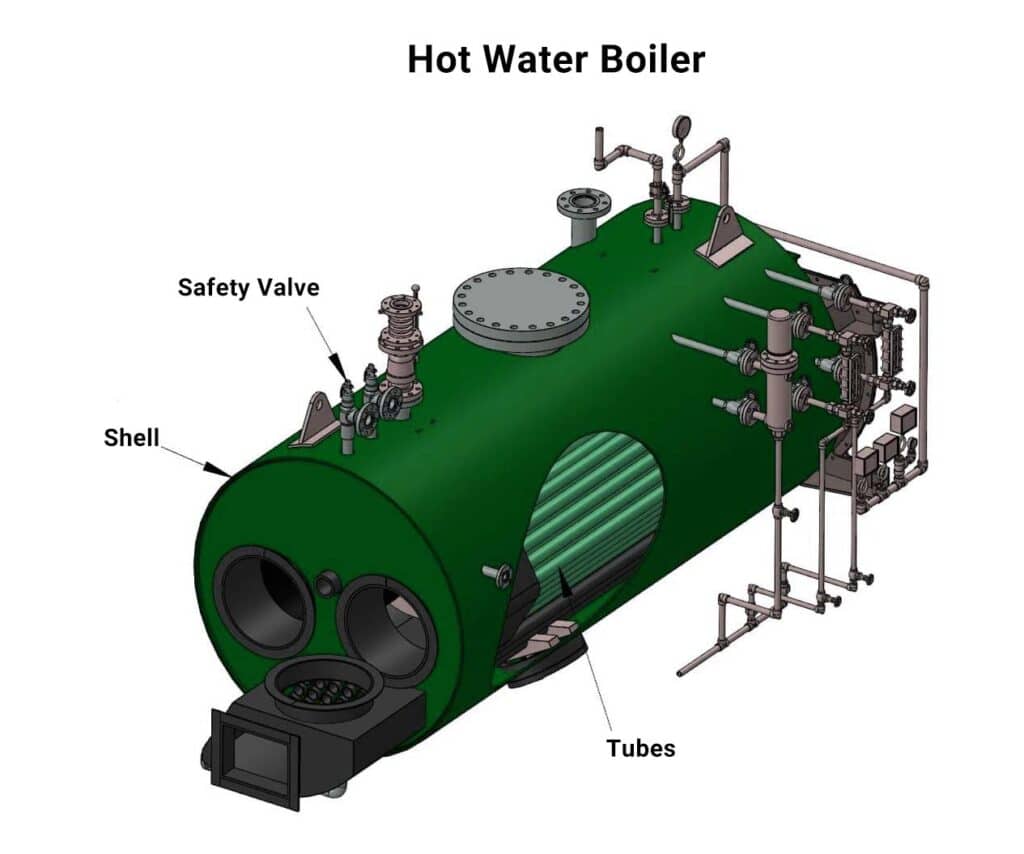

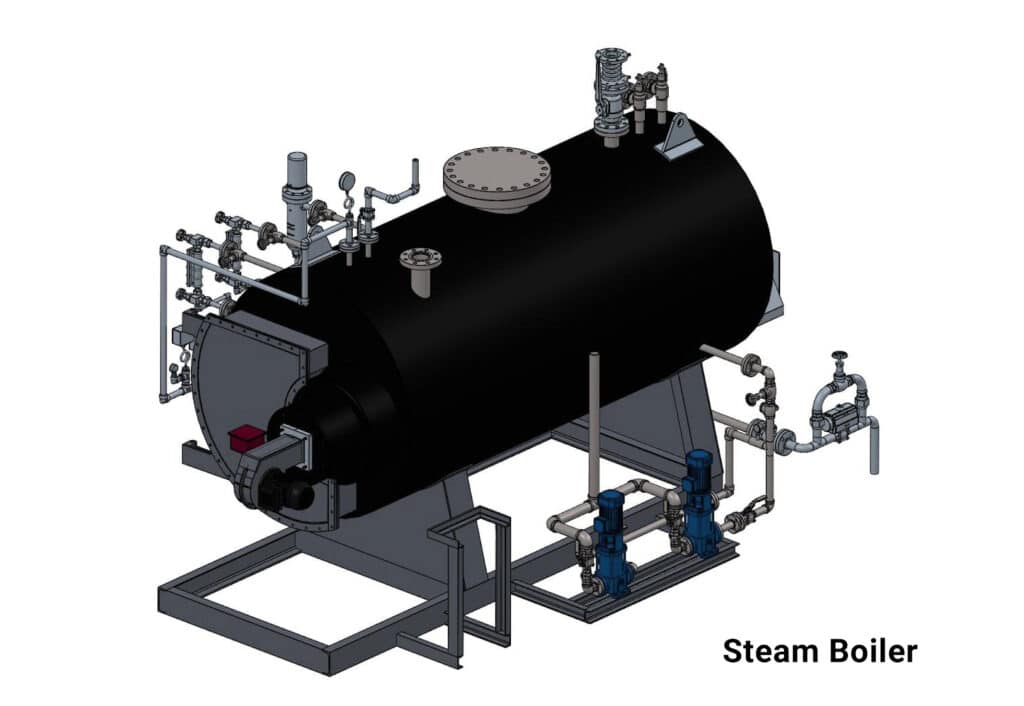

When it comes to boiler systems, pressure relief valves act as vital safeguards, preventing potential disasters arising from excess pressure. Think of them as safety guards, crucial for maintaining balance in industrial settings. Steam boiler pressure relief valves Regular testing becomes paramount, aligning with the National Board Inspection Code’s recommendations, ensuring that these safety valves remain in optimal condition. As we explore pressure relief valves, we’ll uncover their important roles, highlighting the imperative need to test pressure relief valves regularly to avoid dangers linked to too much pressure in low-pressure steam boilers, ensuring safety across industrial processes.

Understanding the Functionality of Steam Boiler Pressure Relief Valves

A. Safeguarding Boiler Safety

The pressure relief valve ais crucial component that continuously monitoring internal pressures in low-pressure steam boilers. Its pivotal role in averting excess pressure aligns with the national board inspection code, emphasizing regular tests to ensure safety. Employing pressure relief valve testing, particularly the annual pressure test not only adheres to safety standards but also aligns with relief valve setting guidelines. This dynamic ensures that boilers operate within safe limits and preventing potential hazards associated with excess pressure.

B. Dynamic Mechanism

Opening and Closing Precision: Operating as a safety valve, the pressure relief valve’s dynamic mechanism carefully coordinates accurate opening and closing actions in response to excess pressure. This careful movement, following the national board inspection code, contributes to the longevity of low-pressure steam boilers. Regular tests, including the annual pressure test, validate the relief valve setting and affirming its ability to effectively open when needed and close seamlessly. Thereby maintaining optimal pressure regulation and overall boiler safety.

Unveiling Causes Behind Steam Boiler Pressure Relief Valve Failure

A. Leakage as a Common Sign

One common indication of pressure relief valve issues is leakage, often attributed to the accumulation of mineral salt, rust, or corrosion. Regular testing, as per the recommended national board inspection code, becomes imperative to identify and address this common challenge in maintaining boiler safety.

B. Build-up of Substances

Mineral Salt, Rust, Corrosion: The integrity of pressure relief valves is compromised by the build-up of substances like mineral salt, rust, and corrosion. This buildup can obstruct proper valve seating while obstructing water flow through the boiler pipe. Following the semiannual testing routine and including the crucial annual pressure test helps detect and address these issues promptly, ensuring the optimal performance of low-pressure steam boilers.

Safeguarding Boiler Safety with Regular Maintenance

A. Preventing Catastrophic Accidents

Regular maintenance serves as a vital defense against catastrophic incidents in low-pressure steam boilers. The pressure relief valve, a key safety component, requires semiannual attention to address hazards associated with excess pressure. Adhering to the recommended maintenance timescale, including an annual pressure test, aligns with national board inspection code standards, minimizing the risk of valve failure.

B. Adhering to Recommended Maintenance Timescales

The essence of boiler safety lies in following recommended maintenance timescales, emphasizing the importance of routine checks and tests. The pressure relief valve, essential for safety, necessitates attention every six months, meeting national board inspection code guidelines. Regular maintenance intervals, incorporating the crucial annual pressure test, not only ensure compliance with safety standards but also enhance the longevity and efficiency of low-pressure steam boilers.

How to Test Steam Boiler Pressure Relief Valve

Testing steam boiler pressure relief valves is an essential maintenance task to ensure they are functioning properly and to maintain the safety of the boiler system. Here’s a general procedure for testing these valves:

1. Review Manufacturer’s Instructions

Always start by consulting the manufacturer’s manual for specific instructions related to your particular boiler and relief valves.

2. Ensure Safety

Ensure the boiler is in a safe condition for testing. This might include shutting down the boiler, allowing it to cool down, and ensuring it is isolated from any power source.

3. Notify Relevant Personnel

Inform all relevant personnel that a valve test is going to be conducted as testing may affect the operation of the boiler or the steam system.

4. Prepare for Testing:

- Pressure Gauge Check: Ensure the boiler pressure gauge is working correctly.

- Clear Area: Ensure the area around the relief valve discharge is clear, as there might be the discharge of hot water or steam.

5. Manual Lift Test (if applicable):

- Slowly Increase Boiler Pressure: Slowly raise the pressure in the boiler by operating it under controlled conditions.

- Manually Operate the Valve: Many steam boiler relief valves have a manual test lever. At the appropriate pressure, lift the lever to manually open the valve. Be cautious, as steam or hot water will be discharged.

- Observe Operation: The valve should open with a noticeable discharge of steam or water. Once you release the lever, the valve should close and the discharge should stop.

6. Observe Automatic Operation:

- If it’s safe and permissible, continue to increase boiler pressure to the set pressure of the relief valve. The valve should open automatically.

- Monitor the pressure gauge to ensure the valve opens at the correct set pressure.

7. Inspect Valve Closure

After the valve opens, reduce the boiler pressure and observe if the valve closes properly and completely. There should be no leakage once the valve closes.

8. Check for Leaks

After the test, monitor the valve for any leaks at operating pressure. A leaking valve might need repair or replacement.

9. Document the Test

Record the results of the test and include whether the valve opened at the correct pressure and any maintenance performed.

10. Regular Scheduled Testing

Schedule regular testing of the relief valve as per the manufacturer’s recommendations and local safety regulations.

11. Professional Assistance

If there are any issues with the valve’s operation or if you are unsure about performing the test safely, seek assistance from a qualified technician.

Conclusion

The careful testing of steam boiler pressure relief valve demands expertise from qualified professionals knowledgeable in boiler operations and safety protocols. Mishandling such critical components can lead to severe consequences, including burns and scalding. It is crucial to strictly follow safety guidelines and local regulations during these procedures. For comprehensive insights into various safety measures and industrial protocols, explore our diverse range of blogs. In THINKTANK, we offer valuable resources on how to test pressure relief valves and other essential topics to ensure the highest safety and efficiency in industrial settings.