At THINKTANK, we specialize in providing custom industrial valve solutions to meet the exacting requirements of our clients. Recently, we worked with a client who needed a batch of eight custom throttle valves for regulating the flow of lubricating oil in their system. In this article, we’ll walk you through the specifications and components of the throttle valve we provided, as well as the function and operating principle that make it an ideal solution for such applications.

Client Specifications

The client required a throttle valve that could efficiently regulate oil flow, with specific material and operational requirements. Here are the key details of the requested product:

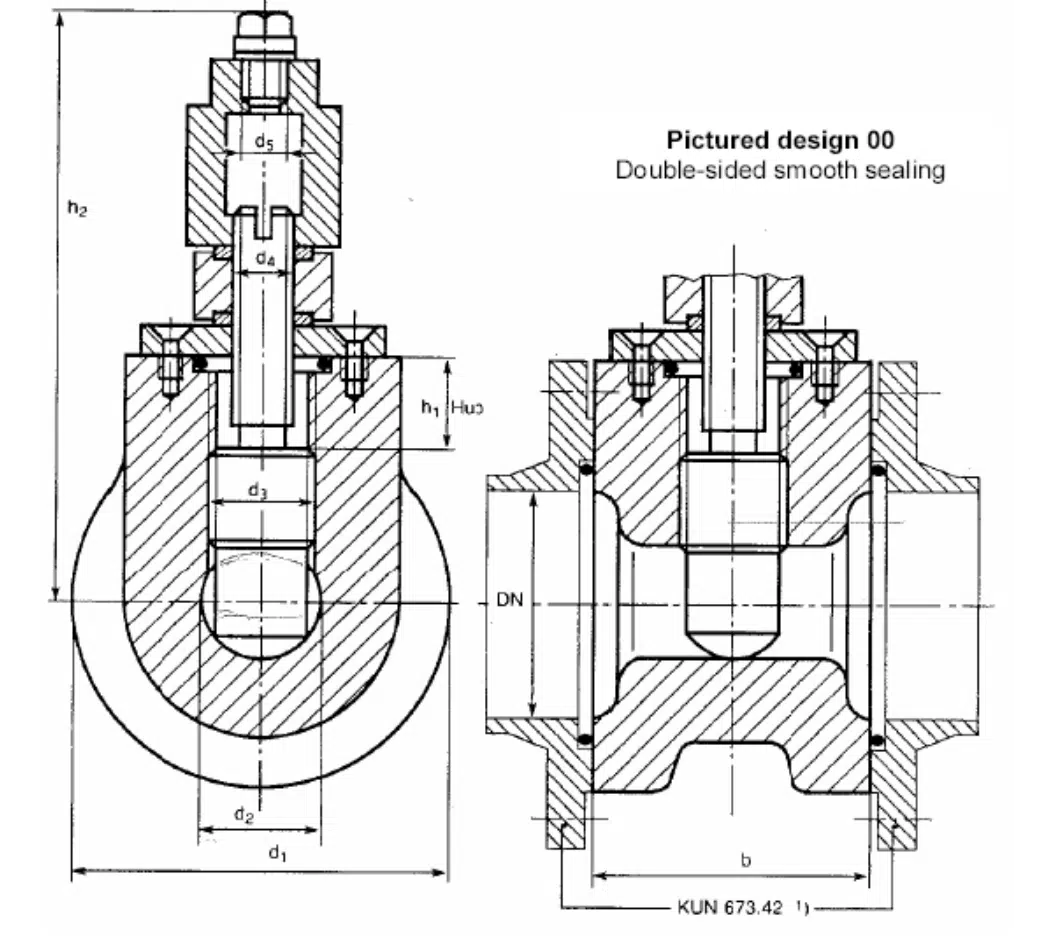

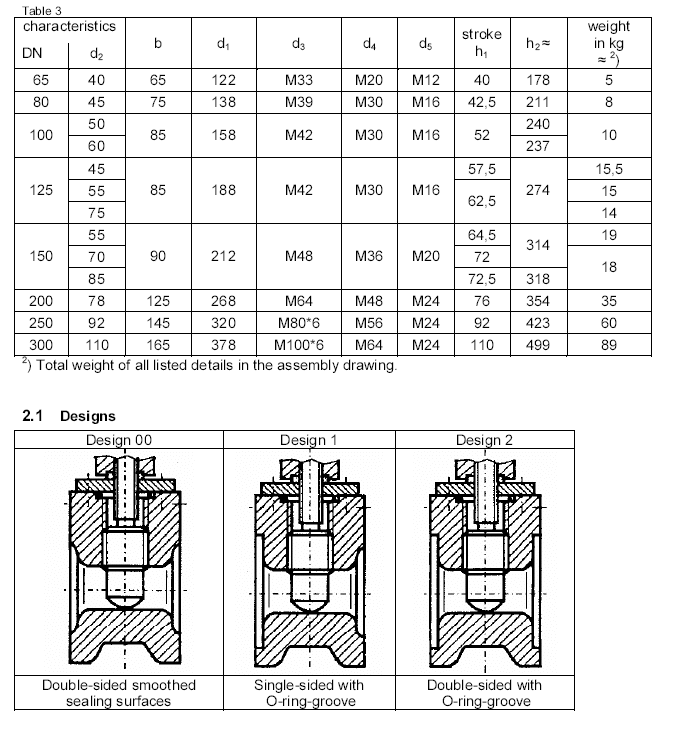

- Type: A00‐DN150x55 (Wafer type, hand-operated throttle valve)

- Design: Double-sided flat sealing surface (A00)

- Nominal Width: DN150

- Inner Diameter (d2): 55

- Line Pressure: 6 Barg

- Material:

- Body: GS‐C25 WCB

- Disc: S355J2+N / Liner: Cu Free Shaft

- Throttling Screw, Flange, Nut, Plug: CK35

- O-Ring: Viton

- Washer: Cu

- Operating Temperature: Min 15°C, normal 70°C, max 80°C (failure)

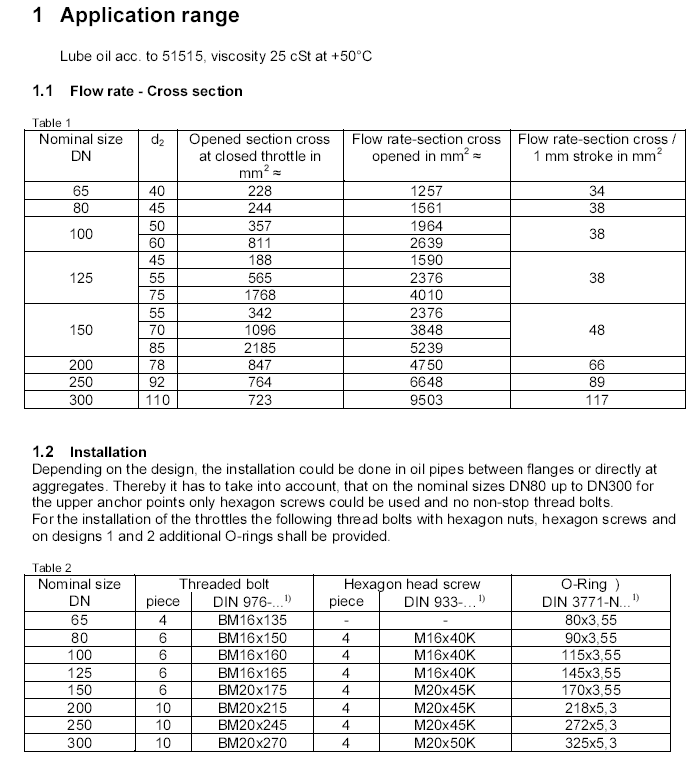

- Medium: Lube oil ISO VG46 & ISO VG32 according to DIN51515

- Flow Rate Data:

- Opened section cross at closed throttle: 342 mm²

- Flow rate-section cross opened: 2376 mm²

- Flow rate-section cross/1 mm stroke: 48 mm²

Throttle Valve Function and Components

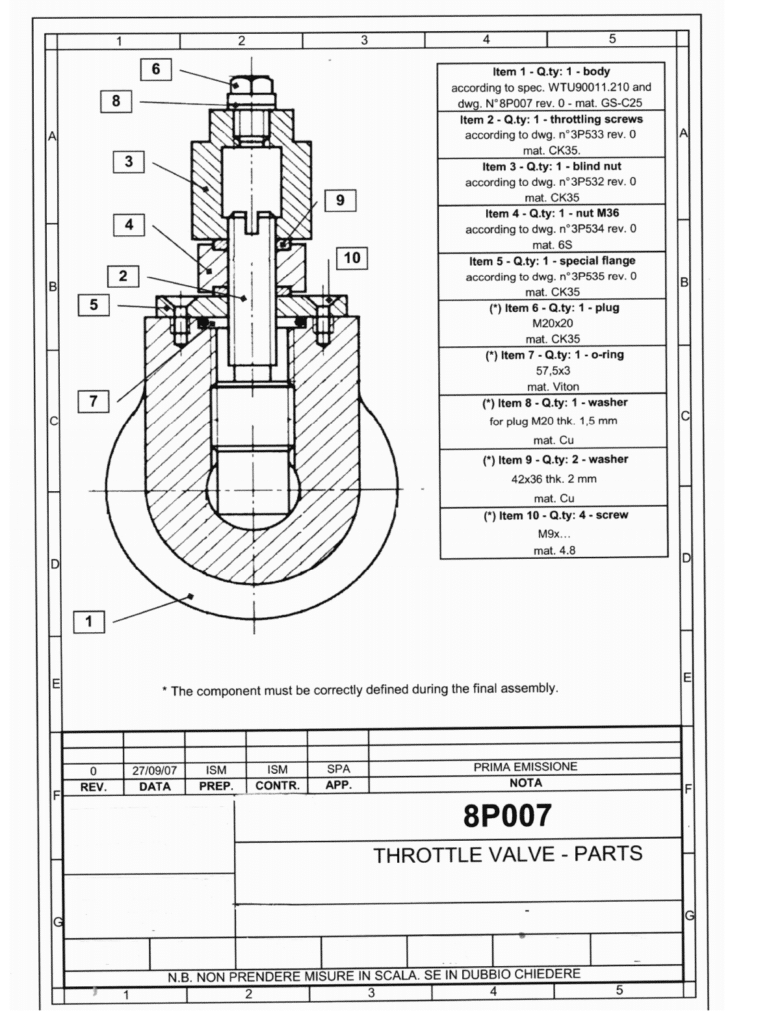

The throttle valve regulates the flow of fluids, typically oil, in industrial applications. The key components of the valve include:

- Throttle Screws (Item 2): These screws control the flow rate of the fluid passing through the valve.

- Blind Nut and M36 Nut (Item 3 & Item 4): These components secure the throttle screws in place, ensuring precise flow control.

- Special Flange (Item 5): Used to connect the valve body to the pipeline.

- Plug (Item 6): Seals off parts of the valve body to prevent leakage.

- O-Ring and Washers (Item 7, 8, & 9): These seal the valve body and prevent leaks.

- Screws (Item 10): These are used for securing and adjusting the valve structure.

Operating Principle For Throttle Valve

The operating principle of the throttle valve is unscrewing the blind nut (Item 3) and loosening the M36 nut (Item 4), you can release the clamping of the throttle screws. Once this is done, the throttle screws can be adjusted by turning with a screwdriver, thereby controlling the flow of fluid. To increase the flow, turn the throttle screw counterclockwise to allow more fluid to pass through. To decrease the flow, turn the throttle screw clockwise to reduce the flow. After adjusting, tighten the M36 nut and blind nut to secure the throttle screws in place and prevent leakage.

Simple to say

- Adjusting the Throttle Screws: To control the flow, first, unscrew the blind nut (Item 3) and loosen the M36 nut (Item 4). This will release the throttle screws, allowing them to be adjusted.

- Increasing Flow: To increase the flow, turn the throttle screw counterclockwise. This will allow more fluid to pass through the valve.

- Decreasing Flow: To decrease the flow, turn the throttle screw clockwise, reducing the amount of fluid passing through.

- Securing the Adjustment: After adjusting the screws, tighten the M36 nut and blind nut to secure the position of the screws, ensuring there are no leaks.

Our Custom Solution

Based on the client’s specific needs, we designed custom throttle valves that met all of their functional and material requirements. These valves ensure optimal flow control and are built to withstand the client’s operational conditions, including managing high pressures and ensuring leak-free performance.

Need Custom Valve Solutions?

At THINKTANK, we are experts in providing customized valve solutions for a wide range of industrial applications. If you’re in need of throttle valves or any other specialized valve products, we can help you design and manufacture a solution meet to your exact specifications.

Feel free to contact us for more details or to discuss your specific needs. We look forward to helping you optimize your systems with high-quality, precision-engineered valve solutions.