| Design | ASME B16.34/AP|600 |

| Face to Face | ASME B16.10 |

| End to End | ASME B16.10 |

| End Flange | ASME B16.5/B16.47 |

| BW End | ASME B16.25 |

| Test | API 598 |

| Specia | NACE MR-01-75 |

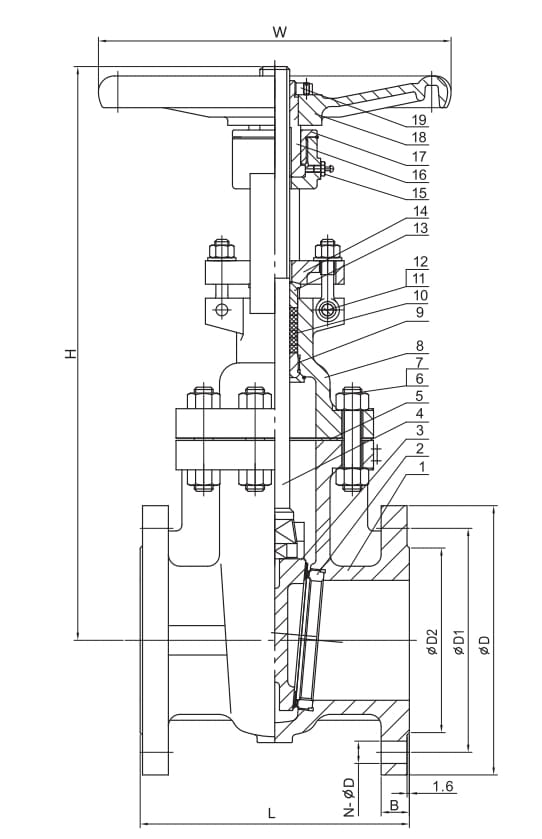

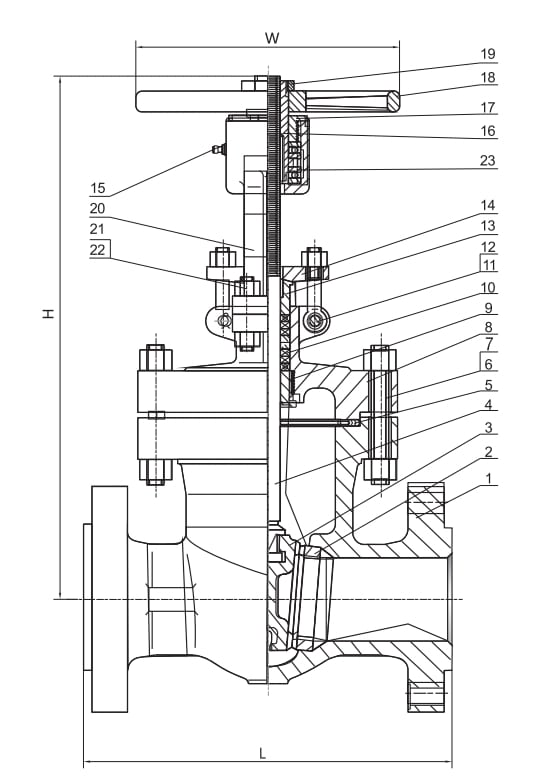

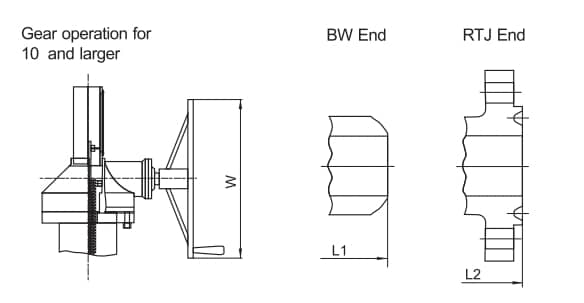

| NO. | Parts Name | Material | |||||||||||||||||||||

| 1 | Body | ASTM A216 GR.WCB | |||||||||||||||||||||

| 2 | Seat Ring | ASTM A105+Stellite Faced | |||||||||||||||||||||

| 3 | Disc | ASTM A216 GR.WCB+13Cr Faced | |||||||||||||||||||||

| 4 | Stem | ASTM A182 GR.F6 | |||||||||||||||||||||

| 5 | Gasket | Soft Iron+Graphite | |||||||||||||||||||||

| 6 | Bonnet Bolts | ASTM A193 GR.B7 | |||||||||||||||||||||

| 7 | Bonnet Bolt Nuts | ASTM A194 GR.2H | |||||||||||||||||||||

| 8 | Bonnet | ASTM A216 GR.WCB | |||||||||||||||||||||

| 9 | Backseat Bushing | ASTM A276 Type 410 | |||||||||||||||||||||

| 10 | Stem Packing | Braided Graphite & Die formed Graphite Ring | |||||||||||||||||||||

| 11 | Eye Bolt Pins | Carbon Steel | |||||||||||||||||||||

| 12 | Gland Eye Bolts | ASTM A307 GR.B | |||||||||||||||||||||

| 13 | Gland | ASTM A276 Type 410 | |||||||||||||||||||||

| 14 | Gland Flange | ASTM A216 GR.WCB | |||||||||||||||||||||

| 15 | Grease Nipple | Carbon Stee | |||||||||||||||||||||

| 16 | Stem Nut | ASTM A439 GR.D-2 | |||||||||||||||||||||

| 17 | Retaining Nut | Carbon Stee | |||||||||||||||||||||

| 18 | Handwhee | Ductile Iro | |||||||||||||||||||||

| 19 | Handwheel Nut | Carbon Stee | |||||||||||||||||||||

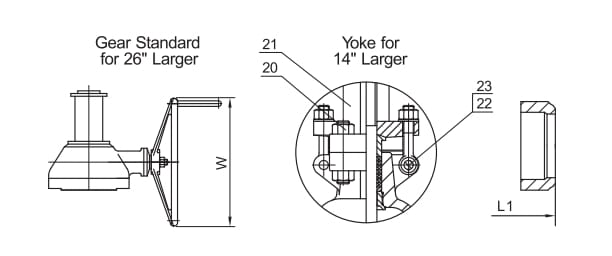

| 20 | Screw | Carbon Steel | |||||||||||||||||||||

| 21 | Yoke | ASTM A216 GR.WCB | |||||||||||||||||||||

| 22 | Yoke Pan Bolt Nuts | ASTM A194 GR.2H | |||||||||||||||||||||

| 23 | Yoke Pan Bolts | ASTM A193 GR.B7 | |||||||||||||||||||||

| Size | in mm | 2 50 | 2.5 65 | 3 80 | 4 100 | 6 150 | 8 200 | 10 250 | 12 300 | 14 350 |

| L/L1 | in mm | 8.50 216 | 9.50 241 | 11.12 283 | 12.00 305 | 15.88 403 | 16.50 419 | 18.00 457 | 19.75 502 | 30.00 762 |

| H | in mm | 14.33 364 | 15.16 385 | 18.11 460 | 21.26 540 | 25.55 649 | 31.42 798 | 37.01 940 | 44.45 1129 | 47.05 1195 |

| W | in mm | 8 200 | 8 200 | 10 250 | 11 280 | 14 350 | 16 400 | 18 450 | 20 500 | 24 600 |

| Weight RF | Kg | 26 | 36 | 55 | 67 | 147 | 228 | 332 | 512 | 715 |

| Size | in mm | 16 400 | 18 450 | 20 500 | 24 600 | 26 650 | 28 700 | 30 750 | 32 800 | 36 900 |

| L/L1 | in mm | 33.00 838 | 36.00 914 | 39.00 991 | 45.00 1143 | 49.00 1245 | 53.00 1346 | 55.00 1397 | 60.00 1524 | 68.00 1727 |

| H | in mm | 52.76 1340 | 78.74 2000 | 85.63 2175 | 103.15 2620 | 112.20 2850 | 121.26 3080 | 125.20 3180 | 129.92 3300 | 148.03 3760 |

| W | in mm | 20 500 | 18 460 | 21 530 | 21 530 | 24 600 | 24 600 | 24 600 | 24 600 | 24 600 |

| Weight RF | Kg | 850 | 1224 | 1400 | 2385 | 3000 | 3300 | 3550 | 4400 | 6050 |

| Design | ASME B16.34/AP|600 |

| Face to Face | ASME B16.10 |

| End to End | ASME B16.10 |

| End Flange | ASME B16.5/B16.47 |

| BW End | ASME B16.25 |

| Test | API 598 |

| Specia | NACE MR-01-75 |

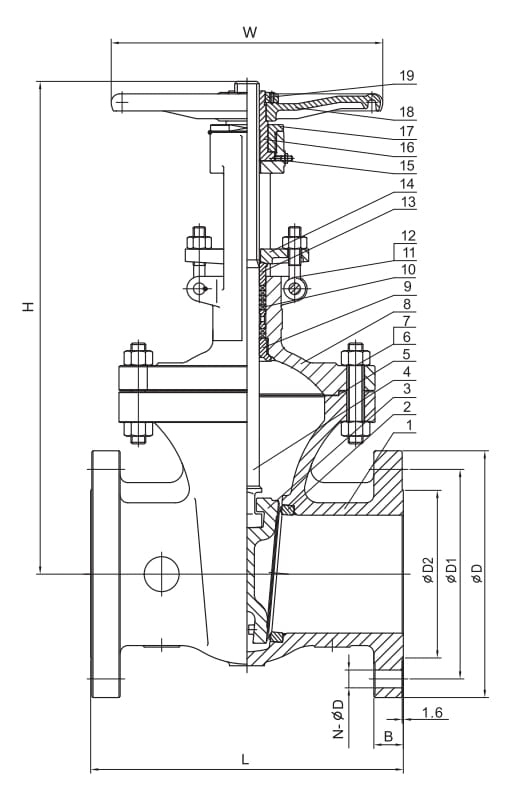

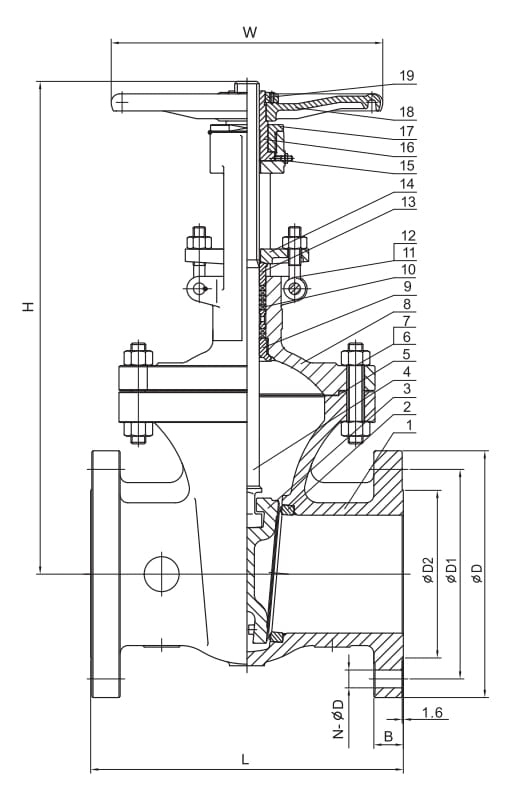

| NO. | Parts Name | Material | |||||||||||||||||||||

| 1 | Body | ASTM A216 GR.WCB | |||||||||||||||||||||

| 2 | Seat Ring | ASTM A105 +Stellite Faced | |||||||||||||||||||||

| 3 | Disc | ASTM A216 GR.WCB+13Cr Faced | |||||||||||||||||||||

| 4 | Stem | ASTM A182 GR.F6 | |||||||||||||||||||||

| 5 | Gasket | Soft Iron+Graphite | |||||||||||||||||||||

| 6 | Bonnet Bolt Nuts | ASIM A194GR.2H | |||||||||||||||||||||

| 7 | Bonnet Bolts | ASTM A193 GR.B7 | |||||||||||||||||||||

| 8 | Bonnet | ASTM A216 GR.WCB | |||||||||||||||||||||

| 9 | Backseat Bushing | ASTM A276 Type 410 | |||||||||||||||||||||

| 10 | Stem Packing | Braided Graphite & Die-formed Graphite Ring | |||||||||||||||||||||

| 11 | Eye Bolt Pins | Carbon Steel | |||||||||||||||||||||

| 12 | Gland Eye Bolts | ASTM A307 GR.B | |||||||||||||||||||||

| 13 | Gland | ASTM A276 Type 410 | |||||||||||||||||||||

| 14 | Gland Flange | ASTM A216 GR.WCB | |||||||||||||||||||||

| 15 | Grease Nipple | Carbon Stee | |||||||||||||||||||||

| 16 | Stem Nut | ASTM A439 GR.D-2 | |||||||||||||||||||||

| 17 | Retaining Nut | Carbon Steel | |||||||||||||||||||||

| 18 | Handwheel | Ductile Iron | |||||||||||||||||||||

| 19 | Handwheel Nut | Carbon Steel | |||||||||||||||||||||

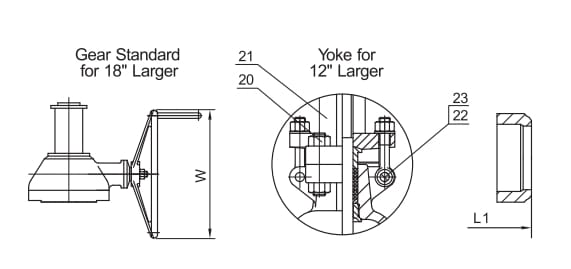

| 20 | Screw | Carbon Steel | |||||||||||||||||||||

| 21 | Yoke | ASTM A216 GR.WCB | |||||||||||||||||||||

| 22 | Yoke Pan Bolt Nuts | ASTM A194 GR.2H | |||||||||||||||||||||

| 23 | Yoke Pan Bolts | ASTM A193 GR.B7 | |||||||||||||||||||||

| Size | in mm | 2 50 | 3 80 | 4 100 | 6 150 | 8 200 | 10 250 | 12 300 | 14 350 |

| L/L1 | in mm | 8.50 216 | 11.12 283 | 12.00 305 | 15.88 403 | 16.50 419 | 18.00 457 | 19.75 502 | 30.00 762 |

| H | in mm | 14.33 364 | 18.11 460 | 21.26 540 | 25.55 649 | 31.42 798 | 37.01 940 | 44.45 1129 | 47.05 1195 |

| W | in mm | 8 200 | 10 250 | 11 280 | 14 350 | 16 400 | 18 450 | 20 500 | 24 600 |

| RF Ends Weight | Kg | 26 | 55 | 67 | 147 | 228 | 332 | 512 | 715 |

| Size | in mm | 16 400 | 18 450 | 20 500 | 24 600 | 26 650 | 28 700 | 30 750 | 32 800 | 36 900 |

| L/L1 | in mm | 33.00 838 | 36.00 914 | 39.00 991 | 45.00 1143 | 49.00 1245 | 53.00 1346 | 55.00 1397 | 60.00 1524 | 68.00 1727 |

| H | in mm | 52.76 1340 | 78.74 2000 | 85.63 2175 | 103.15 2620 | 112.20 2850 | 121.26 3080 | 125.20 3180 | 129.92 3300 | 148.03 3760 |

| W | in mm | 20 500 | 18 460 | 21 530 | 21 530 | 24 600 | 24 600 | 24 600 | 24 600 | 24 600 |

| RF Ends Weight | Kg | 850 | 1224 | 1400 | 2385 | 3000 | 3300 | 3550 | 4400 | 6050 |

| Design | ASME B16.34/AP|600 |

| Face to Face | ASME B16.10 |

| End to End | ASME B16.10 |

| End Flange | ASME B16.5/B16.47 |

| BW End | ASME B16.25 |

| Test | API 598 |

| Special | NACE MR-01-75 |

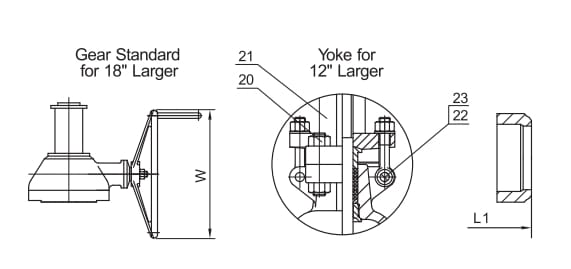

| NO. | Parts Name | Material |

| 1 | Body | ASTM A216 GR.WCB |

| 2 | Seat Ring | ASTM A105+Stellite Faced |

| 3 | Disc | ASTM A216 GR.WCB+13Cr Faced |

| 4 | Stem | ASTM A182 GR,F6 |

| 5 | Gasket, Ring Joint | SS316+Graphite |

| 6 | Bonnet Bolts | ASTMA193 GR.B7 |

| 7 | Bonnet Bolt Nuts | ASTM A194 GR.2H |

| 8 | Bonnet | ASTM A216 GR.WCB |

| 9 | Backseat Bushing | ASTM A276 Type 410 |

| 10 | Stem Packing | Braided Graphite & Die formed Graphite Ring |

| 11 | Eye Bolt Pins | Carbon Steel |

| 12 | Gland Eye Bolts | ASTM A307 GR.B |

| 13 | Gland | ASTM A276 Type 410 |

| 14 | Gland Flange | ASTM A216 GR.WCB |

| 15 | Grease Nipple | Carbon Steel |

| 16 | Stem Nut | ASTM A439 GR.D-2 |

| 17 | Retaining Nut | Carbon Stee |

| 18 | Handwheel | Ductile Iron |

| 19 | Handwheel Nut | Carbon Steel |

| 20 | Yoke | ASTM A216 GR.WCB |

| 21 | Yoke Pan Bolt Nuts | ASTM A194 GR.2H |

| 22 | Yoke Pan Bolts | ASTM A193 GR.B7 |

| 23 | Bearing | Steel |

| Size | in mm | 2 50 | 2.5 65 | 3 80 | 4 100 | 6 150 |

| L/L1 | in mm | 11.50 292 | 13.00 330 | 14.00 356 | 17.00 432 | 22.00 559 |

| L2 | in mm | 11.62 295 | 13.12 333 | 14.12 359 | 17.12 435 | 22.12 562 |

| H | in mm | 14.96 380 | 16.54 420 | 19.69 500 | 22.64 575 | 29.53 750 |

| W | in mm | 8 200 | 10 250 | 11 280 | 12 300 | 18 450 |

RF Ends Weight | KG | 37 | 50 | 82 | 142 | 245 |

| Size | in mm | 8 200 | 12 300 | 14 350 | 16 400 | 18 50 | 20 500 |

| L/L1 | in mm | 26.00 660 | 33.00 838 | 35.00 889 | 39.00 991 | 43.00 1092 | 47.00 1194 |

| L2 | in mm | 26.12 663 | 33.12 841 | 35.12 892 | 39.12 994 | 43.12 1095 | 47.25 1200 |

| H | in mm | 33.46 850 | 64.96 1650 | 68.90 1750 | 74.80 1900 | 79.53 2020 | 85.51 2172 |

| W | in mm | 20 500 | 18 460 | 21 530 | 21 530 | 24 600 | 24 600 |

| RF Ends Weight | KG | 423 | 893 | 1318 | 1720 | 1980 | 2460 |

| Design | ASME B16.34/AP|600 |

| Face to Face | ASME B16.10 |

| End to End | ASME B16.10 |

| End Flange | ASME B16.5/B16.47 |

| BW End | ASME B16.25 |

| Test | API 598 |

| Specia | NACE MR-01-75 |

| NO. | Parts Name | Material |

| 1 | Body | ASTM A216 WCB |

| 2 | Seat | ASTMA105+F6 |

| 3 | Wedge | ASTM A216 WCB+F6 |

| 4 | Stem | ASTM A182 F6 |

| 5 | Gasket | ASTM A182 F304 |

| 6 | Stud | ASTMA193 B7 |

| 7 | Nut | ASTM A1942H |

| 8 | Retained Ring | ASTM A105 |

| 9 | Bonnet | ASTM A216 WCB |

| 10 | Packing | Flexible graphite |

| 11 | Eyelet bolt | ASTM A193 B7 |

| 12 | Nut | ASTM A1942H |

| 13 | Gland | ASTM A105 |

| 14 | Gland Flange | ASTM A216 WCB |

| 15 | Stem nut | ASTM A439 GR.D2 |

| 16 | Stem Nut Retainer | ASTM A105 |

| 17 | Handwheel | Malleable Iron |

| 18 | Handwheel nut | ASTM A194 2H |

| Size | in mm | 2 50 | 2.5 65 | 3 80 | 4 100 | 6 150 | 8 200 | 10 250 | 12 300 |

| L/L1 | in mm | 14.50 368 | 16.50 419 | 15.00 381 | 18.00 457 | 24.00 610 | 29.00 737 | 33.00 838 | 38.00 965 |

| L2 | in mm | 14.62 371 | 16.62 422 | 15.12 384 | 18.12 460 | 24.12 613 | 29.12 740 | 33.12 841 | 38.12 968 |

| H | in mm | 20.00 500 | 18.00 450 | 20.00 505 | 22.64 575 | 31.30 795 | 40.00 1000 | 44.49 1130 | 60.00 1520 |

| W | in mm | 11 280 | 11 280 | 12 300 | 14 350 | 20 500 | 18 460 | 21 530 | 21 530 |

| RF Ends Weight | KG | 70 | 110 | 140 | 178 | 358 | 627 | 1100 | 1310 |

| Size | in mm | 2 50 | 2.5 65 | 3 80 | 4 100 | 6 150 | 8 200 | 10 250 | 12 300 |

| L/L1 | in mm | 14.50 368 | 16.50 419 | 18.50 470 | 21.50 546 | 27.75 705 | 32.75 832 | 39.00 991 | 44.50 1130 |

| L2 | in mm | 14.62 371 | 16.62 422 | 18.62 473 | 21.62 549 | 28.00 711 | 33.13 842 | 39.38 1000 | 45.12 1146 |

| H | in mm | 16.93 430 | 19.29 490 | 21.26 540 | 25.59 650 | 32.87 835 | 46.46 1180 | 60.04 1525 | 63.78 1620 |

| W | in mm | 11 280 | 12 300 | 14 350 | 16 400 | 20 500 | 21 530 | 24 600 | 24 600 |

| RF Ends Weight | KG | 70 | 110 | 175 | 270 | 520 | 915 | 1750 | 2120 |

| Size | in mm | 2 50 | 2.5 65 | 3 80 | 4 100 | 6 150 | 8 200 | 10 250 | 12 300 |

| L/L1 | in mm | 17.75 451 | 20.00 508 | 22.75 578 | 26.50 673 | 36.00 914 | 40.25 1022 | 50.00 1270 | 56.00 1422 |

| L2 | in mm | 17.87 454 | 20.25 514 | 23.00 584 | 26.88 683 | 36.50 927 | 40.87 1038 | 50.88 1292 | 56.88 1445 |

| H | in mm | 19.29 490 | 22.83 580 | 24.80 630 | 28.54 725 | 40.94 1040 | 45.28 1150 | 57.48 1460 | 65.35 1660 |

| W | in mm | 11 280 | 12 300 | 14 350 | 16 400 | 24 600 | 18 460 | 24 600 | 24 600 |

| RF Ends Weight | KG | 100 | 150 | 245 | 390 | 780 | 1355 | 2565 | 3250 |

Avoid your inquiry is delay response, please enter your WhatsApp/Wechat/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 185 1656 9221, or WeChat: +86 199 2125 0077. or call +86 189 5813 8289 directly.

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 199 2125 0077, or WeChat: +86 199 2125 0077. Or call +86 189 5813 8289 directly.

Just leave your name, email, and simple message or requirements, We will contact you within 1 hour.

WhatsApp: +86 199 2125 0077

Skype ID: sowell85

Wechat ID: +86 199 2125 0077