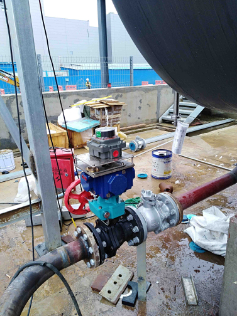

Looking to expand your knowledge of fusible link valves? Here is the right place, this post will approach you with everything you need to know about the fusible safety valves, what is fusible link valve, and what’s the purpose. how they work, where they work for. Before learning you can review part of our project pictures as the following.

The Main Function Of Fusible Link Valves:

Fusible link safety shutoff valves are designed to automatically shut off flammable gases or liquids, solvents, alcohol, toxic liquids, or any other potentially hazardous media when the ambient temperature reaches a set value. In the event of a fire, the fuse of the automatic thermal shut-off device will automatically separate when it reaches a preset value, and then drive the actuator of the valve to close the valve(FC/NO) or open the valve(FO/NC).

The fusible link valve has different temperature settings, which can be freely selected according to the actual situation of the project. Generally, the set temperature of the fuse ball valve should be greater than the ambient temperature by 30°C. It is an ideal choice in the import and export system of flammable storage tanks. In addition, the fuse valve can be reused by simply replacing the broken fuse online during use, thereby reducing the cost of use.

The Fusible Link Oil Shut-Off Valve is a safety device that is designed to prevent fires resulting from oil spills in industrial or commercial applications. It features a heat-sensitive fusible link that will melt when a fire occurs, thus closing the valve and shutting off the oil supply to the fire source.

This valve can be installed in a wide range of applications, including generators, boilers, transformers, and more. It is made of durable materials that can withstand harsh environments and extreme conditions, ensuring long-lasting performance and reliability.

The Fusible Link Oil Shut-Off Valve is easy to install, maintain, and operate, making it an ideal solution for those seeking to improve their safety measures and reduce the risk of fire incidents. It is also available in various sizes and configurations to meet the specific needs and requirements of different applications.

Fusible link valve also called fire fuse valve, high-Temperature fusible valve, emergency shut-off valve, safety shut-off valve, fusible link safety shutoff valves, fire safe ball valve with automatic thermal shut-off device, fire-safe ball valve with automatic thermal shut-off device, fire-safe butterfly valves with automatic thermal shut-off device, thermal electrical shutoff valves.

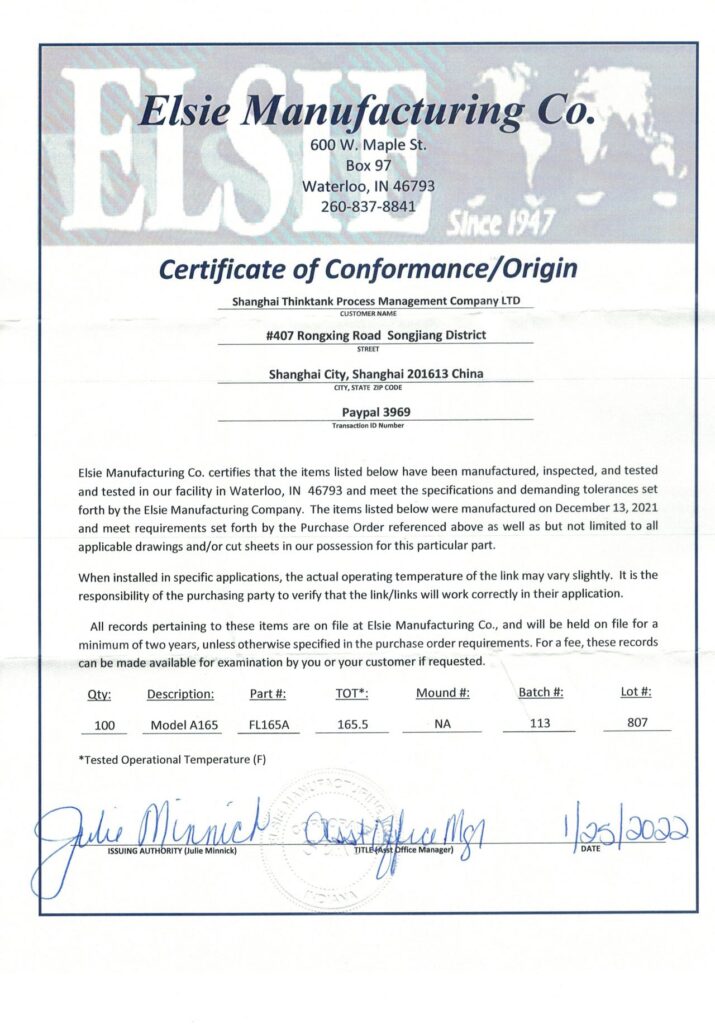

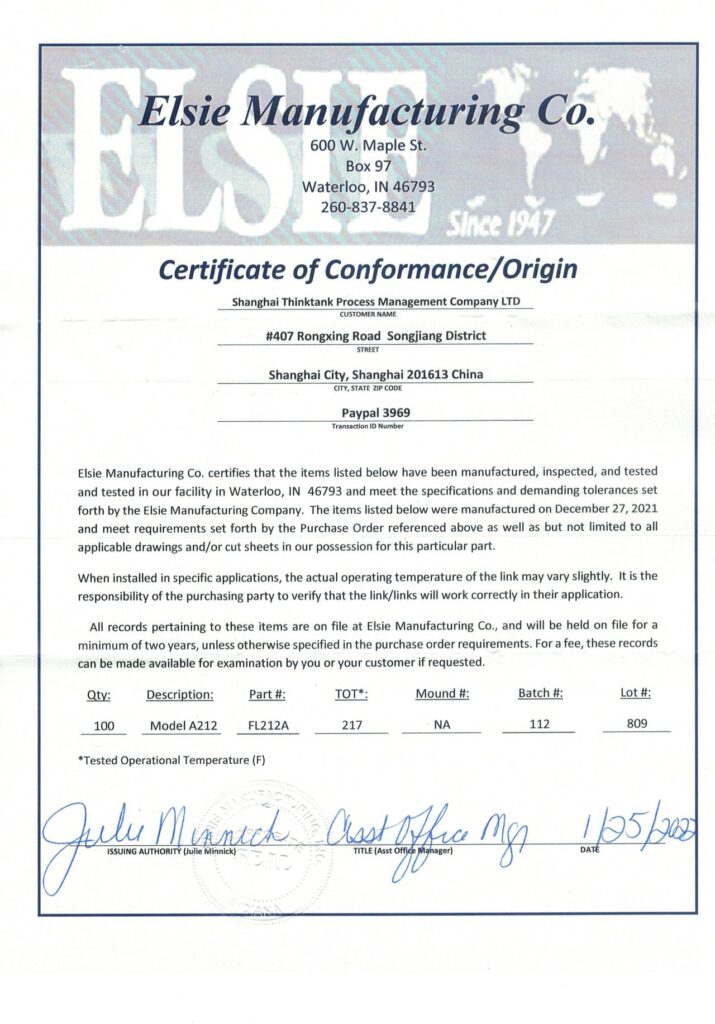

Fusible link certificates from the USA, which we imported from Elsie Manufacturing Company.

Case 1: Emergency Shut-Off Valve Is Used In Methanol Condition

The methanol emergency shut-off valve is a mechanical automatic reset safety protection device that uses a fused alloy chip to lock the spring force. When the ambient temperature reaches 100°C, the alloy dissolves, and the spring force expands to push the spool to close quickly. Widely used in combustible gas/liquid storage tanks and mechanical equipment, applications such as gas stations, oil depots, storage tanks, natural gas, liquefied gas, coal gas, methanol, toluene, biogas, liquid ammonia, ammonia, and fire protection facilities.

Valve Model:FSV

Size: DN15~DN100

Structure Type: Normally Open

Body Material: A216Gr WCB, CF8/304, CF8M/316

Pressure Rating: PN1.6MPa, PN2.5MPa, PN4.0MPa

Suitable Temperature: -50/+80℃

Application Range: Gas, Oil, Methanol, Toluene, Liquefied gas

Product Features: Fireproof and Anti-static

Case 2: Fusible Link Valve For Fire Protection System

Valve model: FSV

Size: DN15~DN200

Structure: Normally open/FC

Body material: carbon steel, stainless steel, brass, aluminum alloy

Nominal pressure: PN1.0MPa ~ PN10.0MPa

Applicable temperature: -30/+120℃, -50/+120℃

Application scope: oil depot, gas station, storage tank equipment

Product features: fireproof and anti-static, when the ambient temperature ≥75±5℃ valve will self-disconnect and shut off.

Fire safety fusable link valve-the fire safety ball valve with automatic thermal shutdown device (Thermal Shut-Off Valves), also known as fire cut-off valve, fire fuse valve, high-temperature fuse valve, without a power supply or air source. It’s s a kind of fire safety fire protection, the device is designed to automatically close the valve in the event of a high temperature or fire. The product has high-quality ball valves with API 607 fire protection certification.

Case 3: Fusible Link Valve For Gas Station

Installation Of Fusible Link Valve (NPT ends) For Gas Station

Step 1. Clamp the inlet end of part of the valve and tighten it on the inlet pipe

Step 2. Use U-shaped bolts or 3-M10 bolts to clamp the emergency shut-off valve to the base

Step 3. Connect the outlet end of the valve to the tanker pipeline: use a wrench to clamp on the octagonal surface of the outlet end of the valve to keep it, otherwise, the shear ring will be broken. Use another wrench to tighten the tanker pipe to be connected.

Note: Do not wrap PTFE tape on the threads, but apply a small amount of gasoline-resistant thread sealant to the pipe head. In order to avoid screwing the valve body, do not over-tighten when tightening. The recommended torque is 180N.m. (The recommended torque for tightening the test thread is 52N.m)

The emergency shut-off valve fastening device must be able to withstand a torque greater than 900N.m applied to each valve, the shear ring must be on the same level as the surface of the connecting foundation, and the height difference between the upper and lower sides must not be greater than 13mm. The fusible link valve is a necessary part of the machine, the user needs to construct it according to the foundation drawing provided by the main engine factory of the submersible pump tanker and strictly controls the relevant dimensions.

ATEX & PED Certificate for Fusible Link Valve

Disposal Of The Fusible Link Valve After Fire Or Damage:

The valve is damaged or closed due to fire or vibration. Check whether the valve body is in good condition. Even if it is slightly damaged, please replace it immediately. In any case, before the valve is put into service again, the entire top of the connection and the top sealing ring should be replaced, and the valve must be retested.

Method of Replacing the Top Device:

- Turn off the fuel dispenser and pump power

- Manually turn off the valve and drain system

- Remove 3 bolts, and remove the pipe from the top of the valve

- Remove the damaged top part

- Remove the old seal

- Install a new seal and a new top device

- Install the 3 bolts and tighten the top device

- Then install the pipes and accessories

- Turn on the tanker and pump power to test whether the system is leaking.

Case 4: Tank Fusible Link Valves

The storage tank fusible link valve is installed on the oil storage tank inlet and outlet pipelines. When the tanker collapses or catches fire accidents, it can automatically and quickly cut off the oil flow. When the storage tank’s ambient temperature reaches a certain value or the fire reaches a certain temperature, the fuse ring of the fusible link valve melts and the valve closes automatically. It does not require an electric/pneumatic actuator to drive the valve.

This kind of structure of the fire blocking valve has a simple structure, ingenious design, and reasonable layout. Its unique structure can automatically trigger a series of mechanism actions after the ambient temperature reaches a certain range, and rely on the mechanical energy (spring elastic potential energy) used as the power source to realize the closing operation of the valve, thereby realizing the purpose of automatically cutting off the medium delivery in a short time. Installing this kind of fire blocking valve on a storage tank containing a flammable and explosive flame-retardant barrier can automatically react in a short time and reduce the output of combustible media as much as possible, thereby contributing to fire control in the event of an accident. Therefore, it can be said that it has many advantages and is particularly suitable for popularization and application in this field, and its market prospect is very broad.

Storage Tank Fusible Valve Features:

- It can automatically cut off in case of fire.

- The fusible link temperature ratings are 165°F (74°C)-360°F (182°C) optional.

- The materials can be made of carbon steel, stainless steel, or fluorine lining.

- The valve body has a ball valve and a butterfly valve

- Connection method: ball valve(thread, welding, flange). Butterfly (valve/wafer, lug, flange)

- Application medium: ammonia, fuel gas, liquefied gas, methanol, oil, combustible gas/liquid

- 304 Stainless steel parts are used to ensure cleanliness during oil transportation and improve corrosion resistance.

Case 5: The Fusible Link Valve Is Used In The Storage Oil Tank

The oil tank fusible link valve is installed on the inlet and outlet pipelines of the flammable storage tank. When the ambient temperature reaches the set value or the fire reaches the set temperature, the fusible link valve can automatically and quickly cut off the valve that closes the pipeline medium. The fusible link valve does not require power or air supply, and it can be automatic close.

How Does The Fusible Link Valve Work In The Oil Tank Application?

Oil tank fusible valves are usually installed on the outlet and inlet of oil tanks or flammable liquid storage tanks. When the ambient temperature of the fusible link valve reaches the set temperature of the fuse link, the flux on the fuse link begins to melt and break, then the fusible link valve starts to drive the valve action under the action of the preload of the return spring, and to make the valve open or close, so as to open or cut off the medium in the valve and achieve fire prevention purposes. There is a fusible ring in the fusible link valve, when the ambient temperature reaches a certain value or the fire reaches a certain temperature, the valve fuse ring will fuse and the valve will automatically close. It does not require an electric/pneumatic actuator to drive the valve.

Fusible link technology was first used for fire protection, particularly for shutting off fuel sources such as oil and gas in the event of a fire. The concept was developed in the early 20th century and has since been widely adopted in various industries and applications to improve safety measures and prevent fires from spreading.

Characteristics Of Oil Tank Fusible Valve

- No need for electric or pneumatic actuator control, and it’s cut off completely mechanically by thermal.

- Pure mechanical control design (applicable to all flammable liquids and gases such as liquefied hydrocarbons in oil tanks).

- The device can be operated remotely and has a signal sensor function.

- Mechanical principle design, no need for manual operation or external force to close the system, the fire itself can trigger the automatic shutdown of the device, safe and reliable.

- According to the requirements of the working conditions, the range of 74 to 200℃ can be customized to close or open.

Technical Parameter:

- Material: cast iron, stainless steel

- Connection: flange, thread

- Size: DN15 to DN200

- Working pressure: 1.6MPa, 2.5MPa, 150LB

- Working temperature: -20~200℃

- Cut-off temperature: 75℃±5℃,

Applicable medium: aviation kerosene, gasoline, diesel, methanol flammable liquid, etc.

Case 6: The Fusible Link Valve Is Used In The Diesel Generator Set

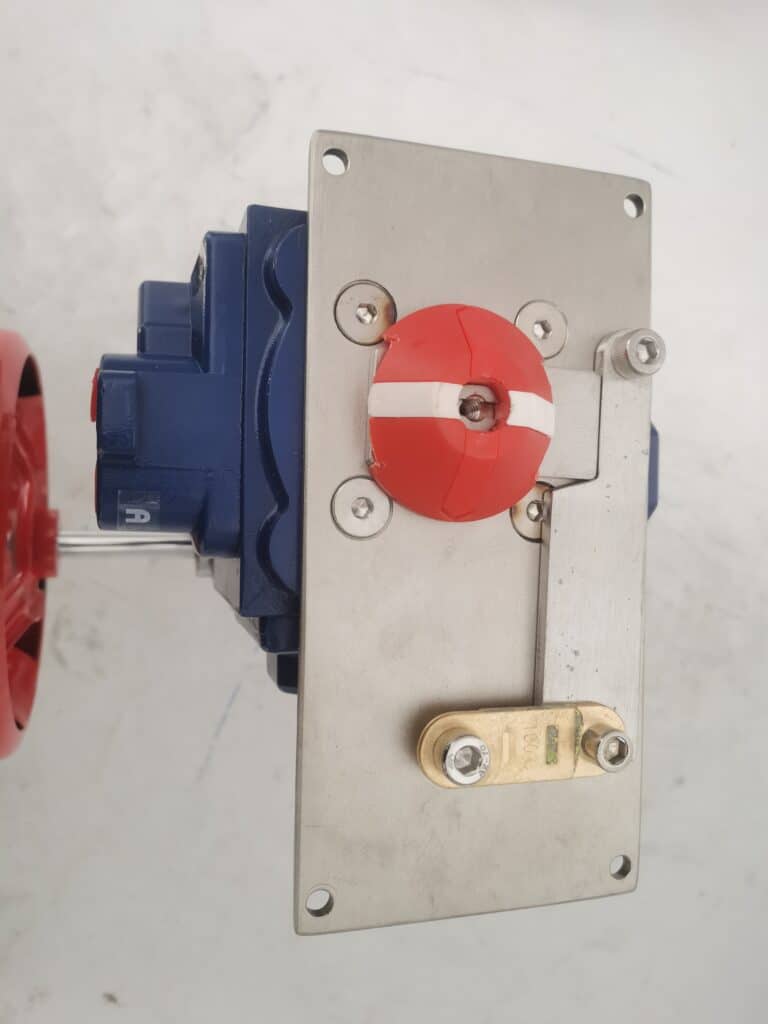

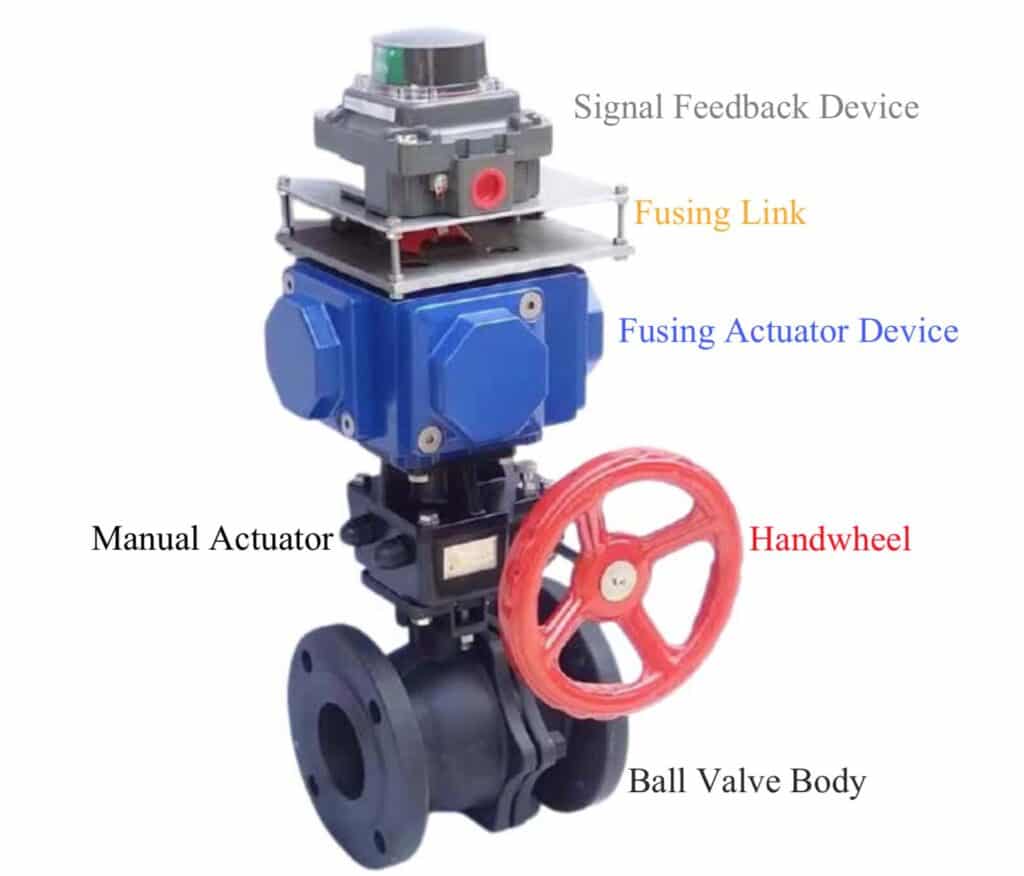

The fusible link valve of a diesel generator set includes a valve body and an actuator. The valve body and the actuator are fixed by a fixed bracket. The actuator includes a shaft, a fuse actuator, a manual(handwheel), an actuator protection cover, and a signal feedback device. The fuse valve can be reused as long as the broken fuse is replaced during use, thereby reducing the use cost.

Many diesel generator sets still generally use manual shut-off valves, and electric or pneumatic shut-off valves. However, the control methods of these valves prevent the operators from being able to close the valves quickly in emergencies during fires, explosions, and other accidents. The shut-off valve cannot be approached due to the harsh conditions at the accident site, so the function of the electric or pneumatic shut-off valve system is damaged. When the coil of the shut-off valve is accidentally charged, the automatic shut-off valve will open automatically, making it can’t to cut off the pipeline. Therefore, the leakage of flammable gas or liquid, solvent, methanol, toxic liquid, or any other potentially dangerous medium may cause a certain amount of personal injury to the person who performs the closing action or cause the failure to close the pipeline in time to further expand the accident.

Fusible Link Valve Features:

- It can automatically cut off in case of fire.

- The fusing temperature is 165°F (74°C) to 360°F (182°C) for optional.

- The materials can be made of carbon steel, stainless steel, or fluorine lining.

- The valve body has a ball and a butterfly type for optional.

- Connection method: ball valve/thread, welding, flange. Butterfly valve/wafer, lug, flange.

- Application medium: ammonia, fuel gas, liquefied gas, methanol, oil, combustible gas/liquid.

- 304 stainless steel parts are used to ensure the cleanliness of oil transportation and improve corrosion resistance.

How To Re-installation of The Fusible Link Valve?

Fusible Link Valve Installation Guide

Fusible Link With Gearbox

When the customer received the fusible link valves, you can re-installation these valves refer to the below guide.

- Remove the 4 screws on top of the actuator.

- Take the limit switch and bracket down.

- Lifting the button on the gear operation, and locking up the handwheel manual.

- Lose the fusible link screws on the top of the bracket, and remove the safety links.

- Use the gear operation to open the valve.

- Screw the fusible link and safety links on the top of the actuator.

- Put the handwheel manual down and put the bottom down.

Fusible Link With Gearbox

- Remove the 4 screws on top of the actuator.

- Take the limit switch and bracket down.

- Lose the fusible link screws on the top of the bracket, and remove the safety links.

- Screw the fusible link and safety links on the top of the actuator.

standard for marine manually operated shutoff valves for flammable liquids online

Emergency Shut-Off Valves (ESV) are valves that are designed to protect critical equipment, the environment, and the vessel crew from harm. They are actuated valves that can quickly stop the flow of flammable fluid in response to a dangerous event. The valves can be actuated remotely from a safe location, ensuring the safety of personnel while also preventing further harm.

Per ABS Marine Vessel Rules 2020, Part 4, Chapter 6, Section 4 – 13.5.3(a) “Every fuel oil pipe emanating from any oil tank, which, if damaged, would allow fuel oil to escape from the tank, is to be provided with a positive closing valve. The valve is to be secured directly on the tank. A short length of extra strong pipe (sch. 80) connecting the valve to the tank is also acceptable. The valve is not to be of cast iron, although the use of nodular cast iron is permissible. The positive closing valve is to be provided with the means of closure both locally and from a readily accessible and safe position outside of the space. In the event that the capacity of the tank is less than 500 liters (132 US gallons), this remote means of closure may be omitted.”

For US flagged vessels emergency shut-off valves are required to be installed in piping connections subject to head pressure on hydraulic oil, lube oil, or fuel tanks. 46 CFR 56.50-60 requires “Valves installed on the outside of the oil tanks must be made of steel, ductile cast iron ASTM A395, or a ductile nonferrous alloy having a melting point above 1,700 deg F and must be arranged with a means of manual control locally at the valve and remotely from a readily accessible and safe location outside of the compartment in which the valves are located.”

Fusible Link Valves Information

Technical Parameters For Fusible Link Fuel Shut-off Valve

Medium: Gas, Liquefied Gas, Petroleum, Chemicals, Water, Foam

Fusing Temperature: 57 Celsius degrees, 74 Celsius degrees, 100 Celsius degrees, 141 Celsius degrees.

Pressure: 0.01-1.6Mpa, 0.01-2.5Mpa, 0.01-2.0Mpa

Failure Position: Valve Close, Valve Open

Body Type: Ball Type, Butterfly Type

Options Accessories: Gear Operator, Signal Feedback Limit Switch, Handle.

THINKTANK’s Fusible Link Valves meet for UL33 Certifications.

- Fire-Safe to API 607

- Materials: SS304, SS316, SS316L, A216WCB

- Link: U.L. listed Thermal, Electro-thermal

- Port: Full Port

- Line Size: ½”, ¾”, 1″, 1¼”, 1½”, 2″(DN15 to DN50)

- End Connections: NPT, Socket Weld, Butt Weld

- U. L. Listed Thermal Link Temp: 165° F (74° C), 212° F (100° C), 286° F (141° C), 360° F (182° C), 500° F (260° C)

THINKTANK’s Fusible Link Ball Valves Flange meet for UL33 Certifications.

- Fire-Safe to API 607

- Materials: S304, SS316, SS316L, A216WCB

- Port: Full Port

- Line Size: 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″, 6″ (DN15 to DN150)

- End Connections: 150 Lb ANSI Flange

- U. L. Listed Thermal Link Temp: 165° F (74° C), 212° F (100° C), 286° F (141° C), 360° F (182° C)

THINKTANK’s Fusible Link Butterfly Valves Flange meet for UL33 Certifications.

- Fire-Safe to API 607

- Materials: S304, SS316, SS316L, A216WCB

- Line Size: 2″, 2 1/2″, 3″, 4″, 6″, 8″, 10″, 12″ (DN50 to DN300)

- End Connections: 150LB Wafer, 150LB Lugged

- U. L. Listed Thermal Link Temp: 165° F (74° C), 212° F (100° C), 286° F (141° C), 360° F (182° C), 500° F (260° C)

Typical Applications

- In the petroleum industry, flammable gas or fluid is transported in pipelines to control combustible medium.

- Emergency cut off the pipeline in the fire to prevent the accident from escalating.

- In the event of a fire, open the fire sprinkler system to extinguish the fire in time.

If you are interested in more information about the fusible link fuel shut-off valve, fusible link valve Singapore, fusible link valve symbol, fusible link ball valve, fusible link ball valve, fusible link valve operation, and 2” fusible link oil safety valves, welcome to send your requirements to our email, [email protected] or WhatsApp +86 185 1656 9221

Final Thoughts

Fusible link valves aren’t complicated as control valves, but it is so important due to their application, we make sure every valve has a fire-safe function, and the fusible link should be verified. THINKTANK supplies fusible link safety valves for many distributors, and they have no worries about the valve quality, delivery time, affordable costs, and reliable performance. Just feel free to contact us if you are working in this niche market, and we believe we can create more value together.

Looking to learn more about Fire Safe Fusible Link Shut Off Valve? Read this.