrease. This is mainly due to reduced air density and poor motor cooling. In such cases, a larger motor model may be required to achieve higher rated output power.

b. Medium Temperature Range: 0 to +50°C

Excessive medium temperatures can cause permanent damage to the pump. If long-term operation at other temperatures is needed, please contact a THINKTANK’s sales representative for appropriate solutions.

c. HPR/HPH Series Pumps are Equipped with a Discharge Check Valve and Pressure Relief Valve

If the ambient temperature exceeds this range or the motor installation is above 1000 meters in altitude, the motor’s output power may decrease. This is mainly due to reduced air density and poor motor cooling. In such cases, a larger motor model may be required to achieve higher rated output power.

Performance Requirements

Temperature

The HPR/HPH system pumps perform best within a temperature range of 2°C to 50°C. For temperatures below freezing, environmentally friendly antifreeze must be used. It is also possible to operate at temperatures above 50°C; however, the volumetric efficiency of the pump will be affected, and the maximum operating temperature must be specified when ordering.

Filter

All water entering the pump must be pre-filtered to a nominal rating of 10μm (absolute value of 25μm). In closed-loop systems, return flow filtration is acceptable. High-pressure filtration can also be used, but it is considered a more expensive option.

Fluid

The standard pump operates well with potable water and industrial water, such as distilled water, reverse osmosis water, or demineralized water. Depending on the operating environment, changes to the sealing material or structure may be required. The standard structure is suitable for seawater, but due to the increased corrosion potential, higher-quality materials may be needed for long-term operation.

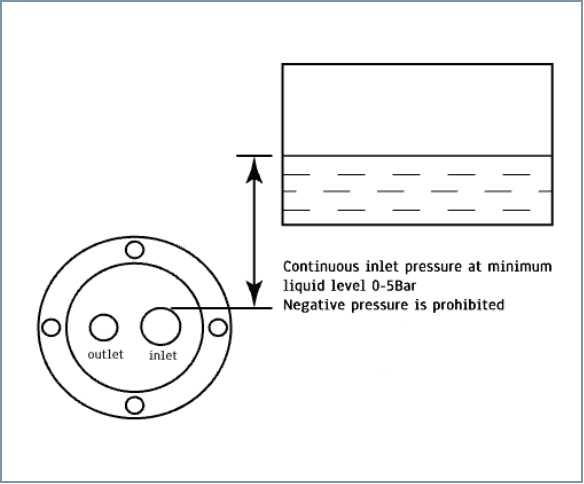

Air Venting

After installation, before the initial start-up, loosen the air vent bolts located at the highest points on both sides of the mounting flange and vent the air completely from the pump before retightening the bolts. If the pump is fully submerged in a tank, these two vent bolts can be completely removed.

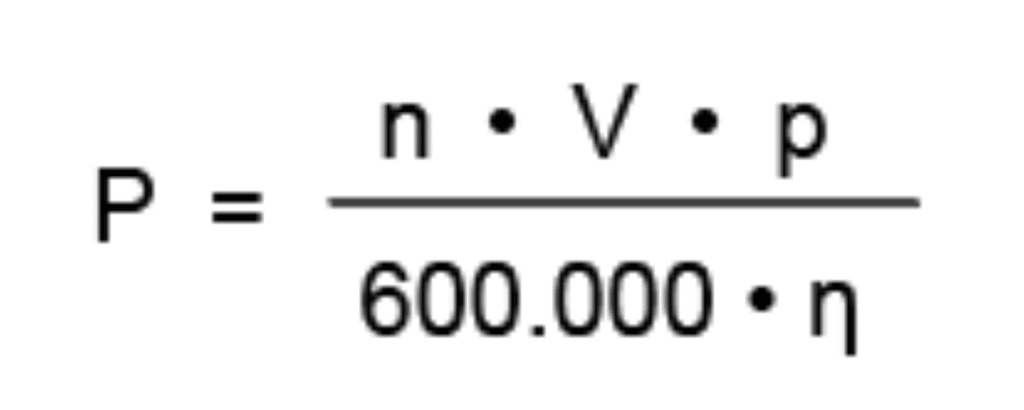

High Pressure Pump Motor Selection

The required motor power can be calculated using the following formula:

- P: Power (kW)

- M: Torque (Nm)

- η: Mechanical efficiency

- p: Pressure (barg)

- n: Rotational speed (rpm)

- V: Geometric displacement (cc/rev.)

Under ideal conditions, the required torque can be calculated using the following formula:

Specification

| Pumps Model | 8 | 10 | 11.5 | 12.5 | 20 | 25 | 32 | 40 | 50 | 65 | 71 | 81 | 100 |

| Displacement (cc/rev) | 8 | 10 | 11.5 | 12.5 | 20 | 25 | 32 | 40 | 50 | 65 | 71 | 81 | 100 |

| Housing Material | ASTM 304 / ASTM 316L / ASF2205 | ASTM 304 / ASTM 316L / ASF2205 | ASTM 304 / ASTM 316L | ||||||||||

| Min. Outlet Pressure(barg) | 30 | ||||||||||||

| Max. Outlet Pressure(barg) | 160 | ||||||||||||

| Inlet pressure,Continuous(barg) | 0.1-5 | ||||||||||||

| Min. speed,Continuousrpm) | 700 | ||||||||||||

| Max. speed (rpm) | 3000 | 3000 | 3000 | 3000 | 3600 | 3600 | 3600 | 3000 | 2000 | 1800 | 1800 | 1800 | 1500 |

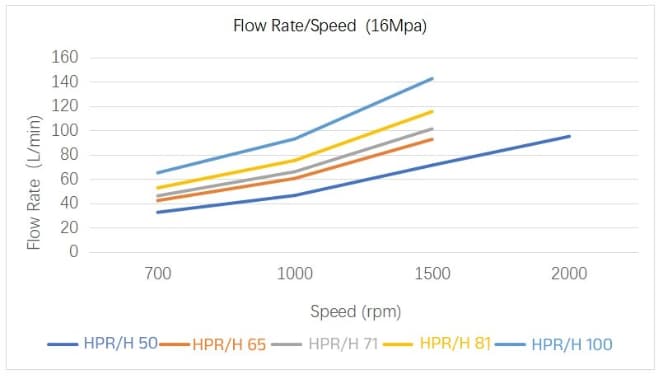

| Flow Rate (L/min) (16Mpa, 700 rpm) | 5 | 6.3 | 7.2 | 7.9 | 12.6 | 15.8 | 20.2 | 25.2 | 32.6 | 42.3 | 46.2 | 52.7 | 65.1 |

| Flow Rate (L/min) (16Mpa, 1000 rpm) | 7.2 | 9.1 | 10.4 | 11.4 | 18.2 | 22.8 | 29.1 | 36.4 | 46.5 | 60.5 | 66.0 | 75.3 | 93.0 |

| Flow Rate (L/min) (16Mpa, 1500 rpm) | 11.0 | 13.8 | 15.8 | 17.3 | 27.6 | 34.5 | 44.2 | 55.2 | 71.3 | 92.6 | 101.2 | 115.4 | 142.5 |

| Flow Rate (L/min) (16Mpa, 2000 rpm) | 14.8 | 18.6 | 21.4 | 23.3 | 38.2 | 46.5 | 59.5 | 74.4 | 95.0 | – | – | – | – |

| Flow Rate (L/min) (16Mpa, 3000 rpm) | 22.8 | 28.5 | 32.8 | 35.6 | 57.0 | 71.3 | 91.2 | 114 | – | – | – | – | – |

| Power Consumption (KW) (16Mpa, 1500 rpm) | 3.4 | 4.2 | 4.9 | 5.3 | 8.5 | 10.6 | 13.6 | 17 | 21.9 | 28.5 | 31.1 | 35.5 | 43.8 |

| Min. Media temperature (°C) | 2 | ||||||||||||

| Max. Media temperature (°C) | 50 | ||||||||||||

| Sound Pressure Level (dB) * | 76 | 76 | 76 | 76 | 78 | 78 | 78 | 79 | 80 | 80 | 80 | 80 | 80 |

| Weight (kg) | 8.6 | 8.6 | 8.6 | 8.6 | 14.72 | 14.72 | 14.72 | 14.72 | 24.8 | 24.8 | 24.8 | 24.8 | 24.8 |

| Integrated Flush Valve | YES | YES | NO | ||||||||||

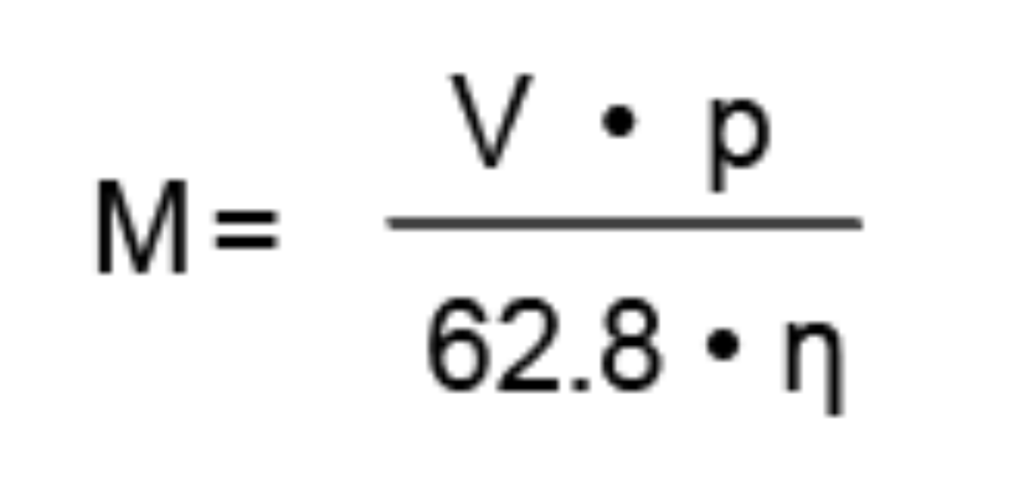

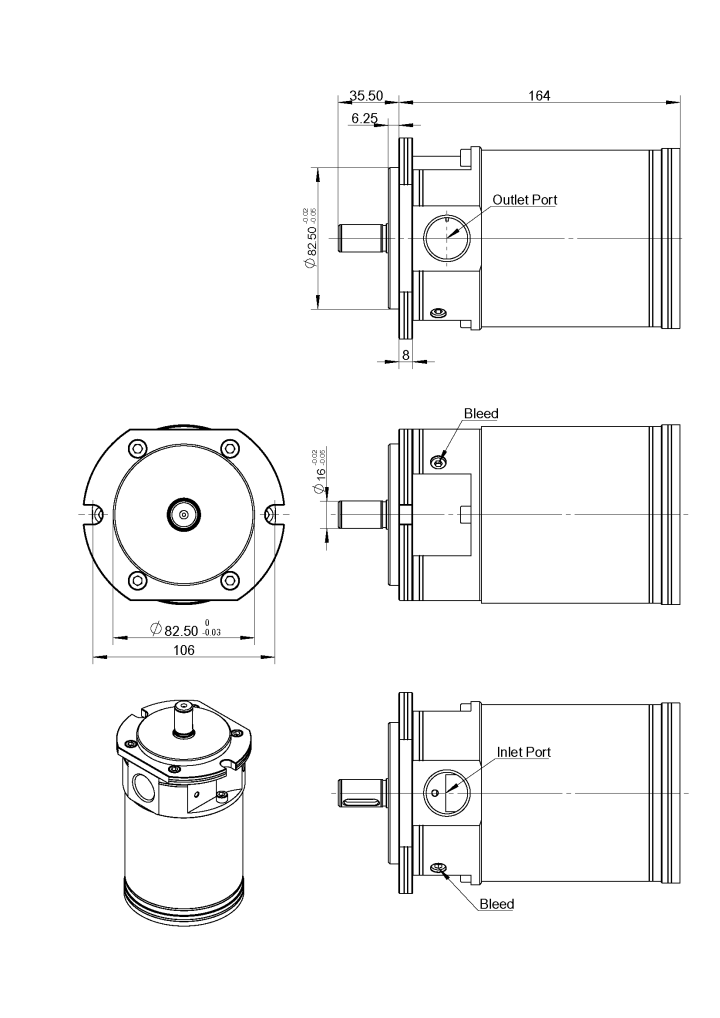

Installation Dimensions (HPR 8~12.5): Option 1

| Parallel key | 5*5*20(DIN6885) |

| Bleed | M5*12 |

| Inlet Port | G 3/4” (T Port) |

| Outlet Port | G 3/4” (P Port) |

Installation Dimensions (HPR 8~12.5): Option 2

| Parallel key | 5*5*20(DIN6885) |

| Bleed | M5*12 |

| Inlet Port | G 3/4” (T Port) |

| Outlet Port | G 3/4” (P Port) |

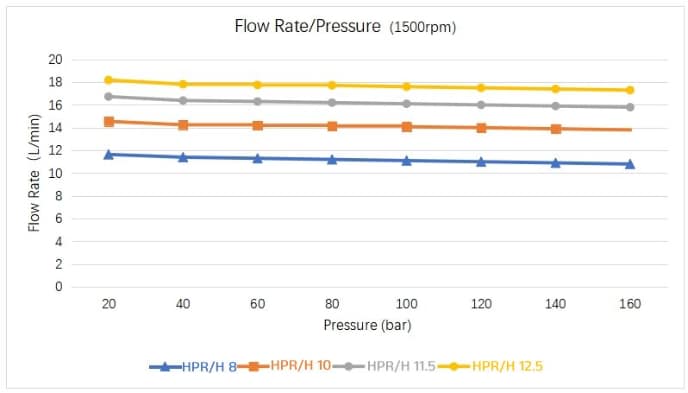

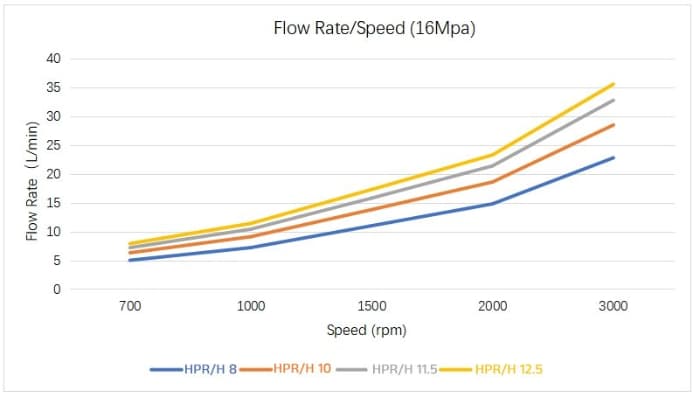

HPR/H 8~12.5 Performance Data

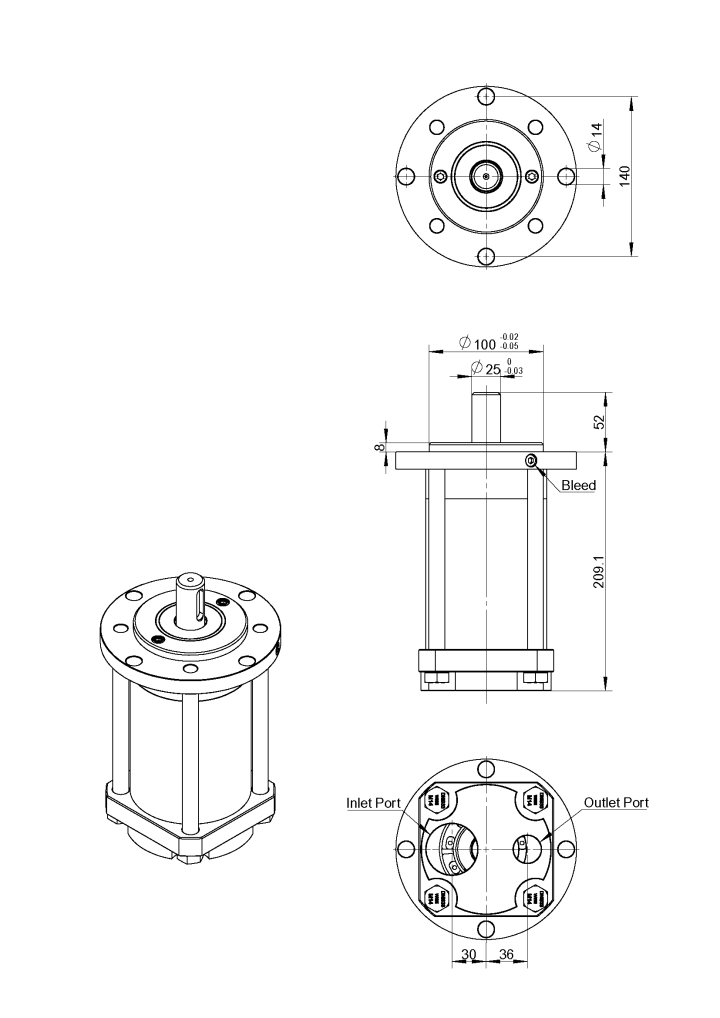

Installation Dimensions (HPR 20~40)

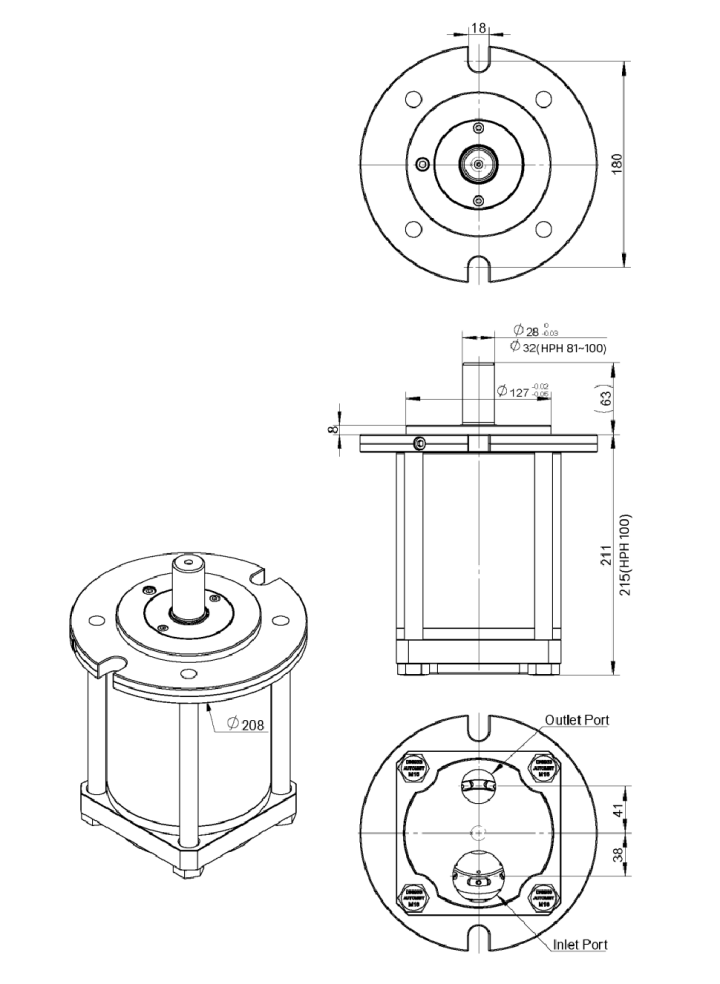

Installation Dimensions (HPR 50~100)

Special Model – HPHS 0.6~1.0

| Pumps Model | 0.6 | 0.8 | 1.0 |

| Code number | TT010200201 | TT010200202 | TT010200203 |

| Displacement (cc/rev) | 4.07 | 5.08 | 6.3 |

| Housing Material | 2205 | 2205 | 2205 |

| Min. Outlet Pressure(barg) | 20 | 20 | 20 |

| Max. Outlet Pressure(barg) | 85 | 85 | 85 |

| Inlet pressure Continuous (barg) | 0.5-5 | 0.5-5 | 0.5-5 |

| Min. speed,Continuous(rpm) | 700 | 700 | 700 |

| Max. speed * (rpm) | 3500 | 3500 | 3500 |

| Flow Rate (m3/H) (85barg,700 rpm) | 0.12 | 0.17 | 0.22 |

| (m3/H) (85barg,1000 rpm) | 0.22 | 0.29 | 0.36 |

| (m3/H) (85barg,1200 rpm) | 0.25 | 0.33 | 0.42 |

| Flow Rate (m3/H) (85barg,1500 rpm) | 0.34 | 0.43 | 0.54 |

| Flow Rate (m3/H) (85barg,1800 rpm) | 0.40 | 0.52 | 0.65 |

| Flow Rate (m3/H) (85barg,2500 rpm) | 0.58 | 0.75 | 0.94 |

| Flow Rate (m3/H) (85barg,3000 rpm) | 0.71 | 0.91 | 1.14 |

| Flow Rate (m3/H) (85barg,3500 rpm) | 0.83 | 1.06 | 1.32 |

| Calculation factor(at maximum speed) | 496 | 509 | 512 |

| Motor selection (KW)(Maximum pressure, maximum speed) | 2.2 | 3.0 | 4.0 |

| Media temperature (°C) | 2~50 | 2~50 | 2~50 |

| Sound Pressure Level (dB) ** | 74 | 74 | 74 |

| Weight (kg) | 3.6 | 3.6 | 3.6 |

| Integrated Flush Valve | YES | YES | YES |

** Sound Pressure Level: Calculated according to EN ISO 3744: 2010 / dB(A) [LPA, 1m], when driven by a motor and operating at maximum working pressure and speed.

Special Model – HPHS 1.5~3.5

| Pumps Model | 1.5 | 1.8 | 2.2 | 2.5 | 3.0 | 3.5 |

| Code number | TT010200204 | TT010200205 | TT010200206 | TT010200207 | TT010200208 | TT010200209 |

| Displacement (cc/rev) | 9.34 | 10.21 | 12.75 | 15.4 | 17.85 | 21.56 |

| Housing Material | 2205 | 2205 | 2205 | 2205 | 2205 | 2205 |

| Min. Outlet Pressure(barg) | 20 | 20 | 20 | 20 | 20 | 20 |

| Max. Outlet Pressure(barg) | 85 | 85 | 85 | 85 | 85 | 85 |

| Inlet pressure Continuous (barg) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

| Min. speed,Continuous(rpm) | 700 | 700 | 700 | 700 | 700 | 700 |

| Max. speed * (rpm) | 3500 | 3500 | 3500 | 3000 | 3500 | 3000 |

| Flow Rate (m3/H) (85barg,700 rpm) | 0.3 | 0.34 | 0.45 | 0.57 | 0.64 | 0.76 |

| (m3/H) (85barg,1000 rpm) | 0.54 | 0.58 | 0.75 | 0.90 | 1.03 | 1.24 |

| (m3/H) (85barg,1200 rpm) | 0.58 | 0.64 | 0.84 | 1.03 | 1.18 | 1.39 |

| Flow Rate (m3/H) (85barg,1500 rpm) | 0.80 | 0.87 | 1.10 | 1.34 | 1.55 | 1.88 |

| Flow Rate (m3/H) (85barg,1800 rpm) | 0.92 | 1.0 | 1.27 | 1.58 | 1.80 | 2.11 |

| Flow Rate (m3/H) (85barg,2500 rpm) | 1.31 | 1.42 | 1.80 | 2.22 | 2.55 | 2.98 |

| Flow Rate (m3/H) (85barg,3000 rpm) | 1.60 | 1.73 | 2.18 | 2.68 | 3.07 | 3.58 |

| Flow Rate (m3/H) (85barg,3500 rpm) | 1.84 | 1.99 | 2.52 | 3.56 | ||

| Calculation factor(at maximum speed) | 519 | 524 | 532 | 535 | 532 | 530 |

| Motor selection (KW)(Maximum pressure, maximum speed) | 5.5 | 5.5 | 7.5 | 7.5 | 11 | 11 |

| Media temperature (°C) | 2~50 | 2~50 | 2~50 | 2~50 | 2~50 | 2~50 |

| Sound Pressure Level (dB) ** | 78 | 78 | 78 | 78 | 78 | 78 |

| Weight (kg) | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 |

| Integrated Flush Valve | YES | YES | YES | YES | YES | YES |

** Sound Pressure Level: Calculated according to EN ISO 3744: 2010 / dB(A) [LPA, 1m], when driven by a motor and operating at maximum working pressure and speed.