The THINKTANK A105 Forged Steel Class 800 Ball Valve features PTFE seats and a reduced bore, making it an ideal choice for a variety of applications including petrochemical, steam, mining, and industrial sectors. This valve is designed according to ASME B16.34 standards and comes with NPT ends compliant with ASME B1.20.1. Each valve undergoes rigorous testing in accordance with API 598 to ensure reliable performance and durability.

Size: DN 1/4“ to DN 2“

Material: ASTM A105

Ends: Threaded female BSP, NPT, BW, or S.W.

Min Temperature: – 30°C in S.S. and – 10°C in Carbon Steel

Max Temperature: + 180°C

Pressure Rating: 800LBS, 1500LBS, 2500LBS

Features:

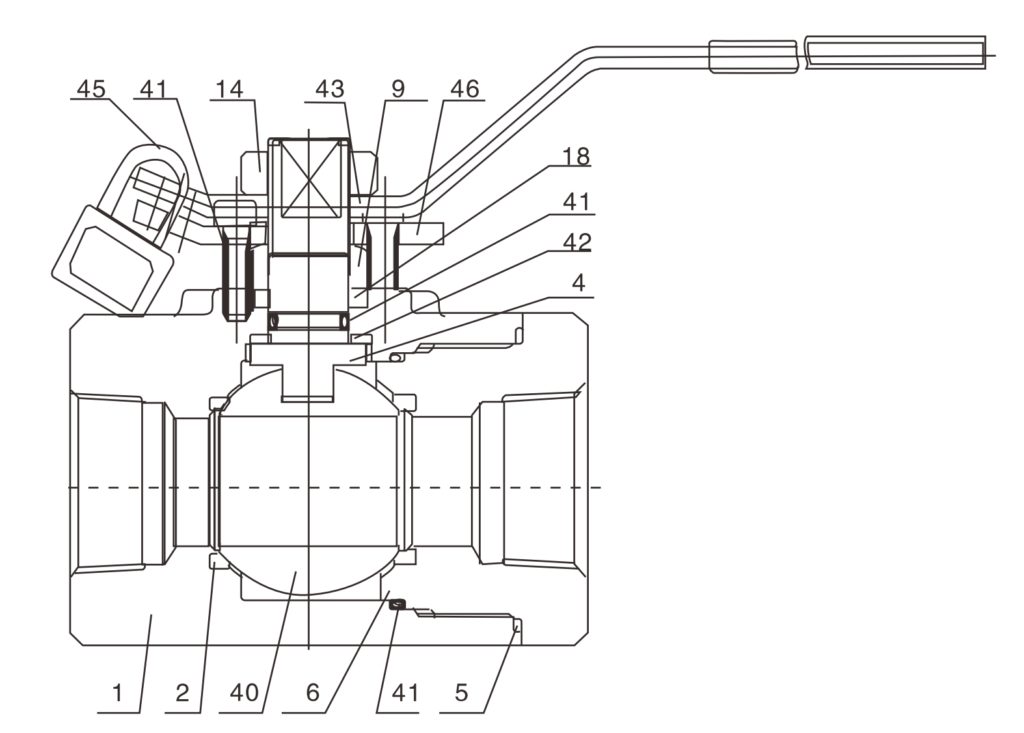

| NO. | Part Name | A105/F6e | LF2/304 | F304(L)/304(L) | F316(L)/316(L) | F51/F51 |

| 1 | Body | A105 | LF2 | F304(L) | F316(L) | F51 |

| 2 | Seat | RPTFE/PEEK | RPTFE/PEEK | RPTFE/PEEK | RPTFE/PEEK | RPTFE/PEEK |

| 4 | Stem | 410 | 304 | 304(L) | 316(L) | F51 |

| 5 | Gasket | PTFE | PTFE | PTFE | PTFE | PTFE |

| 6 | Bonnet | A105 | LF2 | F304 | F316 | F51 |

| 9 | Gland | 410 | 304 | 304L | 316(L) | F51 |

| 11 | lange | A105 | LF2 | F304 | F316 | F51 |

| 14 | Flat nut | 8 | 8 | 8 | 8M | 8M |

| 18 | Packing | PTFE | PTFE | PTFE | PTFE | PTFE |

| 40 | Ball | F6 | F304 | F304(L) | F316(L) | F51 |

| 41 | O-ring | VITON | VITON | VITON | VITON | VITON |

| 42 | Back seat gasket | RPTFE/PEEK | RPTFE/PEEK | RPTFE/PEEK | RPTFE/PEEK | RPTFE/PEEK |

| 43 | Wrench | ANSL1025 | ANSI 1025 | ANSI 1025 | ANSI1025 | ANSI1025 |

| 44 | Screw | B8 | B8 | B8 | B8M | B8M |

| 45 | Lock | Assembly | Assembly | Assembly | Assembly | Assembly |

| 46 | Locator | ANSI 1025 | ANSI 1025 | ANSI 1025 | ANSI 1025 | ANSI 1025 |

One end is welded pipe(butt-welding or socket welding)and the other is the thread, design comply with standard BS5351.

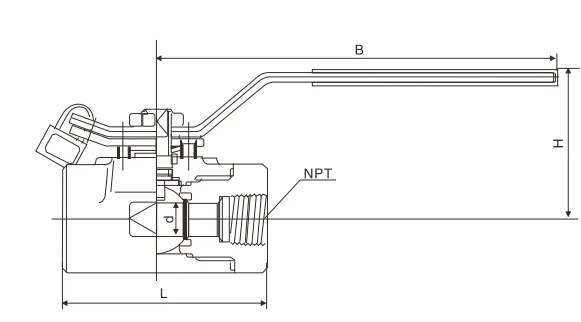

| Size(NPS) Specification | Reduced Port | 一 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 一 | 一 |

| Full Port | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | |

| Face to Face (mm) | L1 | 70 | 70 | 80 | 95 | 115 | 125 | 135 | 155 | 一 |

| Coupling Pipe End to Center (mm) | L2 | 121 | 121 | 121 | 130 | 136 | 140 | 148 | 160 | 一 |

| Center to Handle End (mm) | B | 160 | 160 | 160 | 160 | 170 | 230 | 230 | 280 | 一 |

| Height (mm) | H | 60 | 60 | 60 | 65 | 85 | 105 | 105 | 125 | 一 |

| Flow Port Dimension (mm) | d | 6 | 9 | 12.5 | 17 | 24 | 37 | 37 | 49 | 一 |

| Weight (kg) | 1.2 | 0.9 | 1.3 | 2.2 | 3.5 | 6.5 | 6.5 | 11 | 一 | |

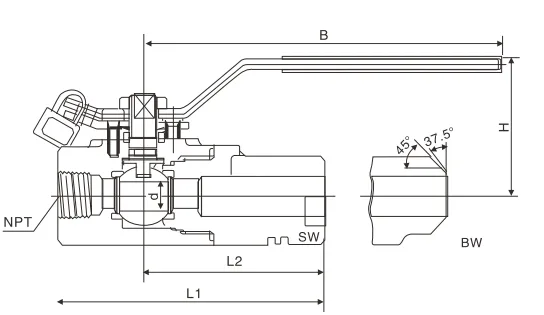

One end is welded pipe(butt-welding or socket welding)and the other is thread, design comply with standard API6D

| Size(NPS) Specification | Full Port | Pressure Rating | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 |

| Face to Face (mm) | L1 | CL1500 | 80 | 80 | 95 | 115 | 125 | 135 | 155 | 155 |

| CL2500 | 一 | 一 | 125 | 135 | 155 | 一 | 155 | 一 | ||

| Coupling Pipe End to Center (mm) | L2 | CL1500 | 121 | 121 | 130 | 136 | 140 | 148 | 160 | 175 |

| CL2500 | 一 | 一 | 136 | 140 | 148 | 一 | 175 | 一 | ||

| Center to Handle End (mm) | B | CL1500 | 160 | 160 | 160 | 170 | 230 | 230 | 280 | 280 |

| CL2500 | 一 | 一 | 230 | 230 | 280 | 280 | 130 | |||

| Height (mm) | H | CL1500 | 60 | 60 | 65 | 85 | 105 | 105 | 125 | 一 |

| CL2500 | 一 | 一 | 90 | 110 | 125 | 一 | 一 | 一 | ||

| Flow Port Dimension (mm) | d | CL1500 | 6 | 9 | 13 | 19 | 25 | 32 | 38 | 一 |

| CL2500 | 6 | 9 | 13 | 19 | 25 | 一 | 38 | 一 | ||

| Weight (kg) | CL1500 | 1.2 | 1.5 | 2.5 | 3.7 | 5.8 | 一 | 11.5 | 一 | |

| CL2500 | 1.5 | 1.9 | 2.7 | 4.1 | 6.3 | 一 | 12 | 一 | ||

A Good Partner Is A Lasting And Effective Investment

Just leave your name, email, and simple message or requirements, We will contact you within 1 hour.

WhatsApp: +86 185 1656 9221

Skype ID: sowell85

Wechat ID: +86 199 2125 0077