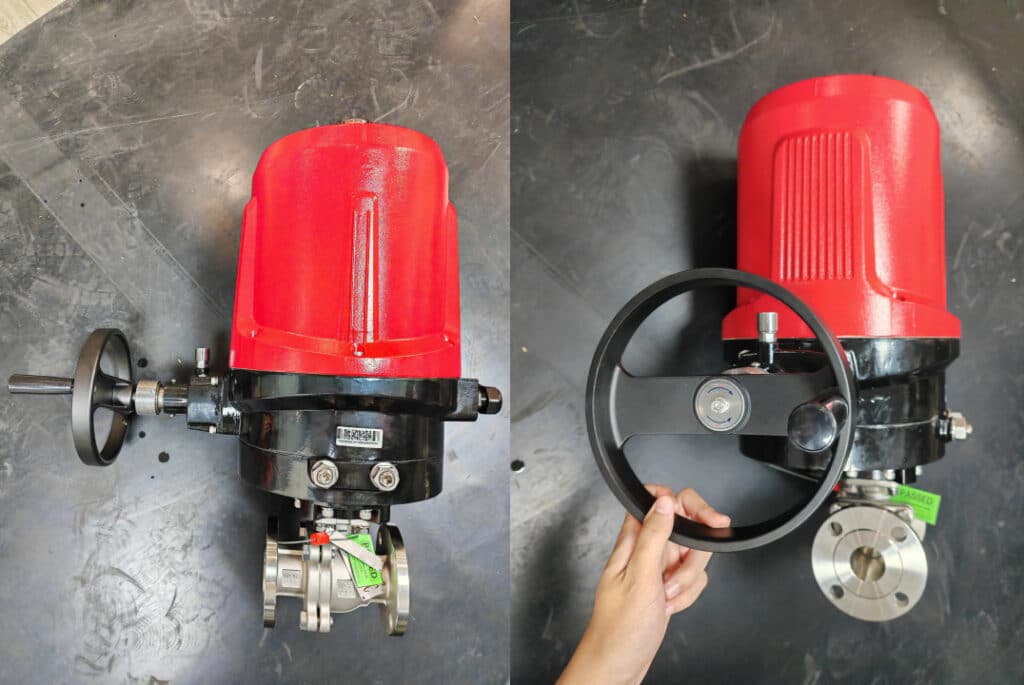

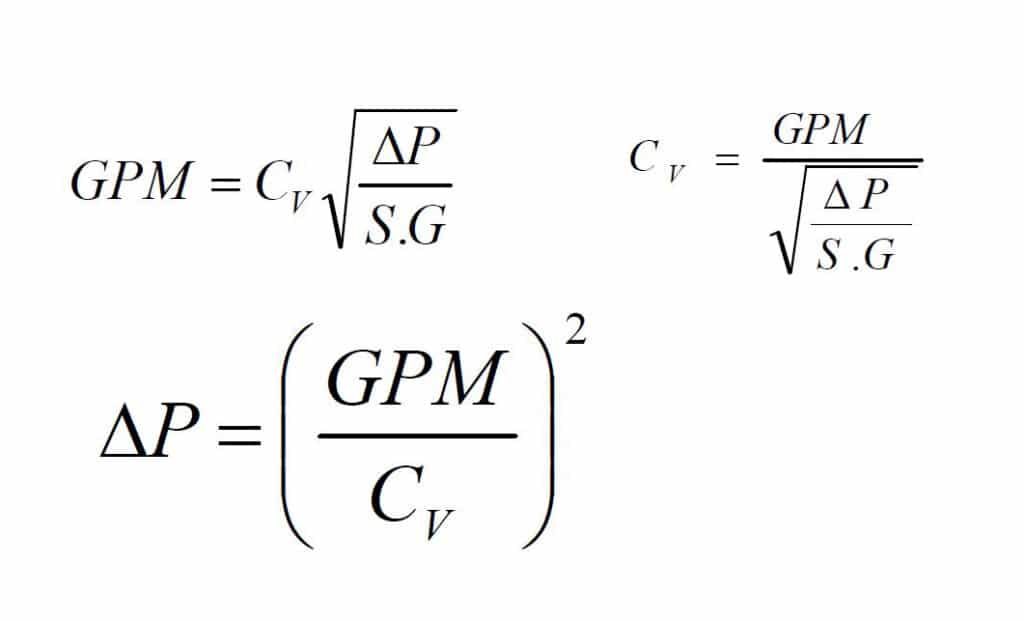

The successful operation of process plants and systems involves the highest level of measurement and control performance. Therefore, the control valve plays a key role in this process. The performance of the control valve can have a significant impact on the plant’s operating efficiency, overall profitability, and asset life cycle costs.

A correctly sized control valve can save a lot of costs, increase process availability, reduce process variability, and reduce maintenance costs. Compared with valves that do not match or are sized incorrectly, control valves with the correct size have a longer service life. Therefore, the correct size of the system control valve should be carefully considered.

Now we know all control valves should be sized and selected in order, to make sure it meets the requirements of end-users.

Because if oversizing the control valves, it will damage the process variability parameters in two side.

First, the oversized valve cost too much, and the flow capacity range is widely, it makes less flexibility in adjusting the controller, especially controlling the valve opening around 25% travel. And this will make a risk of increased process variability.

Secondly, oversized control valves will impair the variability of the process, because an oversized valve will run more frequently at a lower valve stroke, and a low valve opening will cause greater friction on the seal.

Particularly in rotary valves, because oversized control valves provide disproportionately large flow changes for a given valve stroke increment, this phenomenon greatly exaggerates the process variability associated with the dead zone caused by friction.

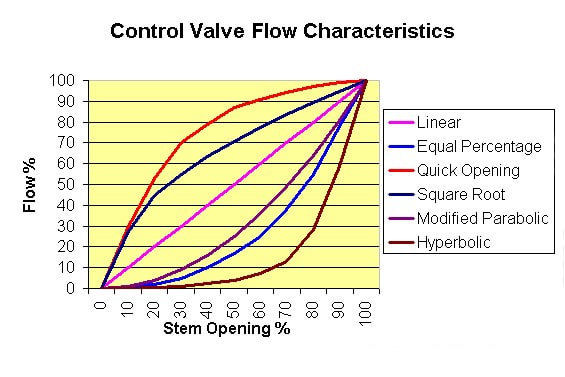

Regardless of the actual inherent flow characteristics of the control valve, the oversized control valve is more likely to act as a quick opening valve, which will result in high flow capacity gains in the low travel.

Meanwhile, when the control valve is oversized, the valve tends to reach system capacity at relatively low travel, making the flow curve flatten out at higher valve travels. For valve travel over about 50%, the valve has become completely ineffective for control purposes because the process gain is close to zero and the valve travel has to vary greatly with little change.

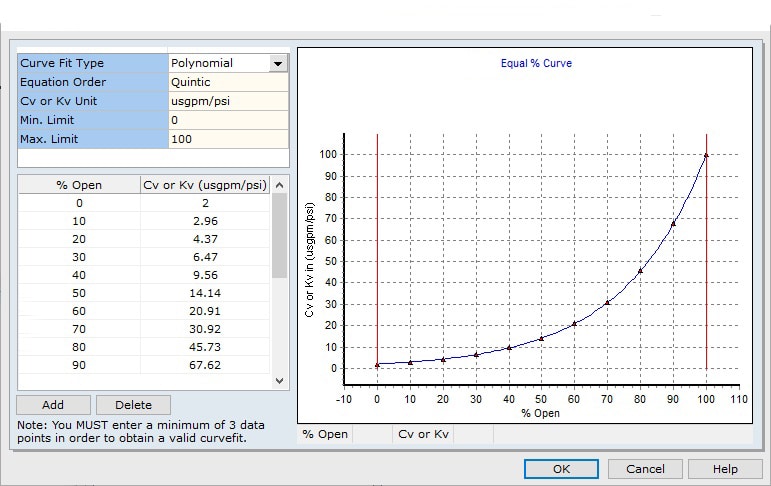

Therefore, when selecting a control valve, it is very important to consider the type, inherent characteristics, and size of the valve.

In this way, no matter from an economic point of view, the accuracy of process management can achieve the maximum benefits.