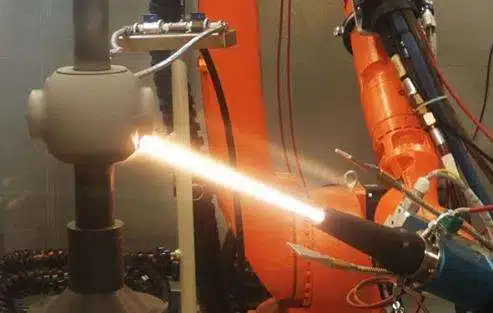

Flashing occurs when a liquid flows through a control valve and evaporates to retain the vapor. Flashing has some characteristics in common with Cho flow and Cavitation, I. E. The process begins with the vaporization of liquid near the Vena Cava. In order to treat the control valve application as a flash application, the downstream pressure must be less than the steam pressure (p 2 < PV) . Flash evaporation is a problem because it limits the flow through the control valve and the liquid-vapor mixture is highly aggressive. Metal corrosion caused by flash looks smooth and shiny. Since valves can not prevent Flash, it is best to select valves with the appropriate geometry and materials to avoid or minimize damage.