Duplex stainless steel is a stainless steel in which the ferrite phase and the austenite phase each account for half of its solid-quenched structure, and the minimum phase content is generally 30%. Duplex stainless steel is formed on the basis of 18-8 austenitic stainless steel by increasing the content of Cr or adding other ferrite elements. It not only has austenite plus ferrite bidirectional structure, but also saves Ni alloy. Due to the characteristics of the two-phase structure of duplex stainless steel, through correct control of chemical composition and heat treatment process, duplex stainless steel can have the advantages of ferritic stainless steel and austenitic stainless steel. Due to the presence of austenite, duplex stainless steel reduces the brittleness of high-Cr ferrite and the tendency of crystal growth, while maintaining excellent toughness and welding performance; while the presence of ferrite increases the yield of austenite Strength, resistance to intergranular corrosion, and chloride stress corrosion resistance.

1. Compared with 316L and 317L austenitic stainless steel, duplex stainless steel 2205 alloy has superior performance in pitting corrosion and crevice corrosion. It has high corrosion resistance. Compared with austenite, The coefficient of thermal expansion is lower and the thermal conductivity is higher.

2. Compared with austenitic stainless steel, duplex stainless steel 2205 alloy has twice its compressive strength. Compared with 316L and 317L, the designer can reduce its weight. Alloy 2205 is especially suitable for the temperature range of -50°F to +600°F. Under strict restrictions (especially for welded structures), it can also be used at lower temperatures.

3. Chemical composition: C≤0.030 Mn≤2.00 Si≤1.00 P≤0.030 S≤0.020 Cr 22.0~23.0 Ni 4.5~6.5 Mo3.0~3.5 N0.14~0.20 (austenite-ferrite type).

UNS: Duplex S31803, Super Duplex S32205, Super Duplex S32750, Super Duplex S32760

EN: 1.4462 ASTM: A240, A276, A479, A789, A790, A182 (Grade F51), A923

CD4MCu, CD4MCuN, CD3MCuN, CE8MN, CD6MN, CD3MN, CE3MN, CD3MWCuN

ASME: SA -240, SA – 479, SA – 789, SA -790, SA -182 (Grade F51), F53, F55, F60, Pgroup 10H NACE: ISO 15156 / MRO175

Design standards: API, ASME, EN, ISO, JIS, DIN, BS, GB

End to End: Flange, Threaded, SW/BW

Pressure Rating: CIass150-2500Lb, 1.0-42.0MPa, JIS10K~40K

Size range: NPS3/8 “-32”, DN10-DN800

Actuator: Pneumatic or Electrica Actuator, Handle, Gear Operation

Material: Duplex S31803, Super Duplex S32750, Super Duplex S32760

1A, 2A, 3A, 4A, 5A, 6A, 1B, 1C

CD4MCu, CD4MCuN, CD3MCuN, CE8MN, CD6MN, CD3MN, CE3MN, CD3MWCuN

F51, F53, F55, F60

Features:

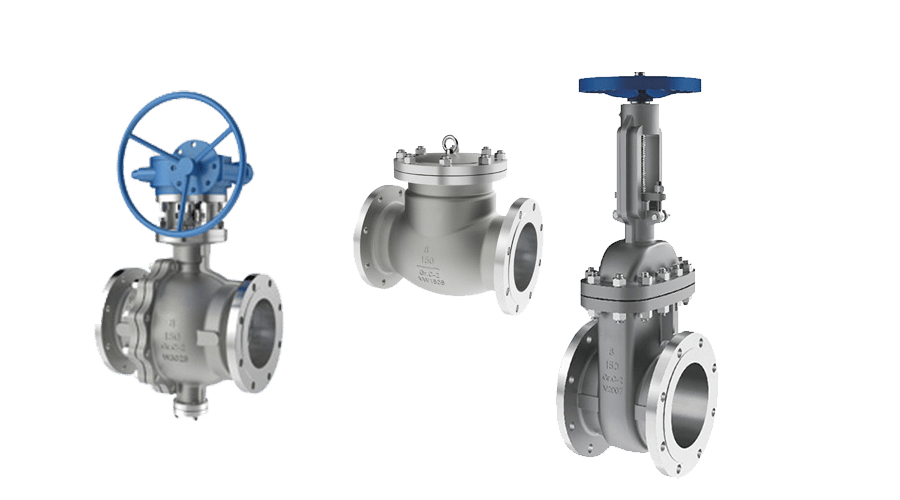

Duplex stainless steel ball valves are more and more popular used for high corrosion applications.

The duplex stainless steel ball valve is a ball-type on-off valve that uses a ball to control liquids. Due to raw material made of duplex stainless steel, so it has excellent performance of corrosion-resisitant. Also, the duplex steel ball valves are particularly resistant to not only chloride stress corrosion but also chloride pitting corrosion. Its PREN value of UNS S31803 is between 38 to 45.

The main application of duplex steel ball valves includes oil&gas, seawater desalination, shipbuilding, pharmaceutical, petroleum, chemical, and so on.

Duplex stainless steel ball valve is also known as S31803, S32205, A351 CD3MN, ASTM A182 F51 and 1.4470.

Design standards: API, ASME, EN, ISO, JIS, DIN, BS, GB

End to End: Flange, Threaded, SW/BW, Wafer

Pressure Rating: CIass150-2500Lb, 1.0-42.0MPa, JIS10K~40K

Size range: NPS1/2"~48",DN15~DN1200

Material: Duplex S31803, Super Duplex S32750, Super Duplex S32760

1A, 2A, 3A, 4A, 5A, 6A, 1B, 1C

CD4MCu, CD4MCuN, CD3MCuN, CE8MN, CD6MN, CD3MN, CE3MN, CD3MWCuN

F51, F53, F55, F60

Applications:

Neutral chloride environment\refining industry\petrochemical and chemical industry\chemical industry pipelines\oil and gas industry\pulp and paper industry\chemical fertilizer industry\urea industry\phosphate fertilizer industry\seawater environment\energy and environmental protection industry\light industry And food industry\food and pharmaceutical industry equipment\high-strength structure

The check valve is kind of a mechanical device used in pipeline systems. The main purpose of the check valve is to prevent fluid back-flow, and it allows fluid only in one way. That is why we called non-return valve or one-way valve.

The principle of the check valve is working on differential pressure, it means the check valve only opens if the inlet pressure is over the outlet pressure. In this situation, if the outlet pressure is higher than inlet pressure, the valve will be closed to preventing fluid back-flow. Also, the check valve can be closed by the hammer weight, or by spring, hydraulic, or cylinder actuator.

One of the key conditions of the check valve is at the pump downstream to protect the expensive and important equipment from flow reversal.

The check valves are very common to use for industrial pipelines. There are 4 types of check valves we are familiar in the site.

A swing check valve is the most widely used check valve. The closure is a disc swing on a hinge or shaft. When flow running, the disc swings off the seat and allows it to flow, and its swings back onto the seat when flow reverses to block the valve. At the opening position, the swing type check valve offers very little resistance to the flow. To achieve optimal performance, usually will use a lever and weight hammer or a lever with springs to quickly close the valve.

The most affect shutoff characteristics of swing type check valve are the disc weight and backflow, so how to make the disc fast response and close tight is all the design factor.

Lift Check valves are particularly suitable for high-pressure service where the velocity of flow is high. In lift Check valves, the disc is precisely guided and fits perfectly into the dashpot. Lift Check valves are suitable for installation in horizontal or vertical pipelines with upward flow.

A lift check valve is also called a piston check valve. It consists of a guided disc that lifts up from the valve seat and creating space for medium to flow. The inlet pressure must be more than the cracking pressure to overcome gravity or a spring force. The valve will close when the inlet pressure decreases below the cracking pressure or there is backpressure.

Dual plate check valves are wafer-type compact valves with a small overall length. They provide excellent hydrodynamic properties that result in very low-pressure losses and they are technically efficient. Their low weight provides advantages during installation, transport, and storage. Dual plate check valves are suitable for liquid, gas, steam, condensate, water supply, oil & natural gas services. With suitable springs, they can be installed in any position.

Nowadays dual plate check valves are widely used in Power Plants, Refineries, Chemical Plants, Wastewater Treatment Plants and Pulp & Paper Mills.

A nozzle check valve is a kind of non slam check valve, which is specifically designed for non slaming when valve closing and preventing excess pressure.

Usually, the non slam check valve is designed with an internal spring to opposing the opening flow pressure from upstream. When the inlet pressure is over the spring force then the valve opens. Again when upstream pressure decreases, the disc will be smoothly pushed back toward the valve seat by spring force.

The nozzle check valve is an ideal solution for complex or important application which requires constant and stable pressure process.

Design standards: API, ASME, EN, ISO, JIS, DIN, BS, GB

End to End: Flange, Threaded, SW/BW

Pressure Rating: CIass150-2500Lb, 1.0-42.0MPa, JIS10K~40K

Size range: NPS1/2"~48",DN15~DN1200

Material: Duplex S31803, Super Duplex S32750, Super Duplex S32760

Features:

Application:

Gate valve is a kind of on/off valve used in the pipe system. The closure component is a gate, that’s why called a gate valve. The gate valve includes a parallel gate valve, wedge gate valve, knife gate valve, and flat gate valve.

The gate valve has well cut-off or shut-off features. As designed to metal to metal seat, so its response to specific operating high-pressure and high-temperature application.

THINKTANK is a China-leading manufacturer of duplex steel valves, with a high performance of corrosion resistance and chloride stress corrosion resistance.

1. Gate valve is a linear type on/off valve, but the ball valve is a rotary type on/off valve.

2. Ball valve has excellent performance of tight sealing than gate valve, and are way less prone to leakage.

3. Ball valve has a longer service life and failure rate than the gate valve.

4. Gate valve is at lower costs than a ball valve.

Design standards: API, ASME, EN, ISO, JIS, DIN, BS, GB

End to End: Flange, Threaded, SW/BW

Pressure Rating: CIass150-2500Lb, 1.0-42.0MPa, JIS10K~40K

Size range: NPS1/2"~48",DN15~DN1200

Material: Duplex S31803, Super Duplex S32750, Super Duplex S32760

Features:

Globe Valve Body Patterns:

The globe valve is most commonly used to open, close, or throttle flow rate in the industrial process.

Its comprised of two halves, Globe valve is a linear motion valve and is primarily designed to stop, start and regulate flow.

Globe valves are named for their spherical body shape with the two halves of the body being separated by an internal baffle.

There are three basic globe valve body designs: Tee type, angle type, and Y type.

The principal variation in Globe-valve design is in the types of discs employed. Plug-type discs have a long, tapered configuration with a wide bearing surface. This type of seat provides maximum resistance to the erosive action of the fluid stream. In the composition disc, the disc has a flat face that is pressed against the seat opening like a cap. This type of seat arrangement is not as suitable for high differential pressure throttling.

Maintenance of Globe valves is relatively easy, as the discs and seats are readily refurbished or replaced. This makes Globe valves particularly suitable for services that require frequent valve maintenance. Where valves are operated manually, the shorter disc travel offers advantages in saving operator time, especially if the valves are adjusted frequently.

THINKTANK is a China-leading manufacturer of duplex steel valves, with a high performance of corrosion resistance and chloride stress corrosion resistance.

Design standards: API, ASME, EN, ISO, JIS, DIN, BS, GB

End to End: Flange, Wafer, Lug

Pressure Rating: CIass150-2500Lb, 1.0-42.0MPa, JIS10K~40K

Size range: NPS1/2"~48",DN15~DN1200

Material: Duplex S31803, Super Duplex S32750, Super Duplex S32760

Application:

Design standards: API, ASME, EN, ISO, JIS, DIN, BS, GB

End to End: Flange, Wafer, Lug

Pressure Rating: CIass150-2500Lb, 1.0-42.0MPa, JIS10K~40K

Size range: NPS1/2"~48",DN15~DN1200

Material: Duplex S31803, Super Duplex S32750, Super Duplex S32760

Application:

Design standards: API, ASME, EN, ISO, JIS, DIN, BS, GB

End to End: Flange

Pressure Rating: CIass150-2500Lb, 1.0-42.0MPa, JIS10K~40K

Size range: NPS1/2"~48",DN15~DN1200

Material: Duplex S31803, Super Duplex S32750, Super Duplex S32760

Application:

The desalination process, especially the seawater reverse osmosis system(SWRO), requires a large number of valves that can treat large amounts of water under high pressure. These valves must also be made of materials that are resistant to corrosion by chloride-rich water and common chemicals. THINKTANK provides a full range of valves to suit various applications in seawater desalination.

1. Duplex steel 2205/2507, Titanium(Ti) High-performance butterfly valves

2. Duplex and super duplex stainless steel triple offset butterfly control valves

3. Duplex and super duplex stainless steel globe type control valves

4. Duplex and super duplex stainless steel check valves

5. Duplex and super duplex stainless steel plug valves

6. Duplex and aluminum bronze self-operated pressure regulators

7. Duplex and super duplex stainless steel ball valves

There are many different methods of desalination, the common two methods are reverse osmosis and multi-stage flashing. Reverse osmosis (RO) desalination forces water through a semipermeable membrane at high pressures to remove salt and other impurities. And multi-stage flashing (MSF) is processes flash water (boils by means of pressure reduction) over several stages to separate freshwater from concentrated brine. Both of these two methods will challenge our valves should meet corrosive environment, high salinity media, and cavitation.

Desalination plants are typically located offshore places where the air can be very humid and corrosive. THINKTANK provides many options for special materials and surface treatments to protect equipment, even in the harshest conditions.

THINKTANK offers Titanium valves, Nickel valves, Monel valves, Hastelloy valves, Inconel valves, Duplex valves, Zirconium valves, Tantalum valves, Super Austenitic valves, NAB C95800 valves, and Stainless steel valves to anti-corrosion of seawater.

Just leave your name, email, and simple message or requirements, We will contact you within 1 hour.

WhatsApp: +86 199 2125 0077

Skype ID: sowell85

Wechat ID: +86 199 2125 0077

Avoid your inquiry is delay response, please enter your WhatsApp/Wechat/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 185 1656 9221, or WeChat: +86 199 2125 0077. or call +86 189 5813 8289 directly.

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 199 2125 0077, or WeChat: +86 199 2125 0077. Or call +86 189 5813 8289 directly.