A butterfly valve is a valve that uses a circular butterfly disc as an opening and closing member and rotates with the valve stem to control the fluid through the valve.

The butterfly valve is a kind of valve that uses a circular disc as an opening and closing member. It is a mechanical device used for regulating the flow of fluids. The opening depends on rotating the valve stem to the disc plate from 0° to 90°. When the disc reaches 90°, the valve is in a fully open state, and if the disc reaches 0°, the valve is in a fully closed state. The disc of the butterfly valve is installed in the diameter direction of the pipeline. The flow capacity is modulated by the angle of the disc.

A butterfly valve is a 90° turn rotational motion valve that is used to on/off or controls the flowing medium in a process. And particularly for large capacity conditions.

● Centric Butterfly Valve

● Lined Butterfly Valve

● Double Eccentric Butterfly Valve

● Triple Offset Butterfly Valve

As a general rule, a butterfly valve is a bi-direction industrial valve, but it does have a preferred flow direction in case protect valve and extend service life, also with lower operating torque.

Ball valve and butterfly valve both can isolate fluids in the processing system. So what is the exact difference between the ball valve and butterfly valve? We are going to describe the difference from 6 points.

| Item | Butterfly valve | Ball valve |

| Weight | Lighter weight even at larger pipe diameters | Very heavy at larger pipe diameter and may require support |

| Installation space | Requires smaller installation space | Requires larger space than a butterfly valve |

| Size | Suitable for larger pipe diameter (above DN 150), particular due to lightweight | Better suited for smaller pipe diameter (below DN 50) |

| Leakage | Prone to leakages at a high-pressure difference | Provides tight seal even at a high-pressure difference |

| Cost | Cheaper than a ball valve, particularly for larger sizes | More expensive compared to a butterfly valve |

| Flow control | Suitable for ON/OFF control but can be used for proportional control. | Functions well for both ON/OFF and modulating control |

| Flow restriction | Valve disc restricts flow creating a pressure drop. | Full port ball valves have no pressure drop. |

| Connection style | It has a flange style with a lug or wafer design | A wide array of connection types with threads or flanges |

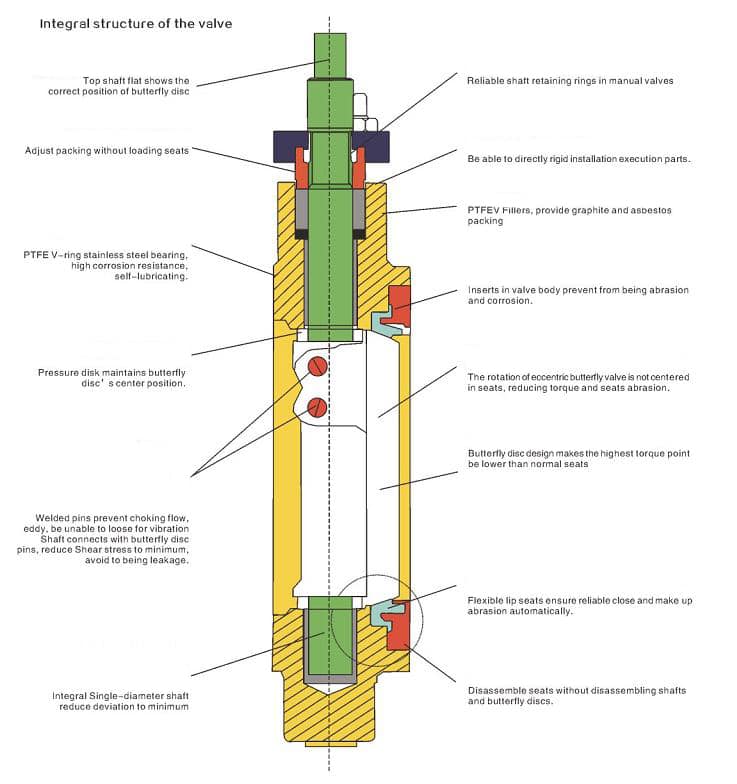

A leader in the design and manufacture of triple offset butterfly valves in China, THINKTANK is committed to producing high-quality valves for our customers. The high-performance butterfly valves are available in Wafer and Lug designs. It has excellent control ability, tight shutoff, long service life, and smooth operation are provided by the double offset design of the disc. Butterfly valves can be used for applications in the Chemical, Petroleum, Hydro Carbons Processing, Pulp & Paper, Water and Wastewater, and HVAC industries. THINKTANK produces high-performance butterfly valves and triple offset butterfly valves for industries across the world.

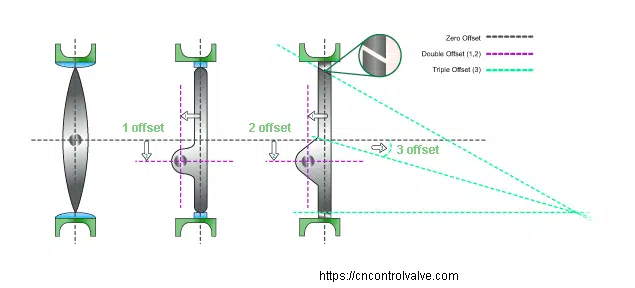

Butterfly valves are a type of quarter-turn rotational motion valve that is used to shut off flow in pipelines. If used for on-off function with normal temperature and low pressure, we recommend selecting a concentric type butterfly valve. For the butterfly valve is mentioned as a control valve to modulate the flow capacity, we recommend using double eccentric or triple eccentric butterfly valves, these types of butterfly valves can suitable for high temperature and high pressure applications in the industry.

Different Offset Design:

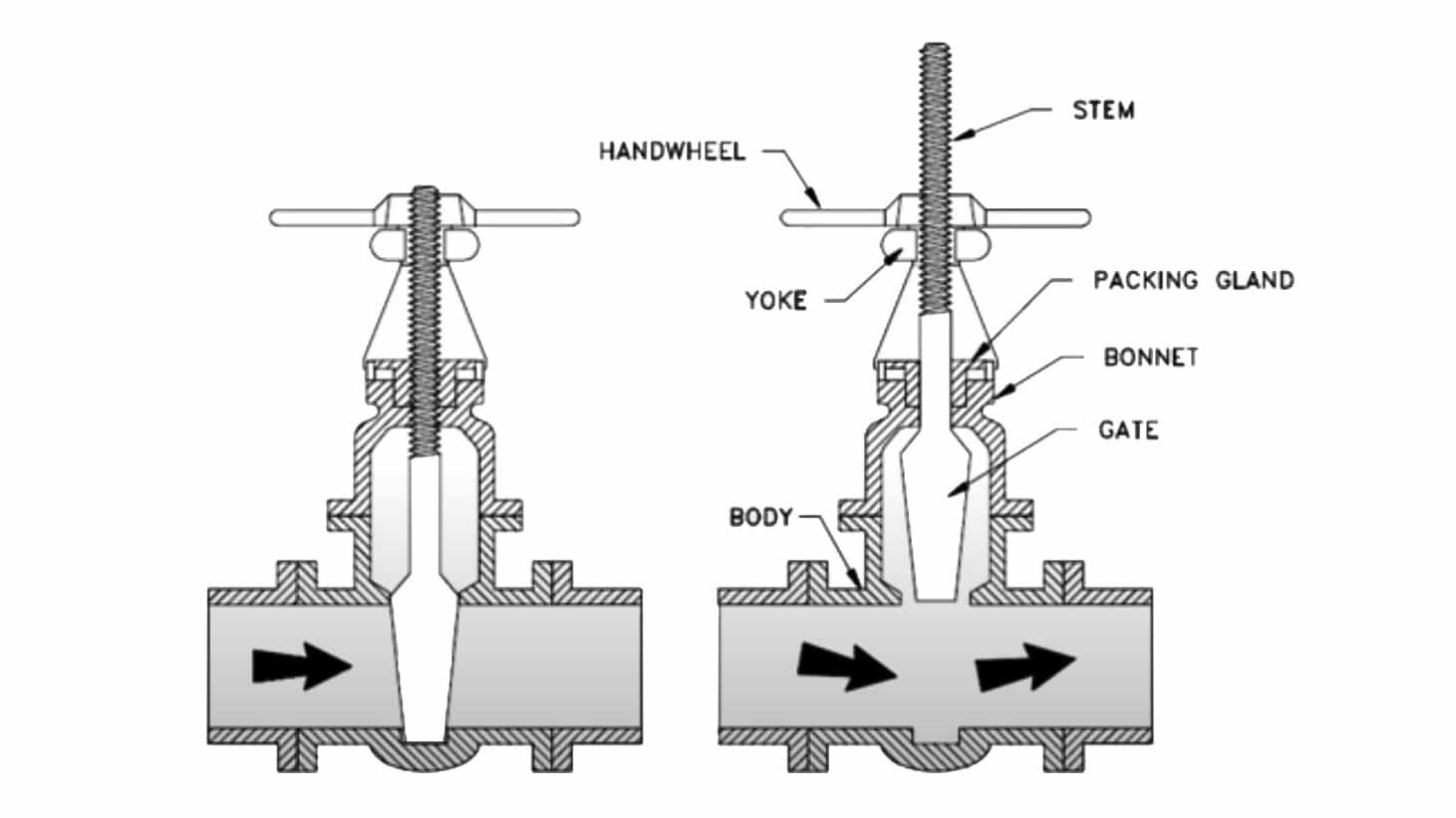

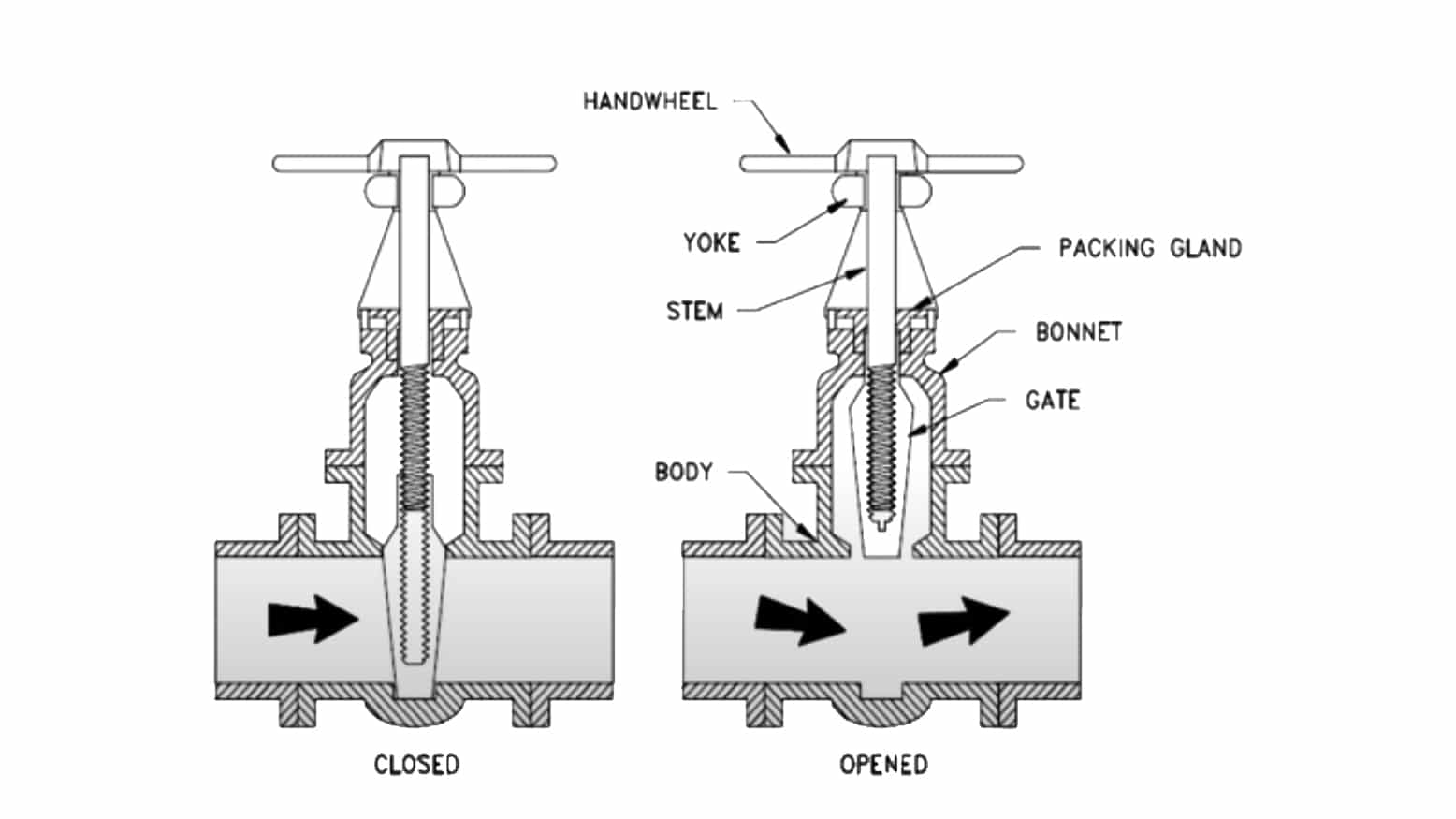

Gate valve is the most common isolation valve in industry, with a linear motion to open and close the flow. As its disc is like a gate, so named a gate valve. There are various types of gate valves, knife gate valves, wedge gate valves, parallel slide gate valves, pipeline slab gate valves, and so on.

Gate valve only works for fully close and fully open, it can not be used for proportion controlling conditions. But as the passageway of a gate valve is unobstructed, which results in minimum pressure loss.

Due to the unobstructed design of valve passage, so it is very common to work for pig during the pipe cleaning procedures.

THINKTANK is one of the well-known high-performance butterfly valve and triple offset butterfly valve manufacturers in China, which focus on control systems for over 10 years. If you are interested in the price of butterfly control valves, just feel free to contact us. <[email protected]>

We are looking for valuable brand customers with long-term cooperation. Only with high-quality quality and service can bring our customers more market share and stable business.

Just leave your name, email, and simple message or requirements, We will contact you within 1 hour.

WhatsApp: +86 185 1656 9221

Skype ID: sowell85

Wechat ID: +86 199 2125 0077

A Good Partner Is A Lasting And Effective Investment