Abstract

Reverse osmosis (RO) has emerged as one of the most effective water purification techniques worldwide. At the heart of its functionality, aside from the semi-permeable membrane, are the metering control valves that ensure optimal flow rates and pressure. This white paper delves into the importance, functionality, and technicalities of metering control valves designed by THINKTANK for RO systems.

In an age where the quality of drinking water has become a global concern, RO systems have established themselves as the gold standard in water purification. The precision of these systems depends significantly on metering control valves. THINKTANK, with its expertise in valve design and manufacturing, has been at the forefront of this innovation.

THINKTANK TRC250/A Metering control valve comes in an expansive variety of materials, tailored for managing liquids, gases, or steam across industrial sectors, research environments, and process pilot plants.

Due to its streamlined dimensions, it stands out as a top pick for tasks like additive injections, sampling, or low-flow hydraulic systems,

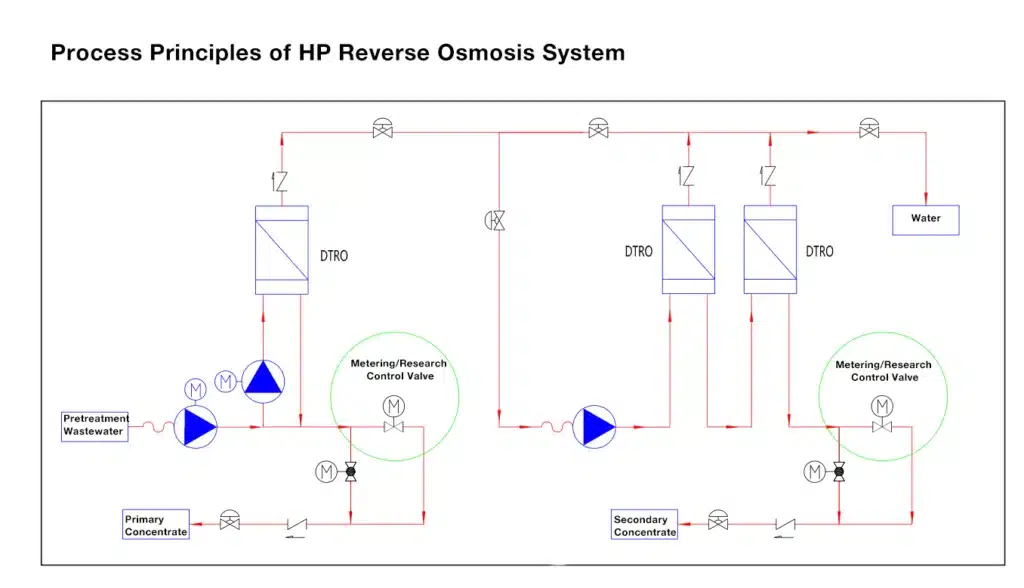

Metering Control Valves in RO Systems

Metering control valves in RO systems are used to regulate the flow of feed water, product water, and brine (waste). Their precision ensures that the system operates efficiently and maintains the desired recovery and rejection rates. They can also help in maintaining the right pressure across the RO membrane, which is crucial for efficient filtration.

Feed Water Flow Control

The valve can regulate the amount of source water entering the RO system. Proper control ensures the membrane doesn’t get overloaded or underutilized.

Product Water Flow Control

After water passes through the RO membrane, purified water (permeate) is produced. The valve ensures the flow rate of this purified water is steady and consistent.

Brine (Concentrate) Flow Control

The rejected water with higher concentrations of salts and impurities is called brine or concentrate. A valve is essential to manage its flow rate and prevent undue pressure on the RO membrane.

Features to consider in a Metering Control Valve for RO Systems

Precision

Given the sensitivity of RO operations, a slight change in flow rate or pressure can impact the system’s efficiency. The valve should offer precise control.

Materials

Since RO systems deal with water, the valve materials should be resistant to corrosion. Stainless steel or high-quality plastic valves are commonly used.

Size & Design

Depending on the RO system’s capacity and design, the valve size and design must be chosen to fit seamlessly and work efficiently.

Maintenance

Over time, scaling or fouling can affect valve operation. Thus, choosing a design that’s easy to clean and maintain can prolong the system’s lifespan.

Technical Specifications of THINKTANK’s Metering Control Valves

| Size(DN) | 3/8″, 1/2″, 3/4″, 1″, 1-1/4″ | |||||||||

| Seat Diameter(dn) | 2.5 | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | 15 |

| Flow Coefficient CV | 0.006 | 0.016 | 0.16 | 0.25 | 0.4 | 0.63 | 1.0 | 1.6 | 2.5 | 4.0 |

| Nominal Pressure | PN16~PN320 | |||||||||

| Body Material | 304、316L、904L、2507、2205、HC276 | |||||||||

| Connection | Threaded Ends(G, NPT, ZG ), Flanged Ends(HG/T20592-2009) | |||||||||

| Rated Travel(mm) | 11 | 16.5 | ||||||||

| Bonnet Type | Standard Type, Cryogenic Type, extension Type, Bellows Type | |||||||||

| Plug Type | Needle, Cage Type | |||||||||

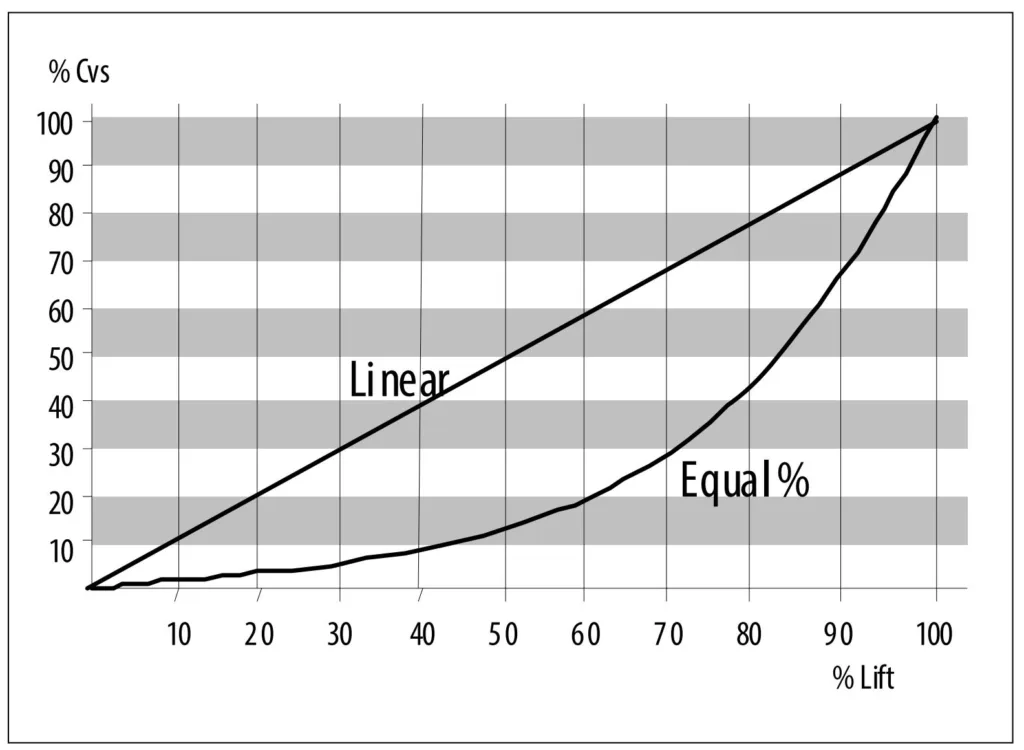

| Flow Characteristics | Equal Percentage, Linear Percentage | |||||||||

Benefits of Using THINKTANK’s Research/Metering Control Valves

- Small size and light weight.

- The valve body is made of raw material forging, high pressure resistance is outstanding, the valve internal parts can be disassembled, reducing the maintenance cost, to ensure that the equipment can be a long-term stable operation, to eliminate leakage.

- High regulation precision, through the electric actuator slowly adjust to control the spool of the valve tiny outlet, to realize the flow of tiny precise control, to maintain the pressure required for the separation of water molecules inside the membrane, to control the discharge of concentrated water.

- Eliminate cavitation, high noise, piping vibration and other problems caused by high-speed fluid flow.

- Fluid passes through labyrinth type valve cage to realize multi-stage pressure reduction. A full range of valve sizes is available with reduced internals and inherently adjustable ratios up to 100:1 to provide a wide range of flow capacities. Packing seal plus O-ring double sealing ensures that the valve has no external leakage.

- Different model of electric actuators are available to meet the needs of low pressure drop to high pressure drop.

Unique Features

- High Precision

All imported precision electric actuator slowly open and close to control the valve core tiny outlet holes, to realize the flow of tiny precise control. - Long Service Time

All contact media materials are used 316L/2507/904L and other materials, the structure of the control valve can be disassembled, low maintenance costs, to ensure the long-term stable operation of the equipment. Different needs using different special treatment of the valve needle to ensure that the service life. - Compact Structure Design

Simple structure, small volume, easy to install, meet the needs of various sizes of flow. - Special Tools

Equipped with special tools and wearing parts to facilitate late maintenance.

Served Industries

- Water & Wastewater

- Chemical

- Gas

- Oil

- General Manufacturing

- Pharmaceuticals

- Aerospace

Specialized Conditions

Concentrated water Metering control valve is a high-precision control valve developed for high-pressure, low-flow fluid control. In the harsh conditions of special water treatment areas, such as waste leachate, seawater desalination, zero discharge of industrial wastewater and other mixed complex composition of the fluid, can provide high-performance regulation and control.

Concentrated water metering control valve in reverse osmosis RO membrane device, high-pressure reverse osmosis DTRO membrane device, high-pressure reverse osmosis STRO membrane device and so on. By controlling the pressure of the membrane in reverse osmosis, it improves the water production rate of the membrane separation equipment and completes the water quality standard treatment.

Electric concentrated water metering control valve is mainly used in the concentrated water discharge outlet of high pressure reverse osmosis membrane device, the product mainly plays the following roles in the whole process:

- By adjusting the opening of the electric concentrated water control valve, it can control the flow rate of concentrated water discharge, regulate the pressure in the membrane, to ensure the pressure required for water separation in the reverse osmosis membrane, so improve the water production rate of the equipment, and reduce the discharge pressure after the concentrated water adjustment valve.

- The electric adjustment is easy to realize remote control.

Flow Characteristic Curve

TRC250/B Servo Motor Control Valve 1.4539 230VAC 50/60HZ

Highly Corrosion Resistant Servomotor Control Valve TRC250/B Developed for RO Systems.

This RO metering valve is designed for precise pressure control in reverse osmosis systems, and the THINKTANK RC250 small control valve is the market leader in this application.

For most RO applications, we commend the highly corrosion-resistant servo-motor control valve TRC250, which has been specially developed for use in RO systems.

This RO metering valve is designed for precise pressure control in reverse osmosis systems, where the THINKTANK RC250/B metering control valve is the market leader in China.

We recommend the AISI 904L (1.4539) stainless steel valve with AISI 316 SS valve internals. For more corrosive media, we offer duplex stainless steel or Hastelloy valves.

The valve can also be fitted with a special 3-point or 4-20mA electric actuator for seawater environments.

Description

- Sizes 1″, 3/4″, 1/2″ and 1/4″

- 904L Valve Body

- Suitable For Reverse Osmosis Water Control

- Many Variants Not Listed Here

Application

Designed for pressure control in reverse osmosis systems.

Connections(available in)

- ¼” NPT ,PN 345

- 3/8″ NPT ,PN 345 bar

- ½” NPT ,PN 345 bar

- ¾” NPT ,PN 100 bar

- 1″ NPT ,PN 100 bar

- Special versions for higher pressures are available.

Valve Body Materials

- 1.4539 (904L)

- 1.4404 (316L)

- Special versions with Duplex® or Hastelloy® materials are available.

Seals Materials

- PTFE herringbone rings are standard.

- Electric actuators

- Special versions for sea water environments

- Normal input 3-point control (switching)

- Optional 4-20 mA input signal (analog)

- Integration of two adjustable limit switches

- Power supply: 230 VAC

Conclusion

The significance of metering control valves in RO systems is undeniable. As a leader in the domain, THINKTANK is committed to ensuring that these vital components are engineered to perfection, ensuring the longevity and efficiency of RO systems globally.

For more information or for inquiries about our range of products, please do not hesitate to contact THINKTANK’s professional team.